Railway coach suspension spring matching method

A technology for railway passenger cars and passenger cars, which is applied in the directions such as the lateral relative moving device between the underframe and the bogie, can solve the problem of difficulty in ensuring a qualified drop-off inspection, low utilization rate of passenger car maintenance stations, and poor bogie frame. Balance the force system and other issues to achieve the effect of reducing vehicle operating failures, reducing the workload of auxiliary maintenance, and reasonable distribution of actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

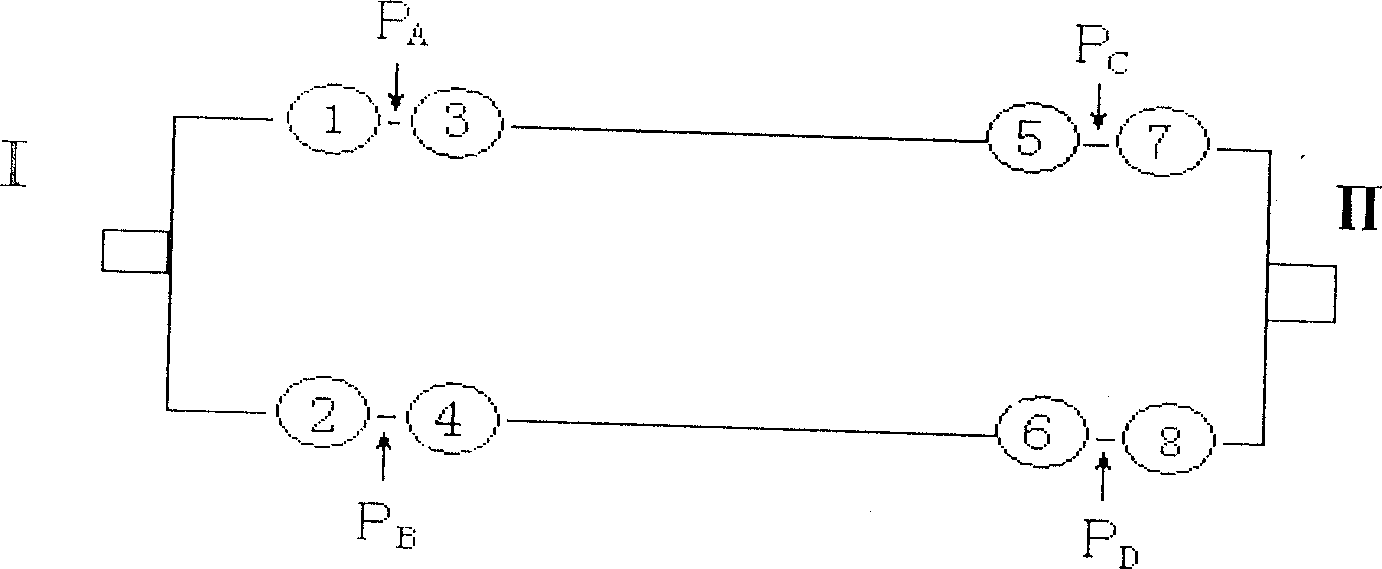

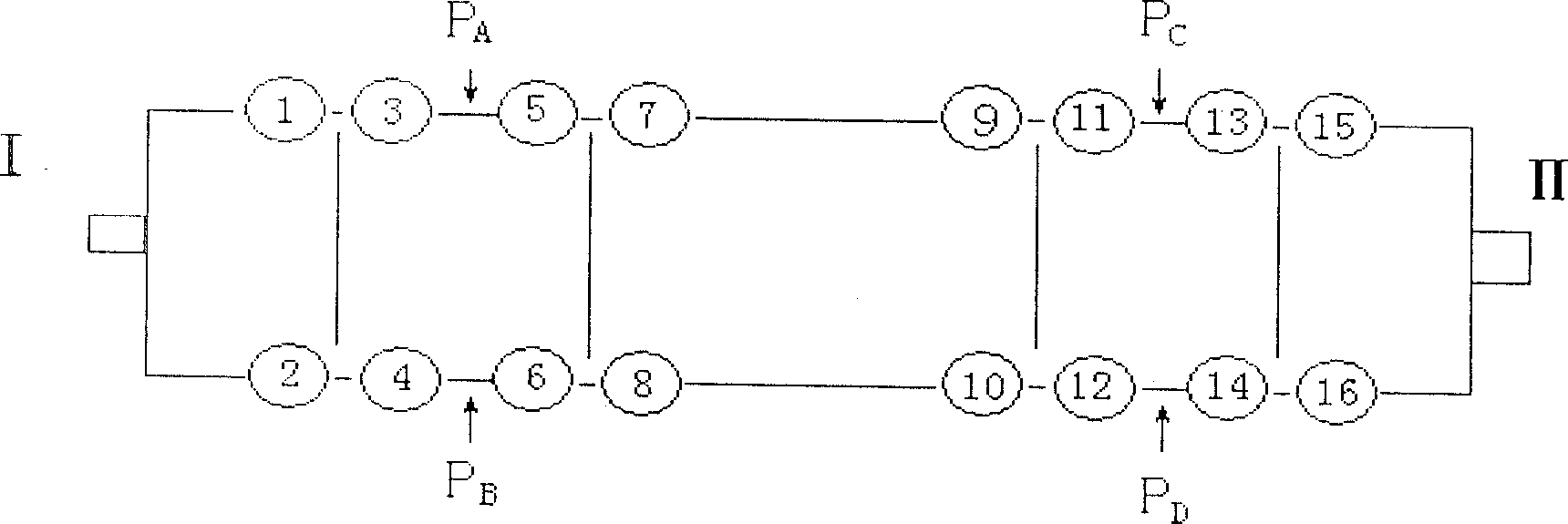

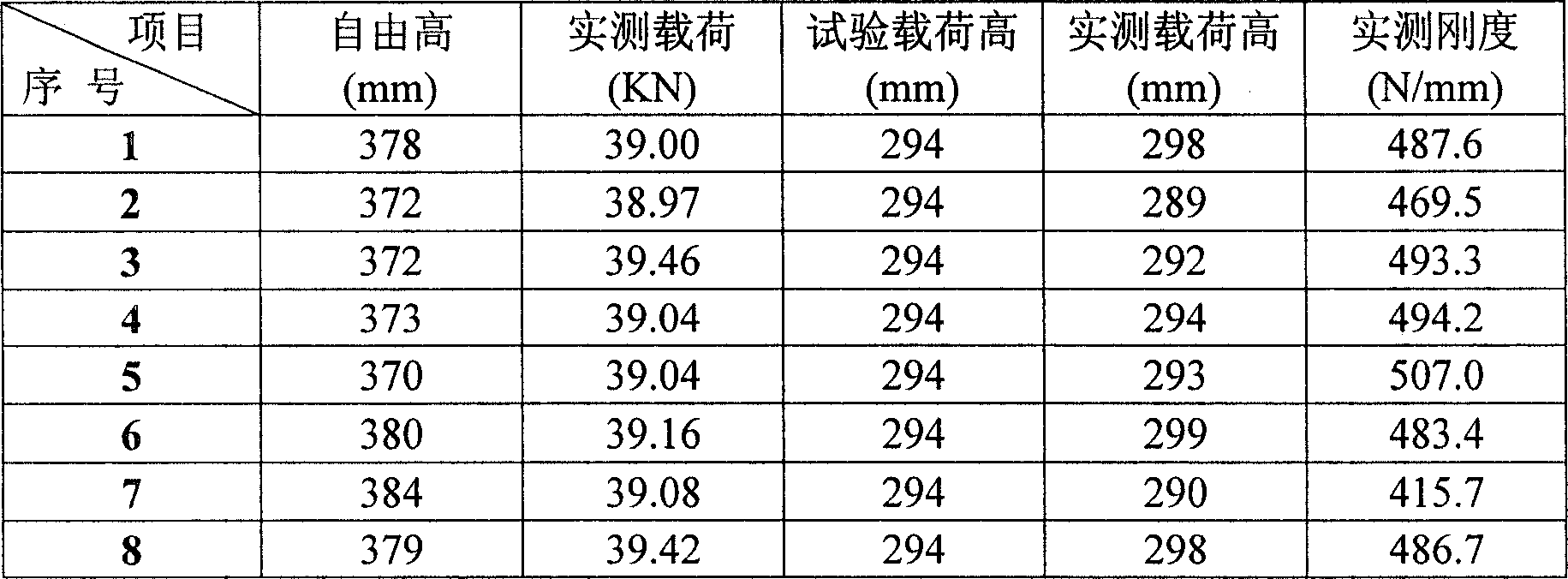

[0013] The selection method of railway passenger car suspension spring, weighing the passenger car body, and measuring the load distribution P of the four supporting positions of the passenger car body A ,P B ,P C ,P D , and according to the load distribution of the four supporting positions, determine the heavy end and light end of the passenger car body, as well as the heavy side and light side of the heavy end and light end; measure the axle box spring and bolster spring According to the free height and stiffness of the springs, the axlebox springs and bolster springs are sorted in descending order of the product of the free height and stiffness of the springs; There are 8 groups, and the 8 bolster springs are divided into 4 groups; the 8 groups of axle box springs are in the order of the product of free height and stiffness (elastic force equivalent) from large to small, according to the outer side of the heavy end and the light end of the heavy end. The outside of one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com