Preparation method of large-size Al2O3 polycrystal

A multi-crystal, large-size technology, applied in the direction of crystal growth, polycrystalline material growth, chemical instruments and methods, etc., can solve the problems of complex operation process and difficult control of multi-crystal, and achieve easy automatic control, sufficient ignition time, and reduced The effect of streamlined operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

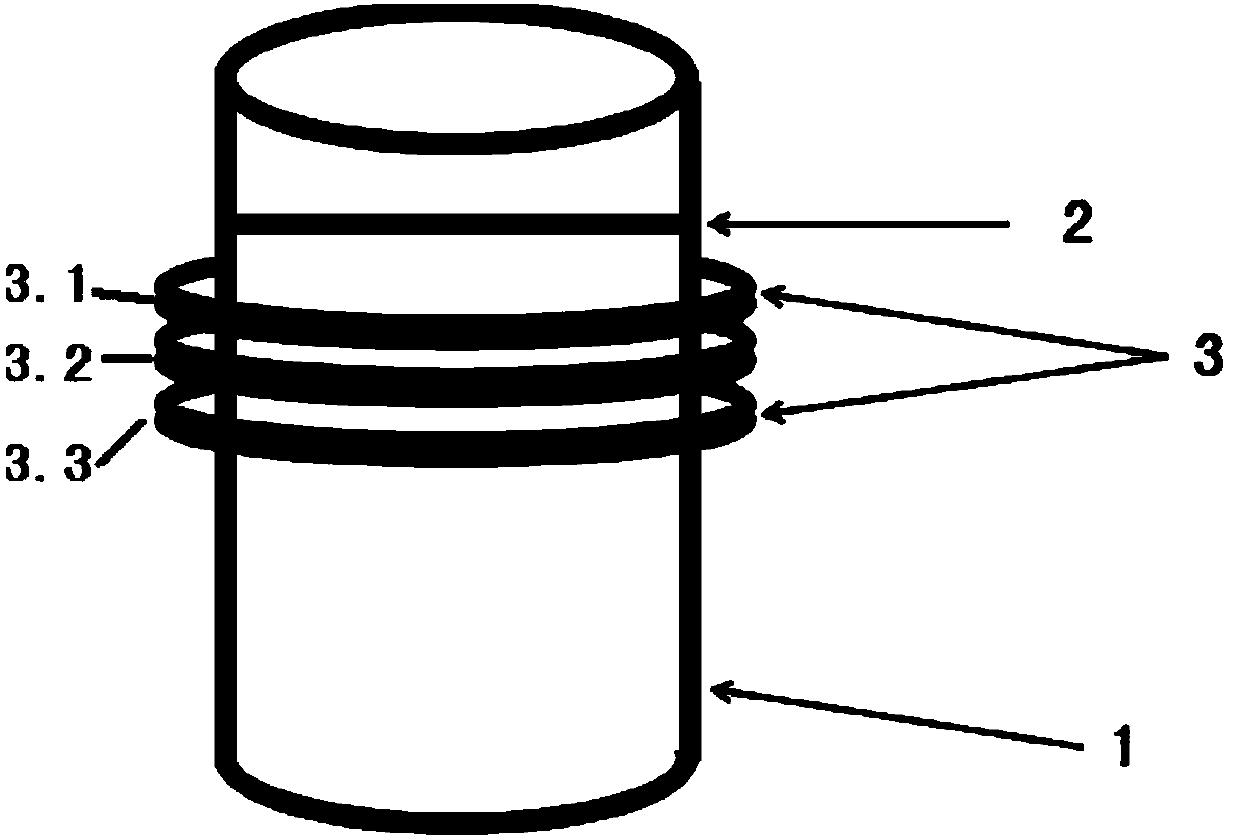

[0022] 1. Before smelting, cover the inner wall of the cylindrical crucible with a layer of high-purity Al with a thickness of 5mm 2 o 3 Powder, the outer wall of the cylindrical crucible is covered with asbestos cloth, insulating board and insulating cloth tape, and the heating induction coil is fixed on the outer wall of the crucible. The inner diameter of the cylindrical crucible is Φ150mm, the height is 600mm, and the thickness is 20mm. First add a layer of high-purity Al with a thickness of 3cm to the bottom of the crucible 2 o 3 Cake material, then add 10cm high high-purity Al 2 o 3 Powder, adjust the height of the crucible to make high-purity Al 2 o 3 The upper surface of the powder is level with the middle of the heating induction coil. Dig a 2cm wide and 2cm deep annular deep groove inside the crucible at a distance of 5-8cm from the inner wall to place high-purity Al particles as a starting fire, and the high-purity Al particles are connected to each other to ...

Embodiment 2

[0027]The difference between this embodiment and Embodiment 1 is that the inner diameter of the cylindrical cold crucible is Φ230mm.

[0028] al 2 o 3 The density of single crystal is 3.8g / cm 3 . Preparation of Al by prior art 2 o 3 The raw material of single crystal is mostly Al 2 o 3 For powder and block materials, the loose stacking density is about 1.8g / cm 3 , the volume will be greatly reduced after smelting, and the productivity will be low. The raw material smelting of the present invention is sufficient, and the obtained Al 2 o 3 The purity of polycrystalline is high, and the bulk density is not less than 3.75g / cm 3 (near Al 2 o 3 single crystal density), can be directly used as the preparation of Al 2 o 3 Raw materials for single crystals, Al prepared by this method 2 o 3 The polycrystalline size can reach 145mm in diameter and 450mm in height, which greatly improves the preparation of Al 2 o 3 Single crystal productivity, more suitable for growing b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com