Deslagging agent used for smelting cast iron and preparation method thereof

A cast iron and slag agent technology, applied in the field of cast iron casting, can solve the problems of micro-cracks and slag inclusions, and achieve the effects of preventing oxidation, strong slag accumulation ability and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A slag remover for cast iron smelting, comprising the following raw materials in weight percentage: 72.2% of silicon dioxide, 15.9% of aluminum oxide, 0.62% of iron oxide, 1.29% of sodium oxide, 3.84% of potassium oxide, 1.31% of calcium oxide, Magnesium 0.54%, the balance is iron and unavoidable impurities.

[0027] The preparation method is as follows: mixing the raw materials in the formula amount, baking at 150°C-160°C for 2-4 hours, and grinding to obtain the slag remover for cast iron smelting.

Embodiment 2

[0029] A slag remover for cast iron smelting, comprising the following raw materials in weight percentage: 75.2% of silicon dioxide, 12.3% of aluminum oxide, 1.24% of iron oxide, 2.48% of sodium oxide, 2.37% of potassium oxide, 1.17% of calcium oxide, Magnesium 0.47%, the balance is iron and unavoidable impurities.

[0030] The preparation method is as follows: mixing the raw materials in the formula amount, baking at 150°C-160°C for 2-4 hours, and grinding to obtain the slag remover for cast iron smelting.

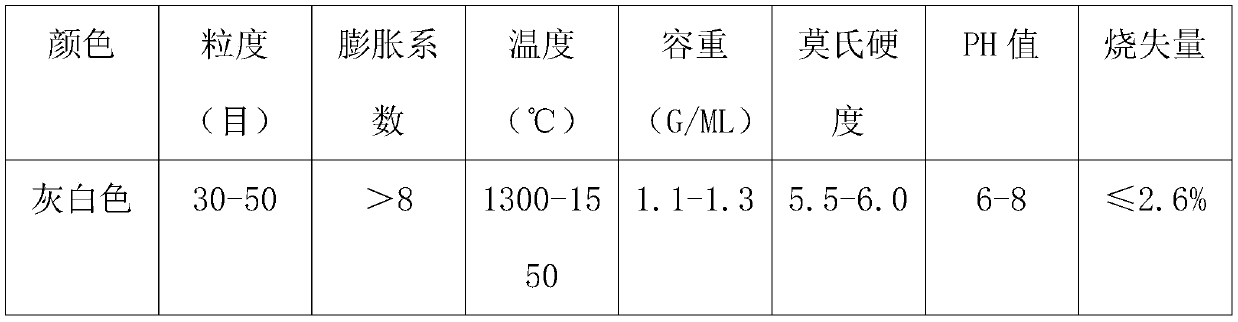

[0031] The performance of the slag remover for cast iron smelting prepared by each embodiment is shown in table 1:

[0032] Table 1

[0033]

[0034] The slag remover for cast iron smelting prepared in the above embodiments is used in iron and steel smelting to solve the problems of pitting corrosion, white spots, fly feet and the like that often occur in cast iron processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com