Patents

Literature

146results about How to "Reduce operational failures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

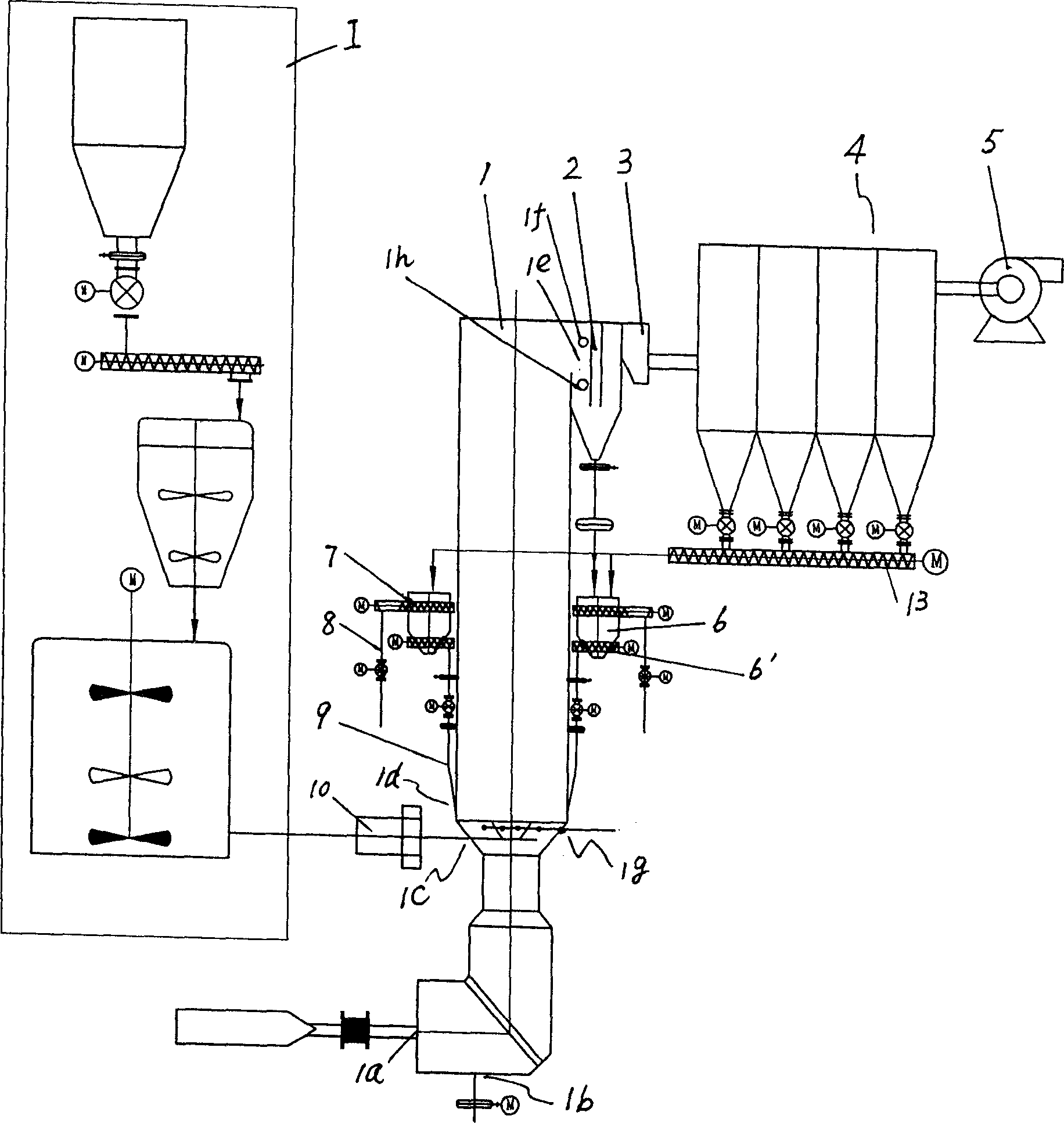

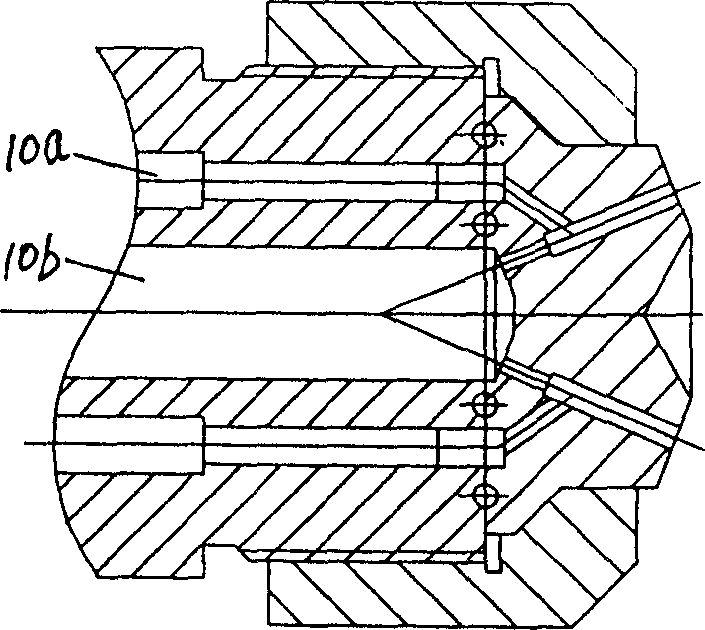

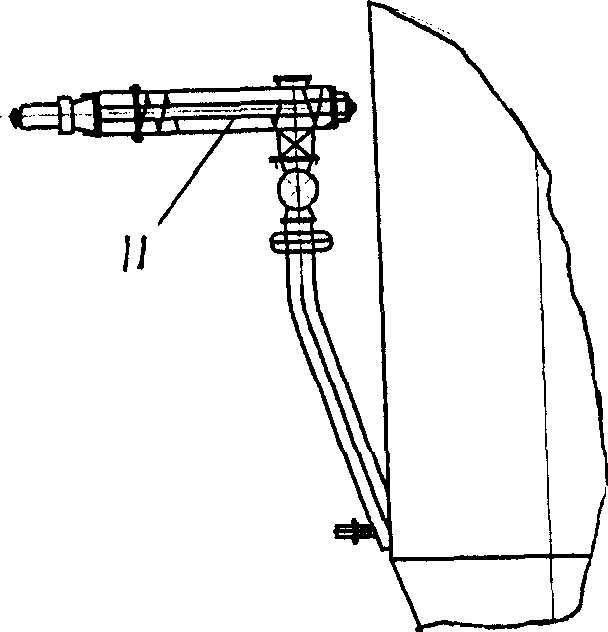

Smoke purifier of domestic refuse incinerator

ActiveCN1896591AAvoid clogging and wearReduce operational failuresCombination devicesIncinerator apparatusActivated carbonSmoke

This invention is a kind of smoke purifier device of domestic garbage incinerator. The system is arranged with lime dry powder and water spraying, lime slurry spraying and active carbon spraying devices to automatically start and adjust spraying to eliminate the acidic gas, toxic gas and dust. This invention includes smoke inlet opening, slag tap, lime dry powder ejector, reaction tower at smoke outlet, pre-dust remover, bag-type dust remover and draught fan. The reaction tower is also arranged with ejectors for water, slurry and atomized air. The active carbon mixer, thermocouple and acidic gas detector are arranged in front of the bag-type dust remover. This invention has little operation failure.

Owner:HANGZHOU NEW CENTURY ENERGY ENVIRONMENTAL PROTECTION ENG CO LTD

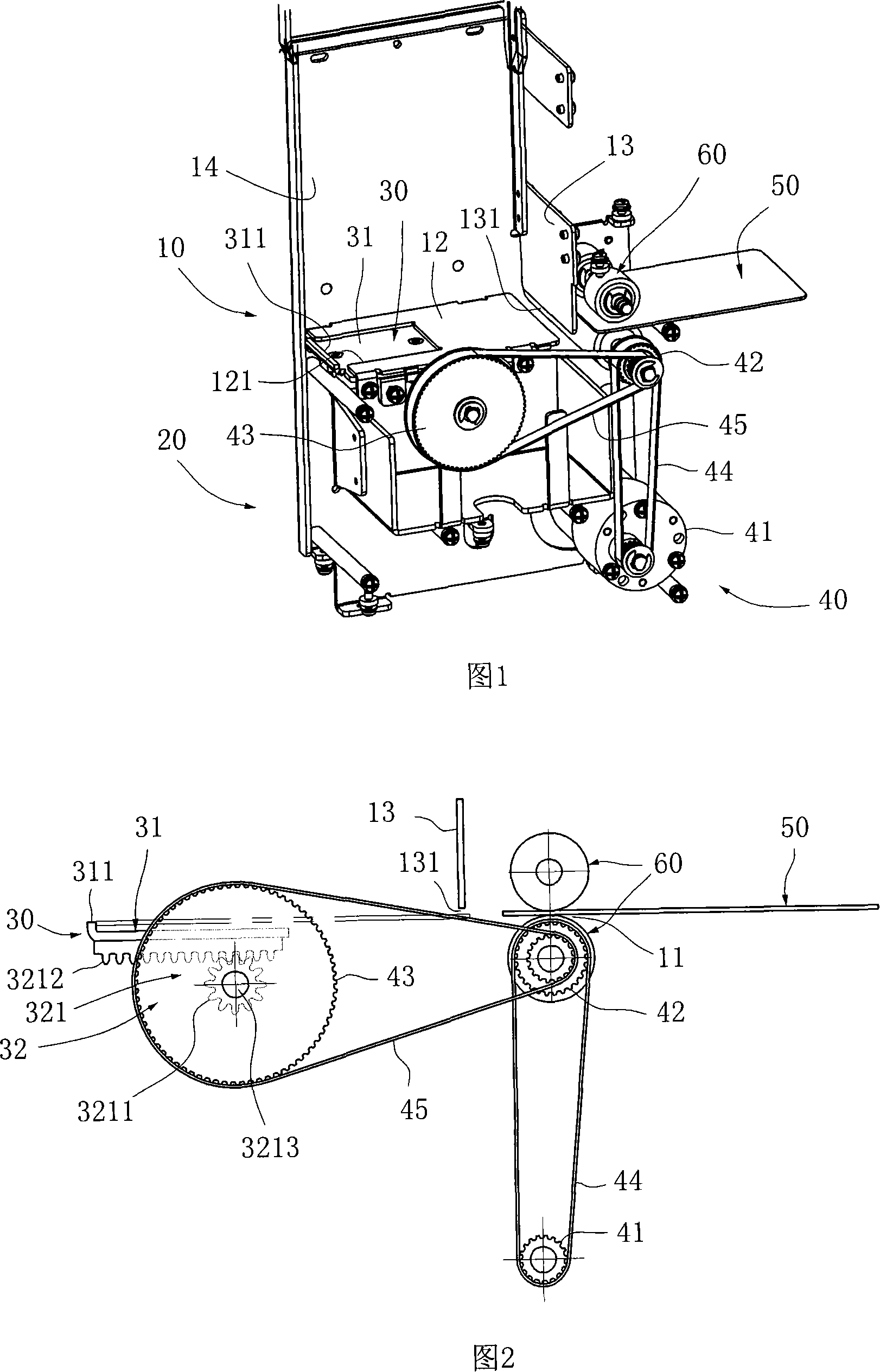

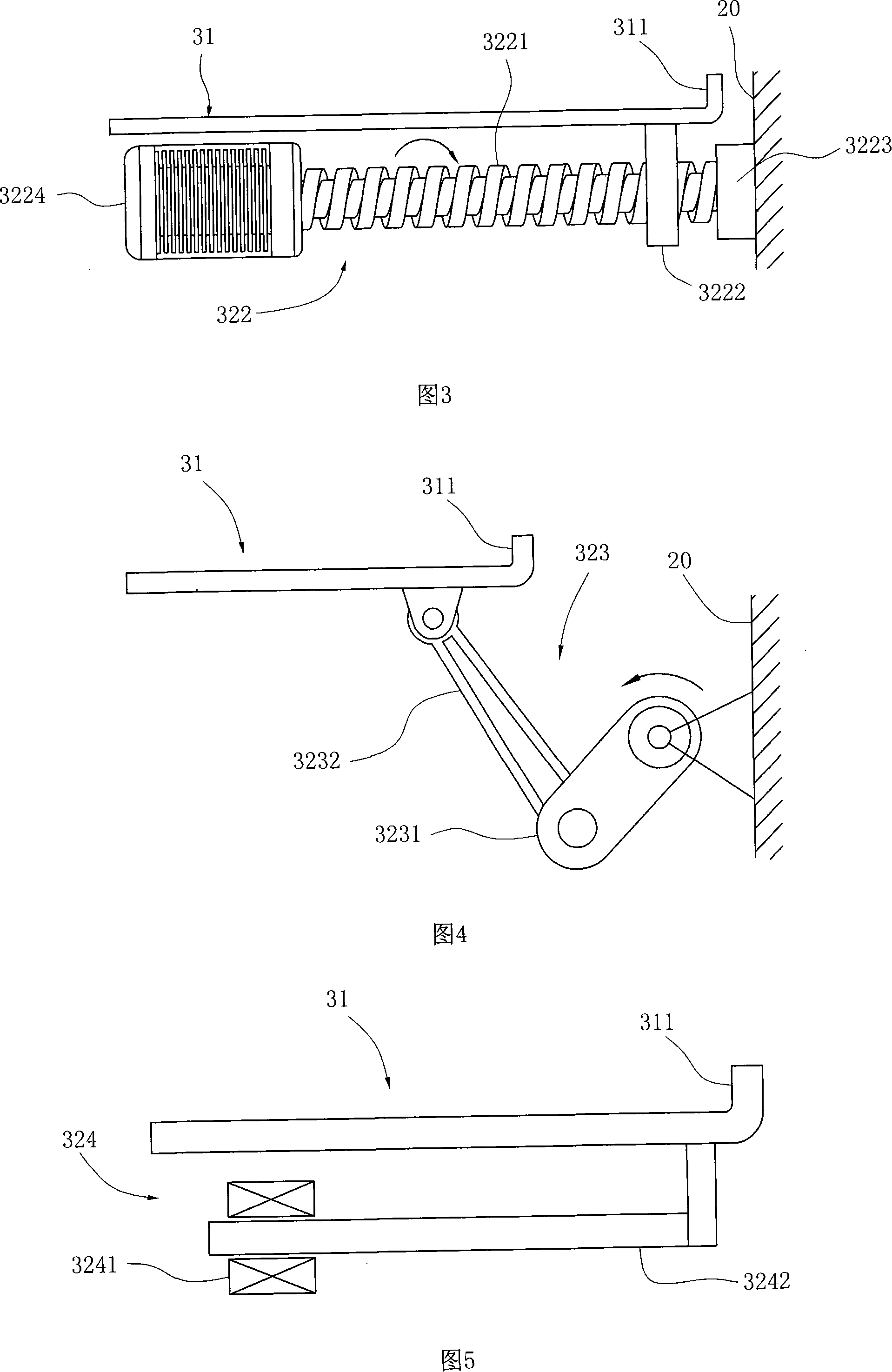

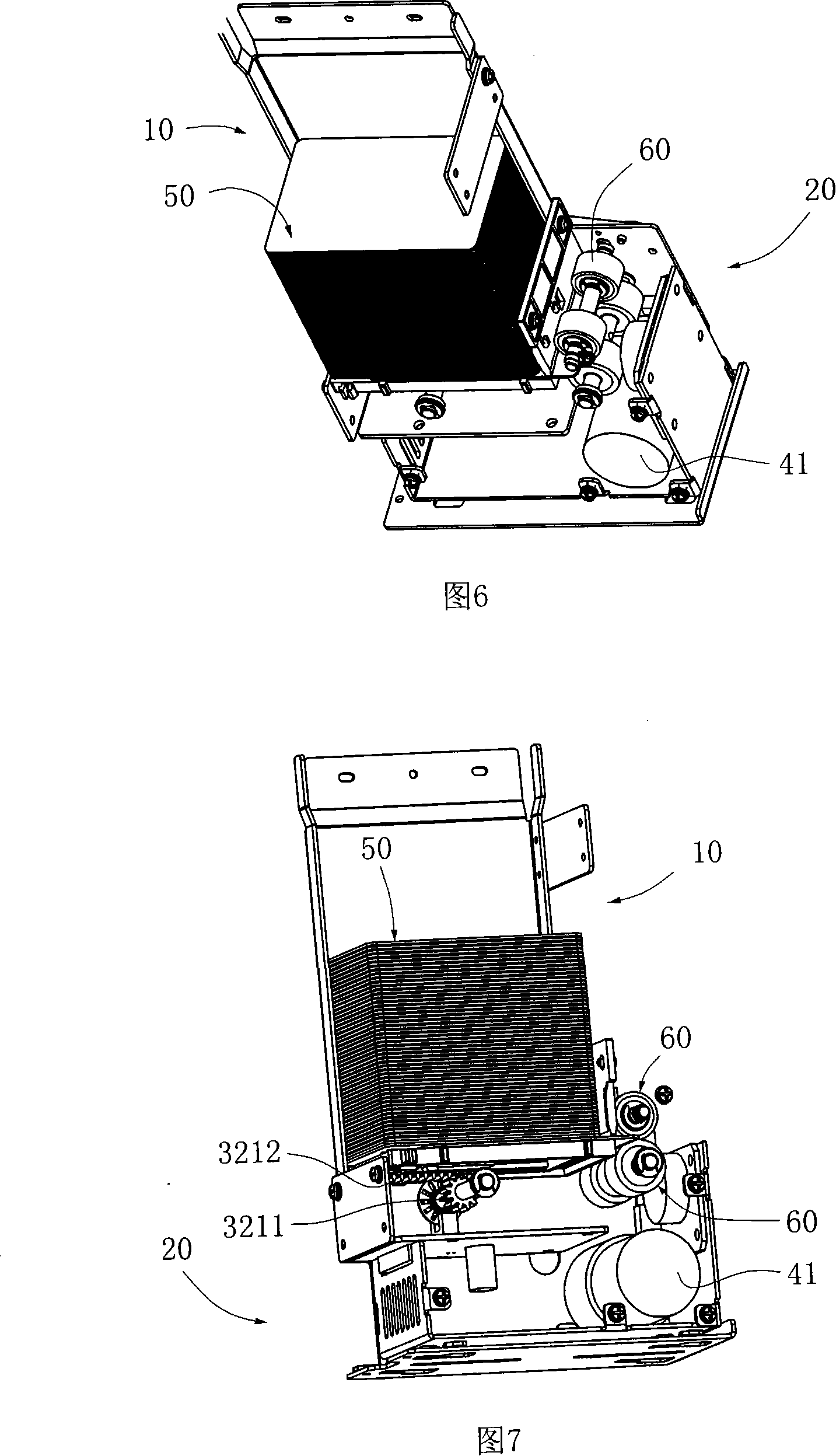

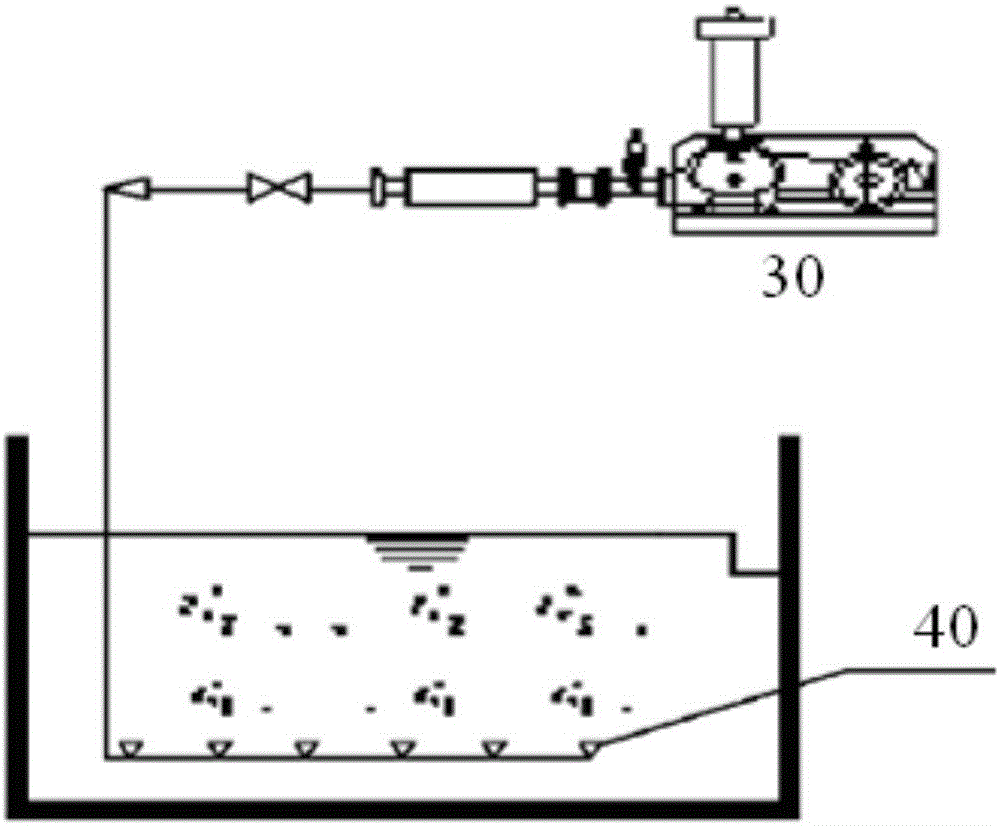

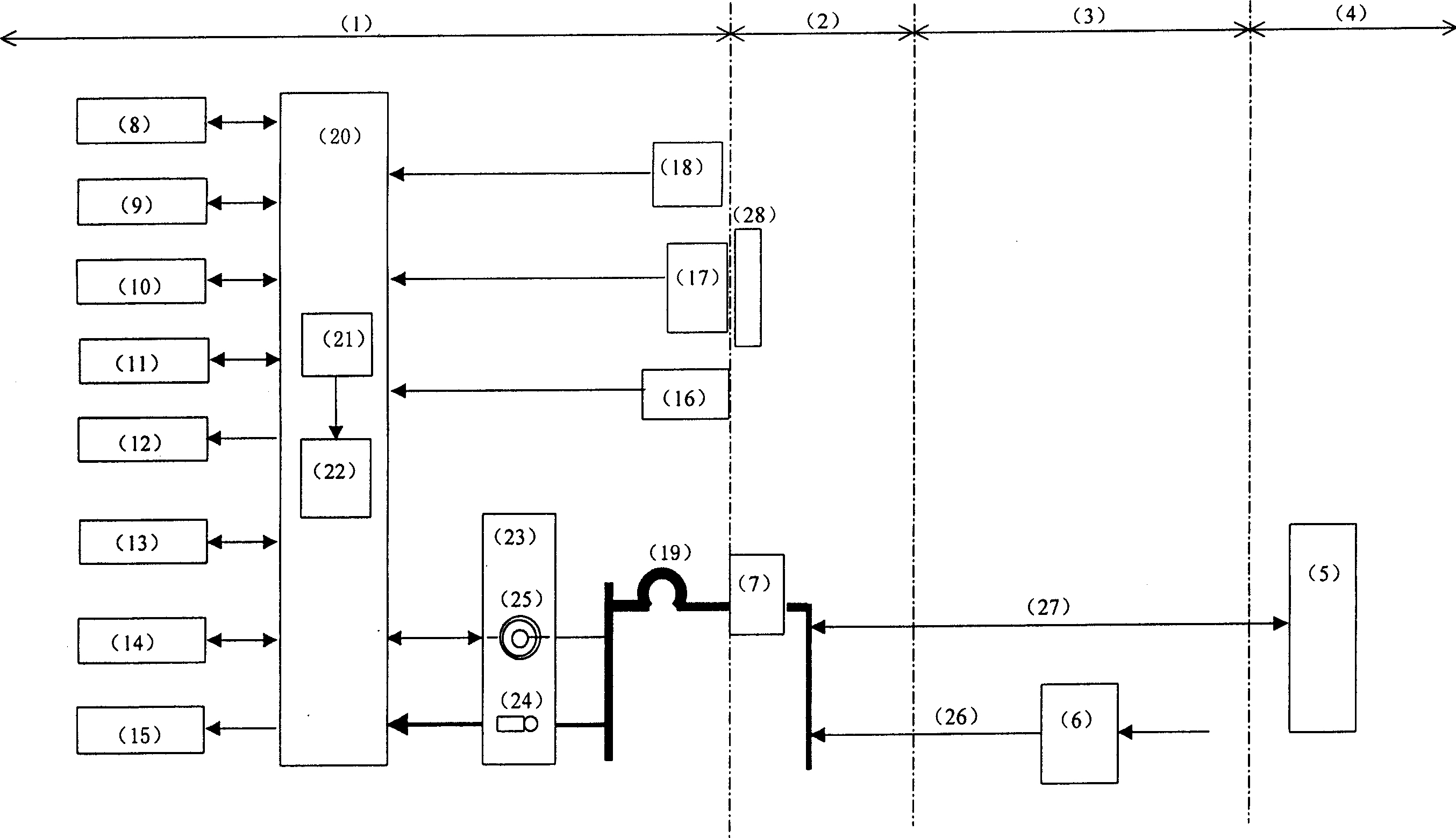

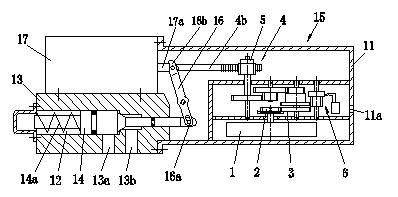

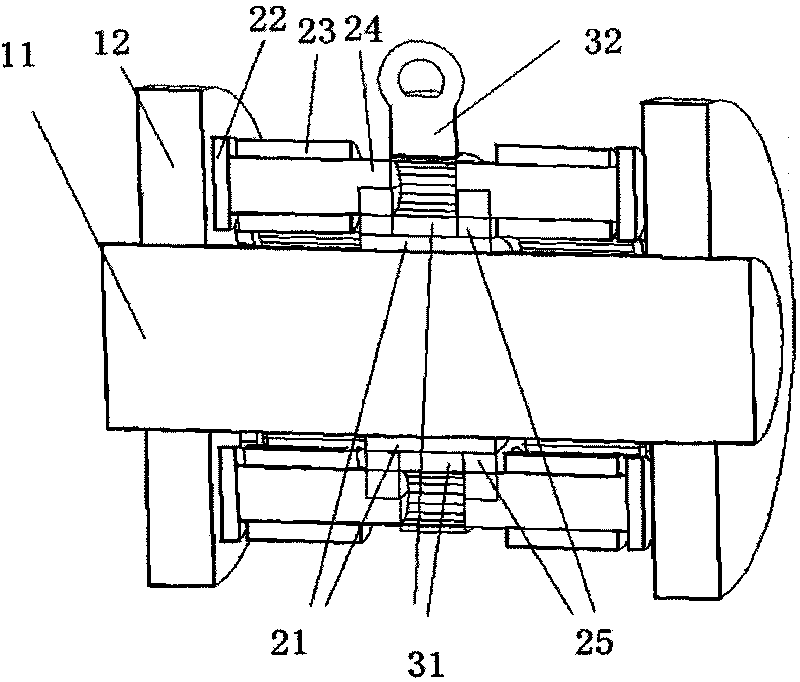

IC card pop-out device

InactiveCN101110104AWork reliablyReduce operational failuresConveying record carriersReciprocating motionResidential community

An IC card pushing device is provided, which comprises an IC card box (10), a machine box (20) positioned under the IC card box, an IC card operation mechanism (30) and a drive mechanism (40). An IC card outlet (11) is positioned on the IC card box (10); a card delivery wheel (60) that can rotate forward and backward is positioned at the IC card outlet. The invention is characterized in that: the IC card operation mechanism (30) is arranged as a card push mechanism that performs to-and-fro motion along the card inlet and outlet direction; in pushing out the card, the card push mechanism acts on an end surface on the IC card (50) kept from the IC card outlet (11), so as to push the IC card to the IC card outlet (11). Therefore, the invention can be applied to a plurality of IC card management systems in bank, garage and residential community.

Owner:深圳市红门智慧停车科技有限公司

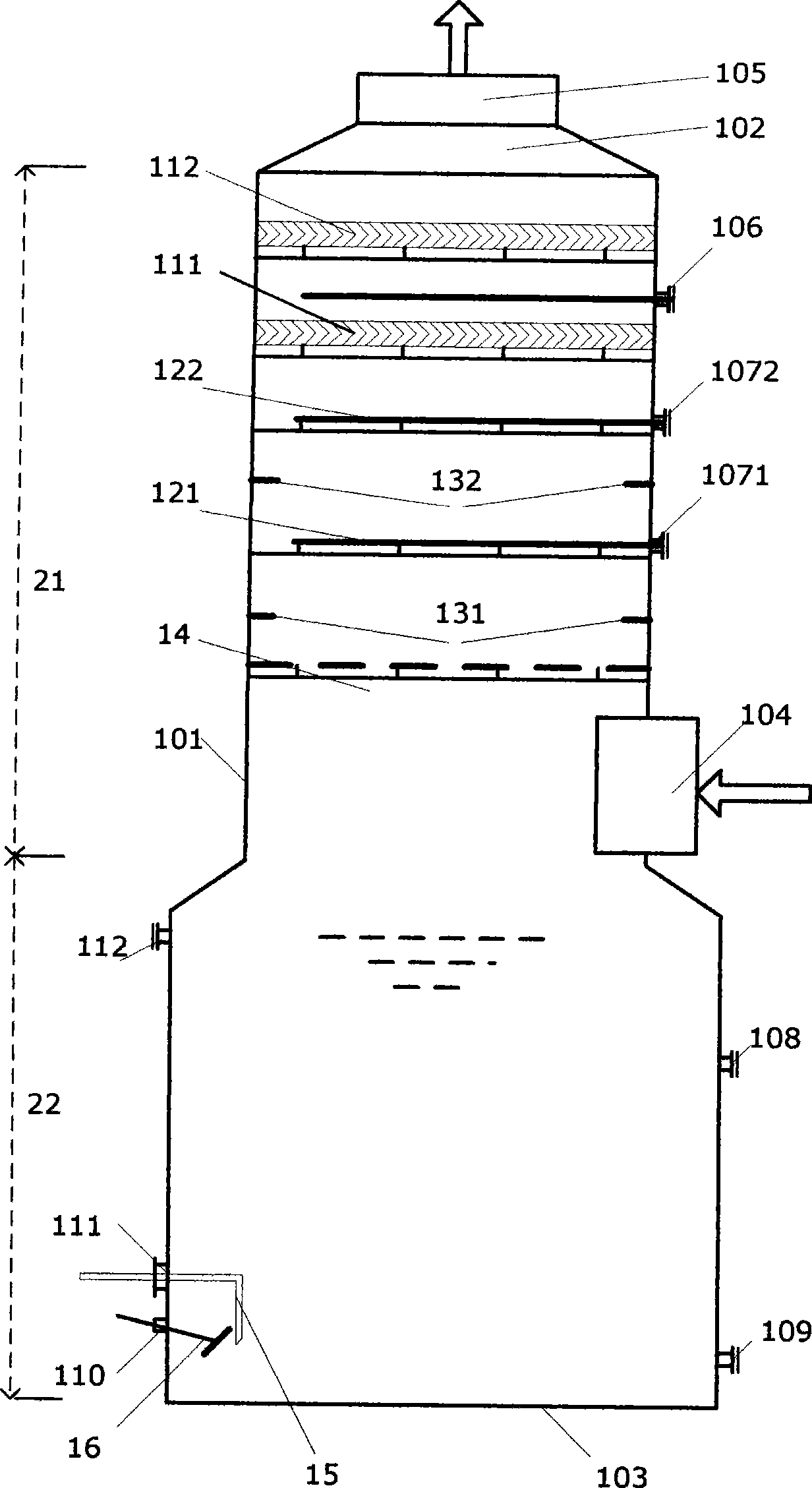

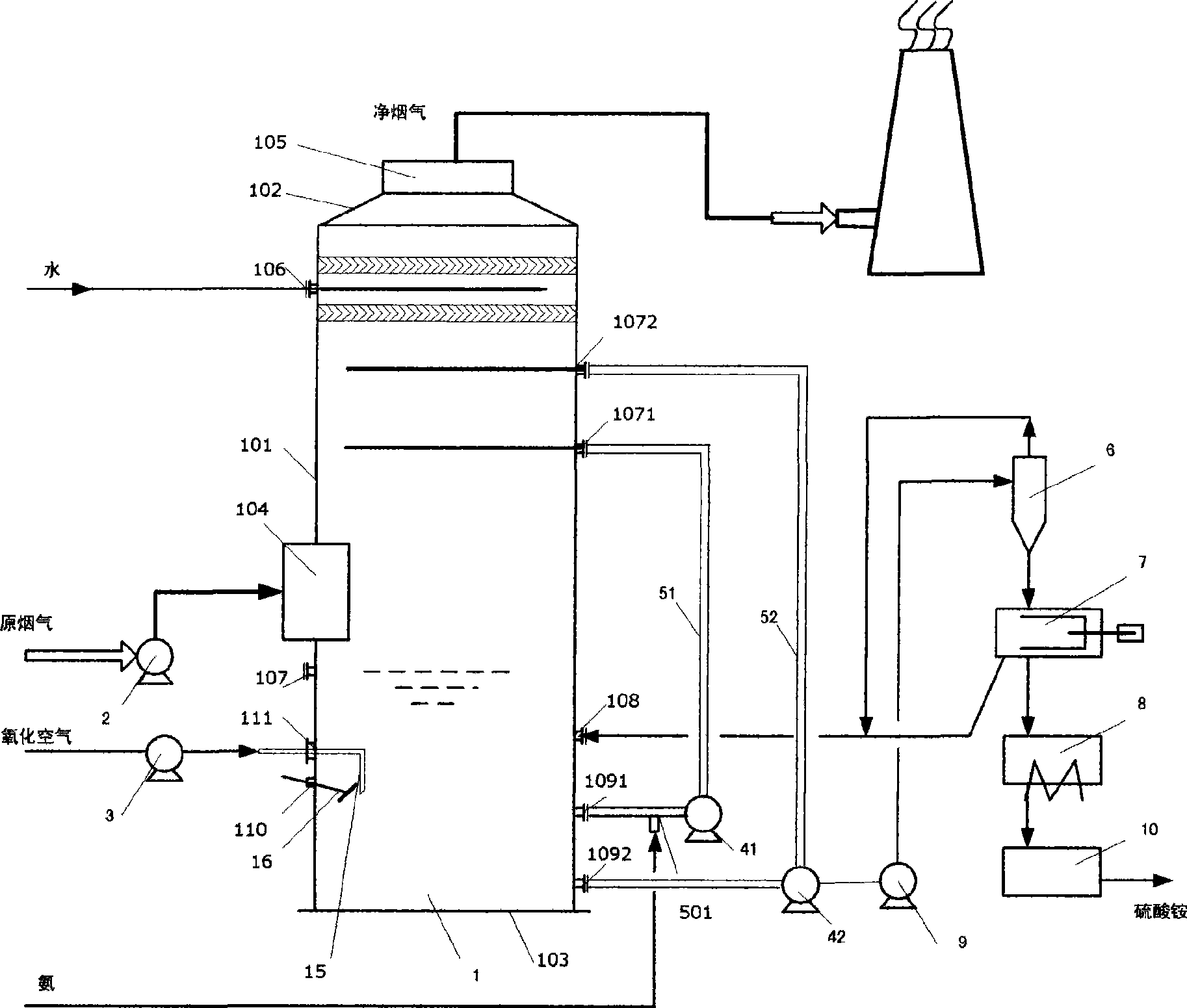

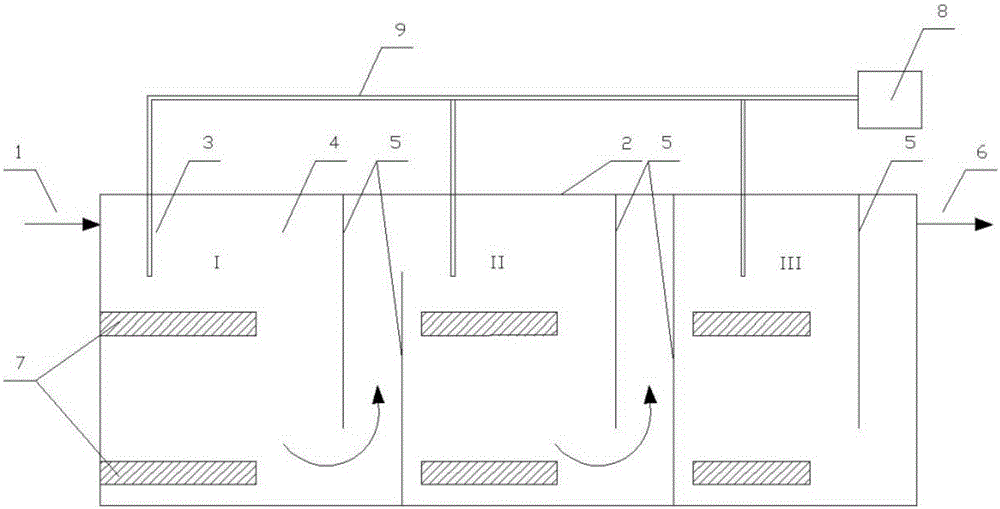

Ammonia process two-stage countercurrent smoke-discharging and treating device, and method thereof

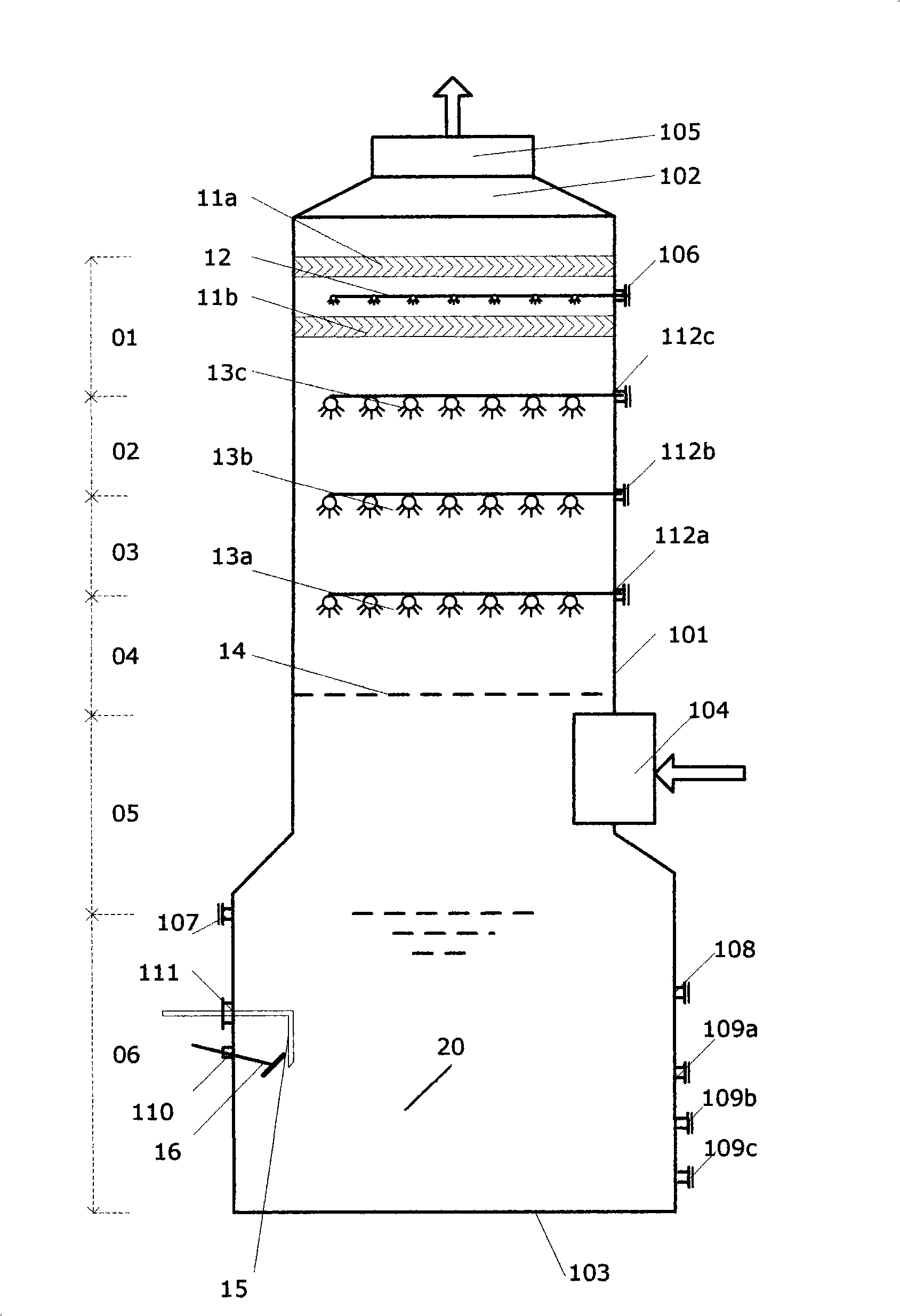

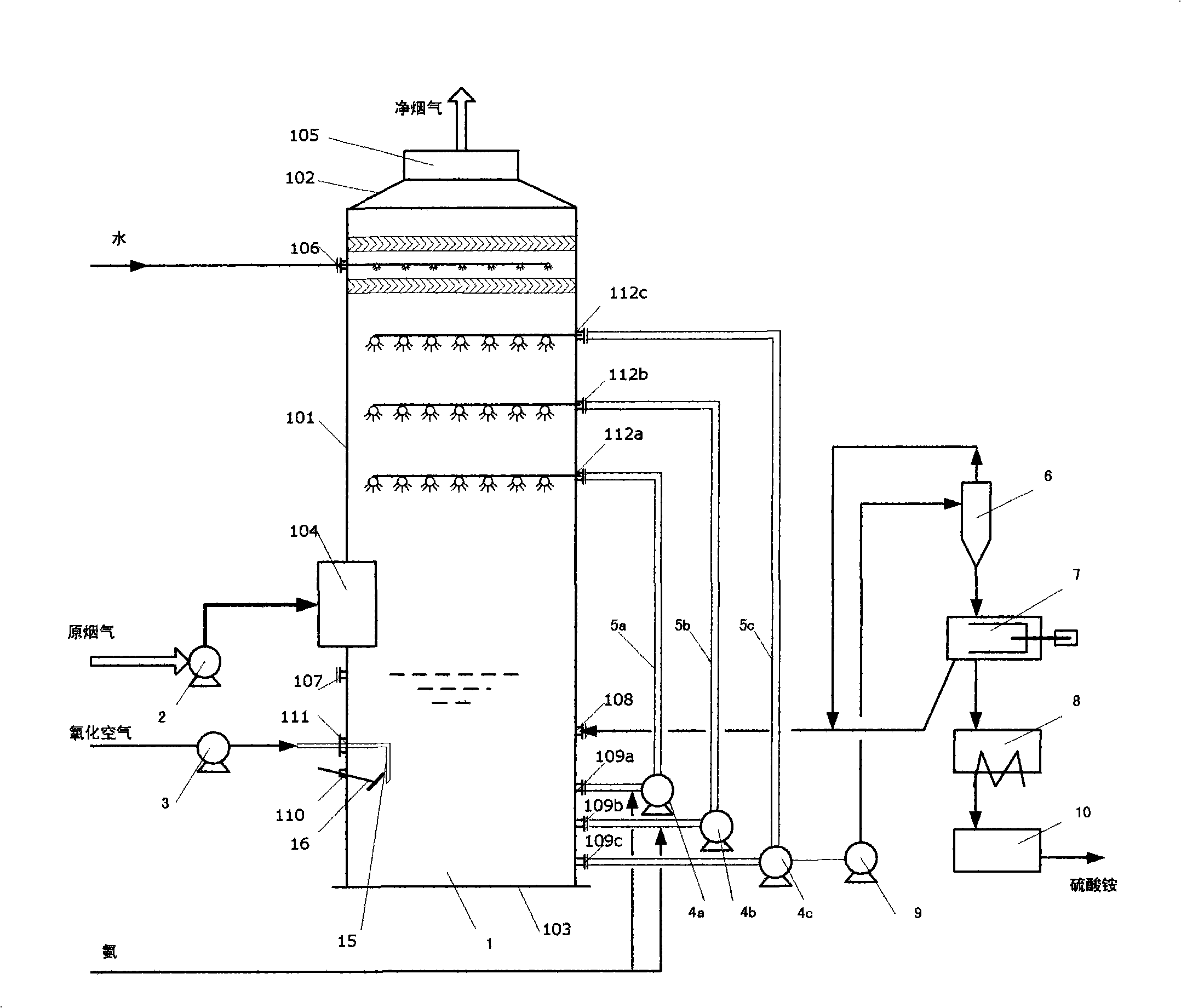

InactiveCN101502753AEscape control worksReduce short circuitDispersed particle separationLiquid ratioTower

The invention discloses an ammoniation two-stage upstream exhaust treatment device and a method thereof, which take volatile ammonia as raw materials and recover acid waste gas as useful products, the innovative essence thereof lies in that the invention provides two-stage independent absorption liquid circulating systems with ammonification and without ammonification, comprising independent two-stage absorption liquid spray devices arranged in a reaction tower to facilitate the method of the invention to comprise seven continuous steps including primary and secondary treatment, in particular to optimize the internal structure and relative size of the reaction tower as well as the size of an absorption liquid circulating tube and circulating load of absorption liquid, therefore, the operating gas-liquid ratio is set as 70-195. Compared with the prior art, the invention has the characteristics of greatly increased stability and reliability in the operation of the device, more effective control of loss due to ammonia escape, low energy consumption, simple structure of the device, reduced scarring and obstruction of the device and saved investment and operating cost, and has obvious application prospect in the field of exhaust purification such as boilers and the like.

Owner:王建敏

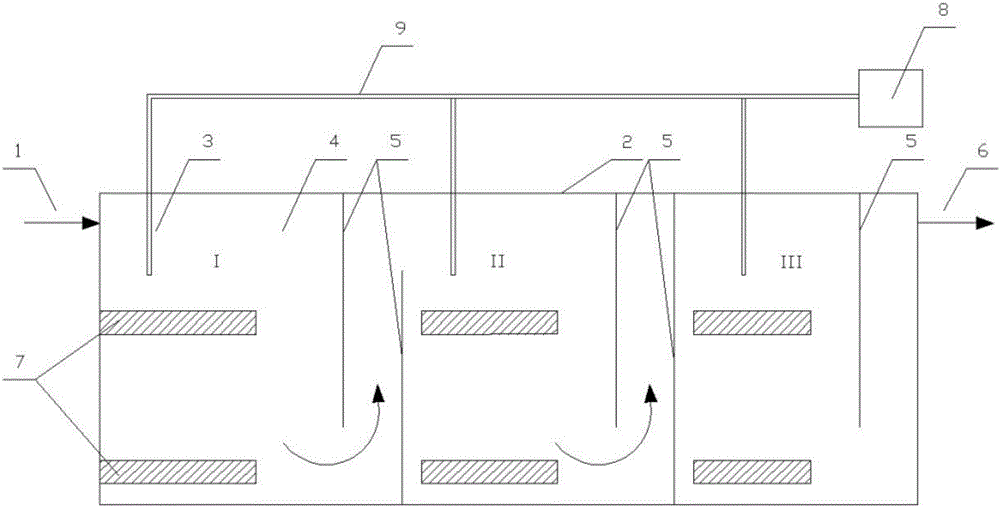

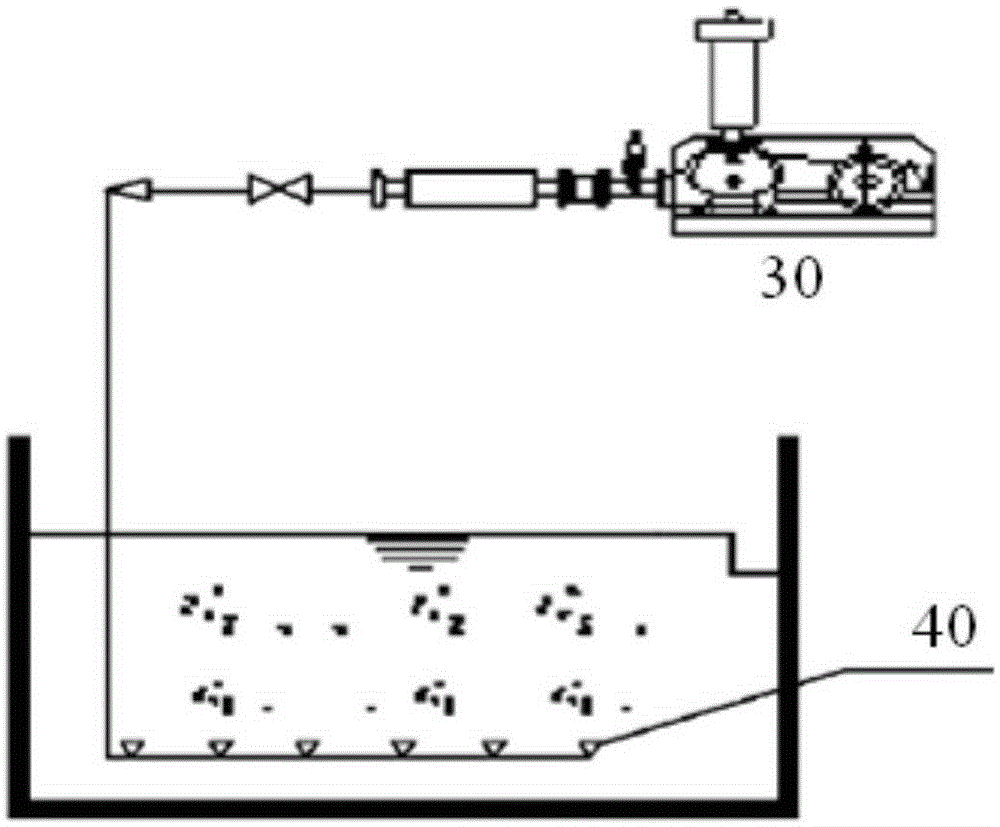

Efficient oxygenation system for confined space

ActiveCN106145315AIncrease hydraulic retention timeIncrease transfer rateTreatment using aerobic processesSpecific water treatment objectivesSludgeConfined space

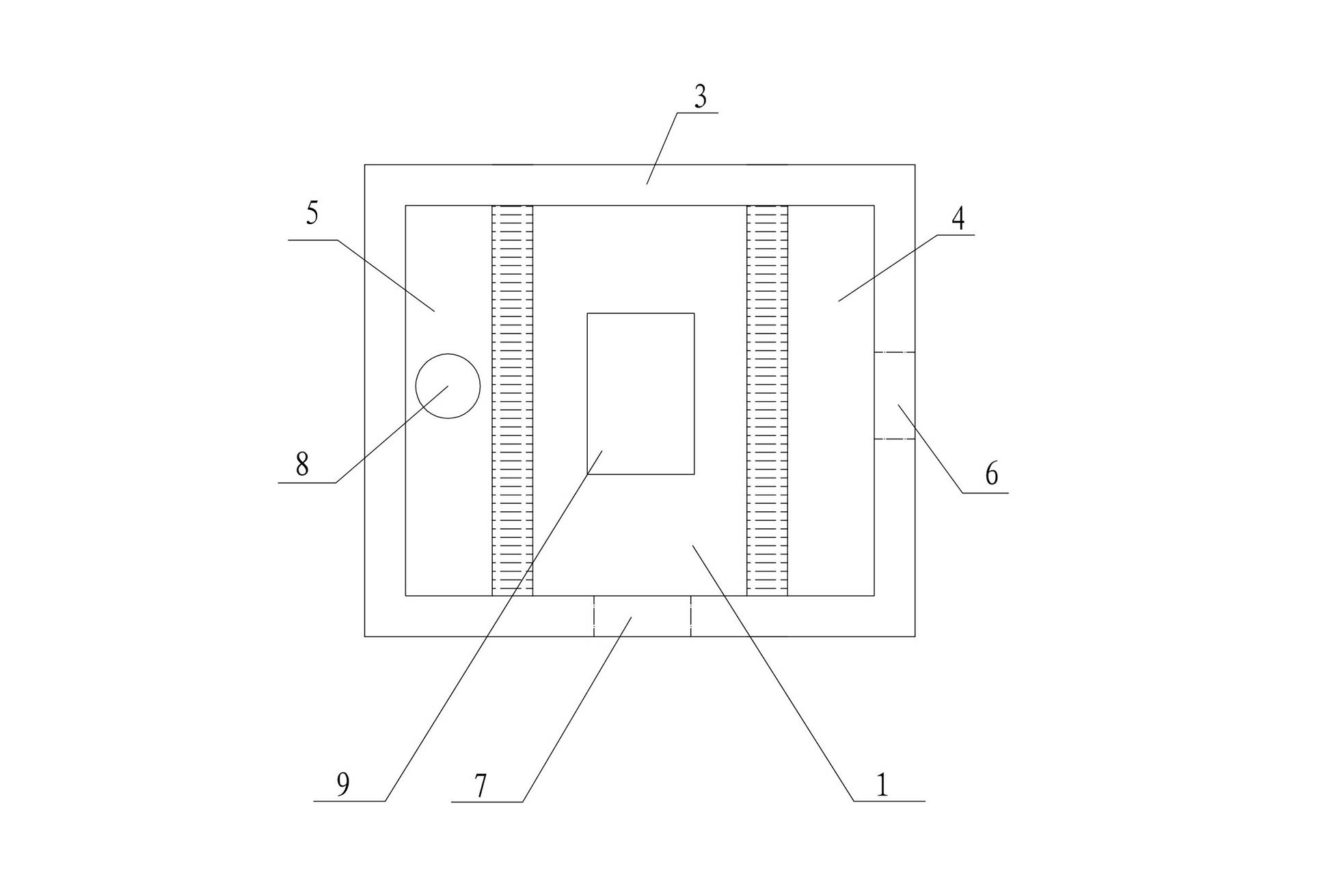

The invention discloses an efficient oxygenation system for a confined space. The system comprises an aeration tank, a plurality of flow guiding plates are arranged in the aeration tank in the water flow direction and divide the aeration tank into a plurality of areas, different quantities of aerators are arranged in the areas in a concentrated mode according to the oxygen dissolving requirements of the areas, the aerators are rotary-cutting and mixed-flowing aeration devices, a flow guiding cutter is arranged over a water outlet of each rotary-cutting and mixed-flowing aeration device and arranged outside a corresponding central air inlet pipe, and a buffer distance is formed between each flow guiding cutter and the corresponding water outlet; each flow guiding cutter is an inverted cone with the conicity of 60 degrees to 65 degrees. According to the efficient oxygenation system for the confined space, the problems that in actual engineering, aeration in an aerobic tank is not uniform, the total oxygen dissolving efficiency is low, sludge in the tank is deposited, the aerators are prone to fall off and be blocked and aged, the oxygen utilization efficiency is rapidly lowered, management and maintenance are inconvenient, and the cost is high are solved.

Owner:SHANGHAI SHIYUAN ENVIRONMENT PROTECTION TECH

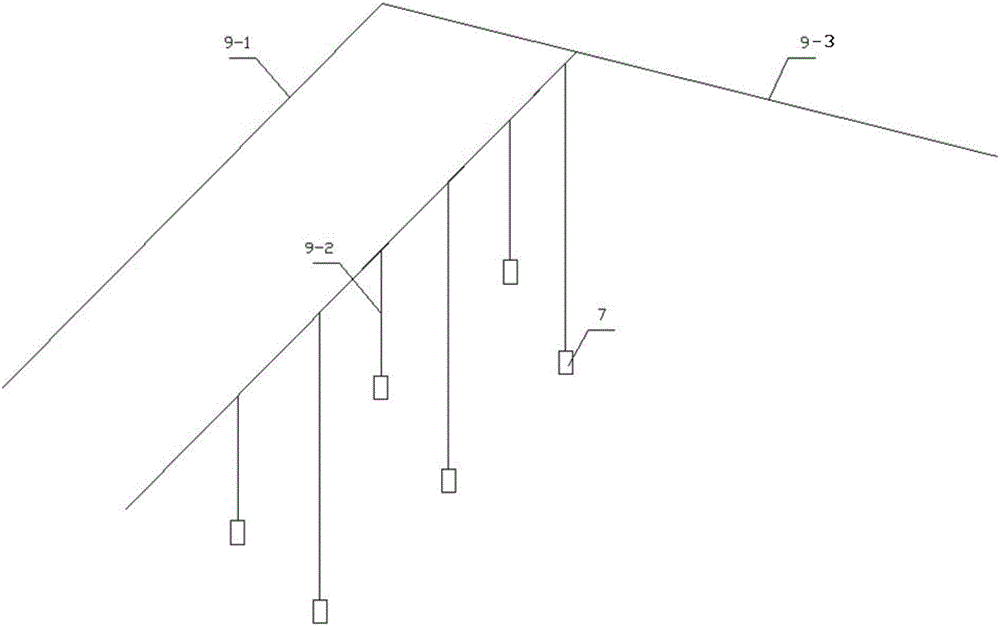

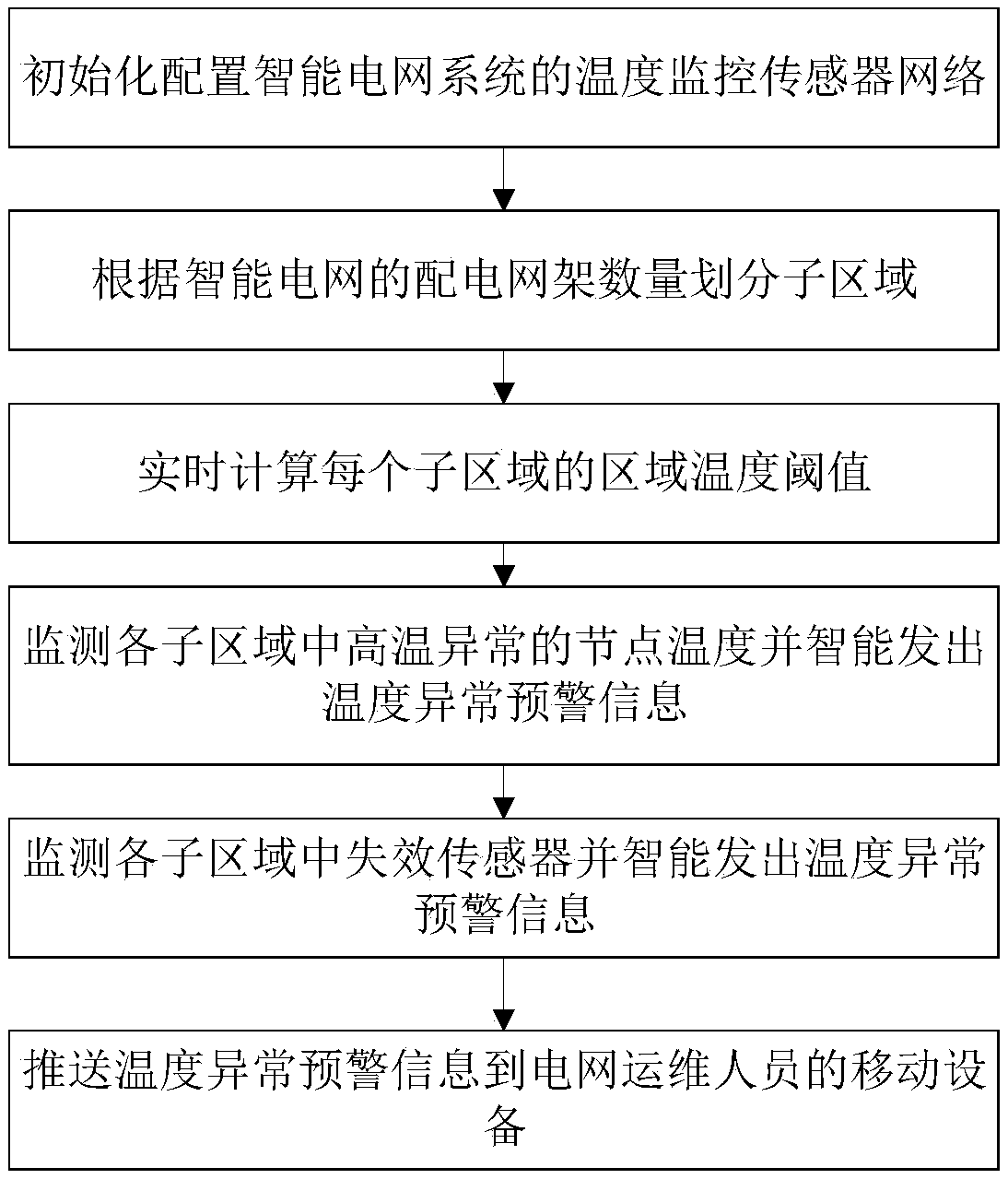

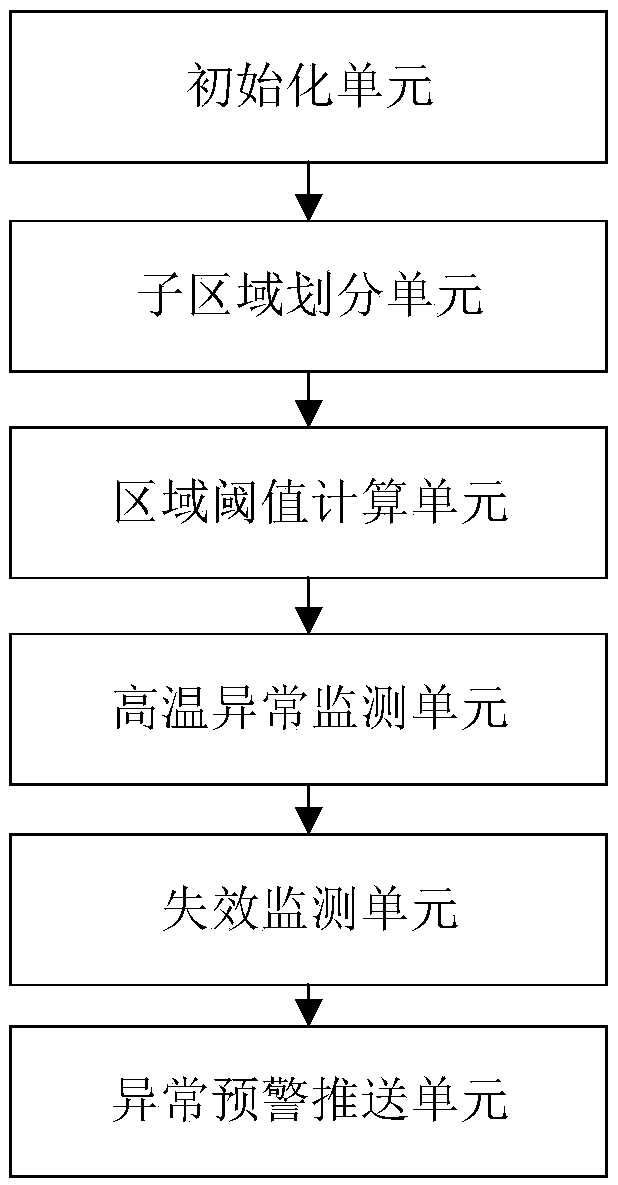

Intelligent power grid fault positioning method and device

ActiveCN109085463AImprove operation and maintenance efficiencyReal-time intelligent judgmentFault location by conductor typesInformation technology support systemDevice MonitorPower grid

The invention discloses an intelligent power grid fault positioning method and device. The method and the device monitor the operation temperature of distribution lines of the intelligent power grid system in real time, determine the normal operating state or abnormal fault operating state, warn about the area where the fault occurred, automatically estimate the location of the high-risk distribution network rack prone to occur fault and make an early warning mark, transmit the information through a communication function to a power grid base station and push it to the power grid operation andmaintenance personnel, so that faults can be processed more timely, and the influence caused by faults on the operation of the power grid is reduced. Measures can be taken in time for potential safety hazards to reduce the occurrence of operational faults. The distribution lines of each remote area are monitored in real time, so that the fault points can be intelligently judged, positioned in time and alarm can be timely raised when the remote areas occur an emergency situation, such as damage and fault of the distribution lines, so as to improve the operation and maintenance efficiency of the power grid.

Owner:GUIGANG POWER SUPPLY BUREAU OF GUANGXI POWER GRID CO LTD

Process method for overhauling main bearing hole of diesel engine cylinder block

InactiveCN101581260AImprove maintenance qualityAvoid scrappingCasingsMachines/enginesNumerical controlEconomic benefits

The invention relates to a process method for overhauling a main bearing hole of a diesel engine cylinder block. The half surface of a main bearing cap of the cylinder block is ground 0.3 to 0.5mm by a grinder, and the half surface with serious deformation is ground 0.6 to 0.8mm; the main bearing cap is provided with the cylinder block, a main bearing bolt is fastened, and the main bearing hole of the cylinder block is processed by a numerical control floor type borer; and centers of a first hole and a last hole are aligned on a main bearing pedestal semicircle of the first hole and the last hole of the main bearing hole of the cylinder block by a dial gauge, the cylinder block is fixed after the alignment, and a boring machine is adjusted to the center of the main bearing pedestal semicircle, so that the boring machine is moved 0.1mm toward the direction of a main bearing pedestal to the utmost. The overhauling process method can obviously improve the coaxiality of the main bearing hole of the cylinder block and the overhauling quality of bores, and reduces the operation trouble of a diesel engine. For the cylinder block of which the main bearing hole is seriously deformed, the overhauling process method can avoid scrapping the cylinder block, prolongs the service life of the cylinder block, and has obvious economic benefit.

Owner:CRRC QISHUYAN CO LTD

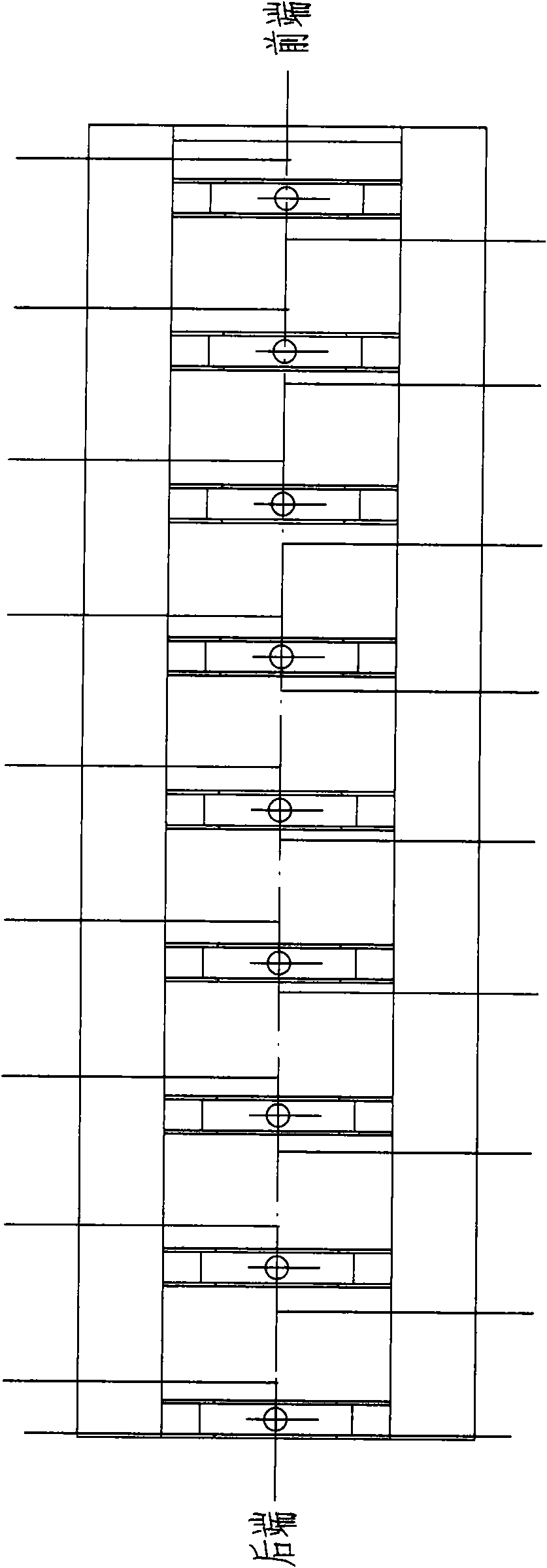

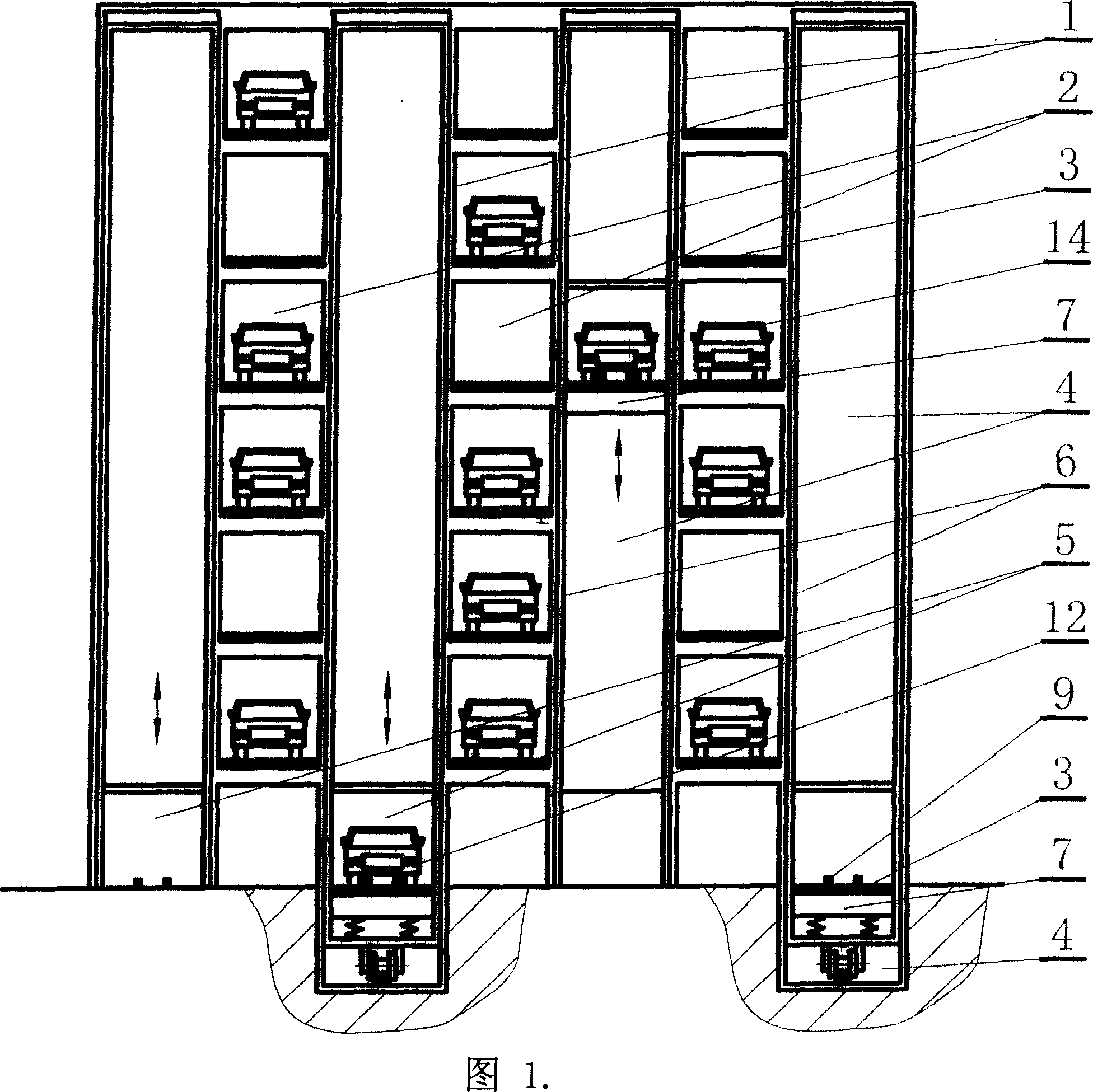

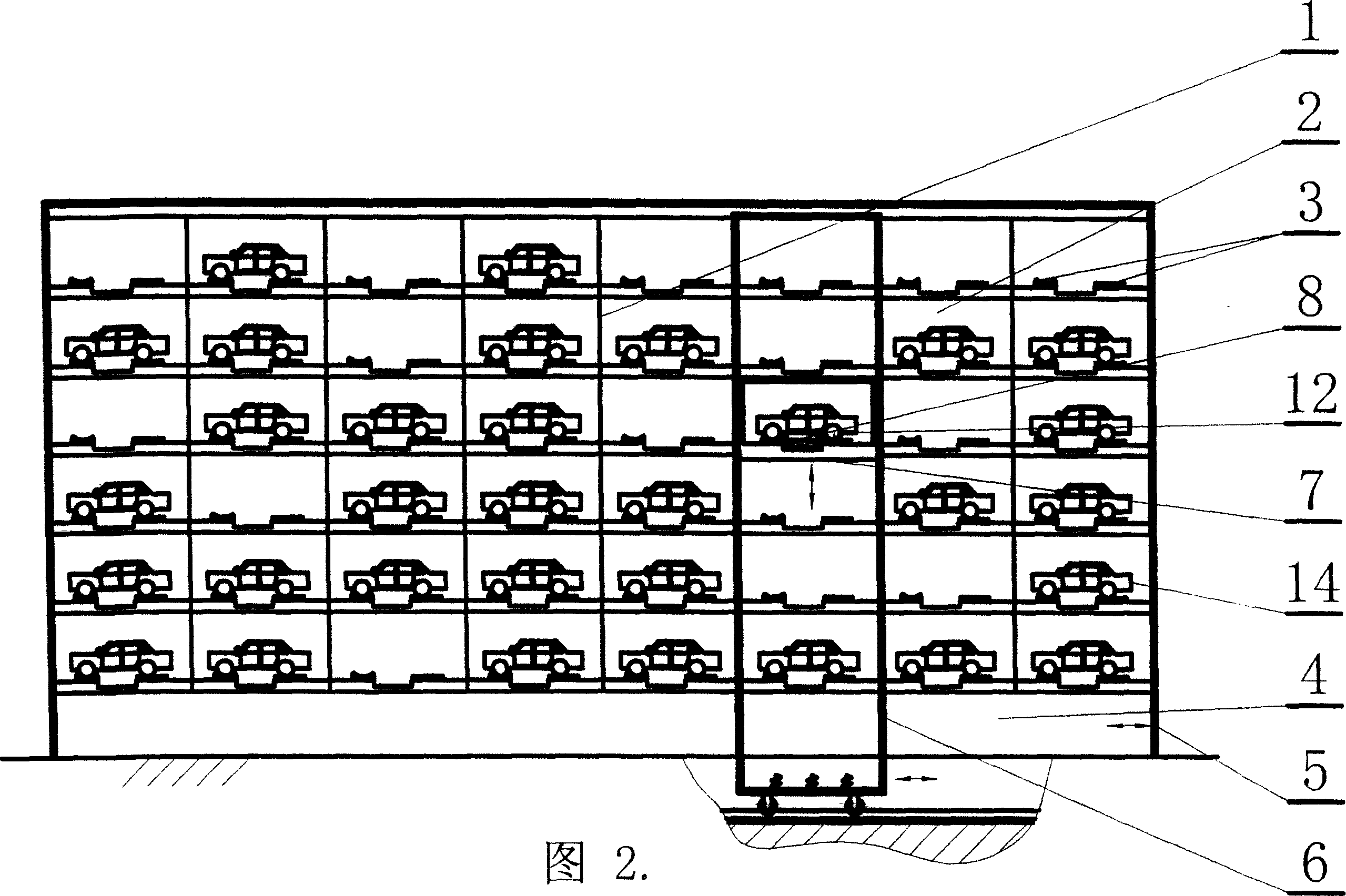

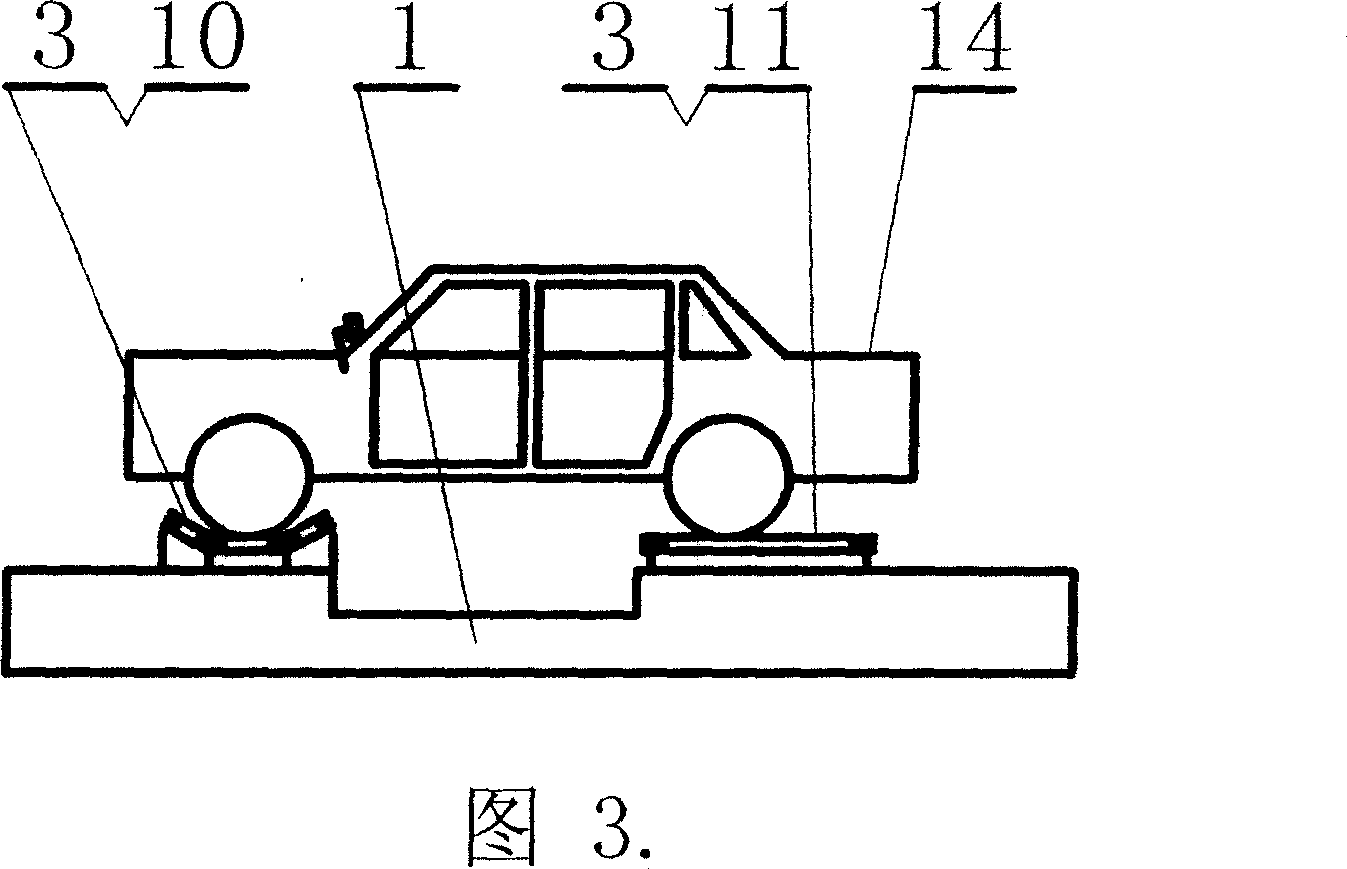

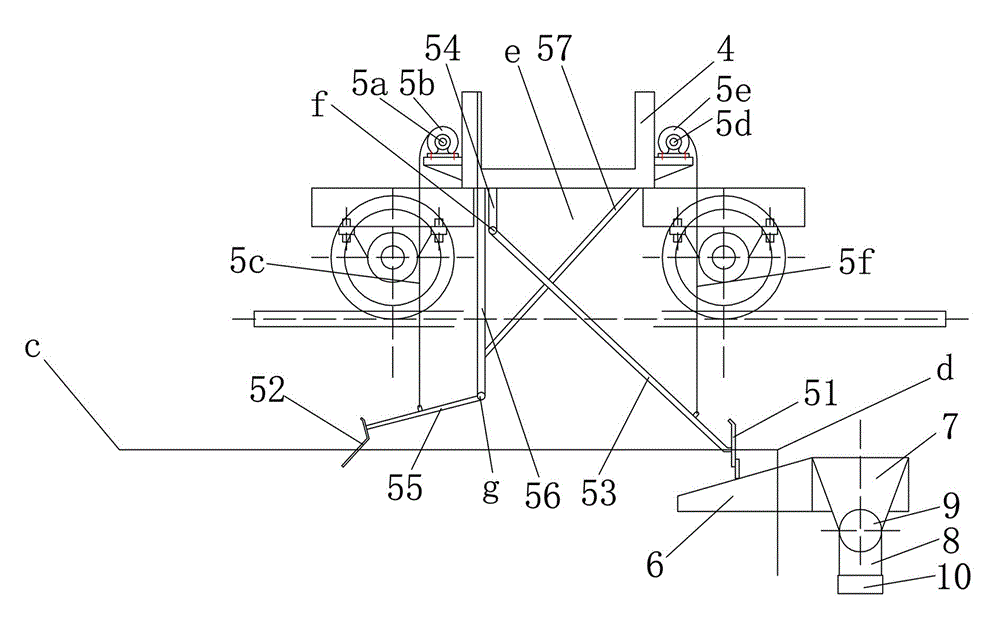

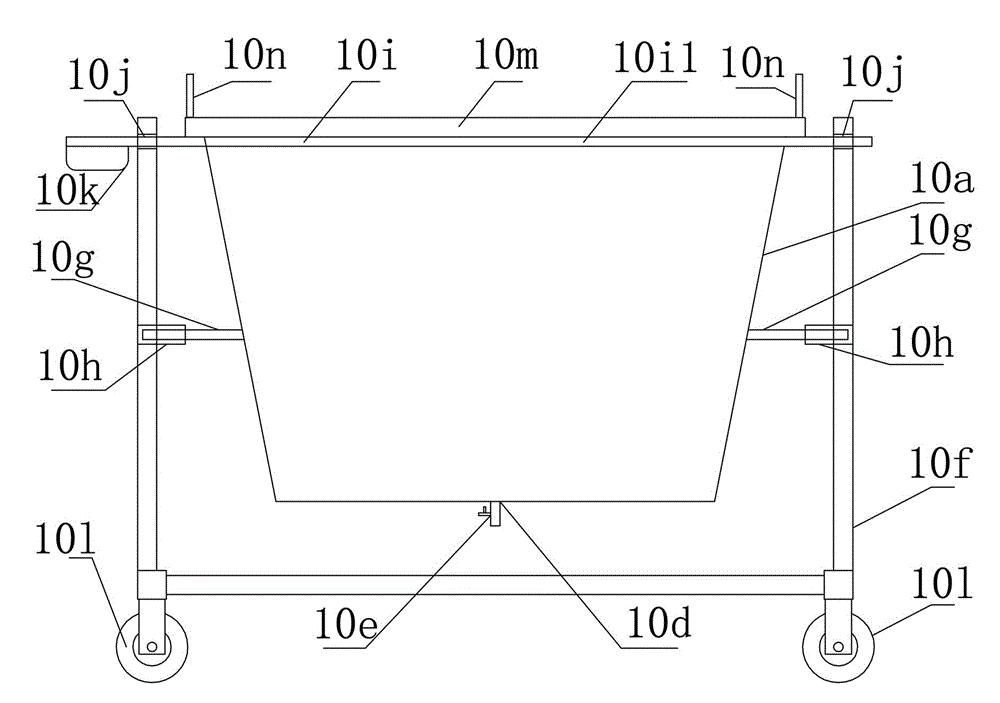

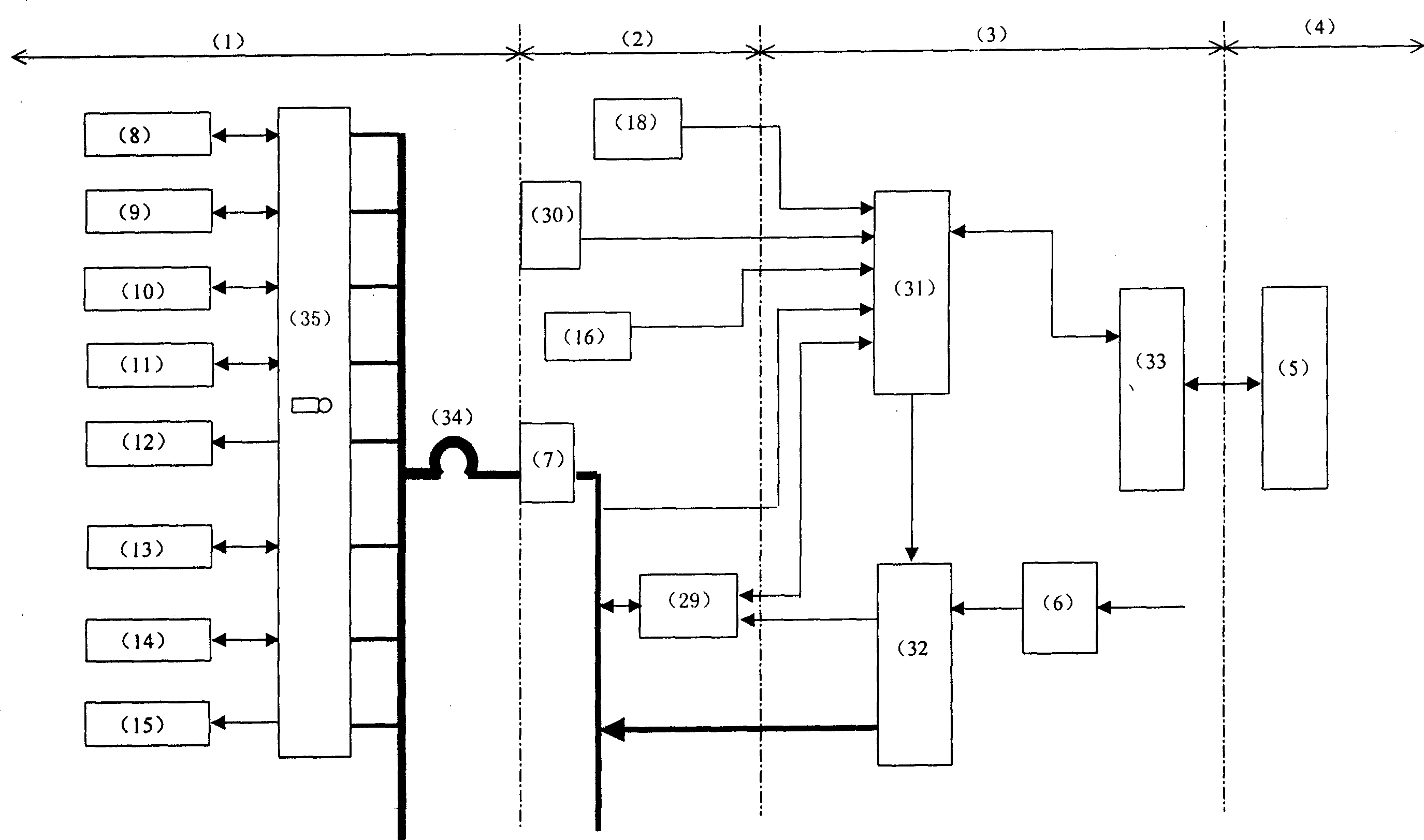

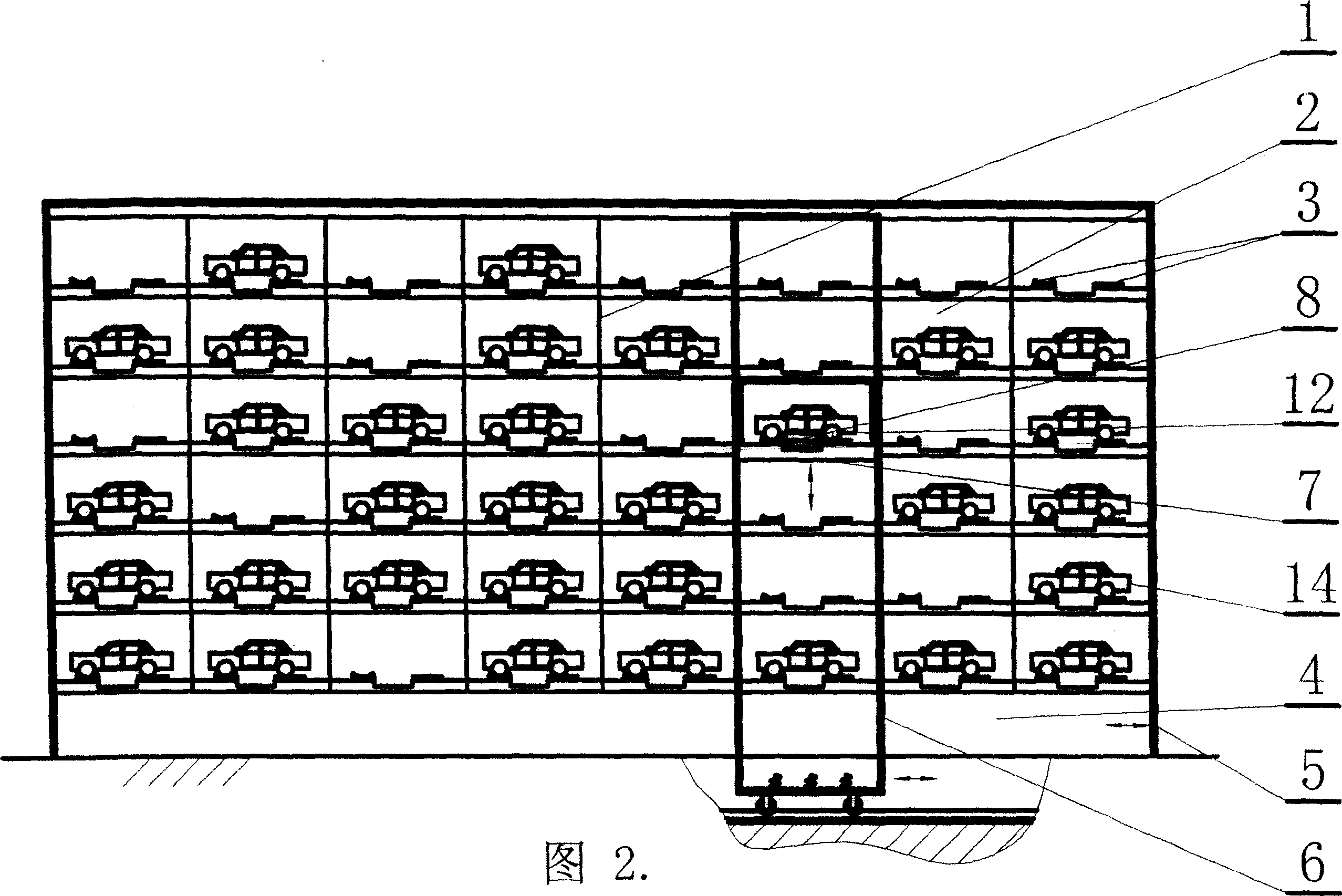

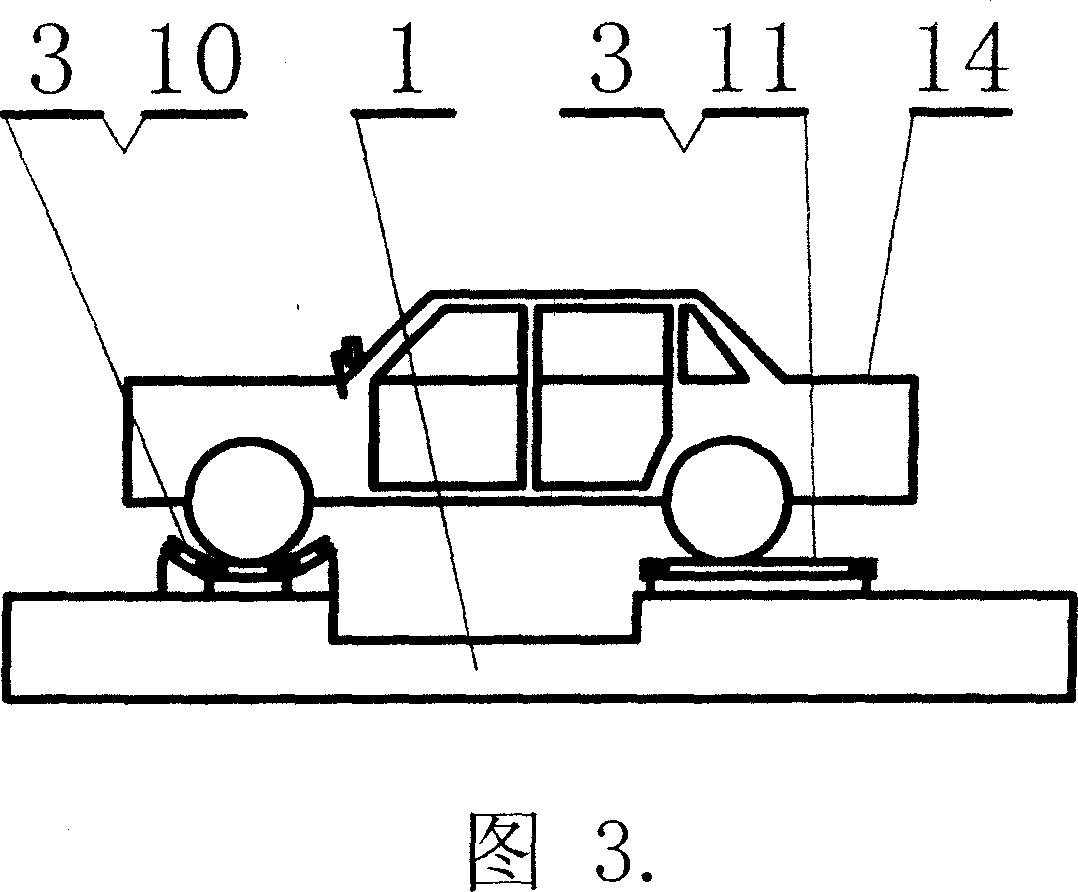

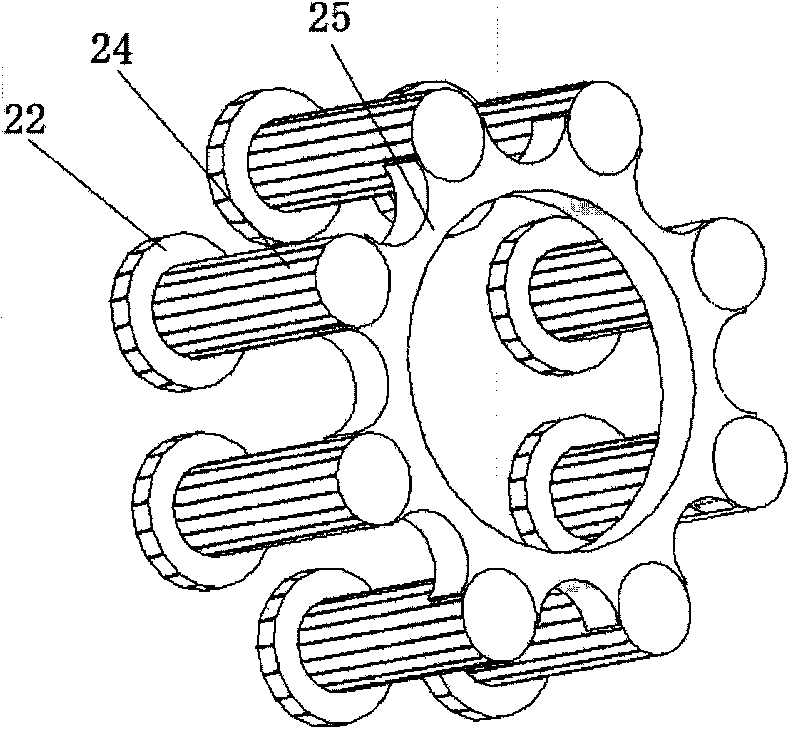

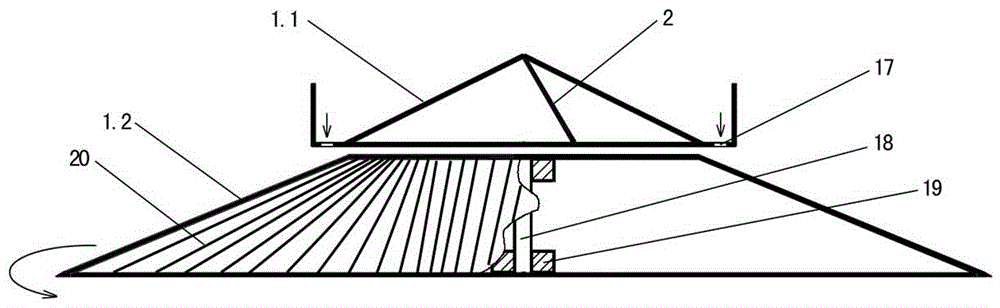

Multilane spacing parallel arranging stacker transport apparatus taking sending type rollaway parking equipment

A traffic engineering equipment parking areas over the roadway alongside stacker interval for handling delivery barrel road store parking equipment, includes : steel-storage, parking, child care up roller wheels, roadway, run stacker, vehicle handling devices, delivery vehicles; roadway with a number of storage-type steel parallel staggered side-by-side arrangement, all of the roadway or the bottom of the top set up run-steel storage in the adjacent roadway between the two, its every vertical layer along the roadway to set up a number of parking areas, each parking zone on the wheel set up child care can be entrusted Raceway up a car, each roadway with a vertical stacker can be mobile, stacker removal vehicles are equipped with lifting devices can be mobile, all the vehicles moving on the same set of wheels asked Raceway up and there can be a two-way horizontal left-to-right move to enter into the parking vehicles delivery agencies for access to super vehicle operations. This present invention vehicles are large space, covers little fields, structure is simple and cost is low, operates high efficiency and reliable.

Owner:SHANGHAI JIAO TONG UNIV

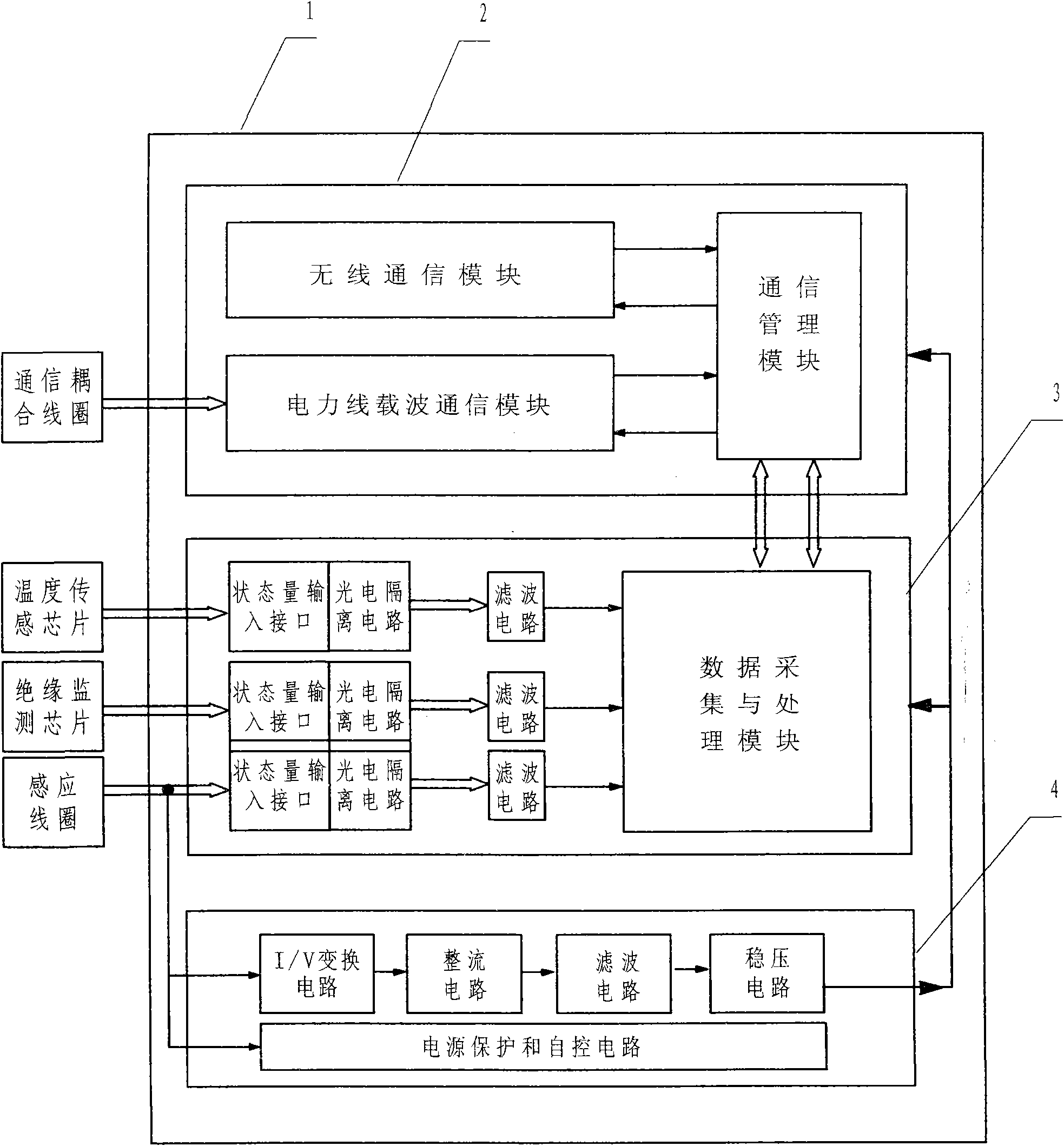

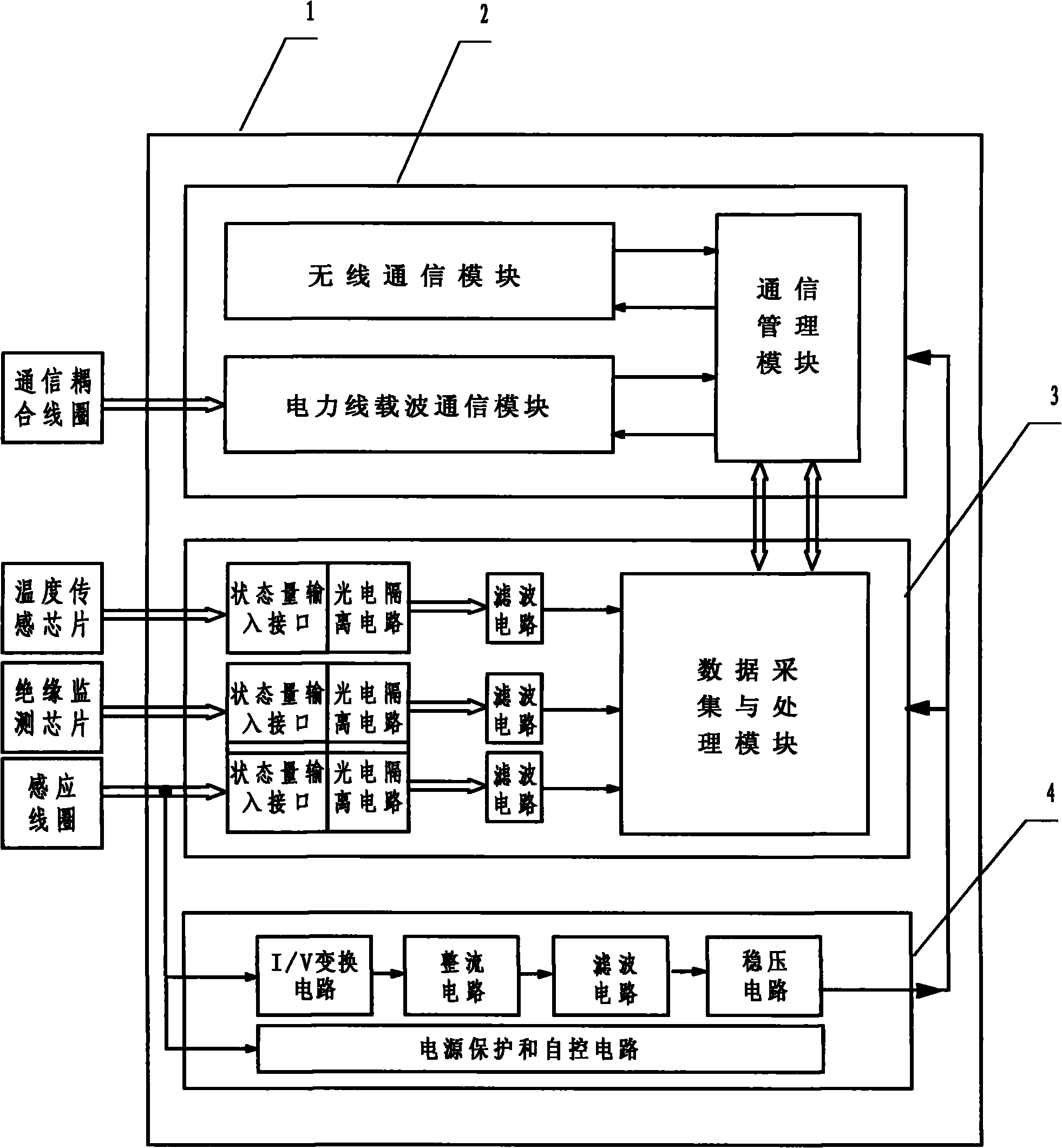

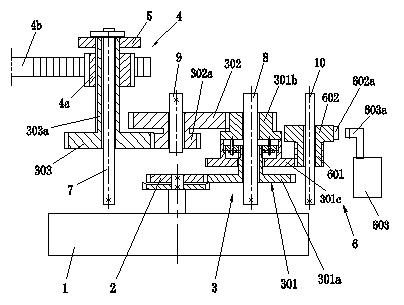

Intelligent 10kV power line state sensor

InactiveCN102313856AAccurate monitoringEasy to installThermometer detailsCurrent/voltage measurementCarrier signalEngineering

The invention relates to an intelligent 10kV power line state sensor. The sensor is characterized in that a sensor insulator (1) is arranged, wherein a communication unit (2), a sensing unit (3) and a power supply unit (4) are insulated and encapsulated in the interior of the insulator; a communication coupling coil used for coupling a carrier signal on a high voltage line and a sensing coil usedfor acquiring alternating current and realizing the sampling of the change of the line current of the power line are arranged outside the insulator; and an insulation monitoring chip and a temperature sensing chip in the sensing unit are also arranged. The sensor disclosed by the invention is applied to real-time monitoring on the temperatures, insulation levels and voltage and current changes ofa 10kV overhead line and a cable line, so as to realize line state abnormal alarming and accident information reporting. The sensor is an intelligent monitoring and sensing device for a 10kV distribution network. The sensor can be accurately controlled, has perfect performance and can powerfully ensure the safe running of a power grid.

Owner:BEIJING TAIYOUMEI TECH

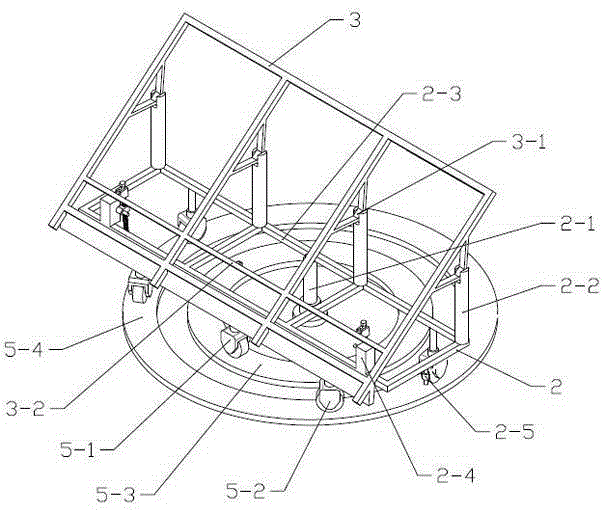

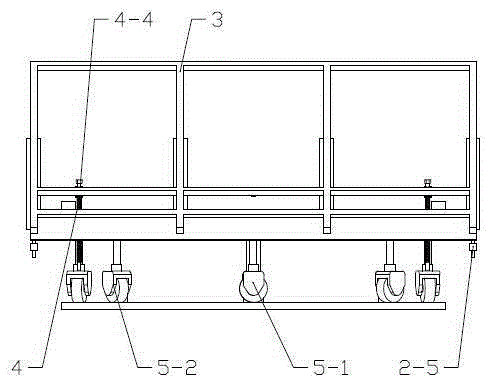

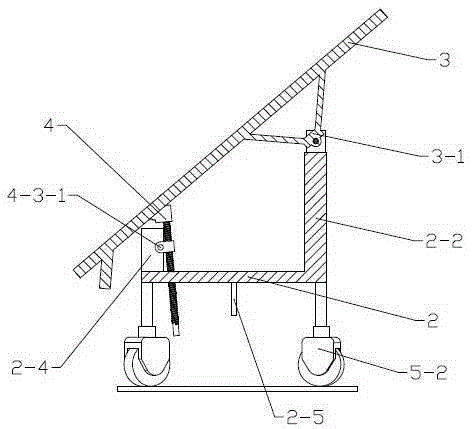

Rotation type photovoltaic panel support frame and support frame set

InactiveCN105429573AReduce installation costsLow operating and maintenance costsPhotovoltaic supportsPhotovoltaic energy generationDaily operationSocial benefits

The invention discloses a rotation type photovoltaic panel support frame. The support frame comprises a rotating frame body which is hinged to the ground through a vertical revolving shaft and is connected with a rotating adjusting mechanism, and an inclined frame body which is hinged to support pillars on the rotating frame body through hinged seats, and a tilt angle adjusting mechanism used for adjusting the tilt angle of the inclined frame body is hinged to a cross beam I of the lower edge of the inclined frame body; by using the support frame, the tilt angle and orientation of a photovoltaic panel can be adjusted according to needs, the daily operation maintenance is convenient, the economic input and human input are reduced, and better economic benefit and social benefit are realized.

Owner:王佩华

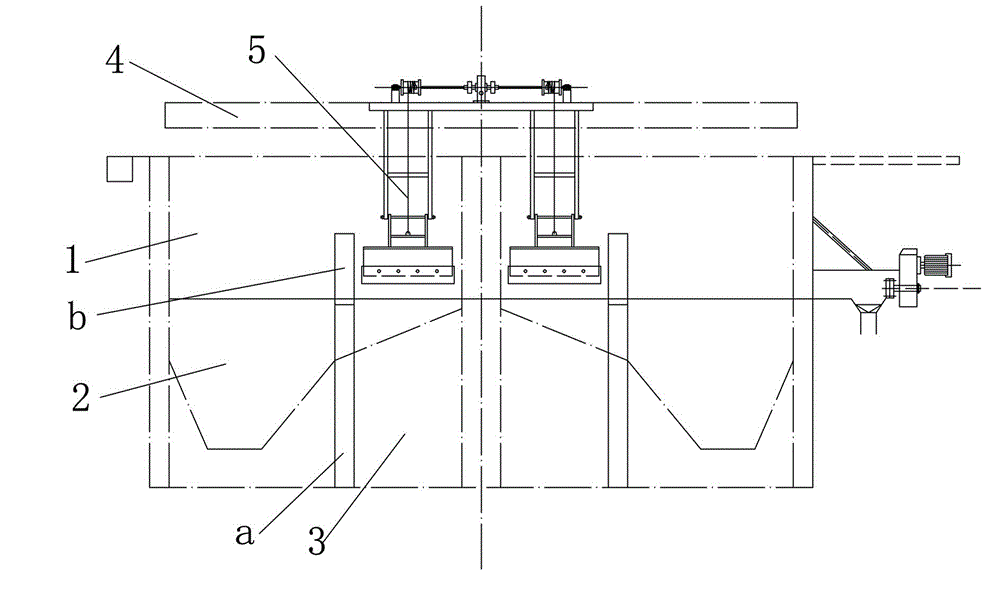

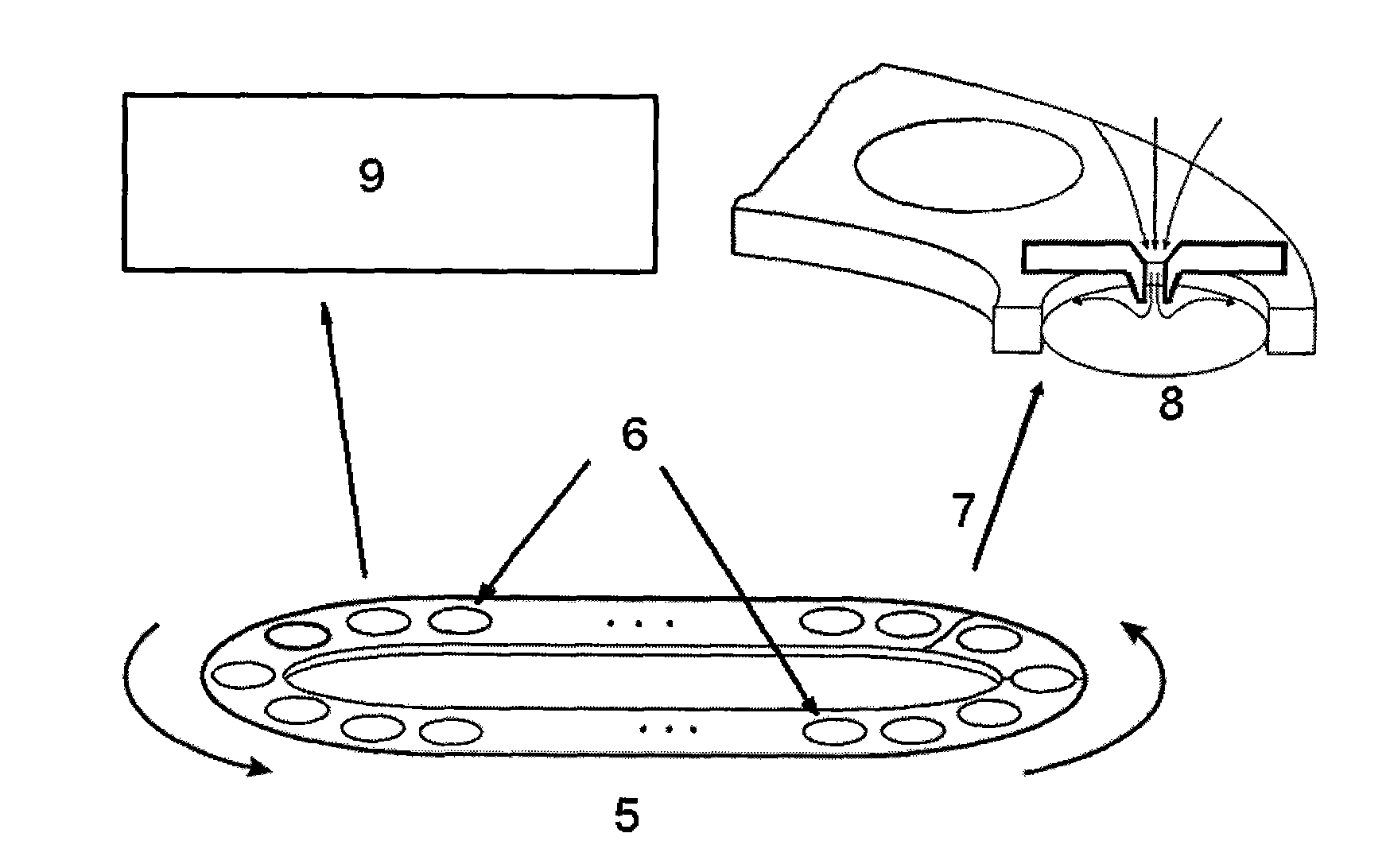

Scum treatment device of aerated grit chamber

InactiveCN103332771AExcellent scraping effectGuaranteed uptimeFatty/oily/floating substances removal devicesSettling tanks feed/dischargeEngineeringWater intake

The invention provides a scum treatment device of an aerated grit chamber, which is obvious in scum scraping effect, runs stably, is high in efficiency, and has less faults. The scum treatment device of the aerated grit chamber comprises an aerated grit chamber, wherein the aerated grit chamber is provided with a grit absorption bridge; the grit absorption bridge is suspended above the aerated grit chamber and moves linearly back and forth along the trend of the aerated grit chamber; the linear moving path of the grit absorption bridge is provided with an initial end close to a water intake part of the aerated grit chamber and a tail end close a water drainage part of the aerated grit chamber; the grit absorption bridge is provided with a grit absorption pump acting on the bottom of a chamber of an aerated grit zone as well as a scum scraping device acting on a chamber surface of an oil removing and scum scraping zone; the scum scraping device comprises a scum scraping plate and a pre-scraping plate which can be installed on the grit absorption bridge at the same time in a lifting mode, are respectively distributed on the chamber surfaces of the oil removing and scum scraping zone along the motion direction of the grit absorption bridge back and forth, and are respectively positioned at the outer side of a space below the grit absorption bridge; when the grit absorption bridge is positioned on the initial end of the linear moving path, the pre-scraping plate is fit to the chamber surface of the water intake part of the grit absorption bridge; when the grit absorption bridge is positioned on the tail end of the linear moving path, the scum scraping plate is fit to the chamber surface of the water drainage part of the aerated grit chamber.

Owner:温州市环境发展有限公司

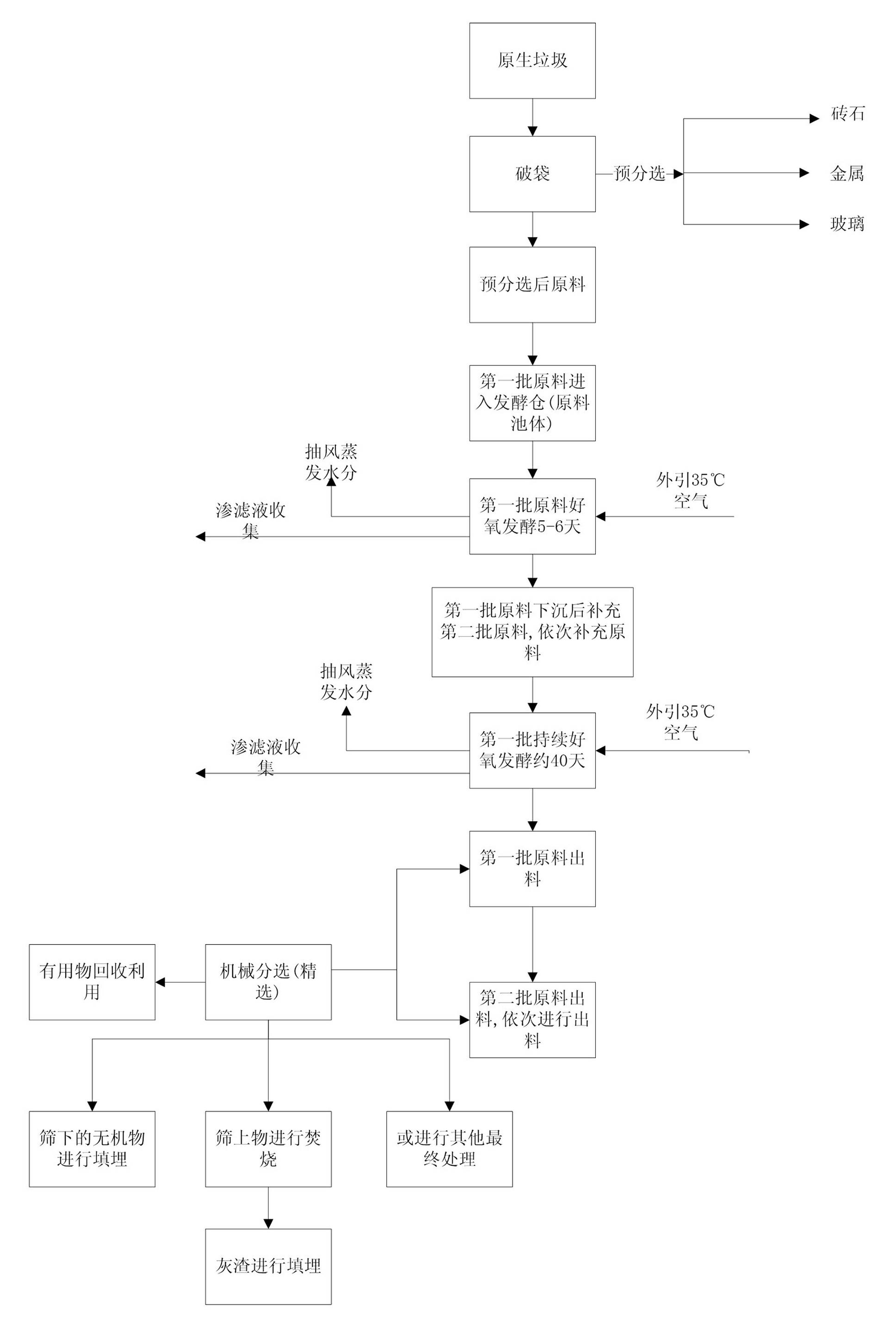

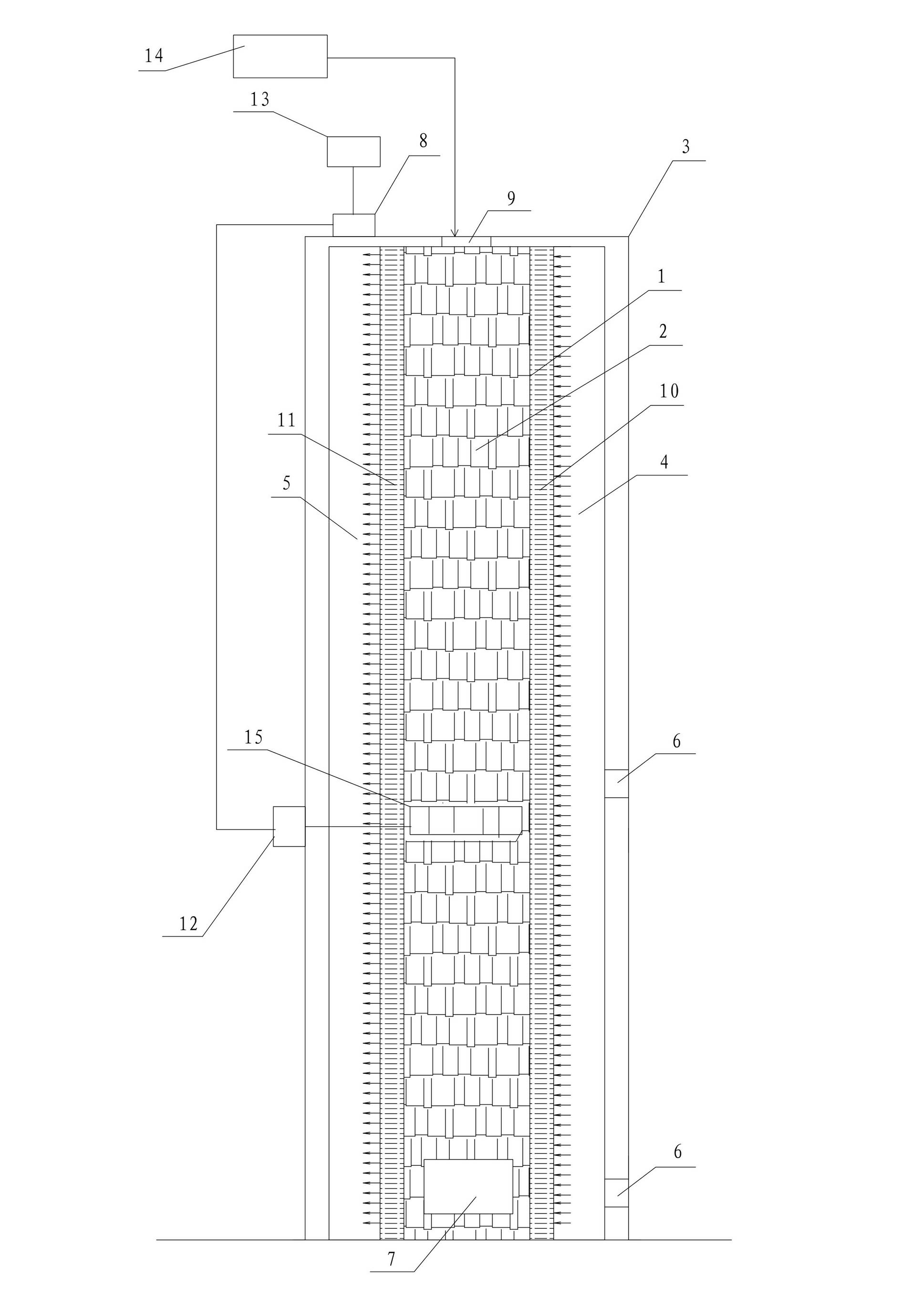

Device and method for large-scale pretreatment of domestic garbage

ActiveCN102626710AReduce moistureImprove low heatSolid waste disposalAutomatic controlSmall footprint

The invention discloses a device and a method for large-scale pretreatment of domestic garbage. The device comprises a vertical cylinder, an air suction component, a double-screw discharge component and a temperature automatic control component, wherein the air suction component is matched with the vertical cylinder; a raw material cavity, an air inlet duct and an air outlet duct are arranged in the vertical cylinder; the air inlet duct and the air outlet duct are oppositely arranged at the two ends of the raw material cavity; the face of the air inlet duct facing the raw material cavity is provided with a plurality of air inlet holes which are communicated with the raw material cavity; the face of the air inlet duct far away from the raw material cavity is provided with more than one air inlet; the face of the air outlet duct facing the raw material cavity is provided with a plurality of air outlet holes which are communicated with the raw material cavity; and the face of the air outlet duct far away from the raw material cavity is provided with more than one air outlet. According to the method, the garbage material is continuously filled into the raw material cavity of the vertical cylinder lot by lot, fermented by intake air and continuously discharged lot by lot. The device has the advantages of simple and compact structure, small floor area and the like; and large-scale, industrial, engineered and continuous flow line production of the pretreatment of the domestic garbage can be realized.

Owner:HUNAN JUNXIN ENVIRONMENTAL PROTECTION CO LTD

Amino multisection counterflow exhaust smoke processing device and method

InactiveCN101513587AEffective controlImprove stabilityDispersed particle separationLiquid ratioEngineering

The invention discloses an amino multisection counterflow exhaust smoke processing device and a method thereof. The invention takes volatile ammonia as raw material and the recovered acid waste gas as useful product. The innovation of the invention essentially lines in providing three independent absorption liquid circulating systems and a standby circulating system, so that the device has six functions comprising uniform gas distribution and gas-liquid separation; the device is provided with six gas-liquid contacting components comprising a uniform distribution device and a foam destroyer; more particularly, the size of an absorption liquid circulating pipe and the absorption liquid circulating quantity are optimized, so that the ratio between the diameters of a circulating pipeline and equipment is 0.04-0.1; meanwhile, the running gas-liquid ratio is set to be 70-195. Compared with the prior art, the stability and reliability of the device are greatly improved, ammonia escape loss can be effectively controlled, the energy consumption is low, and the structure of the device is simple, thus preventing the device from scarring and being blocked as well as saving investment and running cost. Therefore, the invention has obvious advantages in the smoke removing and purifying fields such as a boiler, etc.

Owner:王建敏

Automatic trough-unloading truck with remote controller

InactiveCN1636793AReduce operational failuresStrong real-timeVehicle with tipping movementTransportation itemsPower cableElectric drive

The automatic trough-unloading truck with remote controller for metallurgical industry has on-truck electric equipment connected to and controlled by on-truck control box and driven with the on-truck electric driving equipment; on-truck control box with communication lines and power lines connected to the collecting box; collecting box with communication lines and power lines connected via power-communication cable to ground connecting box; and ground connecting box with communication lines connected to central controller via communication cable and power lines connected to ground power distributor via power cable. The trough-unloading truck is controlled with the ground central controller to complete various detection, control and execution operations.

Owner:BAOSHAN IRON & STEEL CO LTD

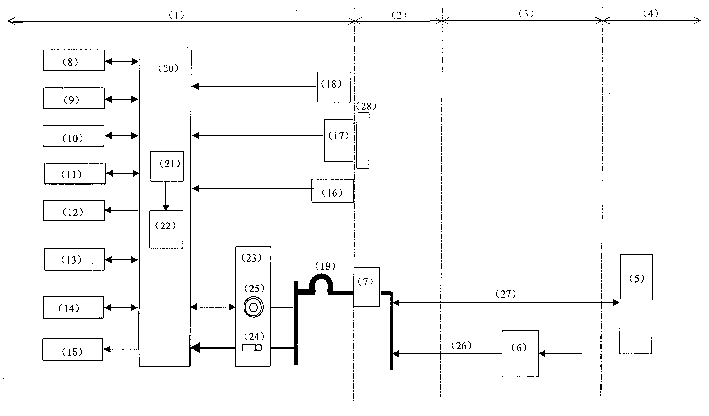

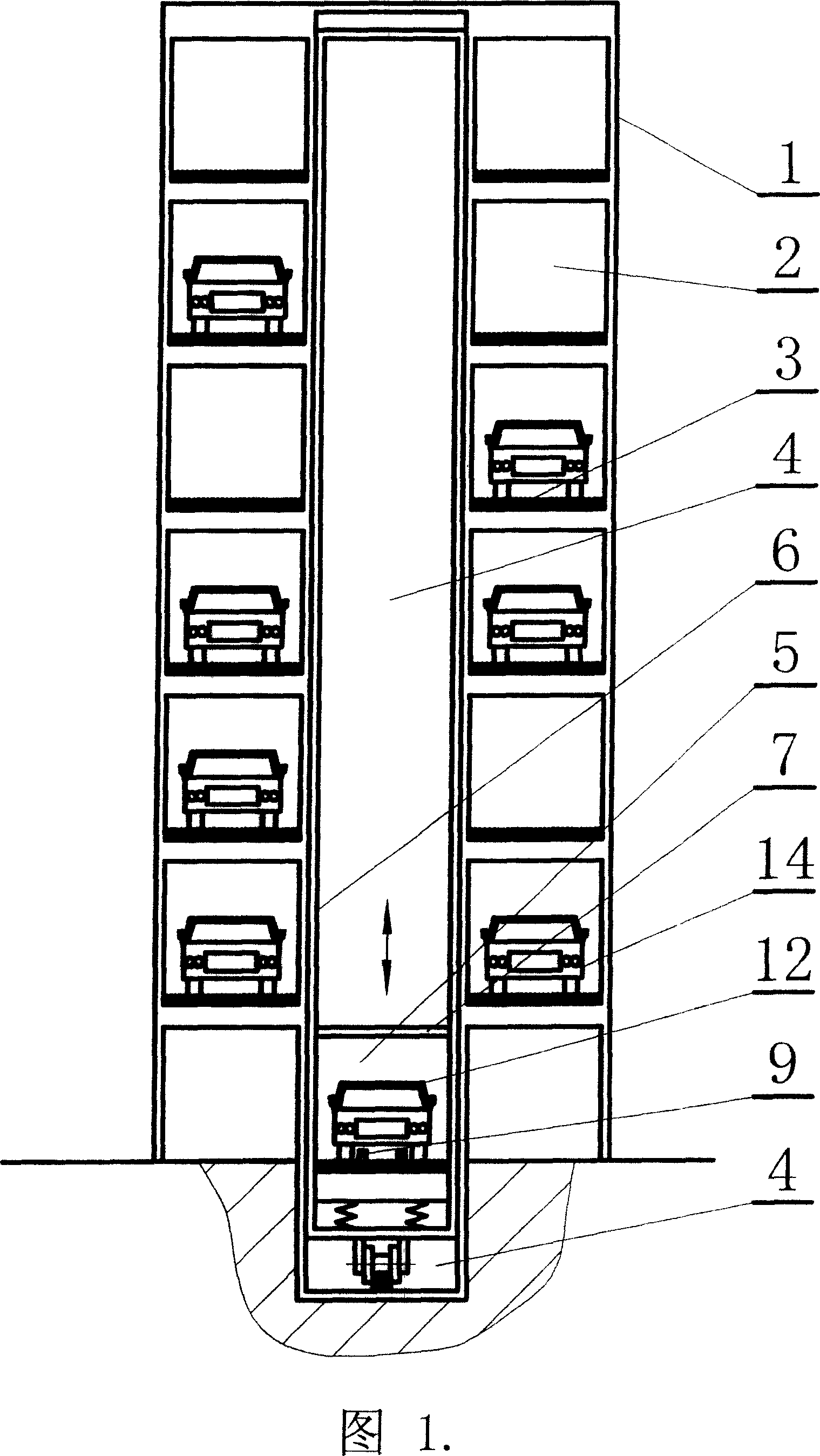

Single lane stacker transport apparatus taking sending type rollaway parking equipment

A store parking equipment of traffic engineering equipment parking area of single roadway stacker removal device delivery barrel road includes: multi-storey steel framework, parking area, carriage wheel care up, roadway, run stacker, vehicle handling devices, delivery vehicles; The roadway lies in the central of multi-storey steel framework, the run stacker was set in the bottom or the top-ins of the roadway, A number of vertical parking areas were settled up on each floor of multi-storey steel framework which is on the bilateral of roadway along the roadway, each parking area on the wheel set up an carriage wheel care up, run stacker can be entrusted in longitudinal movement along the roadway. Vehicle handling devices moves in vertical line, for handling corresponding transportation vehicles were parked in the same location of vehicle handling devices, after vehicle handling devices there can be two-way between horizontal telescopic mobile submerged deposit areas for the delivery of vehicles for institutions to seek access to operations vehicle. This invention can provides large space vehicles, covers little fields, and structure is simple low cost, and is reliable to operate with high efficiency.

Owner:SHANGHAI JIAO TONG UNIV

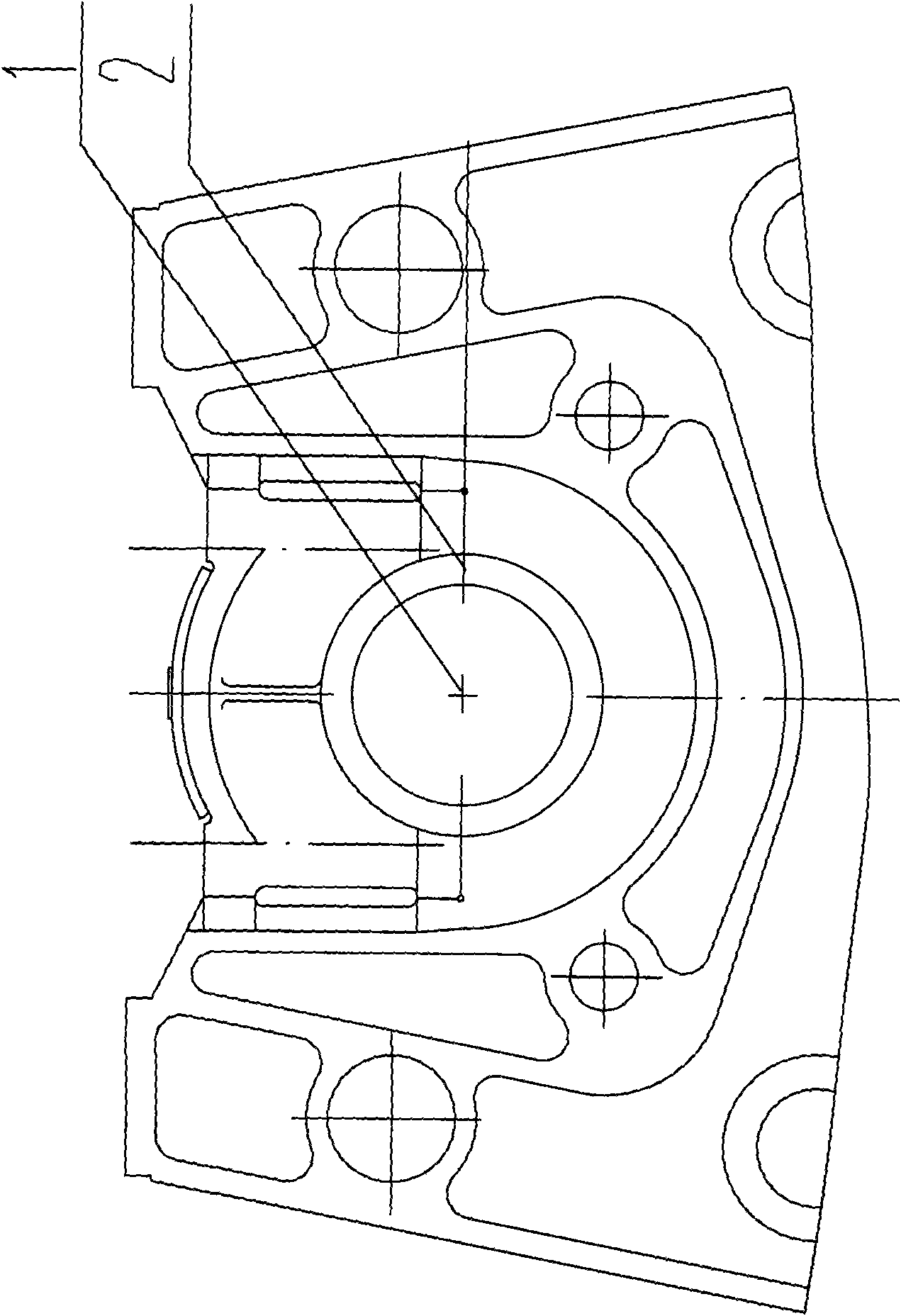

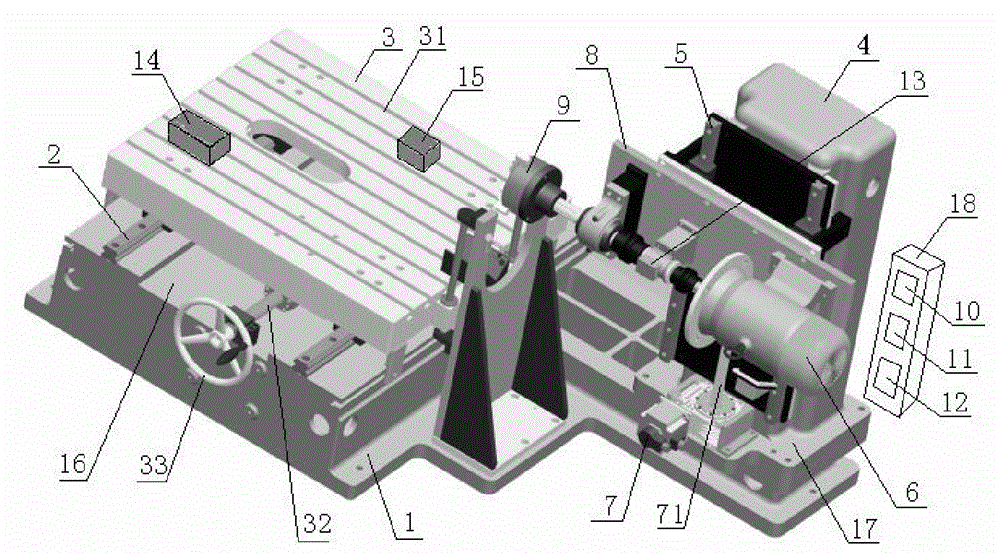

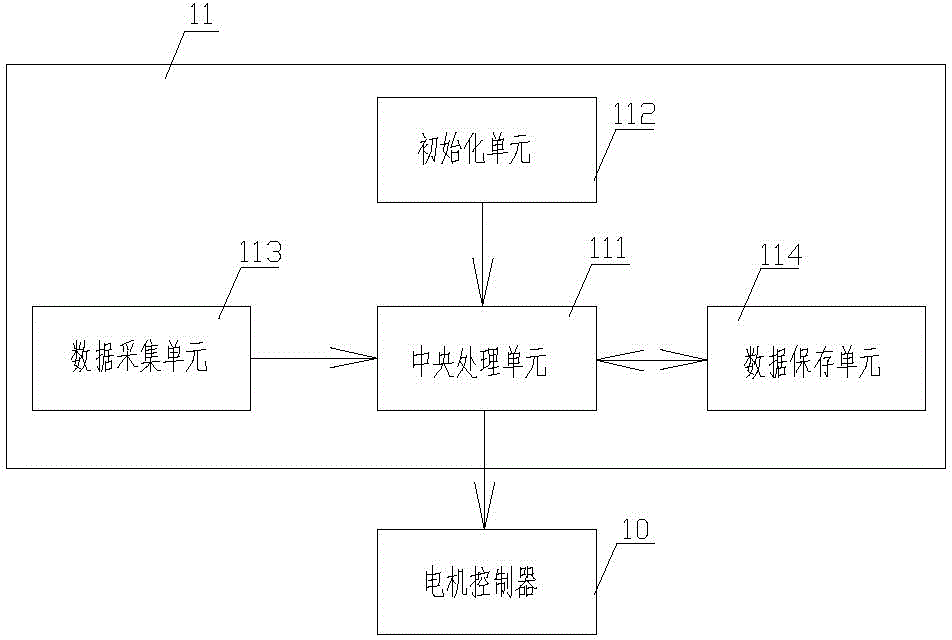

Screw air compressor mainframe performance detection device

InactiveCN102797670AReduce operational failuresGuaranteed uptimePump testingPositive-displacement liquid enginesComputer moduleSlide plate

The invention discloses a screw air compressor mainframe performance detection device. A high-end plane of a high-low box base is provided with a movable platform through two horizontal guide rails; a lifting upright post is vertically arranged on the low-end side of the high-low box base; a lifting slide plate is arranged on the lifting upright post through lifting guide rails, and is driven to lift through a servomotor arranged at the lower end of the high-low box base; a variable frequency motor of which the front end of a rotating shaft is provided with a connector is arranged on the lifting slide plate; a torque sensor is arranged on the rotating shaft of the variable frequency motor; a temperature sensor and a vibration sensor are arranged on a screw air compressor mainframe to be detected; signal output ends of the sensors are connected to the input end of an analog / digital (A / D) conversion module; the input and output ends of an operation detection module are respectively connected with the output end of the A / D conversion module and the input end of a motor controller; and the motor controller controls the variable frequency motor and the servomotor to operate. The detection device performs system detection on the screw air compressor mainframe, so that various technical indexes of the screw air compressor mainframe meet requirements, operation troubles are reduced and normal operation is ensured.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

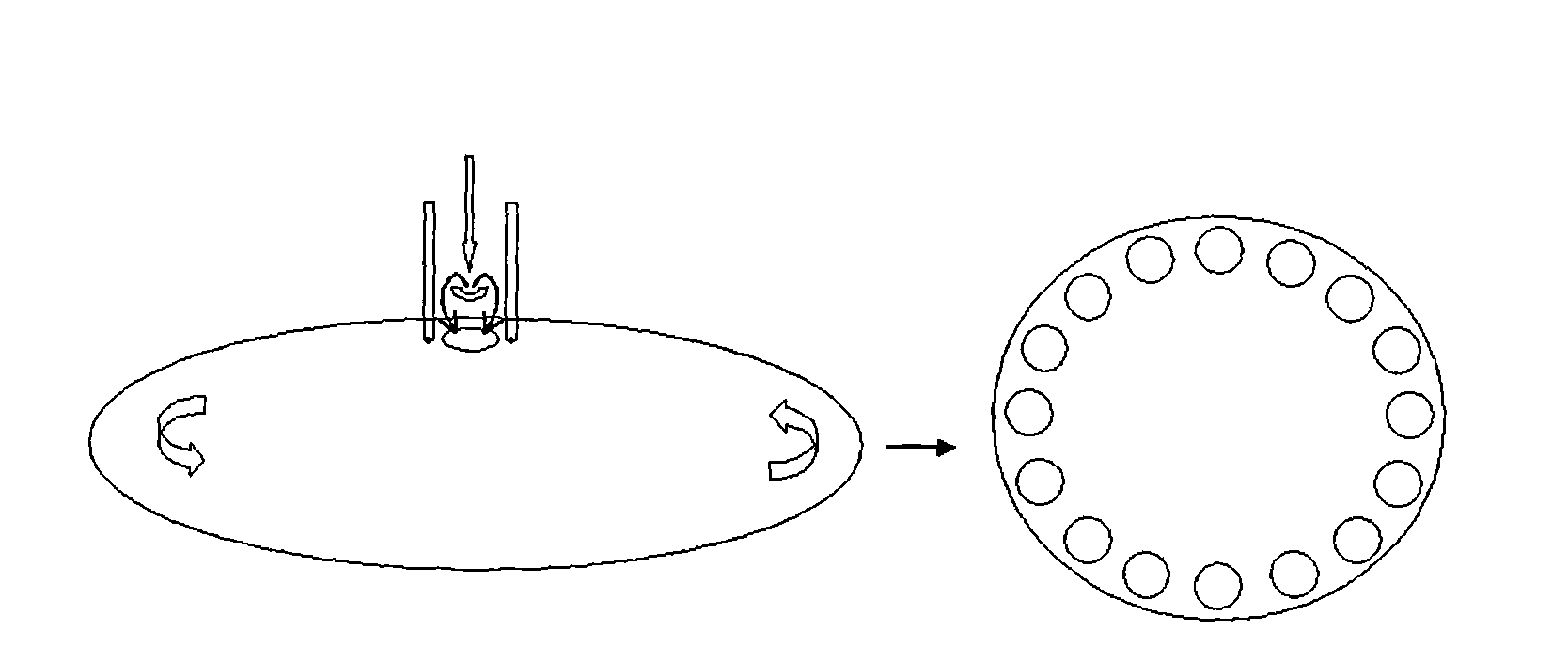

High time resolution microsampling method of atmospheric aerosol

InactiveCN102081066AMonitoring pollutionNo loss of collection efficiencyMaterial analysis by electric/magnetic meansChemical speciesFine particulate

The invention belongs to an aerosol measuring technology, in particular to a high time resolution microsampling method and device of atmospheric aerosol. The invention realizes the high time resolution microsampling of aerosol in the atmospheric environment by combining a fine particle microsampling device and a rapid high-sensitivity detection technology, realizes the tracking measurement of time resolution aiming at components harmful to human bodies in fine particles and monitors the pollution of the fine particle aerosol. The rapid high-sensitivity detection technology provided by the invention comprises an aerosol particle size cutting technology, an aerosol particle size selecting technology, a high-sensitivity aerosol detection technology and a computer control technology. By applying the fine particle microsampling device provided by the invention, unequal sampling times and different sampling frequencies can be finally set according to different chemical species in different particle size ranges, such as PM10 and PM2.5 to obtain a sampling quantity reaching a detection limit; the corresponding sampling area is smaller than 1 cm<2>, and the whole machine has the weight less than 10 kg and is portable.

Owner:FUDAN UNIV

System for efficiently carrying out oxygenation in finite space

ActiveCN105198071AIncrease hydraulic retention timeIncrease transfer rateTreatment using aerobic processesSustainable biological treatmentSewageSludge

The invention discloses a system for efficiently carrying out oxygenation in finite space. The system comprises an aeration tank, wherein a plurality of guide plates are arranged in the aeration tank and divide the aeration tank into a plurality of areas; and different quantities of aerators are arranged in the plurality of areas respectively in a concentrated manner according to the oxygen dissolution requirements of the areas. The system is designed aiming at some defects of existing aeration systems in the actual operational processes and can be applied to aerobic biological treatment units of various industrial wastewater and domestic sewage. The problems of nonuniformity of aeration in aerobic tanks, low overall oxygen dissolution efficiency, accumulation of sludge in tanks, easiness in falloff, blockage and aging of the aerators, quickness in reduction of the oxygen utilization efficiency, inconvenience in management and maintenance, high cost, and the like in actual engineering are solved by adopting the system.

Owner:SHANGHAI SHIYUAN ENVIRONMENT PROTECTION TECH

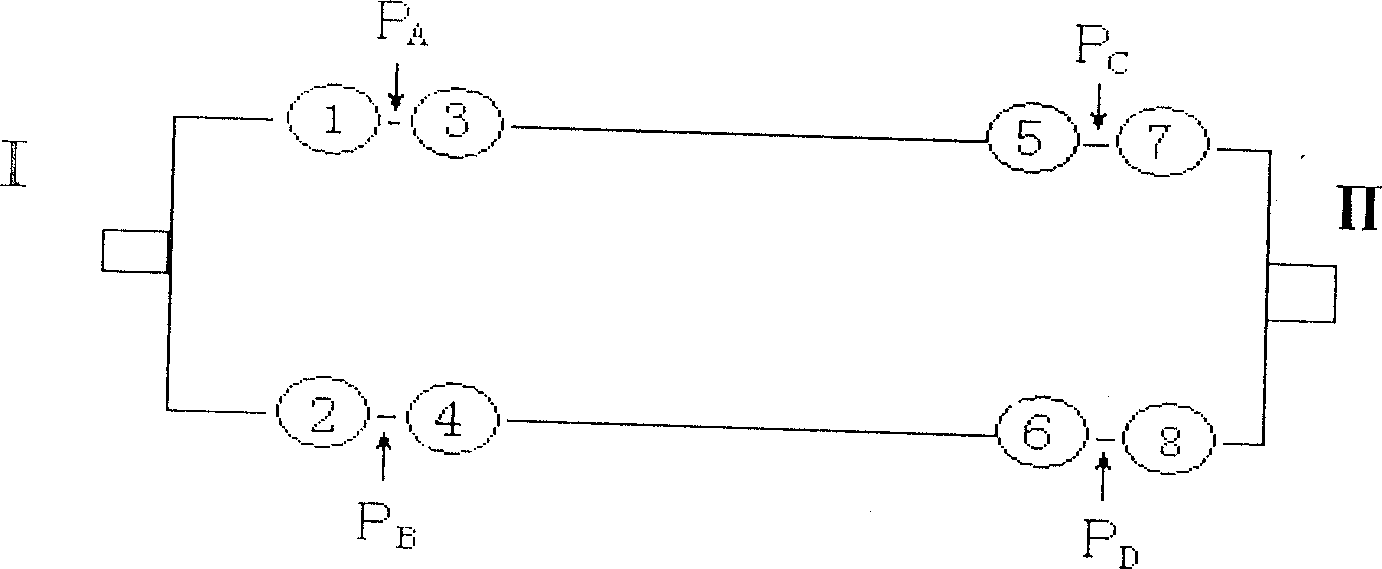

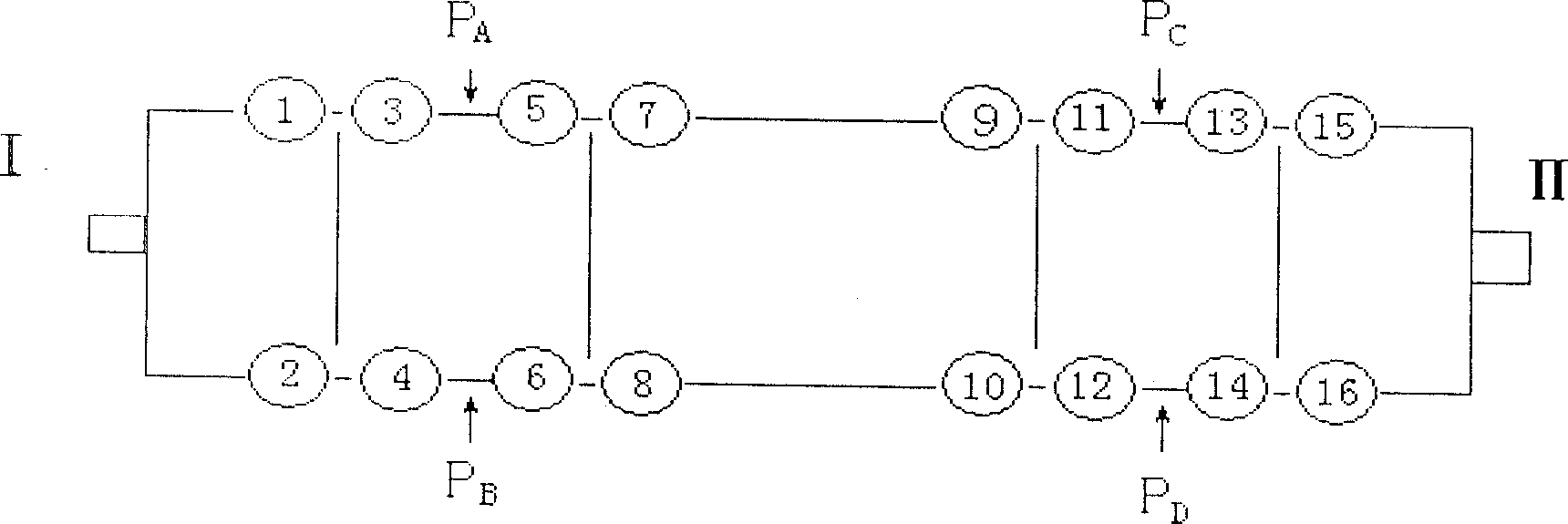

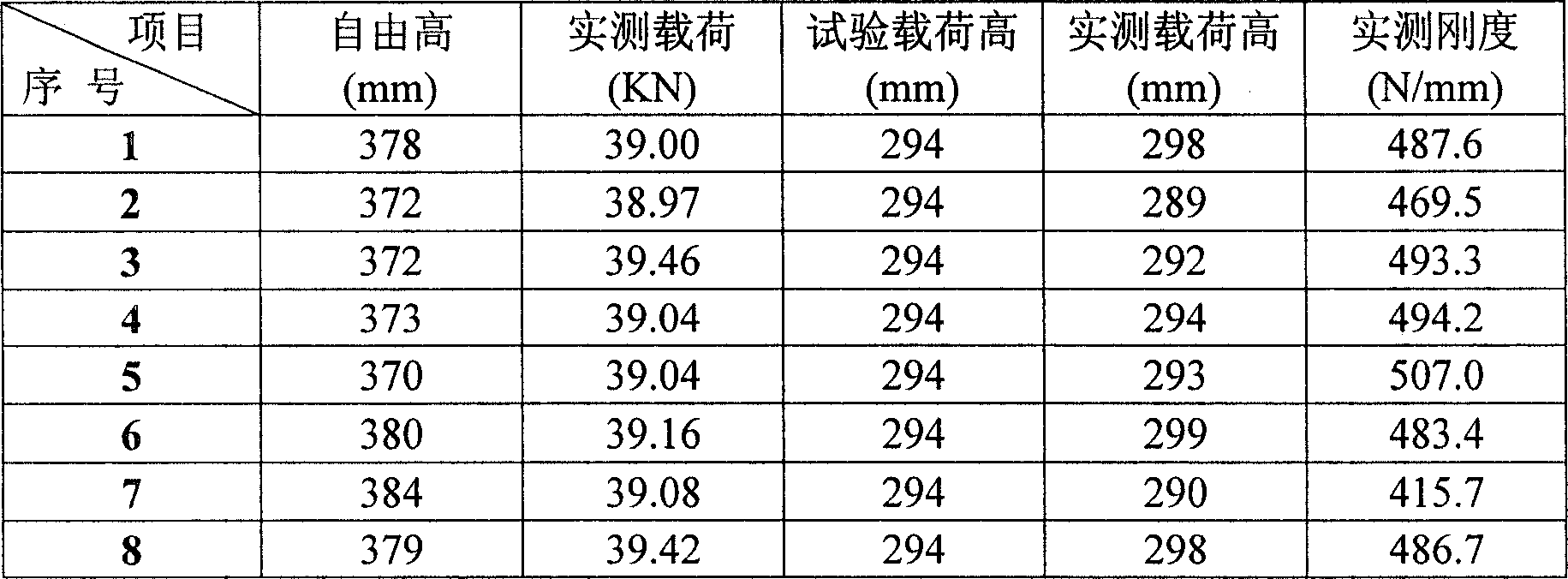

Railway coach suspension spring matching method

InactiveCN1730333AGuaranteed carrying capacityGuaranteed damping effectBogie-underframe connectionsRailway passenger carHardness

The invention relates to suspended mechanical spring in railway carriages for passenger, concrete relates to option processes for suspended mechanical spring in railway carriages for passenger. The invention solves the problem of difficulty in Making sure that carriages for passenger primary pass the test because of lacking of option processes for standard axle box mechanical spring and bolster mechanical spring when carriages for passenger in maintenance. Weighting the body of the carriages for passenger, Gauging partition of load of the four supporting place in the body carriages for passenger, and Ascertaining the heavy end the light end and the heavy side, the light side of the heavy end and the light end according to the partition of load of the four supporting place; gauging the free height and hardness of the vehicle-mounted axle box mechanical spring and bolster mechanical spring, Ordering the axle box mechanical spring and bolster mechanical spring in order of large to small of the product of the free height and the hardness of the mechanical springs; and then optioning in the order of heavy end to light end, heavy side to light side. The invention can reduce the workload of corrective maintenance, improve the success rate of maintenance, essentially make >primary pass the test, and improve maintenance efficiency and quality.

Owner:TAIYUAN RAILWAY RES INST OF SCI & TECH

Reduction smelting batching method for carrying out classification and iron blending on arsenic-containing sulfur-containing nonferrous metal-containing material to recycle nonferrous metals and make solid sulfur and solid arsenic harmless

The invention discloses a reduction smelting batching method for carrying out classification and iron blending on an arsenic-containing sulfur-containing nonferrous metal-containing material to recycle nonferrous metals and make solid sulfur and solid arsenic harmless. The reduction smelting batching method comprises the steps that furnace charge raw materials are batched after being classified, and requirements are as follows: slags generated after smelting are high-silicon high-calcium slags, and the weight ratio of SiO2 to Fe to CaO in the slags is (30% to 35%) to (18% to 23%) to (16% to 20%); the level of main metals in a batched material is 18% to 45%; the content of Cl<-> is smaller than or equal to 2.5%; the total water content is smaller than or equal to 13.5%; the content of calcium oxide is 5% to 10%; and silicon, sulfur and arsenic in the batched material are subjected to classification and iron blending. According to the reduction smelting batching method, the level of arsenic and lead contained in smoke and the level of lead in the slags, sulfur and iron slags and an arsenic iron eutectic alloy are greatly reduced, the smelting direct recovery rate of the main metal lead is increased, production cost is reduced by 2% to 5%, approximately 65% or more of sulfur in the furnace charge can be cured in the sulfur and iron slags, pollution to the atmosphere is reduced, approximately 90% or more of arsenic in the furnace charge can be cured in the stable and nontoxic arsenic iron eutectic alloy, the arsenic iron eutectic alloy can be adopted as a counterweight materialto replace relatively expensive steel and iron counterweight materials, and arsenic is subjected to harmless and resource way developing treatment.

Owner:YAN XIN ENVIRONMENTAL PROTECTION & TECH CO LTD

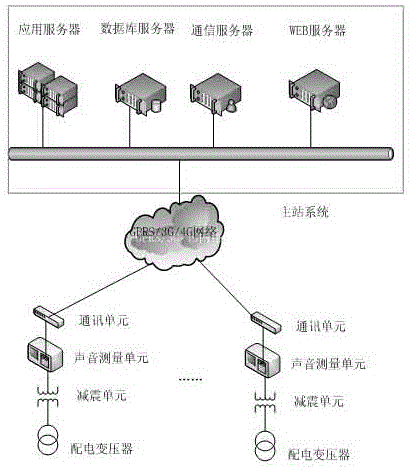

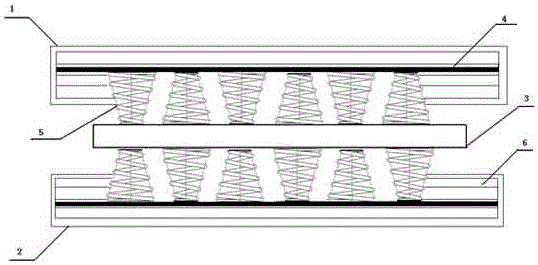

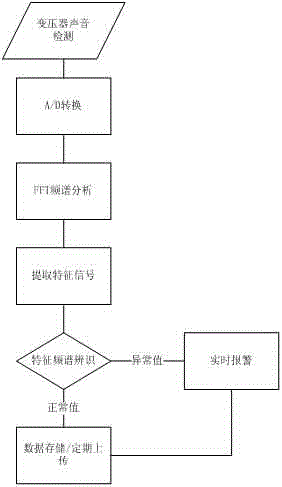

Transformer noise detection damping system

InactiveCN106441831AReduce noise pollutionReduce operational failuresMachine part testingNon-rotating vibration suppressionNoise controlDistribution transformer

The invention discloses a transformer noise detection damping system comprising a damping system, a sound measuring unit, a communication unit, and a main station system. The damping unit is a device used for damping of a transformer. The sound measuring unit is used for monitoring the operation sound of the transformer during operation, and is used to transmit the operation sound to the main station system by the communication unit. The main station system is used for processing feedback information. The invention provides a solution, which is capable of combining transformer noise control and transformer state monitoring, is easy to implement, and has low monitoring costs. With the gradual popularization and application of the transformer noise detection damping system, the noise pollution of the distribution transformer on nearby residents is effectively reduced, and at the same time, the operation state of the distribution transformer can be continuously monitored, and an important support is provided to improve power supply reliability and reduce the various operation faults of the distribution transformer.

Owner:JIANGSU SOUND CUBIC ENVIRONMENTAL PROTECTION TECH

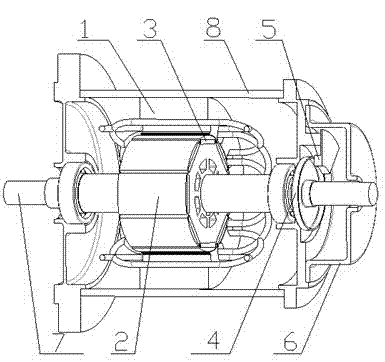

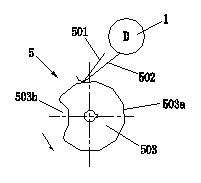

Brushless direct-current (DC) motor

InactiveCN103036385AControl rotationSo as not to damageStructural associationHall elementMotor shaft

The invention belongs to the technical field of brushless direct current motors, discloses a brushless direct-current (DC) motor, and aims at preventing a Hall element from being damaged due to the fact that the temperature of a stator rises. The brushless DC motor comprises a shell, a motor shaft, the stator, a rotor and a magnetic steel piece, wherein a magnetic ring is fixed on the portion, outside the shell, of the motor shaft, the Hall element is mounted on the outer wall of the shell, the distance between the Hall element and the magnetic ring is shorter than an induction range of the Hall element, and the Hall element is connected with a controller. The Hall element is arranged outside the DC motor, the Hall element cannot be affected by the rise of the temperature inside the DC motor and cannot be damaged due to the rise of the temperature of the Hall element. According to the brushless DC motor, the structural mode of a traditional DC motor is broken through, a convention is broken, the Hall element is innovatively arranged outside the shell of the motor, an unexpected effect is obtained, a hard problem which is not solved in a long term is solved, operation troubles of the brushless DC motor can be reduced greatly, and reliability of the brushless DC motor is greatly improved.

Owner:河北首力科技有限公司

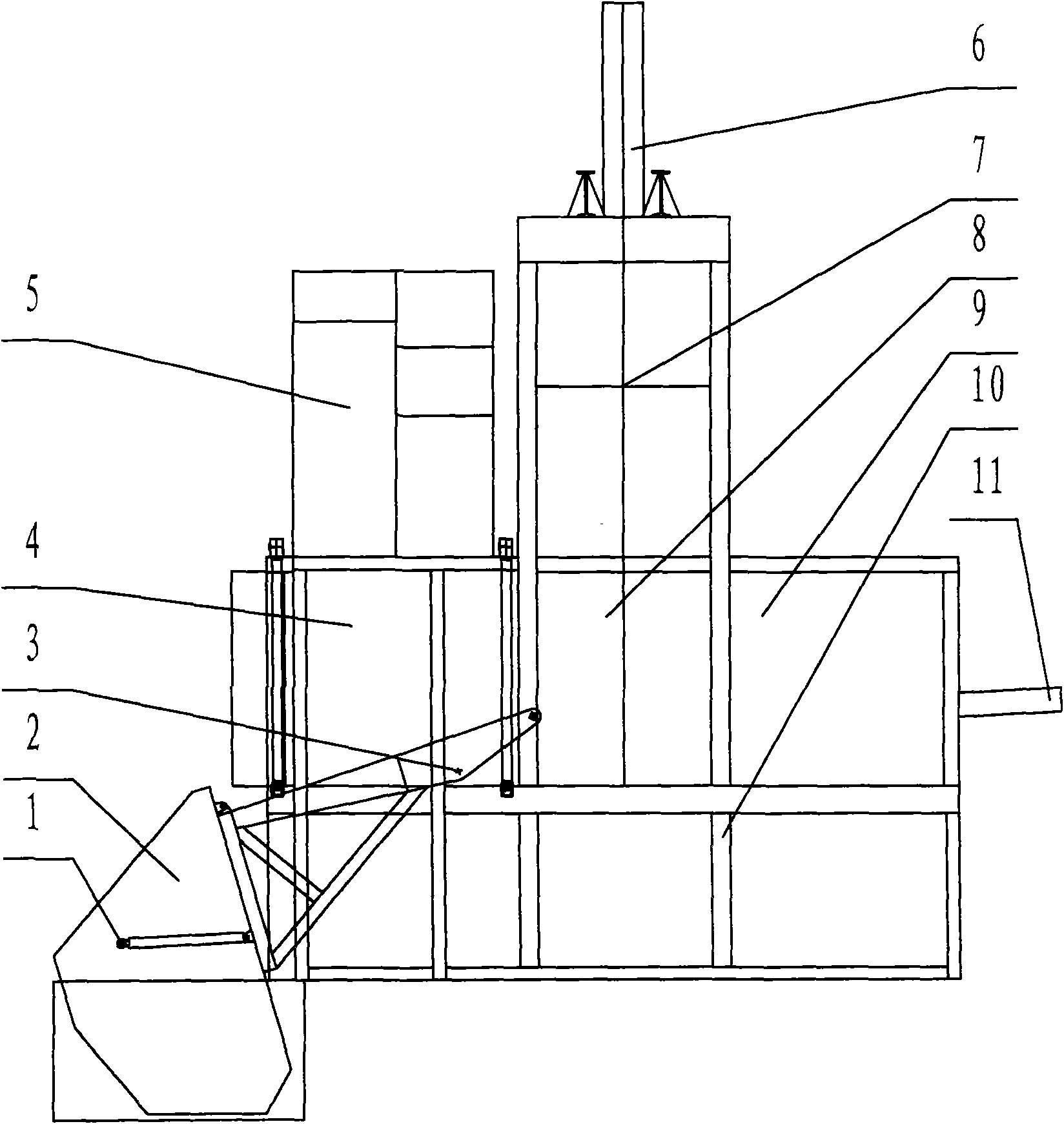

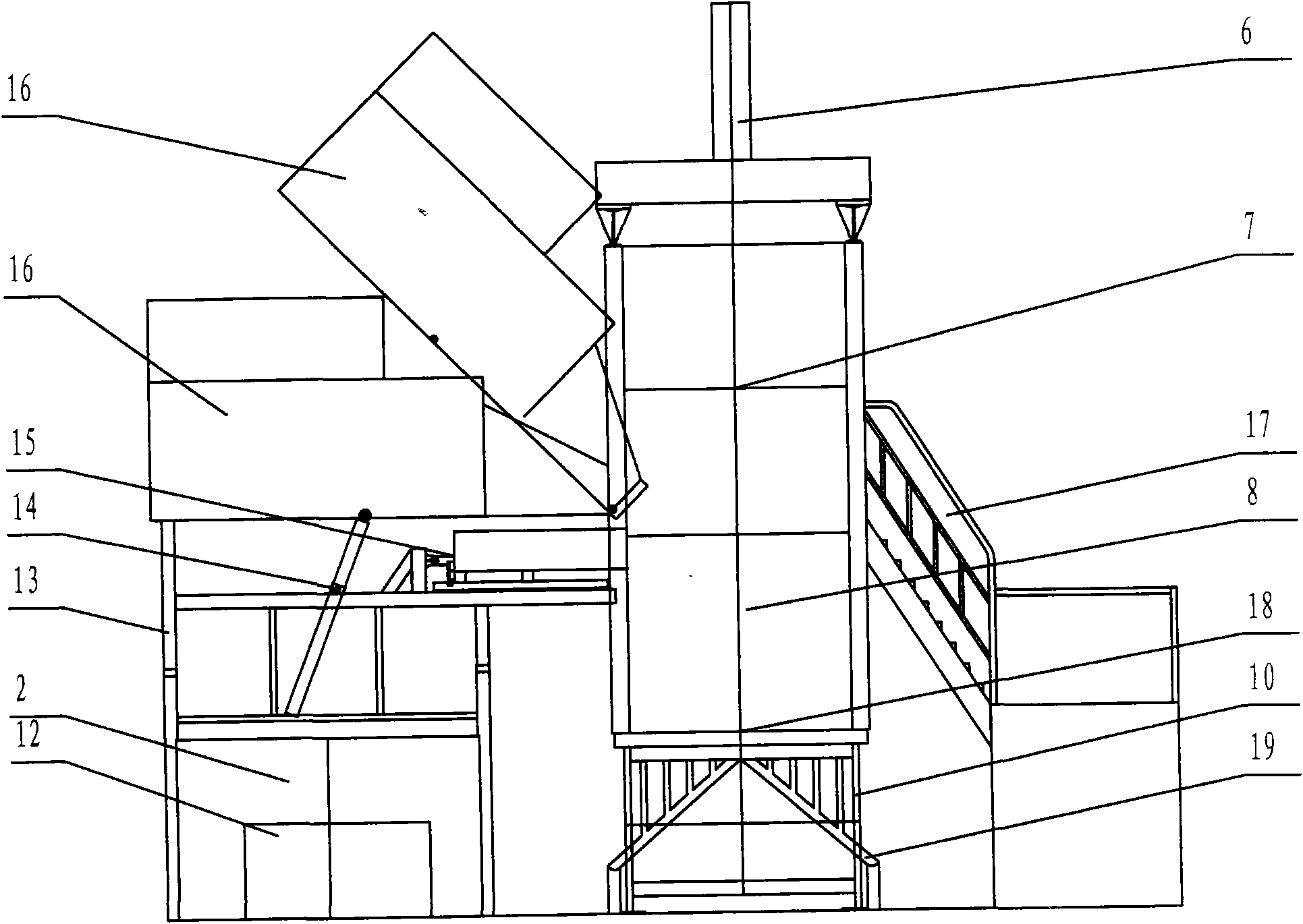

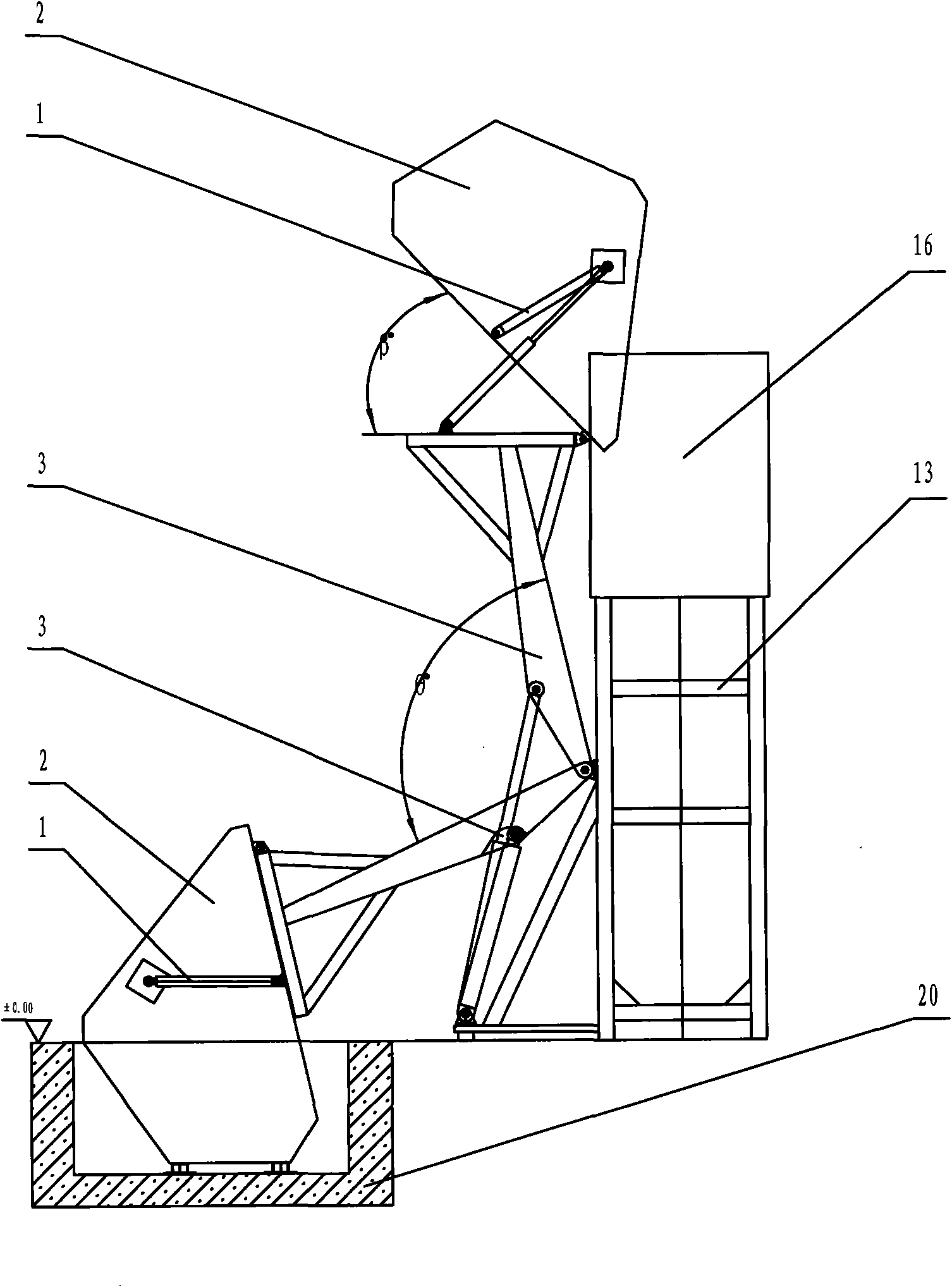

Integrated vertical garbage compressor

ActiveCN101817439AIncrease productivityImprove transport efficiencyRefuse transferringLoading/unloadingAbove groundGas compressor

The invention discloses an integrated vertical garbage compressor, which comprises a box body, a compact garbage transferring mechanism (11) and a garbage compressing mechanism (7), wherein the box body integrates a garbage compressing bin (8), a compact garbage block storage bin (4) and a compact garbage block transferring mechanism installation bin (9); and the compressor is characterized by also comprising garbage receiving mechanism, a garbage storage mechanism, a garbage heap shape processing mechanism (15) and a compressing bin sewage potential energy discharging mechanism (19); and the mounting height of the box body requires meeting truck loading height of a high compact compressing block during loading for outward transportation. The garbage compressor can simultaneously execute the working procedures of the storage, the delivery and the compression of loose garbage, thereby improving garbage transferring efficiency; and when the compact garbage block is loaded, the compressing bin is not required to be lifted, which not only reduces operating failures of equipment, but also changing kinetic energy sewage discharging into potential sewage discharging by improving a sewage discharging surface from below ground to above ground, thereby the invention saves energy, discharges completely and greatly improves working environment.

Owner:FUJIAN BAIJIE SANITATION MACHINERY CO LTD

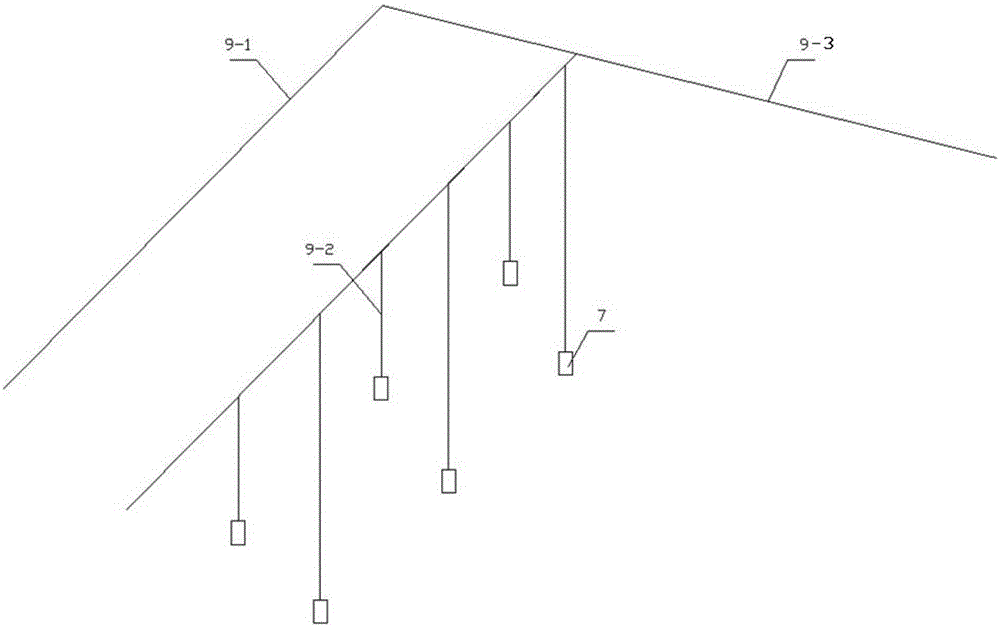

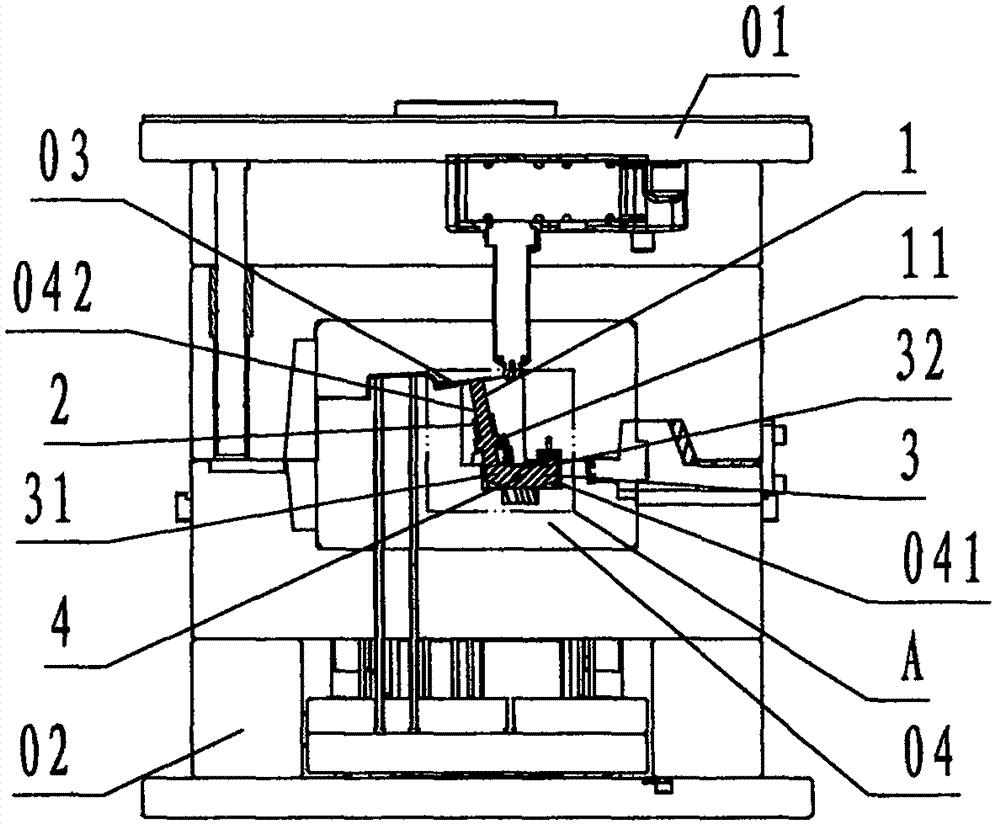

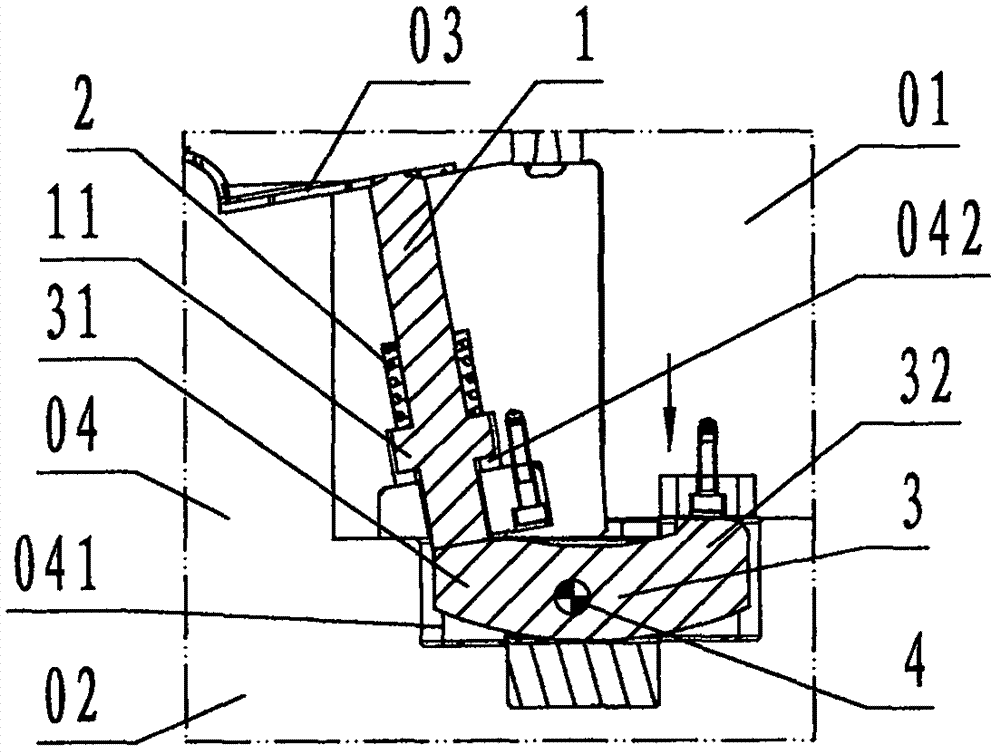

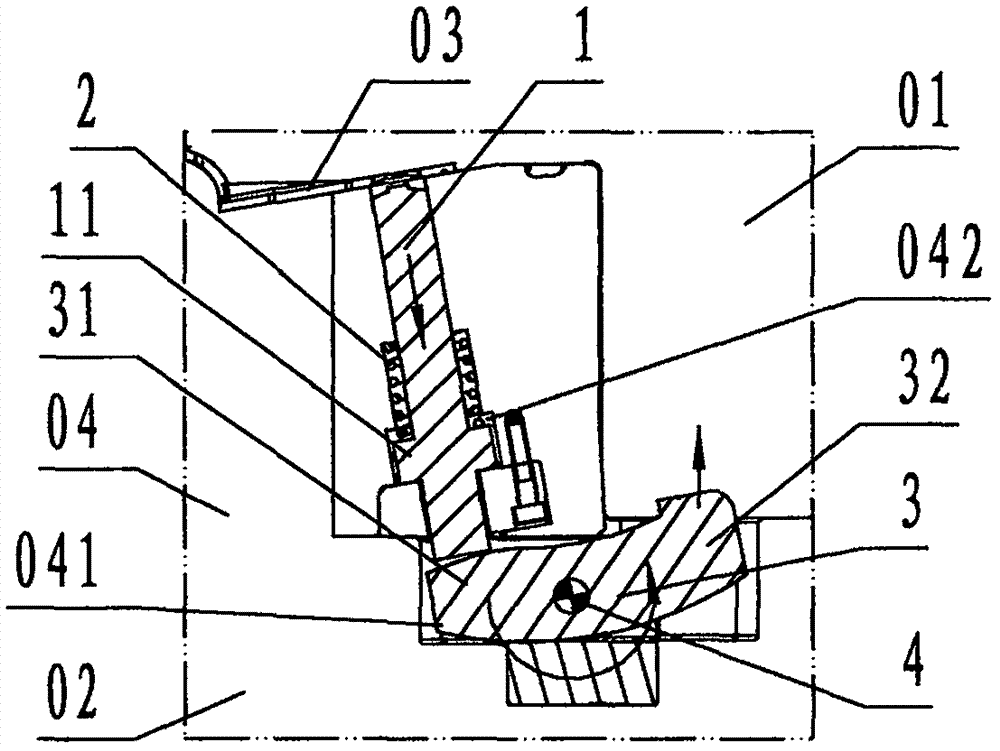

Simple inclined core pulling device for injection mold

The invention discloses a simple inclined core pulling device for an injection mold. The simple inclined core pulling device comprises an inclined pulling core (1), a spring (2), a skid (3) and a rotating shaft (4), wherein the inclined pulling core adopted in the invention is a cylindrical stepped steel member provided with a profile surface and a blocking platform; the skid is an arc block-shaped steel member having two upwarped ends; a shaft hole is formed in the skid; a left part of the skid is a resistance arm; a right part of the skid is a power arm; a skid groove for mounting the skid and an inclined pulling guide hole are formed in a mold core of the mold; the skid is rotatably arranged in the skid groove through the shaft hole and the rotating shaft; the inclined pulling core is located in the inclined pulling guide hole in a sliding manner; the spring is located in the inclined pulling guide hole; a lower end of the inclined pulling core is in contact with the resistance arm of the skid; the power arm of the skid is in contact with a fixed mold. A technical scheme that the spring works, the skid is rotated anticlockwise and the inclined pulling core is separated from a product when the mold is opened, and the fixed mold forces the power arm to reset, the skid is rotated clockwise and the inclined pulling core is reset when the mold is closed is adopted, so that the injection mold achieves the purposes of simplifying a structure, working reliably and reducing costs.

Owner:NINGBO RUIYUAN MOLD & PLASTICS

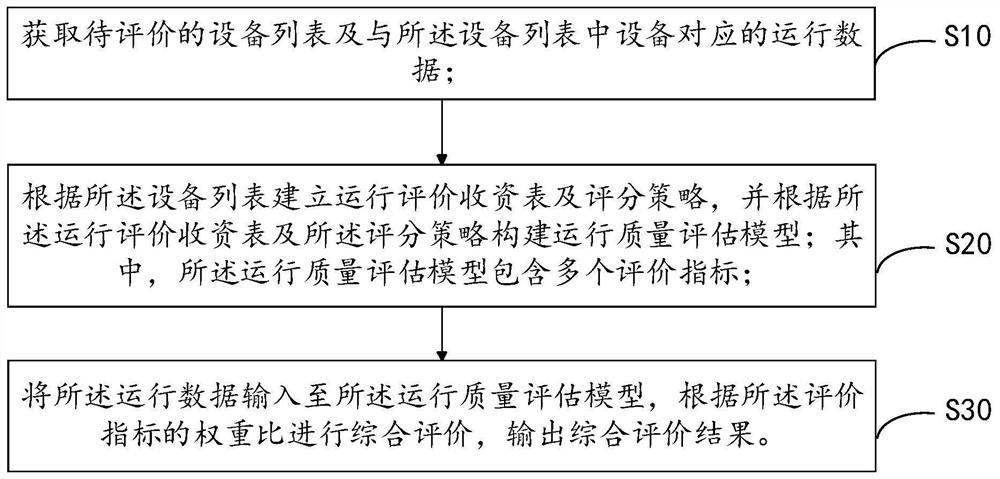

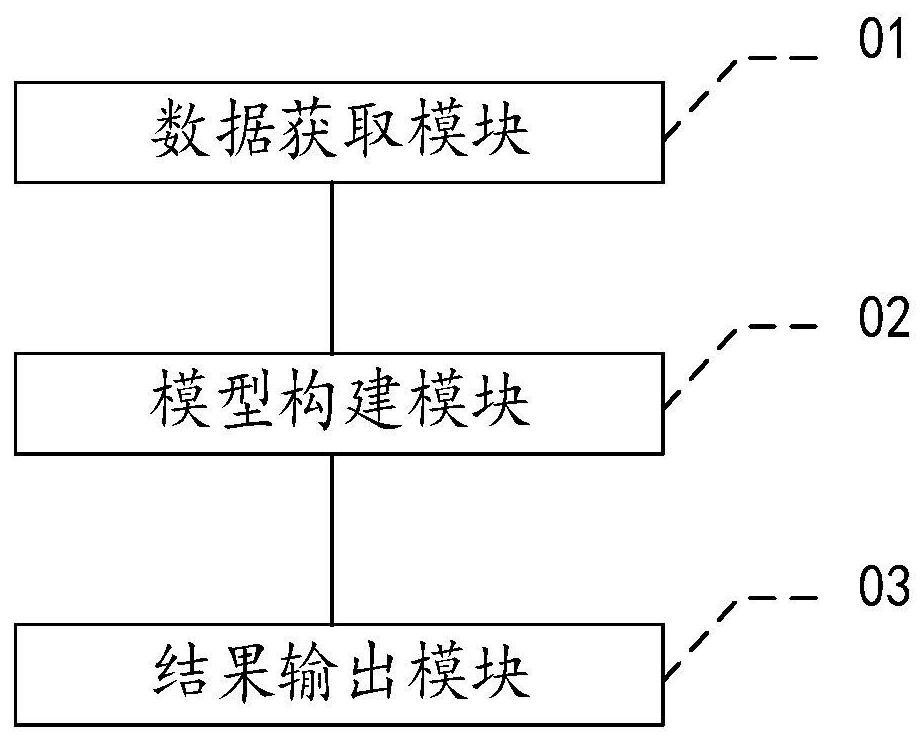

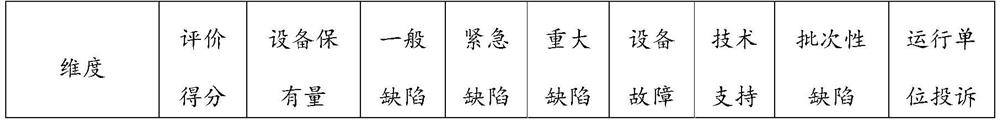

Method and system for evaluating operation quality of power equipment, terminal equipment and medium

ActiveCN112766783AQuality improvementReduce operational failuresResourcesEvaluation resultTerminal equipment

The invention discloses a power equipment operation quality evaluation method and system, terminal equipment and a medium. The method comprises the steps of obtaining a to-be-evaluated equipment list and operation data corresponding to equipment in the equipment list; establishing an operation evaluation information collection table and a scoring strategy according to the equipment list, and constructing an operation quality evaluation model according to the operation evaluation information collection table and the scoring strategy, wherein the operation quality evaluation model comprises a plurality of evaluation indexes; inputting the operation data into the operation quality evaluation model, performing comprehensive evaluation according to the weight ratio of the evaluation indexes, and outputting a comprehensive evaluation result. According to the evaluation method for the operation quality of the power equipment, the equipment quality can be scientifically and objectively evaluated, meanwhile, standards and guidance can be provided for work such as equipment purchasing, supplier evaluation and differentiated operation and maintenance, and the method is beneficial for supervising and urging suppliers to further improve the equipment quality, reduce equipment operation faults and reduce the operation and maintenance workload.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

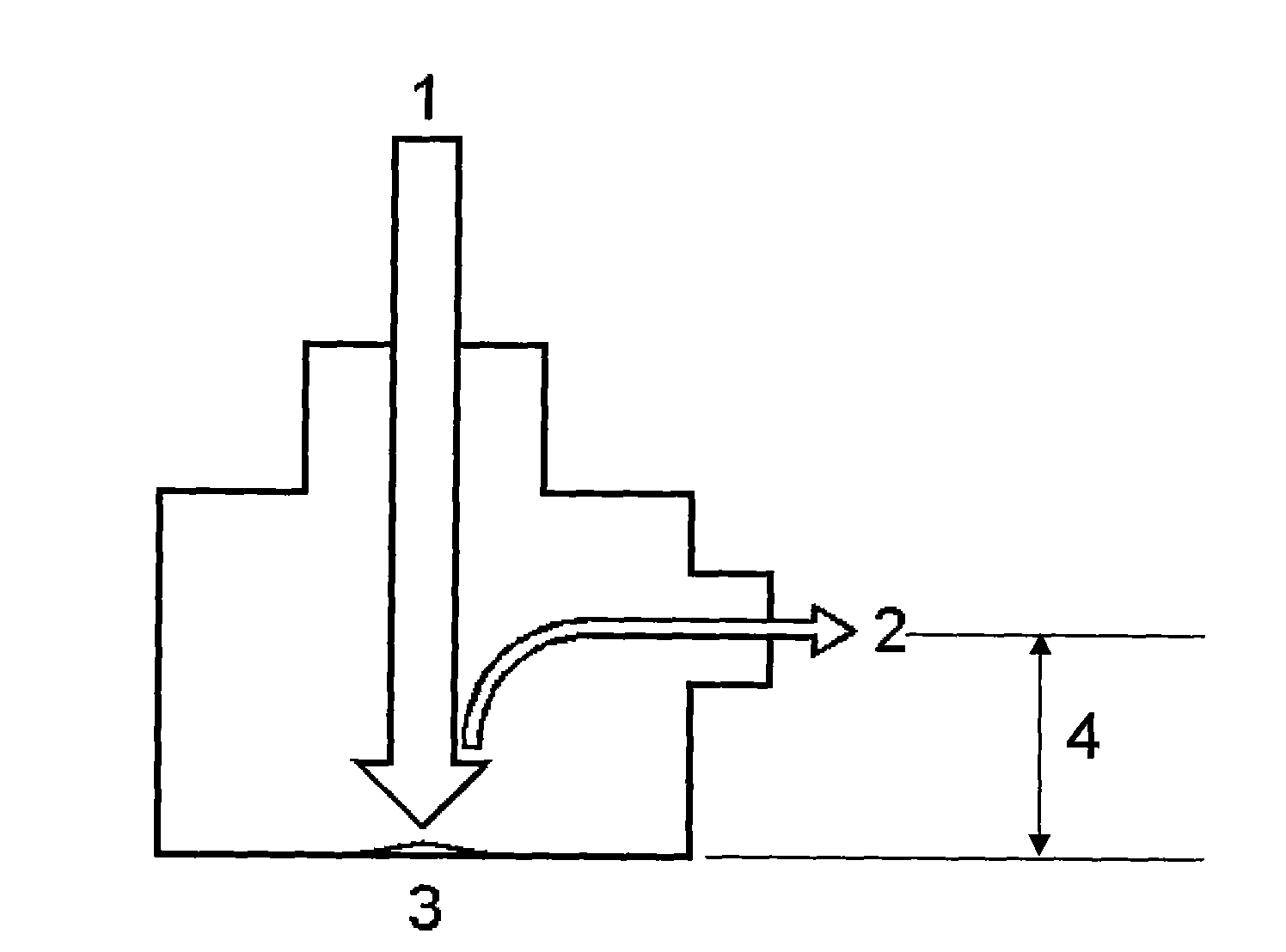

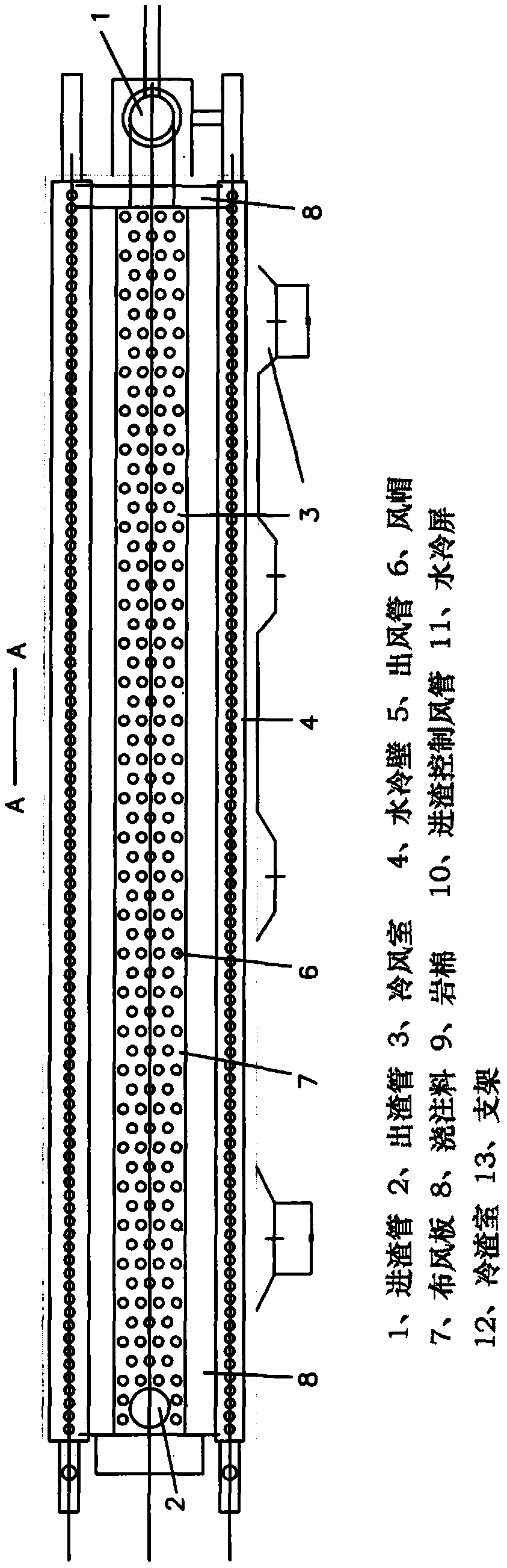

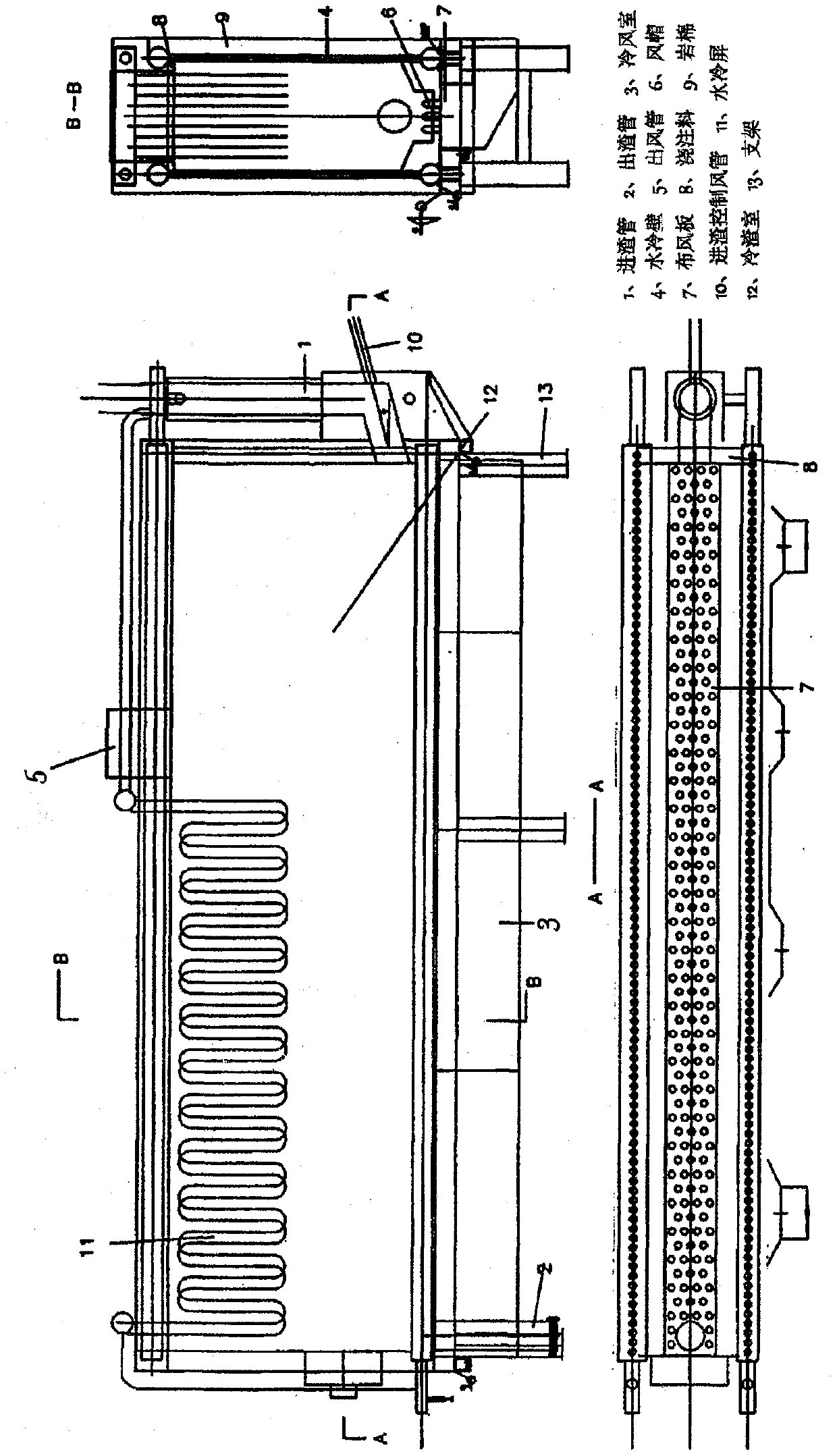

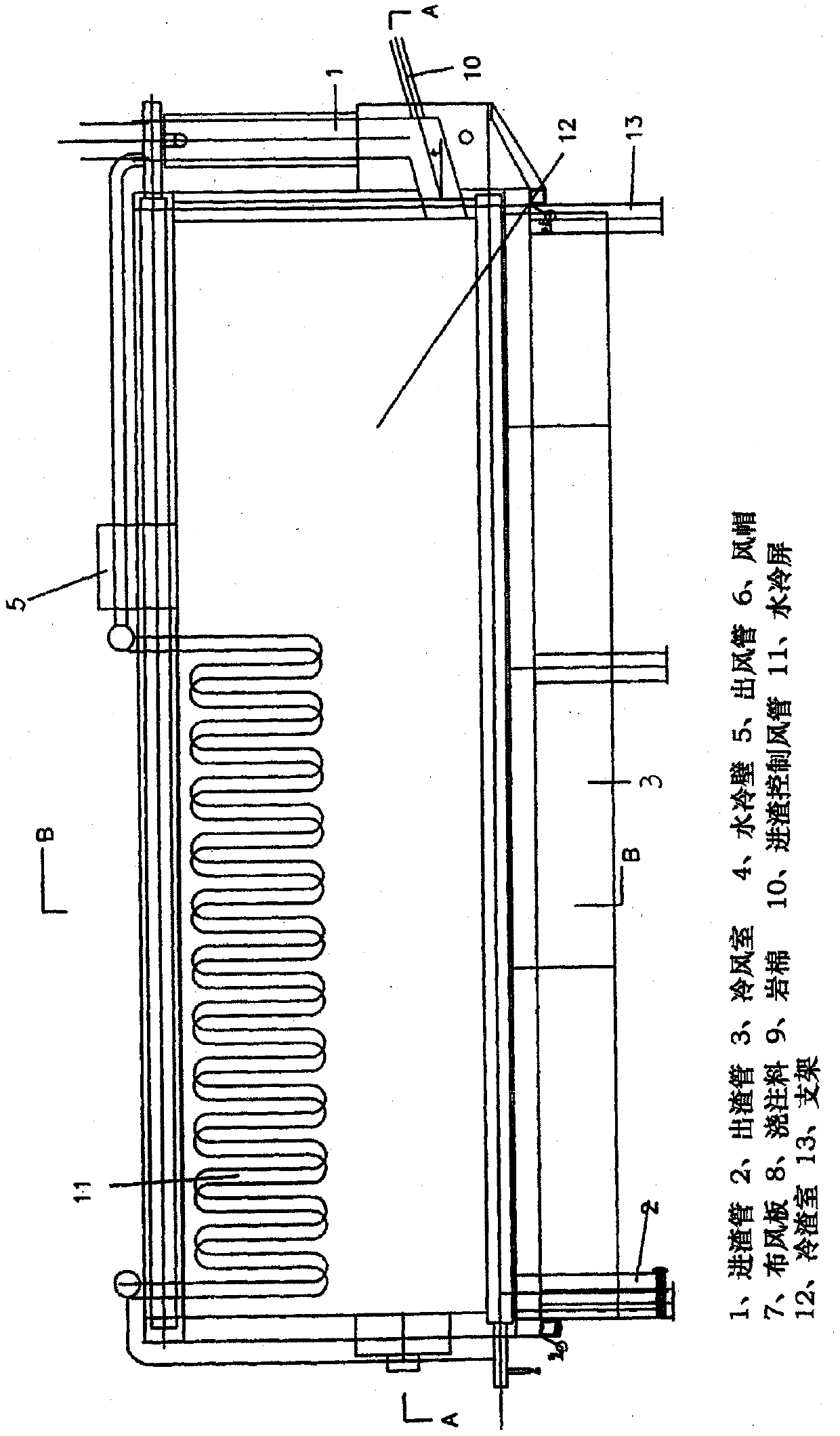

Wind and water combined slag cooler for fluidized bed

PendingCN110671697AAvoid cokingReduce collisionFluidized bed combustionApparatus for fluidised bed combustionSlagFluidized bed

The invention provides a wind and water combined slag cooler for a fluidized bed. The wind and water combined slag cooler is mainly used as a bottom slag cooling and discharging device for a boiler ofa circulating fluidized bed. Coking and slag blocking phenomena of the slag cooler for the fluidized bed are eliminated, the operation of the wind and water combined slag cooler is not limited by theparticle size of bottom slag, and slag inlet and outlet control is simple and convenient. First, a material discharge opening or an accident slag discharge opening is not formed in a slag inlet high-temperature area of the slag cooler in any forms, a whole wind-distribution plate is complete and uniform from a slag inlet to a slag outlet, and only one slag outlet is formed to prevent the coking phenomenon due to a bad fluidizing effect of the high-temperature area; second, wind caps are arranged in a crossed manner in the wind-distribution plate, small holes in the wind caps are inclined downwards by a certain angle, and the diameters of the small holes of the wind caps are 6-8 mm; third, the interior of the slag cooler is a complete cavity, and is not divided by a partition wall; fourth,wind control is adopted in the aspect of slag inlet control, and a slag inlet pipe section connected with the slag cooler forms an inclined angle of 14-25 degrees with the horizontal plane; and fifth, a water-cooled wall is prevented from being worn by a wear-resistant sheet, and spraying is performed on scenes to resist wear.

Owner:冯大勇

Electromagnetic electric control valve

InactiveCN102644795AReduce power-on run timeWith energy saving effectOperating means/releasing devices for valvesElectric controlSupport point

An electromagnetic electric control valve comprises a valve body (13) with a valve cavity (12), an electromagnet (17) for driving a valve core (14) to move, a return spring member (14a) acting on the valve core (14), a lever member (16) which can swing around a supporting point of the lever member (14) and is used for pushing the valve core (14) to move and an electric control device (15) for keeping working states of the valve core (14) after displacement. An inlet (13a) and an outlet (13b) on the valve body (13) are respectively communicated with the valve cavity (12), and the valve core (14) is arranged in the valve cavity (12). One end (16a) of the lever member (16) is connected with the extending end of a valve rod of the valve core (14), and the electromagnet (17) is provided with amoving iron core push rod (17a) capable of pushing the other end (16b) of the lever member (16). A connecting member (4b) of a retention mechanism (4) in the electric control device (15) is connectedwith the end (16b) of the lever member (16). The electromagnetic electric control valve has the advantages of being energy-saving, stable and reliable in operation and the like.

Owner:北京天易传动科技股份有限公司

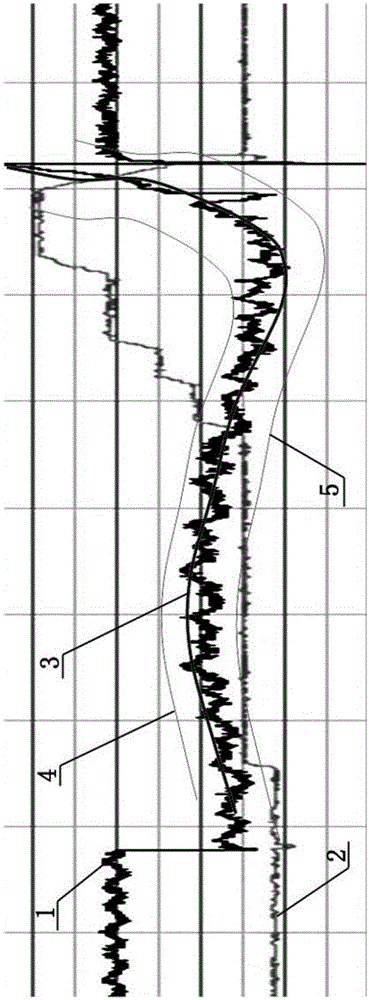

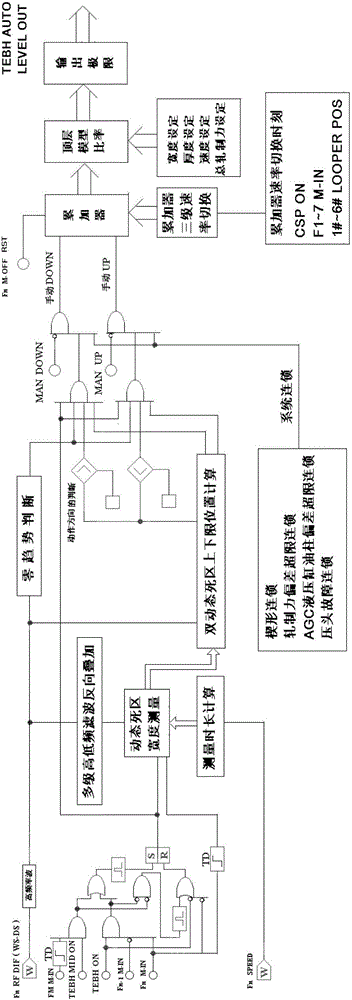

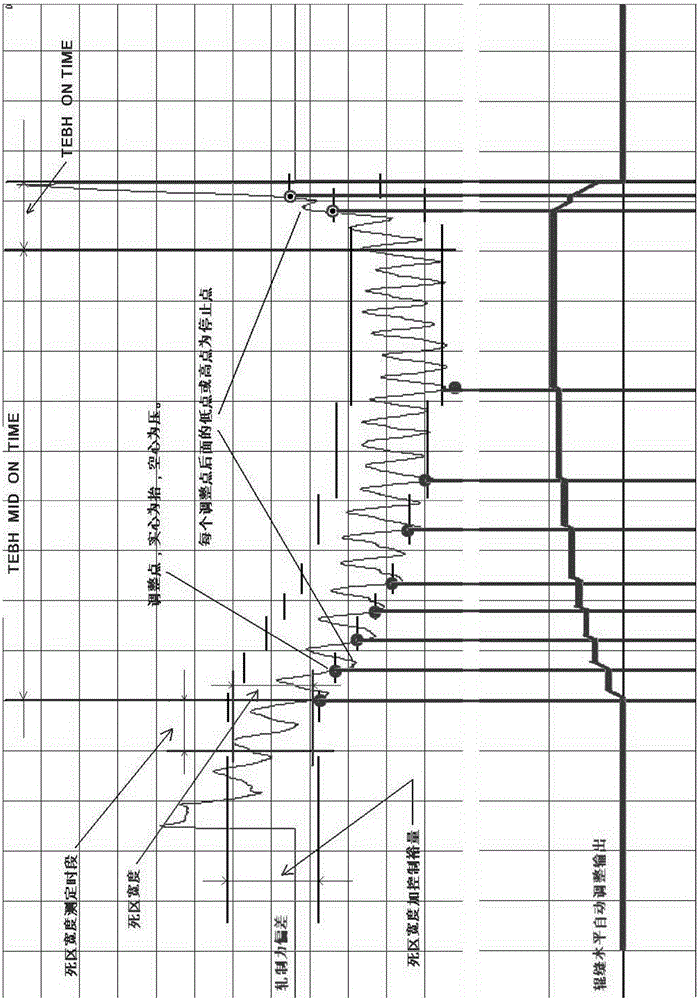

Automatic adjusting system adopting double-dynamic dead zone control mode for roll gap levelness of finish rolling mill

ActiveCN106734242AReduce operational failuresImprove stabilityRare end control deviceRoll force/gap control deviceStrip steelControl mode

The invention relates to an automatic adjusting system adopting a double-dynamic dead zone control mode for roll gap levelness of a finish rolling mill. According to the automatic adjusting system, the middle-rear material shape of rough rolling feeding material is adjusted by using a finish rolling front machine frame, so that the adjusting burden of rolling of a rear machine frame is reduced; the shape of the tail part of strip steel is revised by a middle frame, and smooth rolling of a tail machine frame is guaranteed; and a roll gap levelness value of a machine frame of the rolling mill is automatically adjusted by the rolling mill according to the rolling force deviation changes of the machine frame of the rolling mill, deviation of the tail part of the strip steel is controlled, operation faults of the strip steel are reduced, and the stability of the rolling process of the strip steel is improved. The automatic adjusting system has the advantages that dynamic control over the roll gap levelness of the rolling mill in the rolling process of hot rolled strip steep is realized, the rolling stability is effectively improved and the occurrence of a tail-throwing accident is effectively inhibited.

Owner:ANGANG STEEL CO LTD

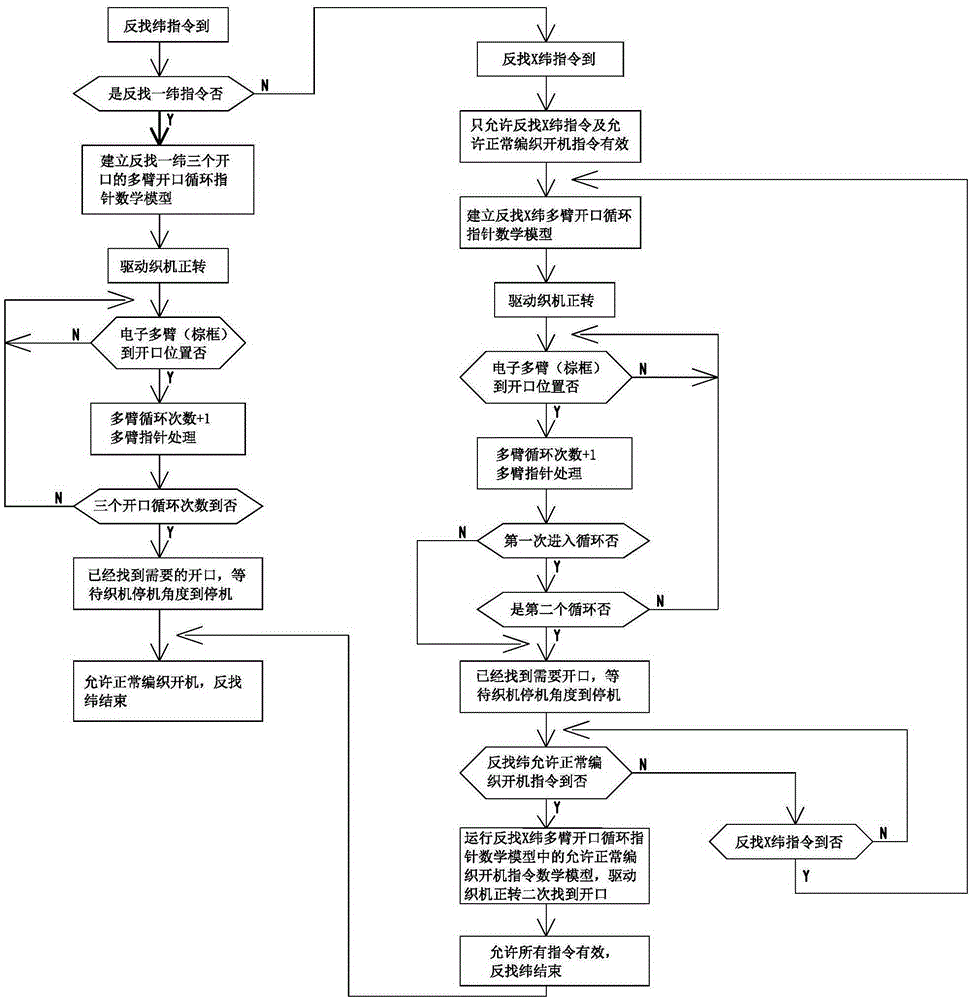

Reverse weft finding control method for weaving machine

ActiveCN105297236AAvoid the defect of high impact force in forward and reverse rotationReduce operational failuresDobbiesLoomsMachine controlMathematical model

The invention discloses a reverse weft finding control method for a weaving machine, belonging to the technical field of weaving machine control. According to the method, software program is combined with a mechanical structure; control system software controls the number of openings which are correspondingly formed by reversely finding a weft each time according to a weft finding weft instruction, an opening pointer is built to correspondingly point at the corresponding weft number, an electromagnet which participates the control of an electronic dobby shedding mechanism is determined, and an opening pointer program with a dobby shedding cycle pointer mathematic model is operated; driving of the electronic dobby shedding mechanism is achieved to form a previous weft opening of reversely found final target weft through operation of the dobby shedding cycle pointer mathematic model; the pointing direction of the opening pointer firstly retreats back to at least one previous weft from the next weft of the final target weft, and then the final target weft is implemented in an opening forming process; and an electromagnet participating the control is found out. The defects of large positive and negative operating impact force of a traditional pick finding mode mechanism are avoided; weft finding can be achieved at a normal running speed; and the efficiency is improved.

Owner:ZHEJIANG KANGLI AUTOMATIC CONTROL TECH

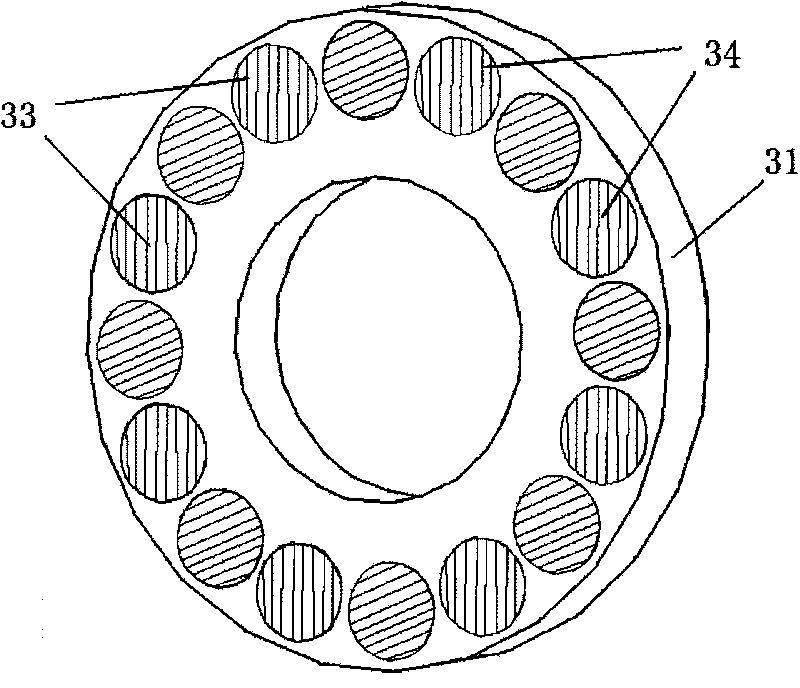

Automotive hybrid eddy current retarder

InactiveCN101699730AReduce energy consumptionReduce volumeAsynchronous induction clutches/brakesEngineeringEddy current

The invention discloses an automotive hybrid eddy current retarder. A rotor disk is fixedly sleeved on each end of a rotating shaft; a fixed disk is fixedly sleeved on the middle of the rotating shaft; two stator tooth groups with brackets are arranged between the fixed disk and the rotor disk symmetrically and respectively; the brackets are sleeved on the rotating shaft; each stator tooth group has 8 stator teeth; one end of each stator tooth is connected with a magnet yoke and the other end thereof is fixed on the bracket; an axial gap is preserved between the magnet yoke and the rotor disk; the windings corresponding to the two symmetrical stator tooth groups have the same winding direction; the windings on the two adjacent stator teeth in each stator tooth group have opposite winding directions; the fixed disk is uniformly distributed with 16 holes along a circumferential direction; 8 cylindrical permanent magnets and 8 cylindrical iron cores are embedded into the 16 holes alternately; and the cylindrical permanent magnets are magnetized axially and the magnetizing directions of the adjacent permanent magnets are opposite. Two working states, namely a electric eddy current retarder state or a permanent magnet retarder state, are realized, energy consumption is reduced, volume and temperature rise are reduced and operation faults are reduced.

Owner:JIANGSU UNIV

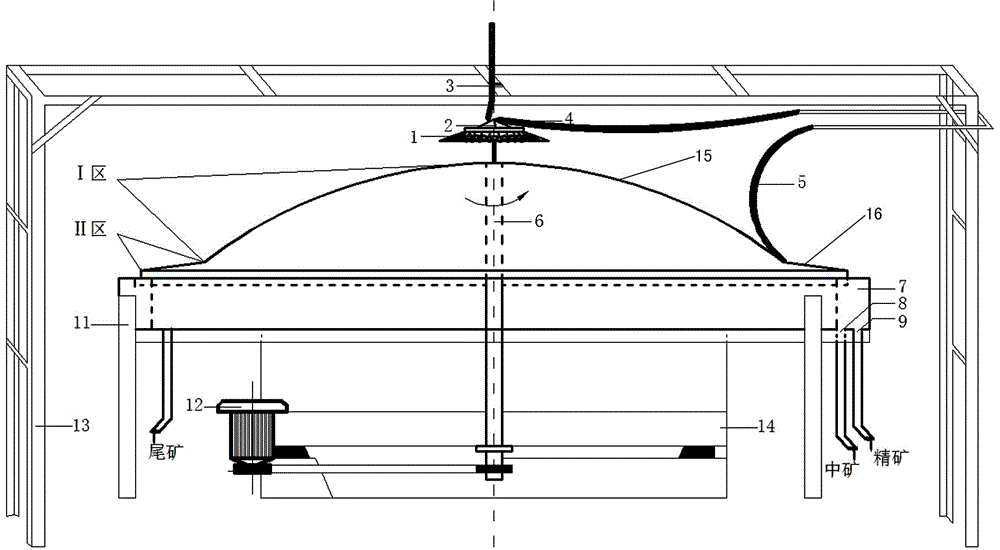

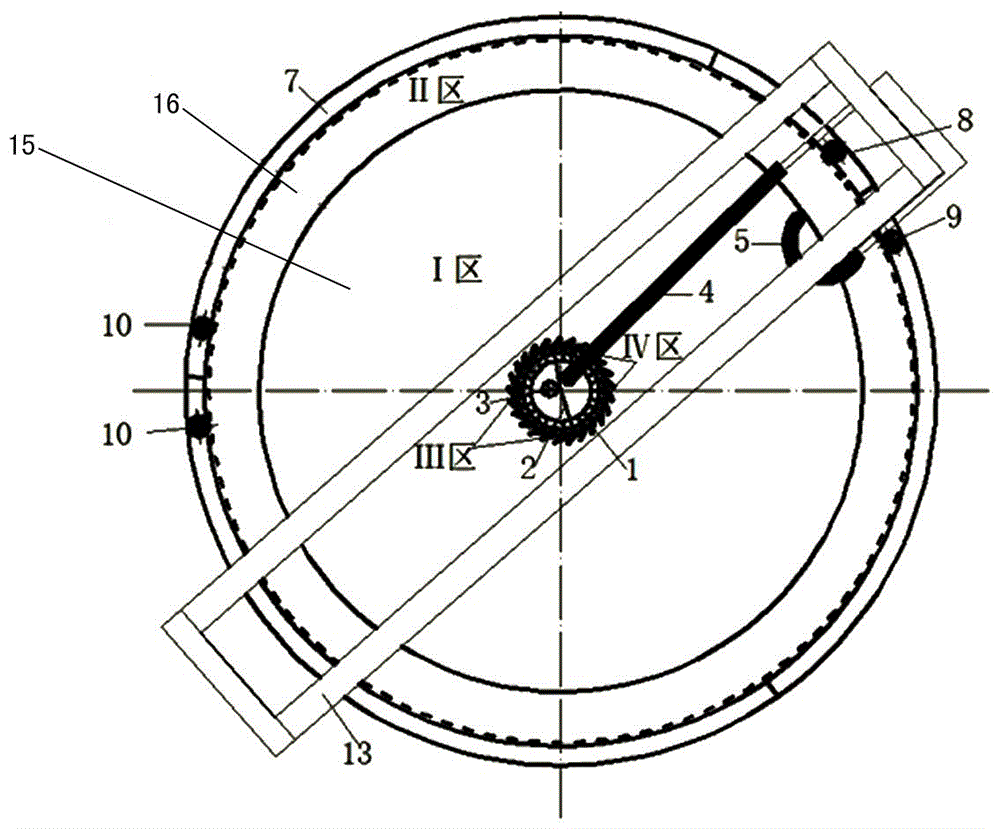

Arc surface spreading flow film sorting machine

ActiveCN106824500AIncrease centrifugal accelerationRaise the lower limit of granularityWet separationSurface spreadingEngineering

The invention discloses an arc surface spreading flow film sorting machine, and relates to equipment capable of continuously sorting fine-particle refractory minerals under combined effect of gravity and turning force. The equipment mainly consists of a rotary sorting disc driven by a driving device, an ore and water feeding device and an ore receiving and discharge device; the upper surface of the sorting disc is a spherical arc surface with a curvature radius of 0.58-2.27 m; the outer edge of the spherical arc surface is connected with a lap of annular inclined surface for forming an angle of 3-8 degrees with the horizontal plane; a flushing water pipe is mounted on the annular inclined surface; an ore receiving groove below the sorting disc in the flushing water pipe is provided with middling, concentrate and tailing discharge ports in sequence at intervals; an ore separation flushing disc is arranged rightly above the sorting disc; the upper part of the disc is a conical surface fixed disc, and the lower part is a movable disc provided with a rotating shaft; an ore feeding pipe mouth and a water feeding pipe mouth are aligned to the fixed disc; a series of leakage holes are formed in the bottom of the fixed disc, and are aligned to the movable disc; and a series of baffle plates aslant dispersed are arranged on the surface of the movable disc. The machine is suitable for environment-friendly, efficient, energy-saved and continuous sorting of 0.2-0.037 mm fine-particle valuable minerals.

Owner:昆明理工凯吉思科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com