Automotive hybrid eddy current retarder

A hybrid, retarder technology, applied in asynchronous induction clutches/brakes, etc., can solve the problems of inability to provide braking torque, long working response time, small braking torque, etc., to improve work performance, reduce manufacturing and The effect of running costs and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

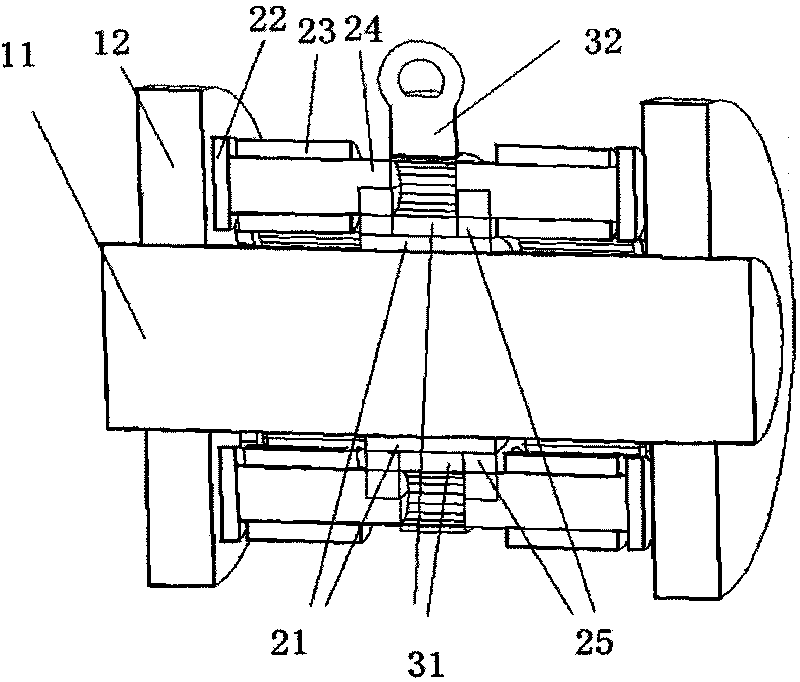

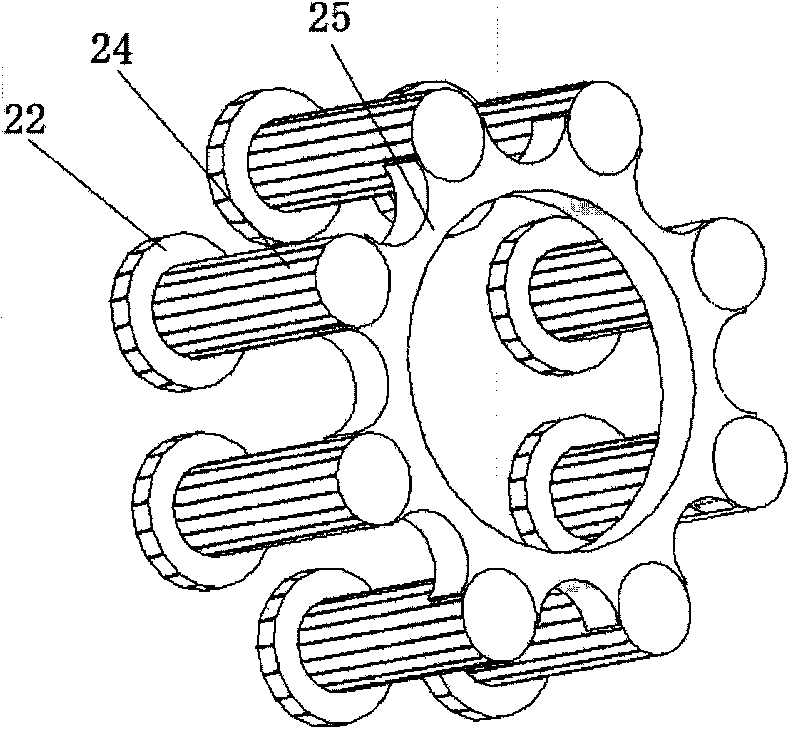

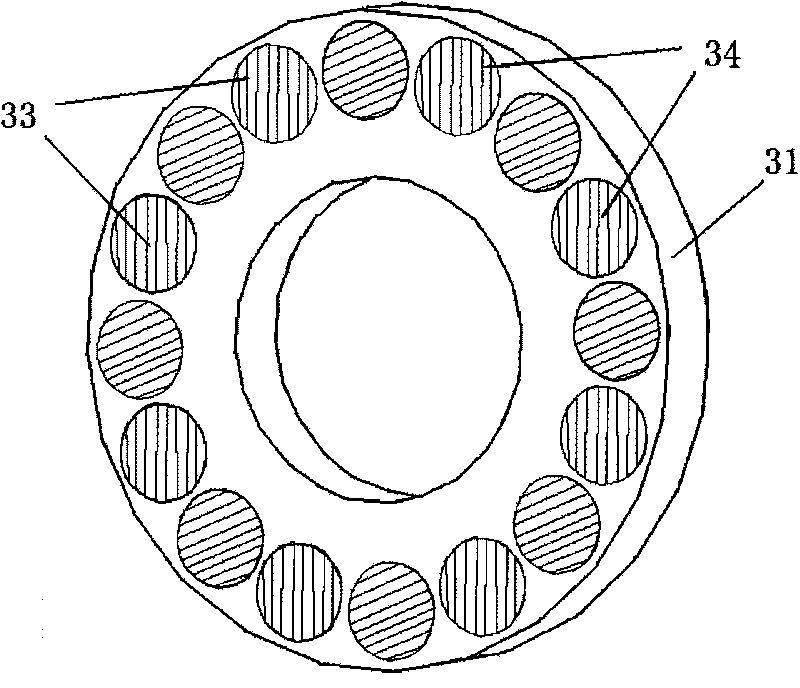

[0016] Such as figure 1 , 2 As shown, the two ends of the rotating shaft 11 are fitted with a rotor disk 12 , and the middle of the rotating shaft 11 is fitted with an annular fixed disk 31 . Between the fixed disk 31 on the left side and the rotor disk 12, and between the fixed disk 31 on the right side and the rotor disk 12, a set of stator tooth sets with brackets 25 are arranged symmetrically, and the brackets 25 are sleeved on the rotating shaft 11. That is, the fixed disk 31 is arranged between the two brackets 25 , and the two stator tooth groups are symmetrically arranged on both sides of the fixed disk 31 . Wherein, each group of stator teeth has 8 stator teeth 24 , and each stator tooth 24 is wound with a winding 23 . One end of each stator tooth 24 is connected to a corresponding magnetic yoke 22 , and the other end is fixed on a bracket 25 . There is a gap in the axial direction between the yoke 22 and the rotor disk 12 .

[0017] The bearing 21 is fixedly slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com