Automatic adjusting system adopting double-dynamic dead zone control mode for roll gap levelness of finish rolling mill

A dead-zone control and automatic adjustment technology, applied in the direction of tail end control, rolling force/roll gap control, etc., can solve the problems such as the inability to accurately judge the variation trend of rolling force deviation, and the lack of control, so as to improve The effect of reducing the production operation rate, tail flick rate, and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings of the specification, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

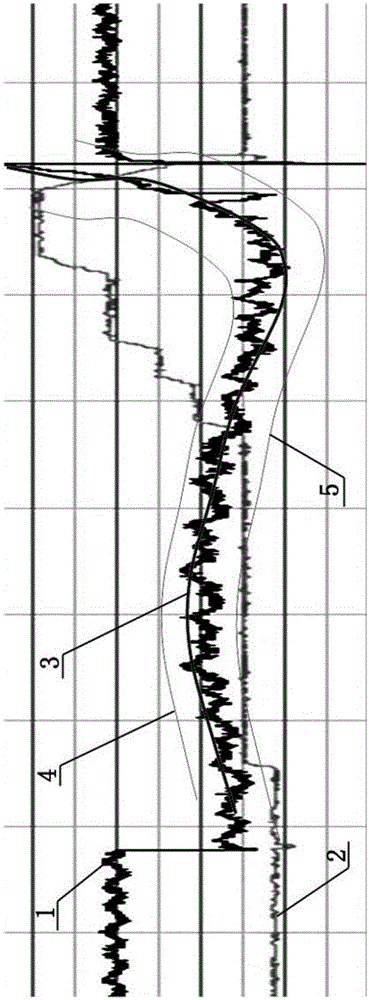

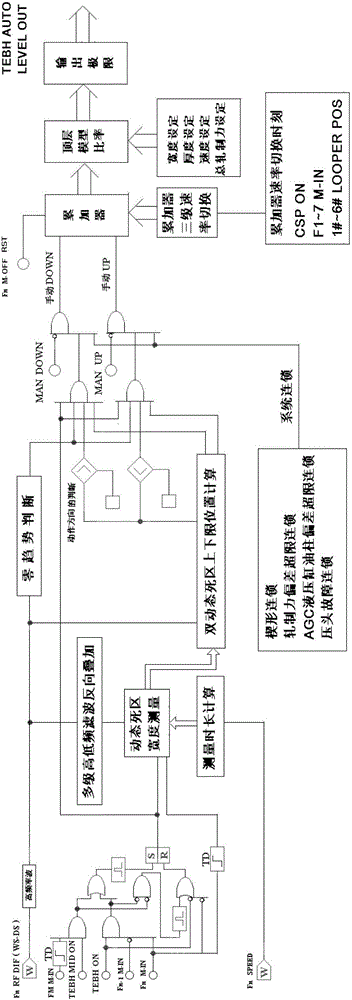

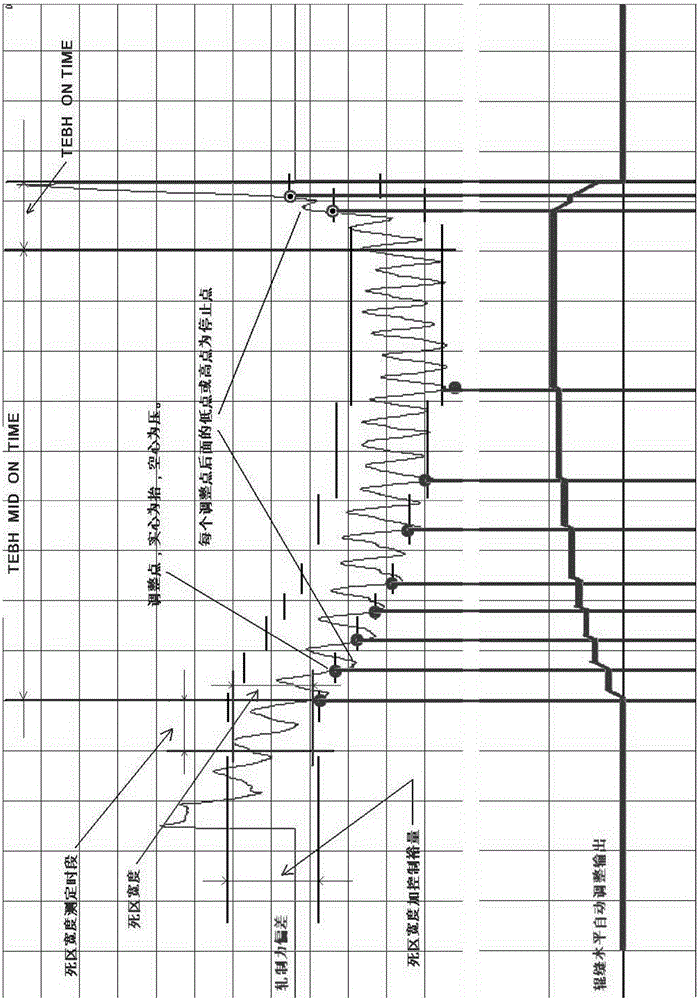

[0042] The automatic adjustment system for the roll gap level of the finishing mill with dual dynamic dead zone control (hereinafter referred to as this system) adopts different methods to deal with the different characteristics of each interference. The electrical clutter interference and the rolling machinery vibration interference are conventional The high-frequency filtering method solves the problem of roll eccentricity interference, rolling mill acceleration and deceleration interference, and strip watermark change interference. The core dual dynamic dead zone judgment control technology and zero trend judgment are independently developed by this system.

[0043] Control principle:

[0044] The variable dead zone means that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com