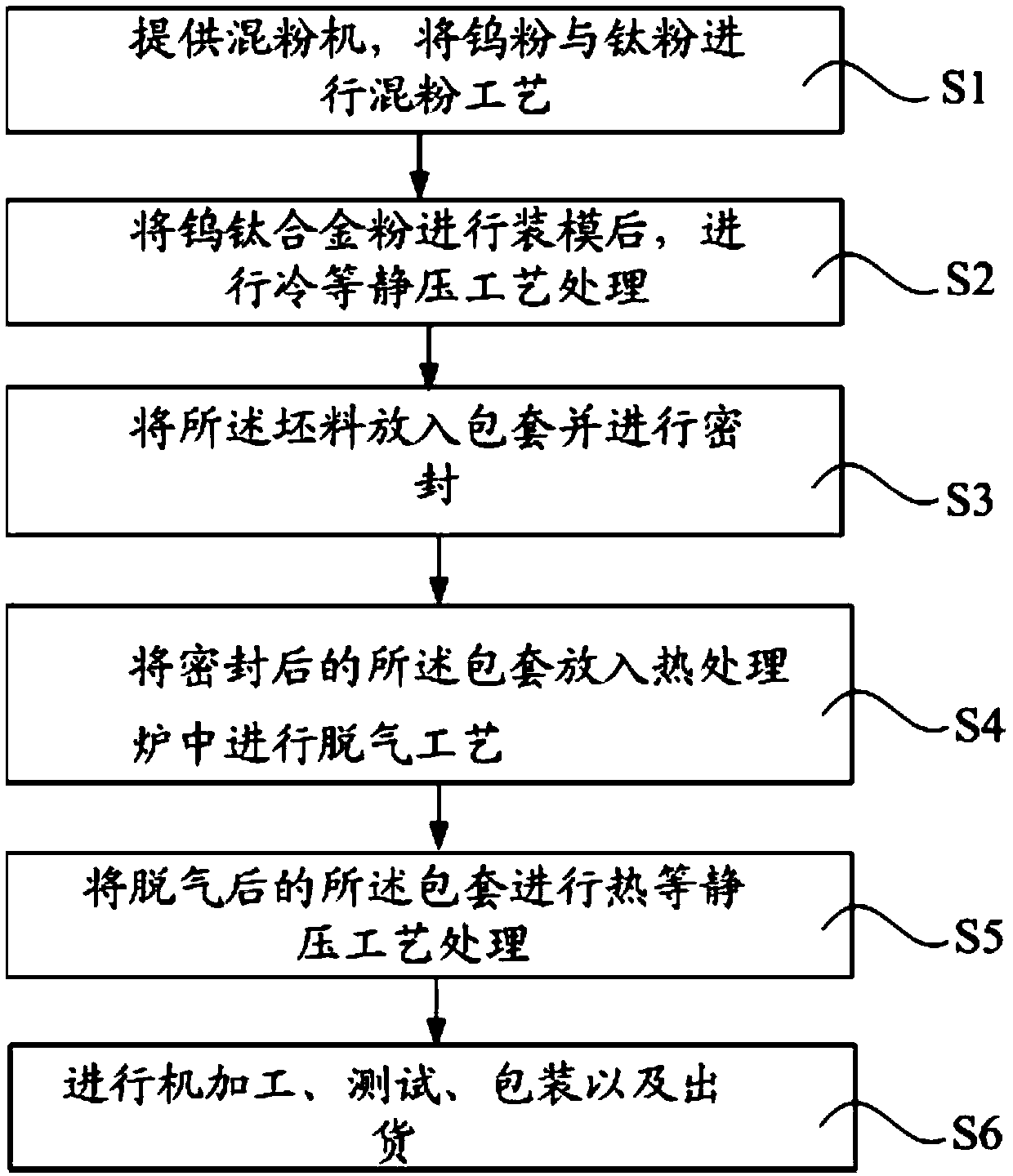

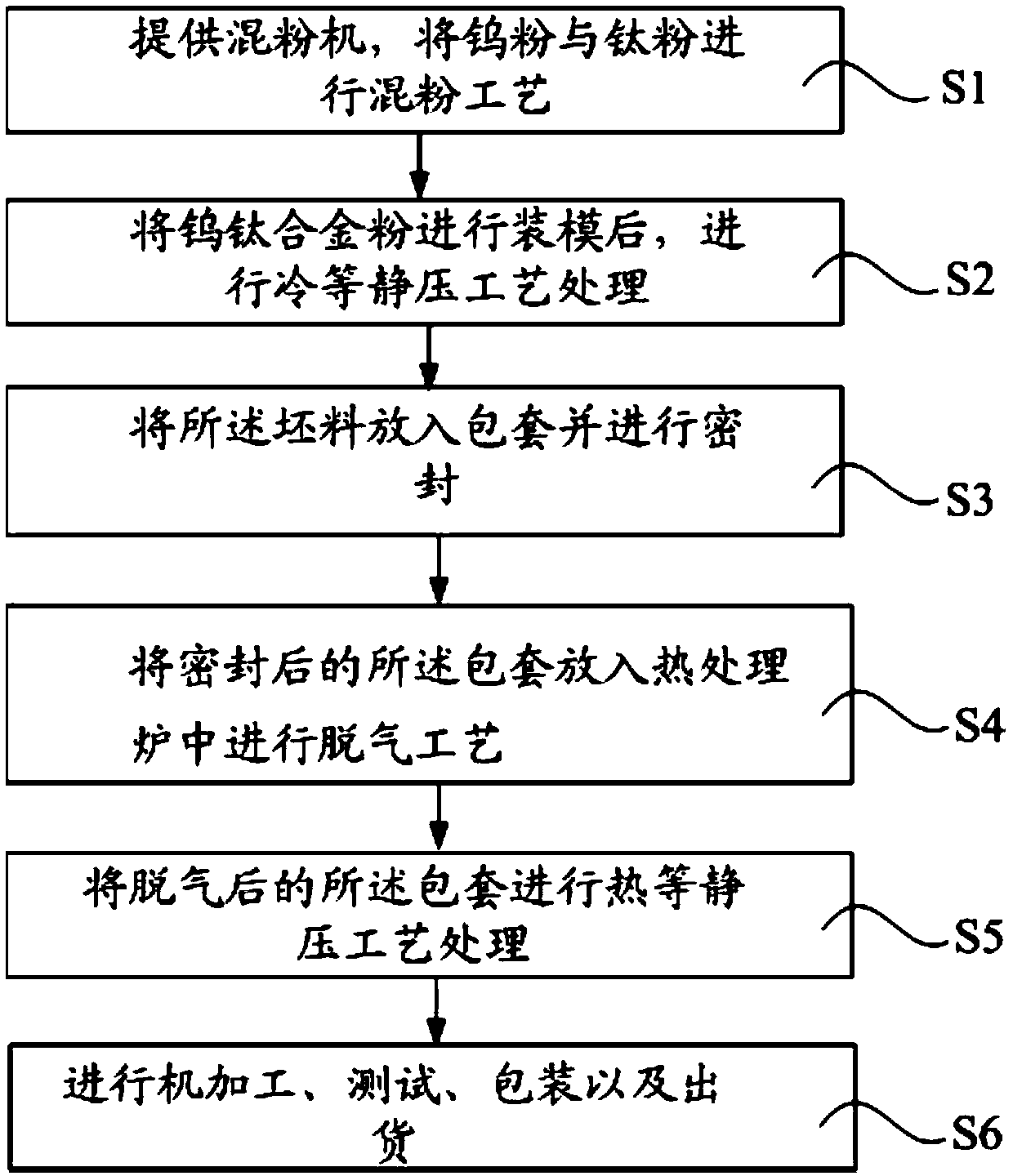

Preparation method of tungsten-titanium alloy target material

A technology of tungsten-titanium alloy and target material, which is applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problems of low density, impurity mixing, uneven microstructure of target material, etc., and achieve microstructure Uniform and guaranteed density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It is known from the background technology that tungsten-titanium alloy sputtering targets occupy a crucial position in the semiconductor industry, and the density requirements and demands for tungsten-titanium alloy sputtering targets are also increasing.

[0023] The analysis found that the hot pressing method is used to make the tungsten-titanium alloy target in the prior art. During the hot-pressing sintering process, the tungsten-titanium alloy powder is put into the vacuum hot-pressing sintering mold and selected according to the size requirements of the finished product The size of the vacuum hot pressing sintering mold; compacting the tungsten-titanium alloy powder filled in the vacuum hot pressing sintering mold to obtain a single tungsten-titanium alloy target blank, and then further machining the tungsten-titanium target blank to obtain In the finished product of tungsten-titanium target material, in the process of processing, the pollutants in the furnace are ea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com