Single lane stacker transport apparatus taking sending type rollaway parking equipment

A technology of parking equipment and stacker, which is applied in the field of single-lane stacker carrier pick-up and delivery type raceway storage parking equipment, can solve the problems of consumption, customer service impact, high investment cost, etc., and achieve simple structure and high efficiency. Utilization rate and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

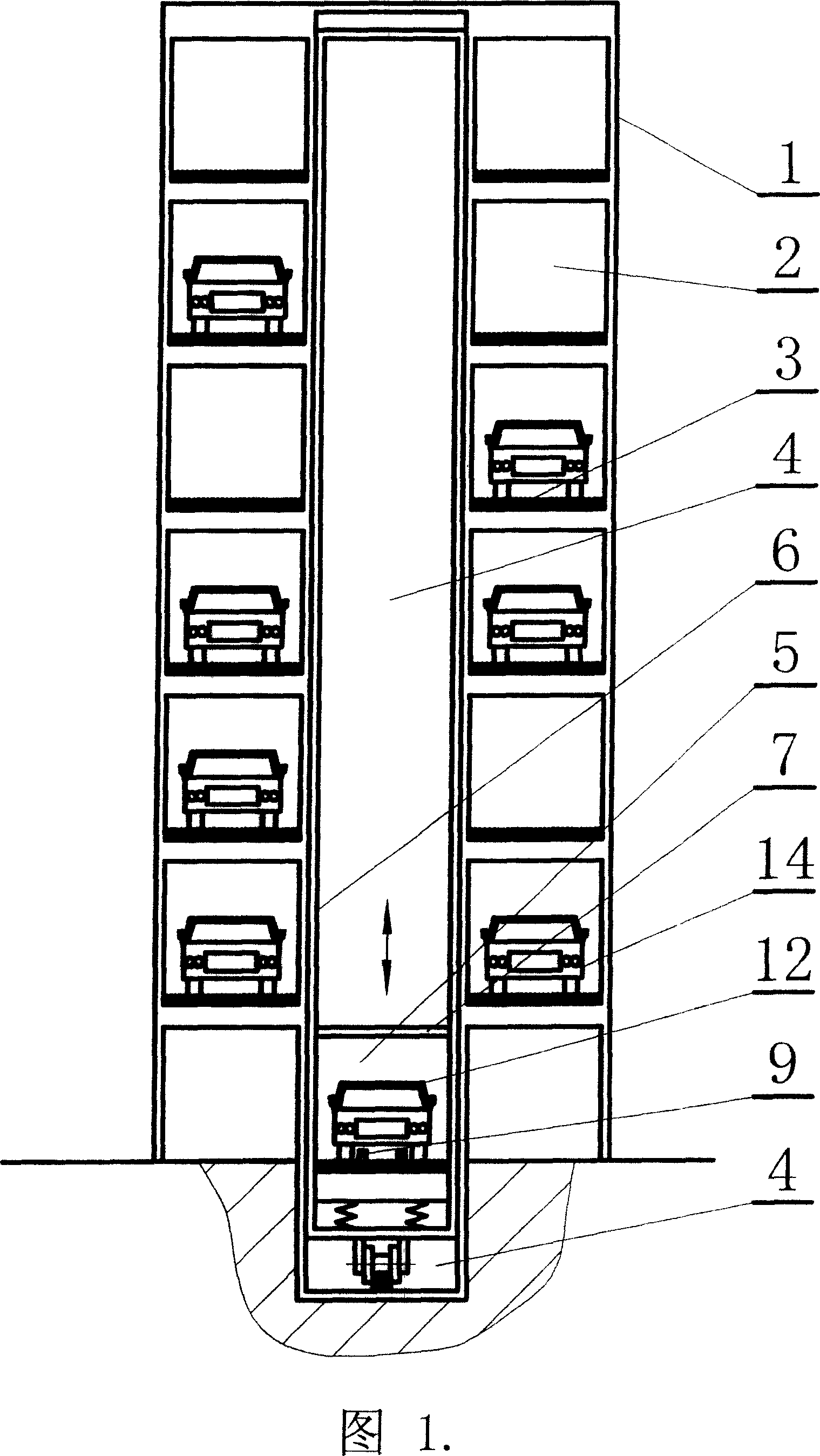

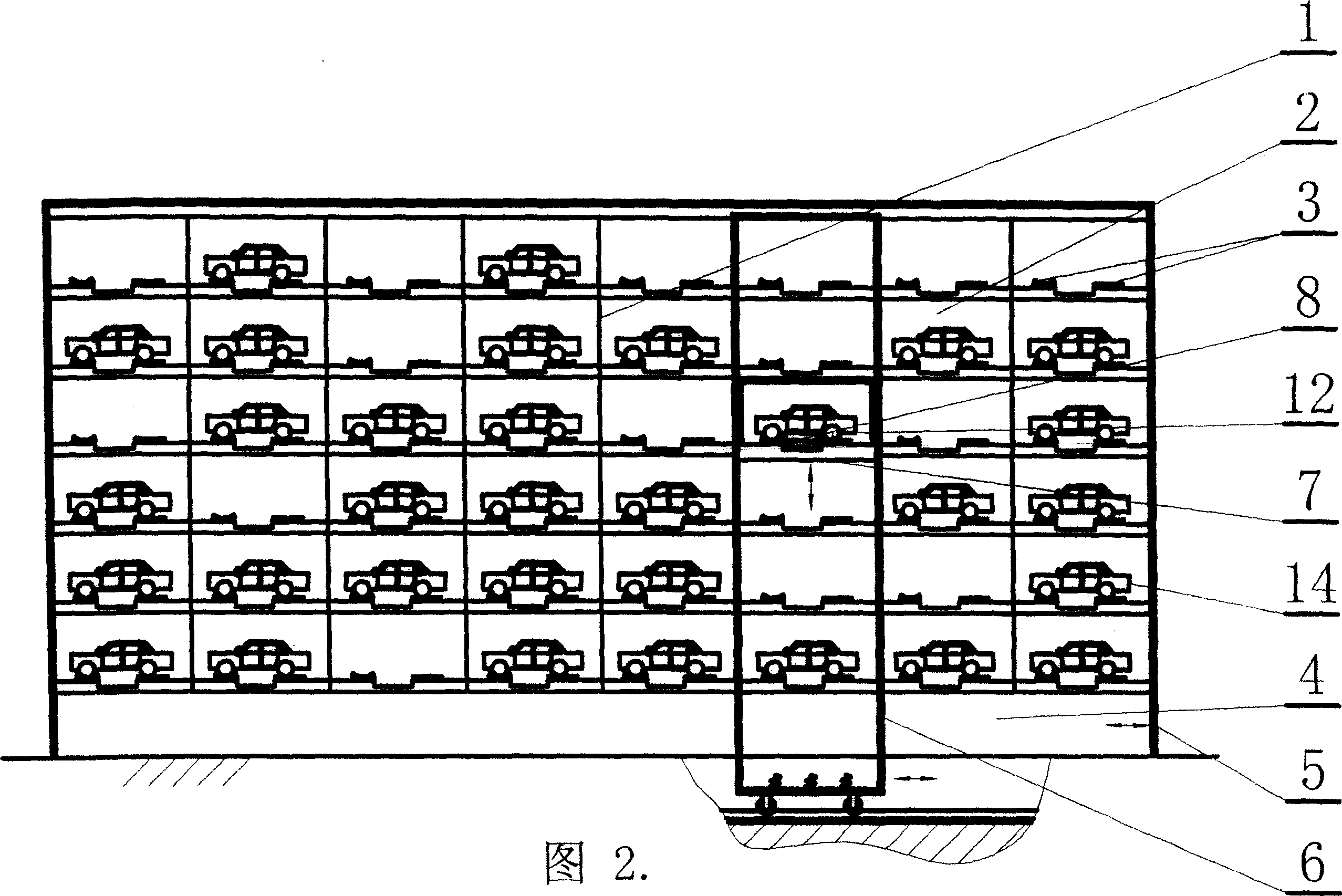

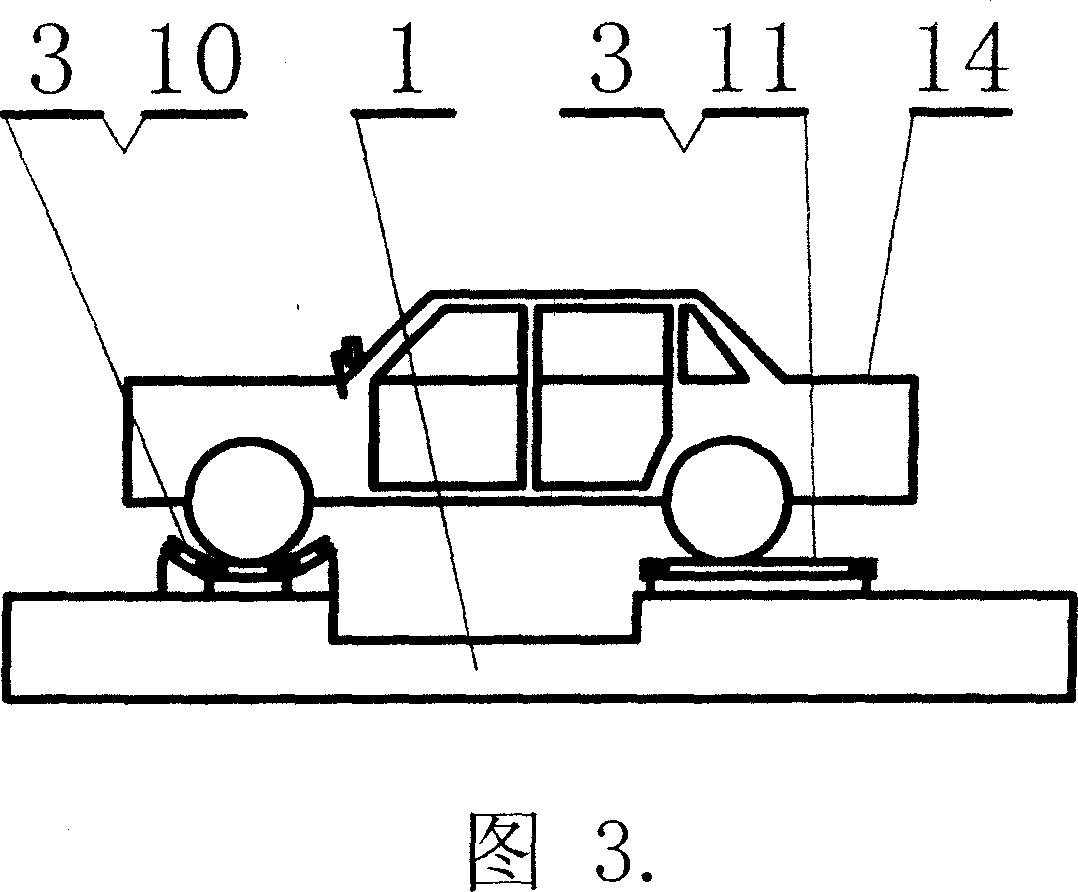

[0032] As shown in Fig. 1, Fig. 2, Fig. 3, Fig. 4 and Fig. 5, this embodiment includes: a multi-layer storage type steel frame 1, a car storage area 2, a wheel supporting raceway 3, a roadway 4, a vehicle entrance and exit 5, Stacker 6, vehicle carrier 7, vehicle pick-up and delivery mechanism 8, positioning actuating rod 9; roadway 4 is located in the middle of multi-layer warehouse-type steel frame 1, and the bottom of roadway 4 is provided with vehicle entrance and exit 5, and there are more on both sides of roadway 4 On each layer of warehouse-style steel frame 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com