Screw air compressor mainframe performance detection device

A detection device and air compressor technology, applied in the direction of machine/engine, pump testing, mechanical equipment, etc., can solve the problems affecting the normal operation of screw air compressors, and cannot be systematically detected, so as to ensure normal operation and reduce operating failures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

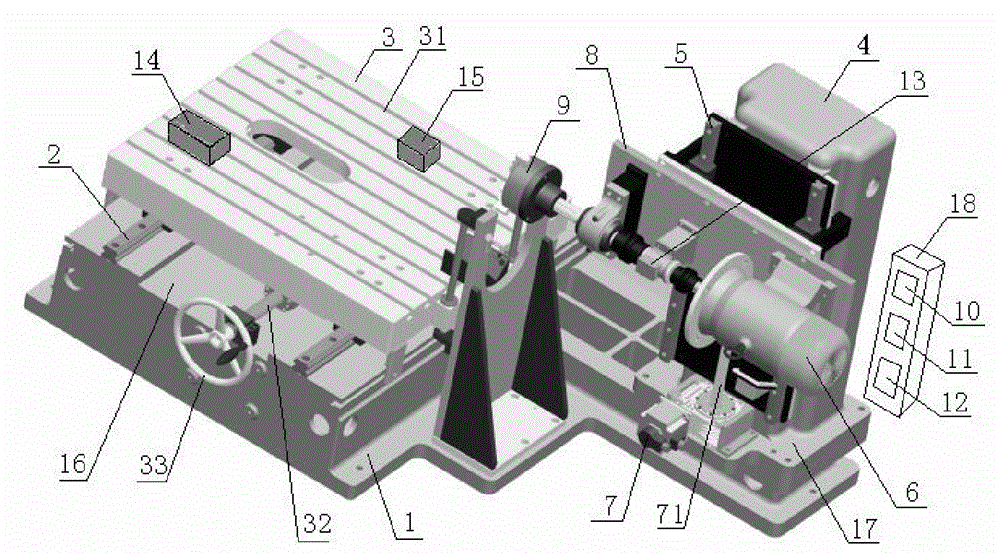

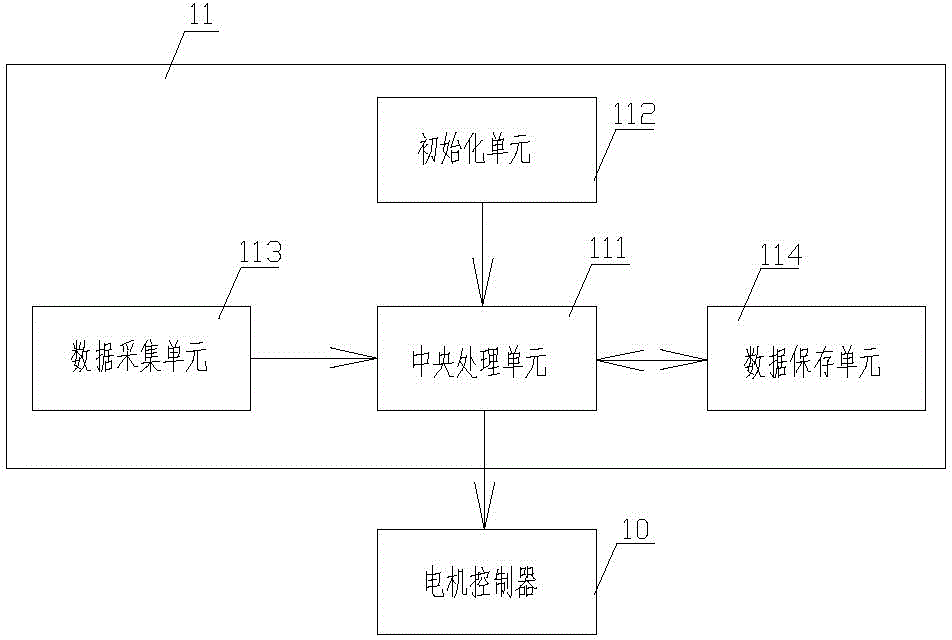

[0012] Such as figure 1 As shown, the screw air compressor host performance testing device of the present invention includes a high and low box base 1, two horizontal guide rails 2, a platform 3, a lifting column 4, two lifting guide rails 5, a frequency conversion motor 6, a servo motor 7, a lifting slide 8, Connector 9, motor controller 10, operation detection module 11, A / D conversion module 12, torque sensor 13, temperature sensor 14, vibration sensor 15 and electric control box 18, the two horizontal guide rails 2 are respectively arranged at intervals The high-end plane 16 of the high and low box seat 1, the platform 3 is arranged on the two horizontal guide rails 2 and can move along the horizontal guide rails 2 through the screw rod 32 and the hand wheel 33, and the lifting column 4 is vertically arranged on the two horizontal guide rails 2. On one side of the low end plane 17 of the high and low box seat 1, the two lifting guide rails 5 are vertically spaced on the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com