Wind and water combined slag cooler for fluidized bed

A slag cooler and fluidized bed technology, applied in the field of slag cooling and discharging devices, can solve the problems of poor cost performance of the slag cooler, small slag discharge, high slag discharge temperature, etc., and achieve less operation failure, large slag discharge, cooling slag swift effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

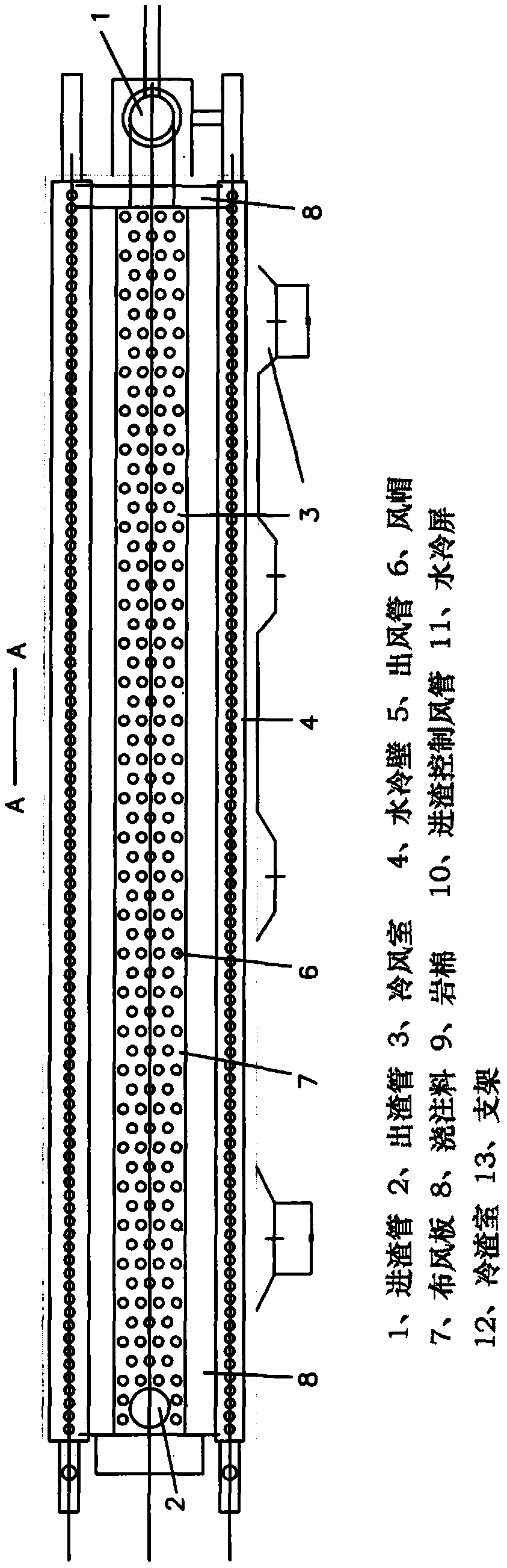

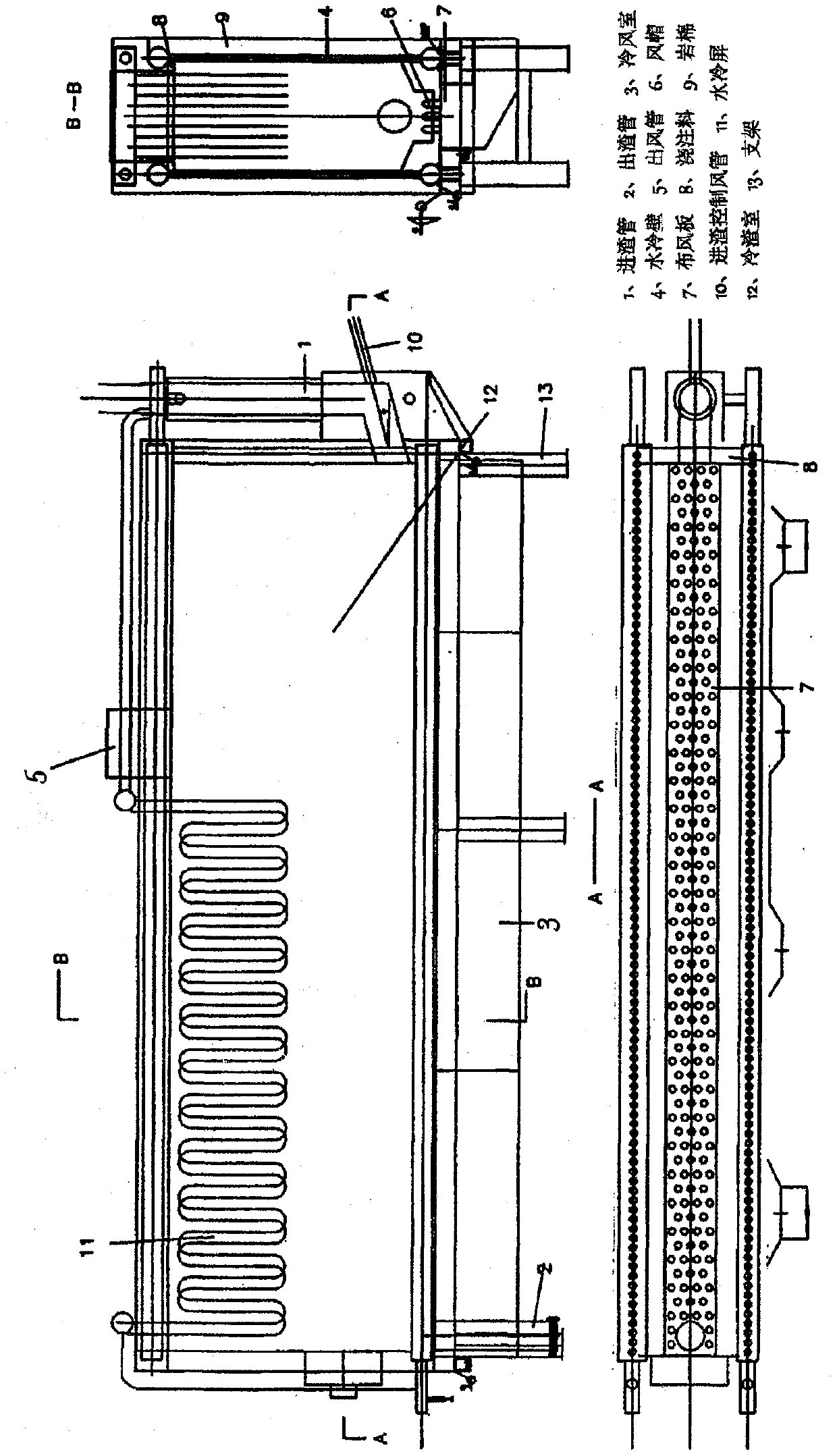

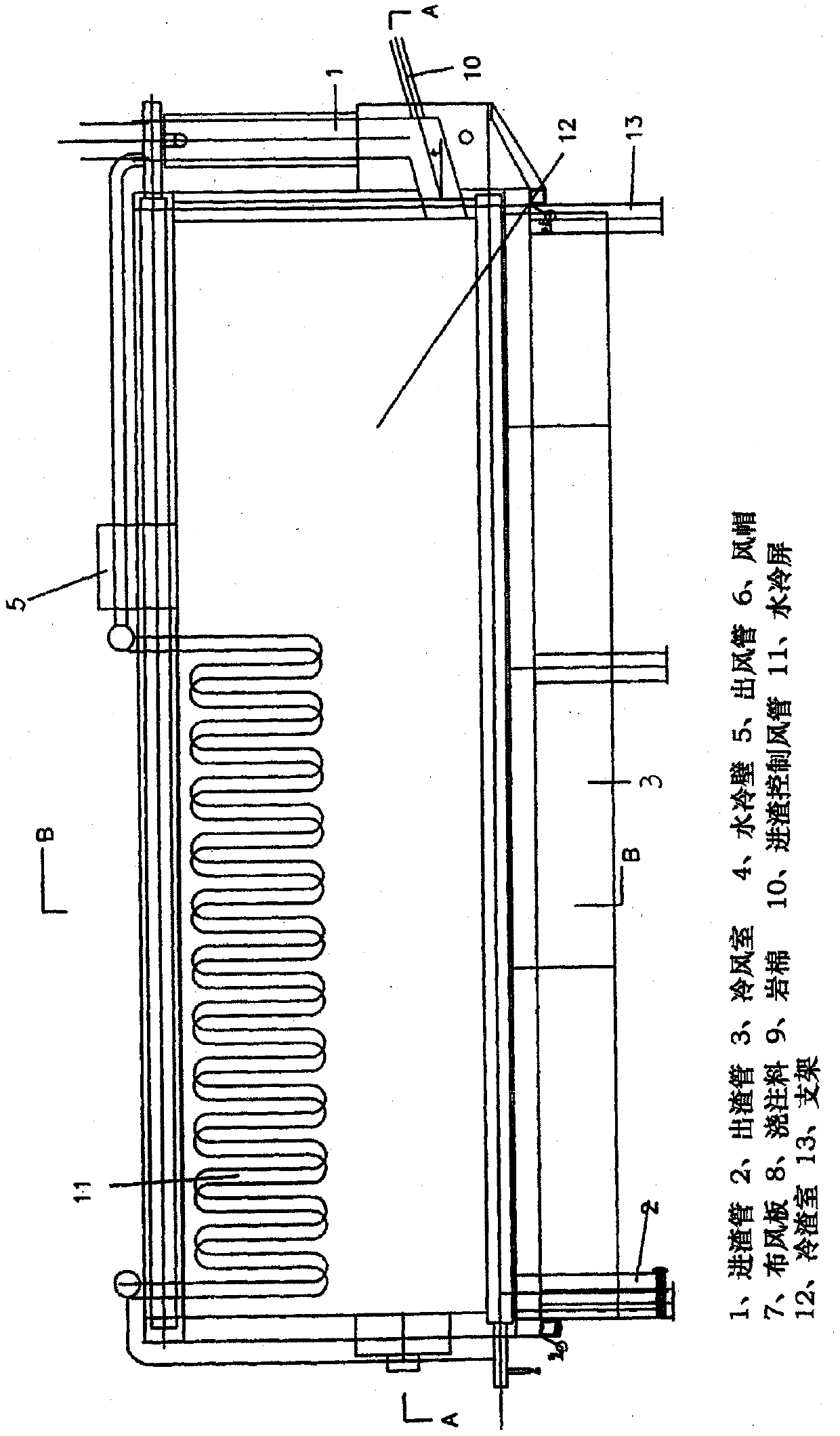

[0046] 1. The air distribution plate is made of 20#G by laser cutting and opening, and the base of the air cap is welded.

[0047] 2. The cold air chamber under the air distribution plate is sheared and welded by steel plates, and connected to the air inlet pipe and valve.

[0048] 3. The water cooling wall on the air distribution plate is composed of membrane tubes. The wear plate is machined from flat iron and welded to the water wall.

[0049] 4. The hood is casted by alloy, installed on the base of the air distribution plate, and then poured with castables.

[0050] 5. The slag inlet pipe and the slag outlet pipe are respectively welded to the slag inlet side plate of the slag cooler and the slag outlet of the air distribution plate.

[0051] 6. The hot air return pipe is welded on the top of the slag cooler

[0052] 7. Complete the welding and installation of other shells and brackets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com