Electromagnetic electric control valve

An electric control valve and electromagnetic technology, applied in valve details, valve devices, engine components, etc., can solve problems such as uneven thermal expansion and contraction of the valve body and valve core, affecting stability and reliability, and coil burnout. Reach the effect of reducing power-on running time, short power-on running time, and improving operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

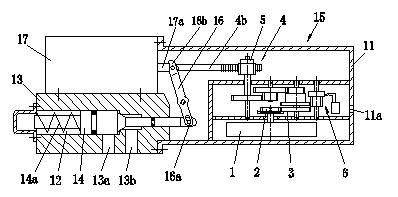

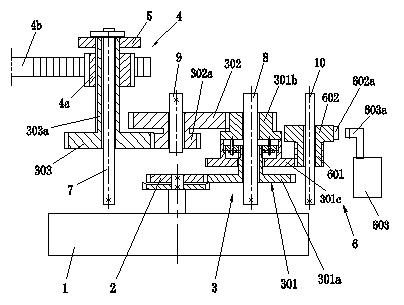

[0048] See attached picture.

[0049] The present invention comprises: a valve body 13 with a valve cavity 12, an inlet 13 a and an outlet 13 b are arranged on the valve body 13, the inlet 13 a and the outlet 13 b communicate with the valve cavity 12 respectively, and a valve core 14 is arranged in the valve cavity 12;

[0050] An electromagnet 17 for driving the spool 14 to move;

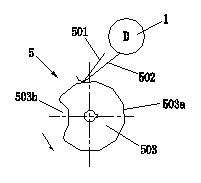

[0051] Acting on the return spring part 14a of the valve core 14; there are various structural forms of the valve core 14 and the return spring part 14a. figure 1 and Figure 11 As shown, the spool 14 is a cylindrical structure, which cooperates with the circular valve cavity 12. The middle section of the spool 14 is the working section for shutting off or connecting the inlet 13a, and the valve stem at the left end is provided with a return spring for the spool 14 to reset. Part 14a, the valve stem of the right segment protrudes from the valve body, and the figure is a normally closed valve.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com