Automatic trough-unloading truck with remote controller

An automatic unloading and remote communication technology, which is applied in the direction of motor vehicles, loading and unloading vehicles, vehicles used for freight transportation, etc. The effect of less investment and fewer operating failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

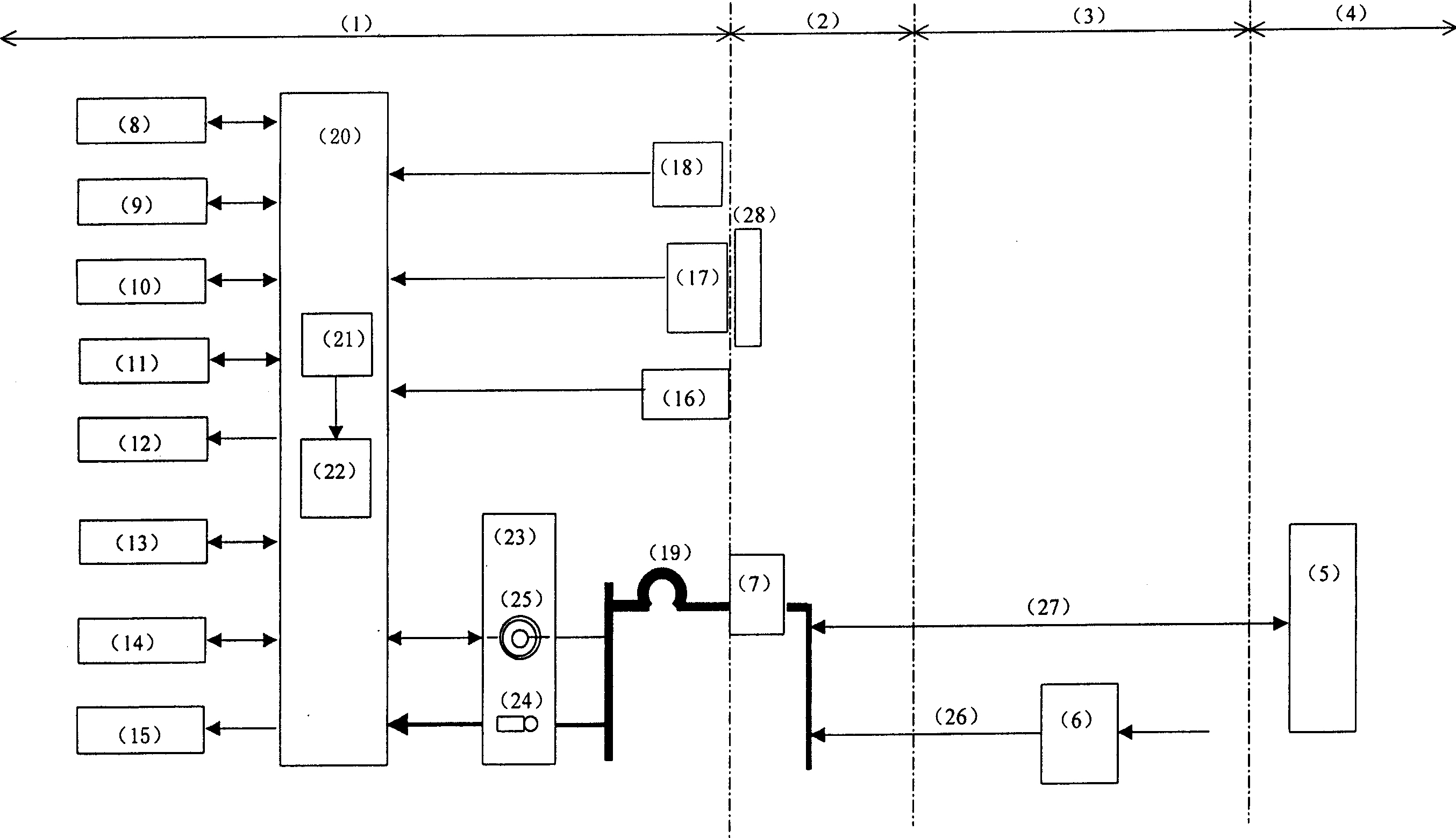

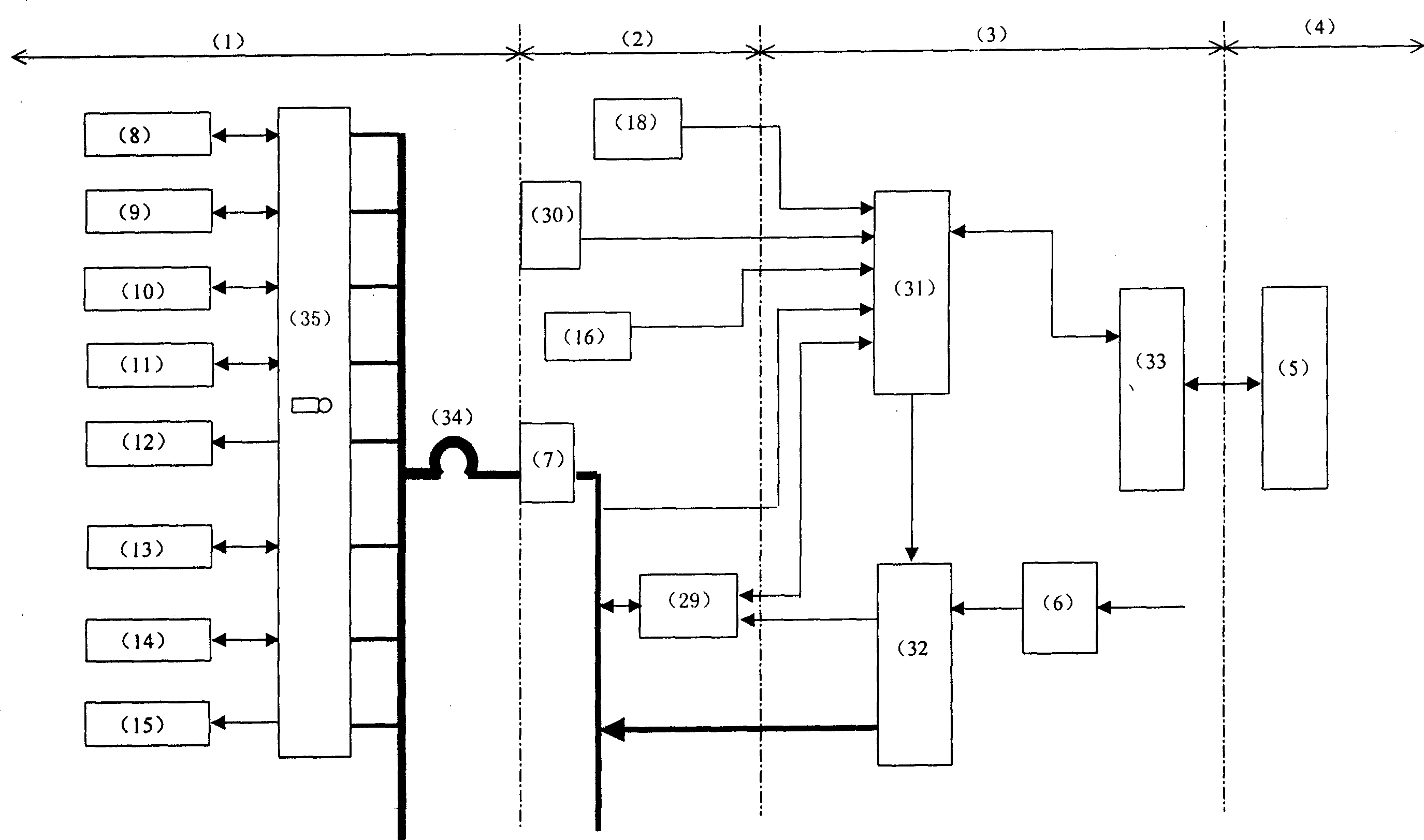

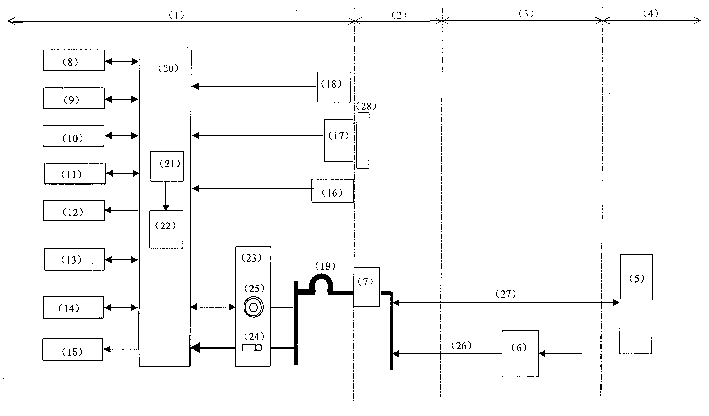

[0014] see figure 1 , the trough automatic unloading vehicle 1 with remote communication control is equipped with cable coiling parts 9, unloading car running parts 8, unloading chute parts 10, various detectors 11, walking sound and light alarm 12, material level gauge 13. Automatic centralized lubrication device 14, on-board control box 20, current collector box 23, coded slot position detection device 17, limit switch 16, on-board operation box 18, power supply and communication cable 19, etc. The cable winding part 9 is composed of a cable reel, a cable reel driving motor, a cable tightness detection device, a cable reel braking device and the like. The collector box 23 includes a power collector slip ring 24 and a communication brushless collector device 25 . The running part 8 of the unloading vehicle is composed of a driving motor, a brake of the running motor, a brake state detector and the like. The discharge chute part 10 is composed of a moving chute, a chute dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com