Automatic control device of rotation type electric smelting magnesium furnace and electrode current control method

A technology of automatic control device and fused magnesia furnace, which is applied in furnace control device, furnace, furnace components, etc., can solve the problems such as the feeding amount and feeding time interval cannot be strictly guaranteed, the current fluctuation is large, and the electrode lifting action range is large. , to achieve the effect of improving the smelting process, reducing power consumption and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0030] In this embodiment, the basic equipment parameters of the fused magnesium furnace are: the diameter of the furnace body is 2500 mm, the height of the furnace body is 3000 mm, the diameter of the graphite electrode is 400 mm, the design production capacity is 15 tons / furnace, and the rated voltage of the smelting process is It is 120 volts, the smelting current is 14,000 amperes, and the transformer capacity is 3,000 kVA;

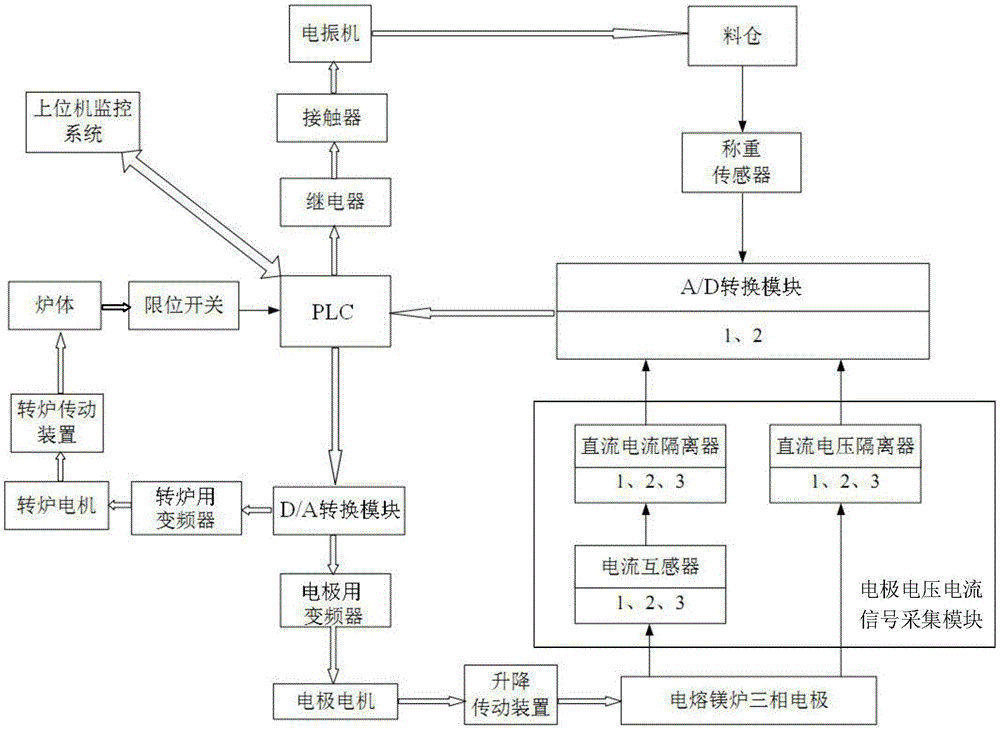

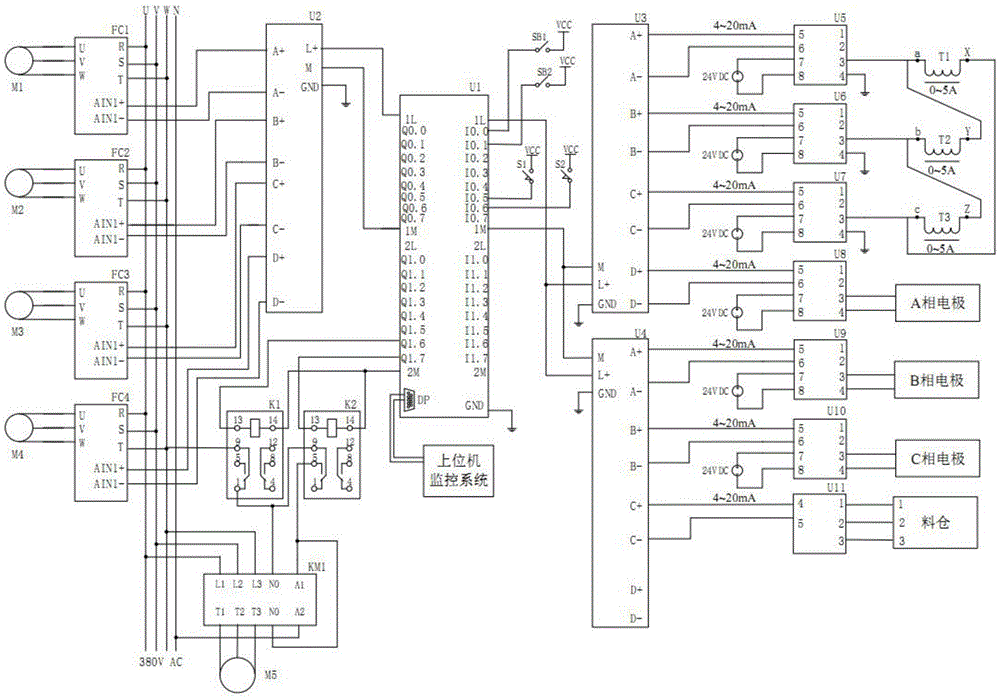

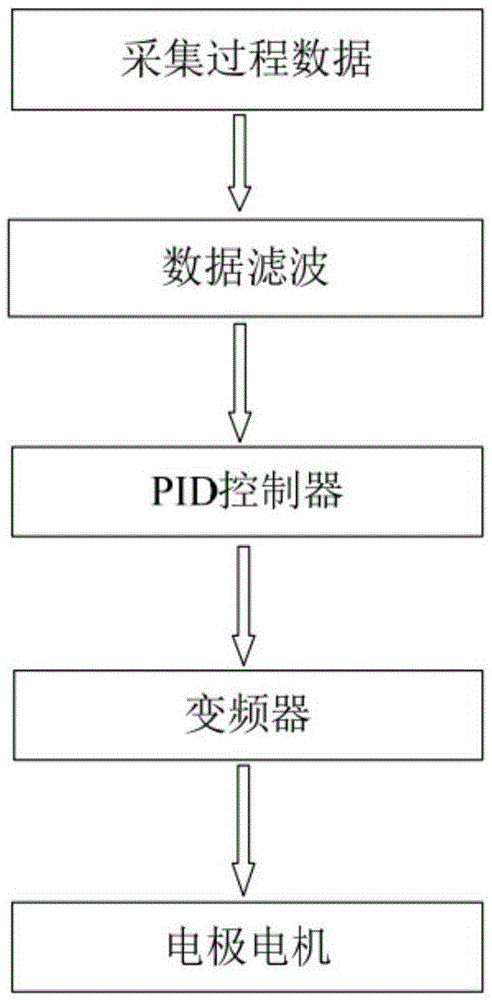

[0031] The rotary type electric fused magnesium furnace automatic control device of the present embodiment, such as figure 1 As shown, including: PLC, electric vibration machine, converter motor, limit switch for converter rotation positioning, frequency converter for converter, electrode motor, frequency converter for electrode, D / A conversion module, weighing sensor, electrode voltage and current signal acquisition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com