Advanced oxidation device for wastewater

An advanced oxidation and ozone generation device technology, applied in the direction of oxidation water/sewage treatment, water/sewage multi-stage treatment, water pollutants, etc., can solve the problem of low ozone utilization efficiency, large energy consumption, low ozone utilization efficiency, etc. problems, to achieve the effect of improving the effect of ozone oxidation treatment, improving utilization efficiency and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

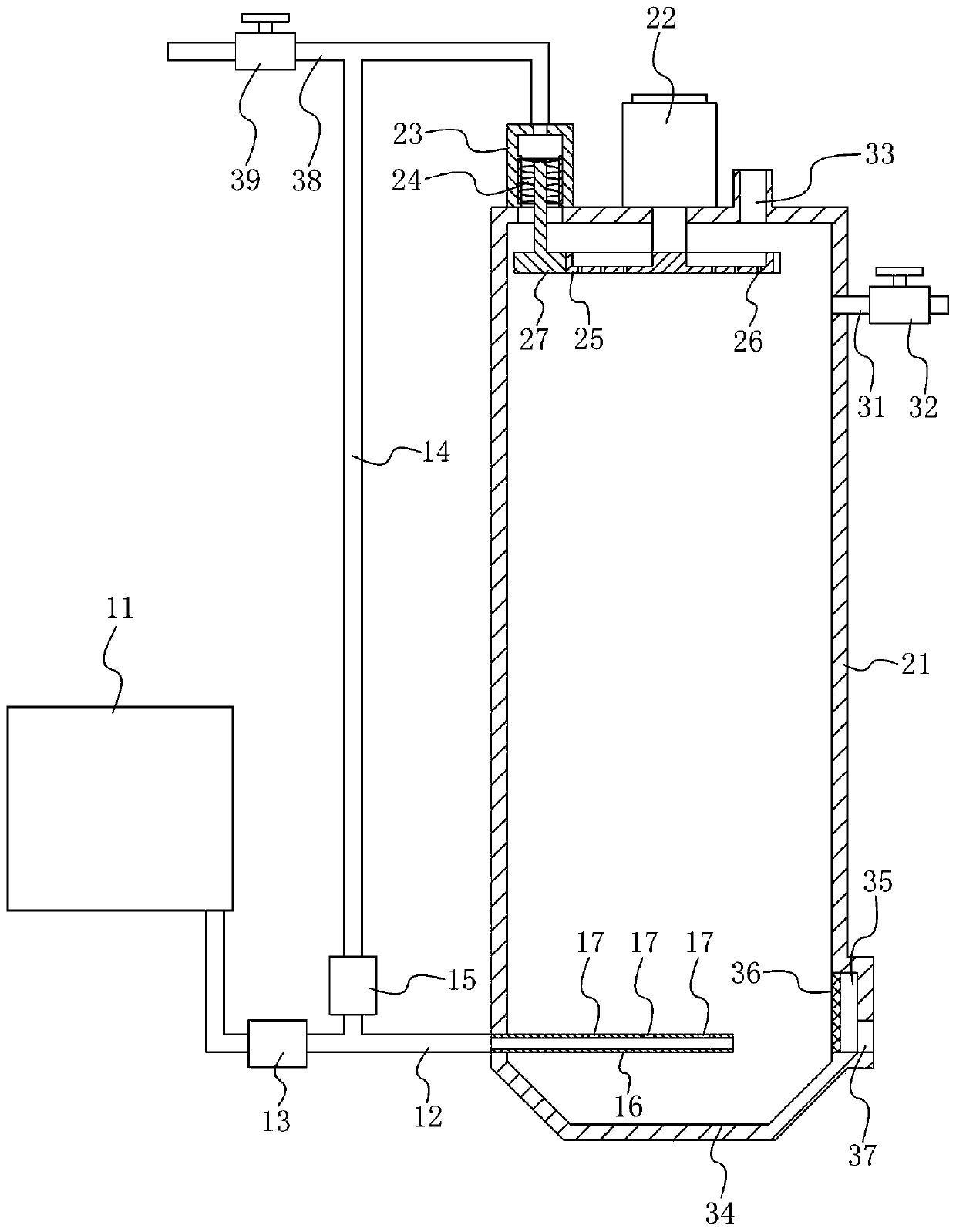

[0031] Wastewater advanced oxidation unit, such as figure 1 Shown, comprise ozone generator 11 and reaction tank 21, ozone generator 11 comprises oxygen generator and ozone generator, and oxygen generator produces oxygen and transports in the ozone generator, and ozone generator utilizes the oxygen production that oxygen generator produces ozone. Gas delivery pipe 12 is provided between ozone generator 11 and reaction tank 21, and gas delivery pipe 12 two ends are communicated with ozone generator 11 and reaction tank 21 respectively, and reaction tank 21 is provided with circulation pipe 14, and circulation pipe 14 is connected with reaction tank 21 respectively. It is communicated with the gas delivery pipe 12, the reaction tank 21 is provided with an overflow pipe 31, and the overflow pipe 31 is equipped with a drain valve 32, and the overflow pipe 31 is highly higher than the junction of the gas delivery pipe 12 and the reaction tank 21 and lower than the circulation pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com