Brushless direct-current (DC) motor

A technology of DC motors and motor shafts, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve problems that affect the wide application of brushless DC motors, restrict the development of brushless DC motors, and reduce the reliability of brushless DC motors. , to achieve significant economic and social benefits, reduce operational failures, and increase reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

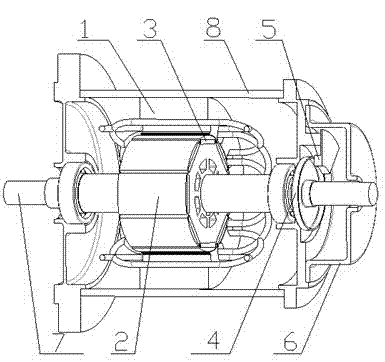

[0013] The brushless DC motor of the present invention includes a casing 8 , a motor shaft 7 , a stator 1 , a rotor 2 , a magnetic steel 3 , a magnetic ring 4 and a Hall element 5 .

[0014] As shown in the figure, the rotor 2 is installed on the motor shaft 7, the magnet steel 3 is installed on the rotor 2, and the stator 1 is outside the rotor 2.

[0015] The figure shows that a magnetic ring 4 is fixed on the motor shaft 7 outside the casing 8, and a Hall element 5 is installed on the outer wall of the casing 8. The distance between the Hall element 5 and the magnetic ring 4 is smaller than the sensing range of the Hall element 5. The Hall element 5 is connected with the controller. A protective cover 6 is installed outside the Hall element 5 , and the edge of the protective cover 6 is connected with the outer wall of the motor casing 8 .

[0016] After the stator 1 is energized in the present invention, the rotor 2 rotates, the rotor 2 drives the motor shaft 7 to rotate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com