Process method for overhauling main bearing hole of diesel engine cylinder block

A process method and main bearing technology, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of main bearing holes of the machine body that cannot be repaired, scrapped, and have a short service life, so as to avoid machine body scrapping, obvious economic benefits, The effect of reducing operational failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will now be described in further detail in conjunction with the accompanying drawings and preferred embodiments.

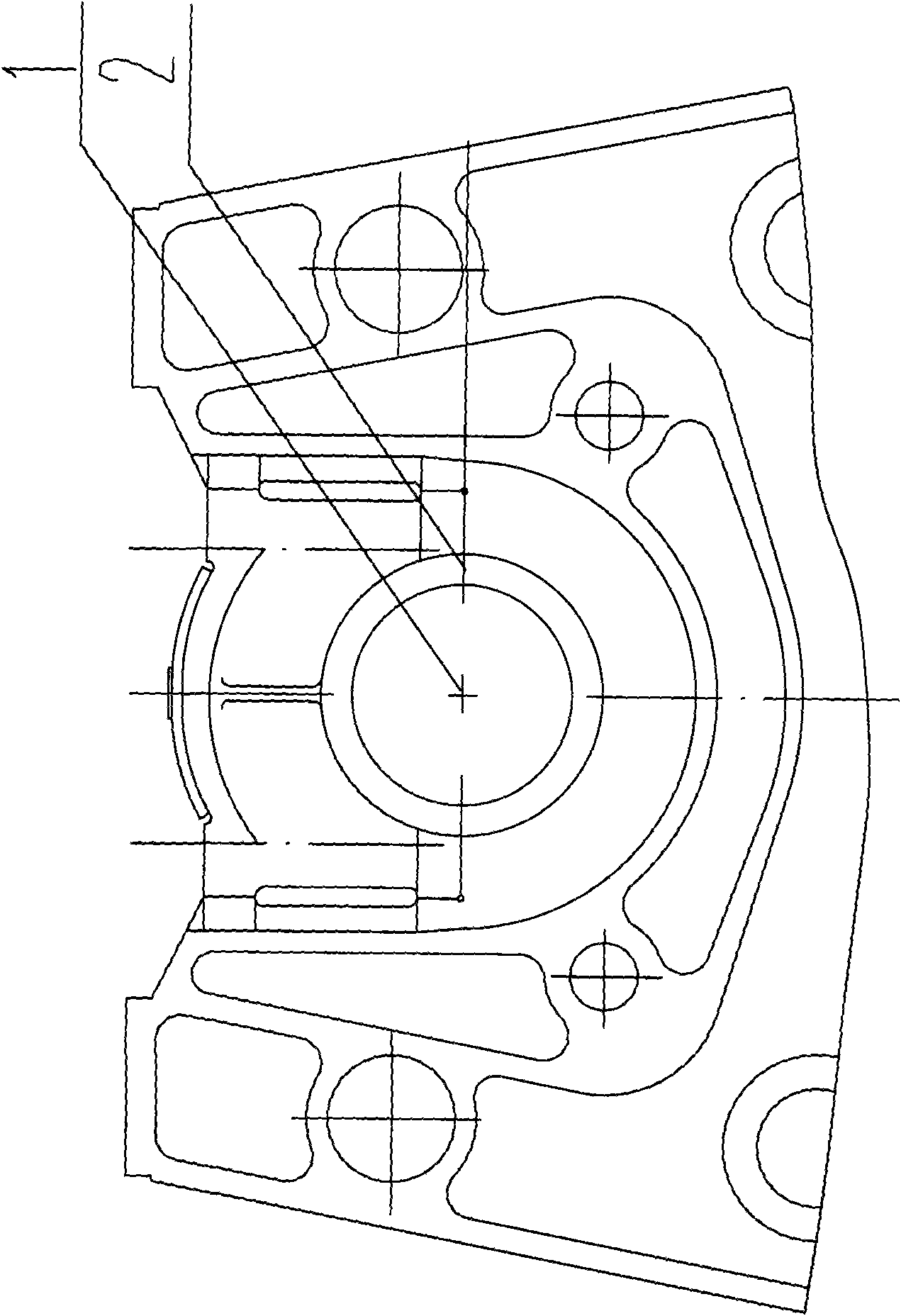

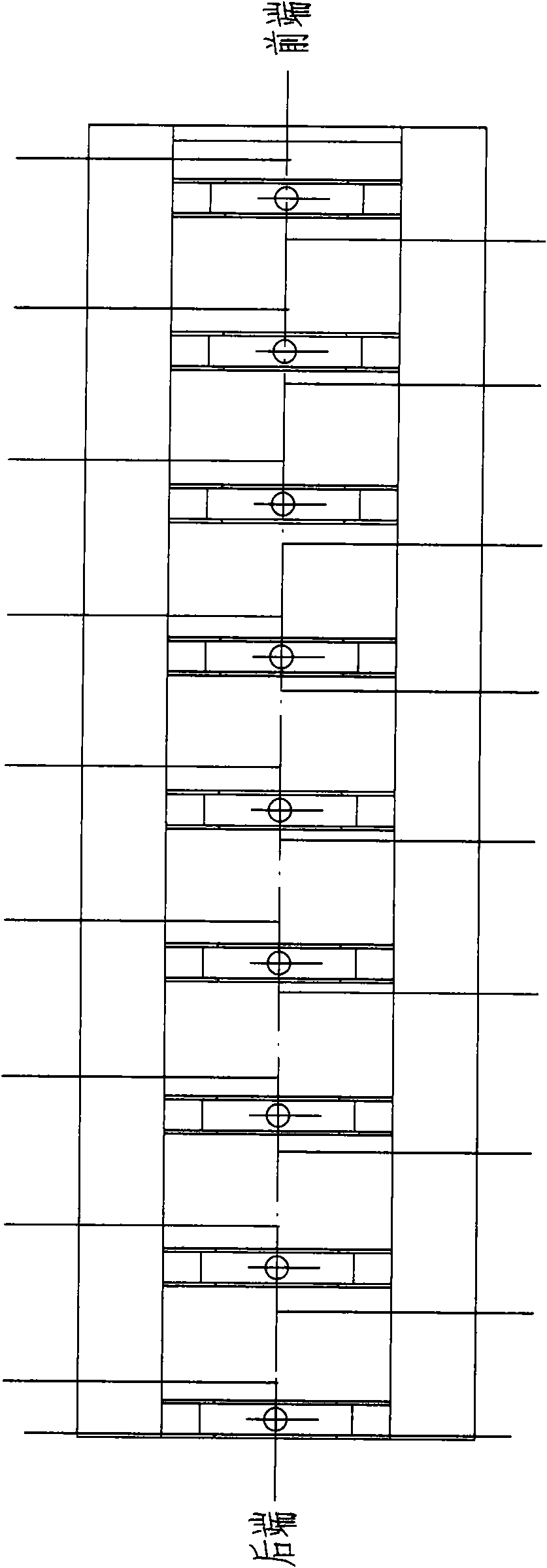

[0011] figure 1 It is a schematic diagram of the structure of the present invention. Use a grinder to grind the Huff surface 2 of the main bearing cap of the body to 0.3∽0.5mm, and grind it to 0.6∽0.8mm if the deformation is serious. Install the main bearing cap on the body and tighten it according to the technical requirements. For the main bearing bolts, use a CNC floor boring machine to process the body main bearing hole 1, first adjust the position of the body main bearing hole 1 on the floor boring machine. Align the center of the first hole and the last hole with a dial indicator on the semicircle of the main bearing seat of the first hole and the last hole of the main bearing hole 1 of the body, fix the body after alignment, and adjust it again to prevent The position of the body changes after being compressed. Adjust the bori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com