Scum treatment device of aerated grit chamber

A technology for aeration, sand settling and treatment equipment, which is applied in the direction of flotation water/sewage treatment, feeding/discharging device of settling tank, flocculation/sedimentation water/sewage treatment, etc. It can solve problems such as scum cannot be removed, Achieve the effect of eliminating oil residue, less failure and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

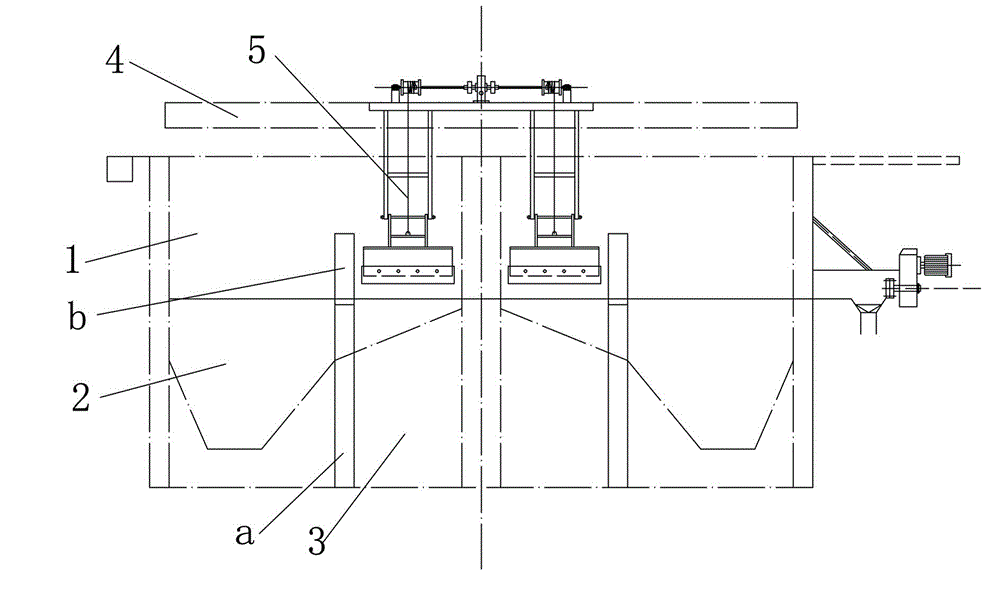

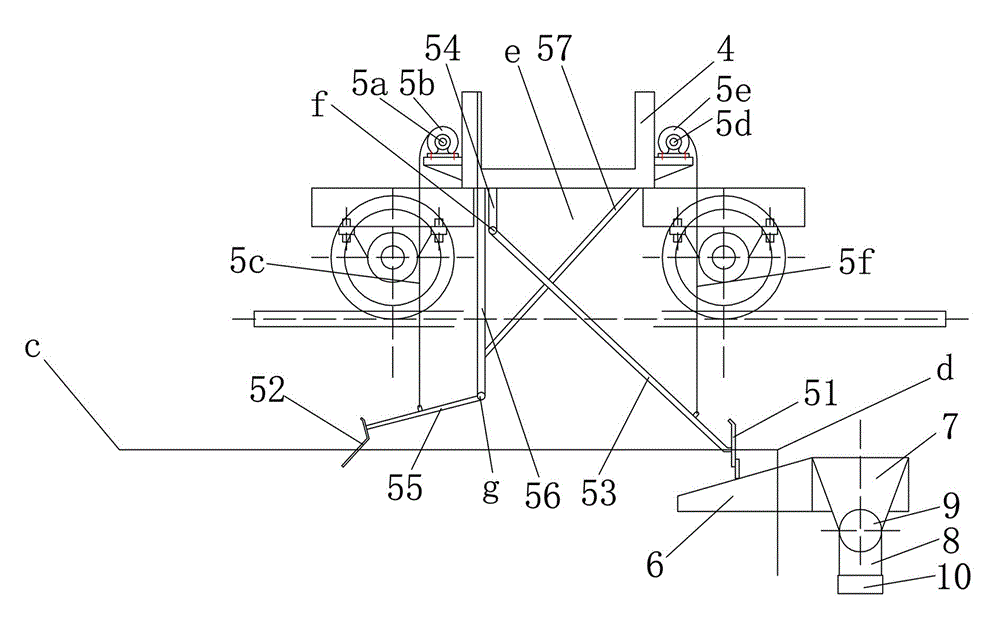

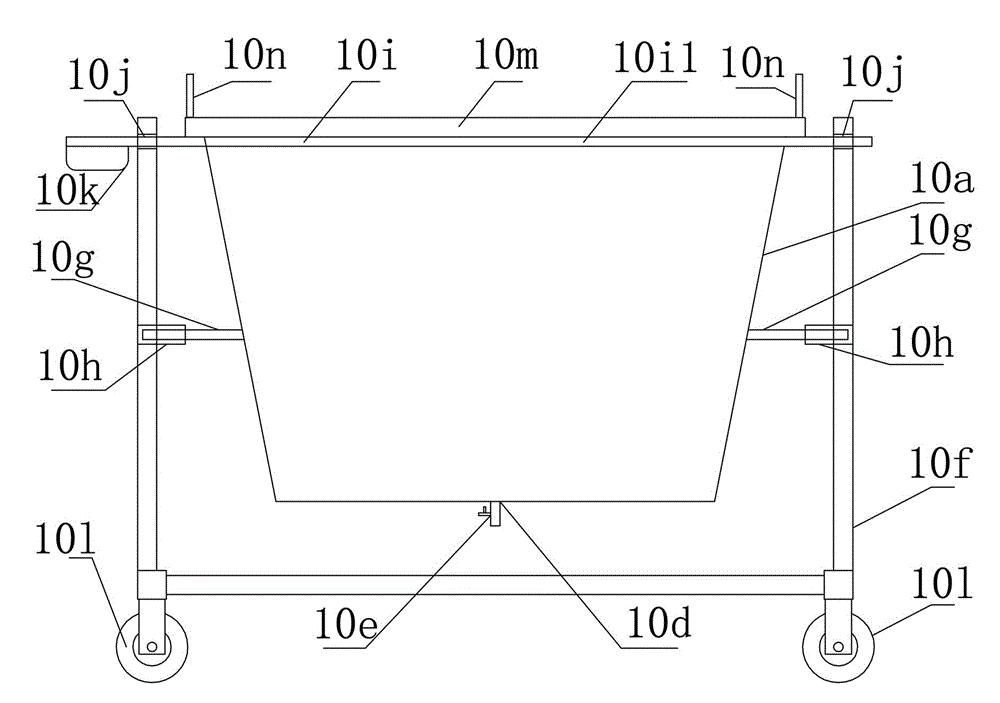

[0020] Such as figure 1 , figure 2 Shown, the aerated grit chamber scum treatment device embodiment of the present invention,

[0021]Including aeration grit chamber 1, the bottom of aeration grit chamber 1 is slope-shaped, aeration grit chamber 1 is divided into aeration grit chamber 2 and oil and slag removal area 3, aeration grit chamber 2 and removal Barrier a and partition b are arranged between the oil scraping area 3. Partition b and bar a are vertically arranged in a straight line and partition b is located above bar a. The top of partition b is higher than the pool surface and the bottom of bar a is connected to the pool In this way, the sand and gravel can be blocked at the bottom of the aerated grit chamber 2 and the oil residue will enter the oil removal and scraping area 3 through the grid bar a and float on the pool surface. The aerated grit chamber 1 has a sand suction bridge 4, The sand-absorbing bridge 4 is suspended above the aerated grit chamber 1 and mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com