Side-blown smelting equipment

A technology for smelting equipment and furnace body, which is applied in the direction of lighting and heating equipment, which can solve the problems of unfavorable environmental protection, high energy consumption, and low processing capacity, and achieve the effect of reducing energy consumption and improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

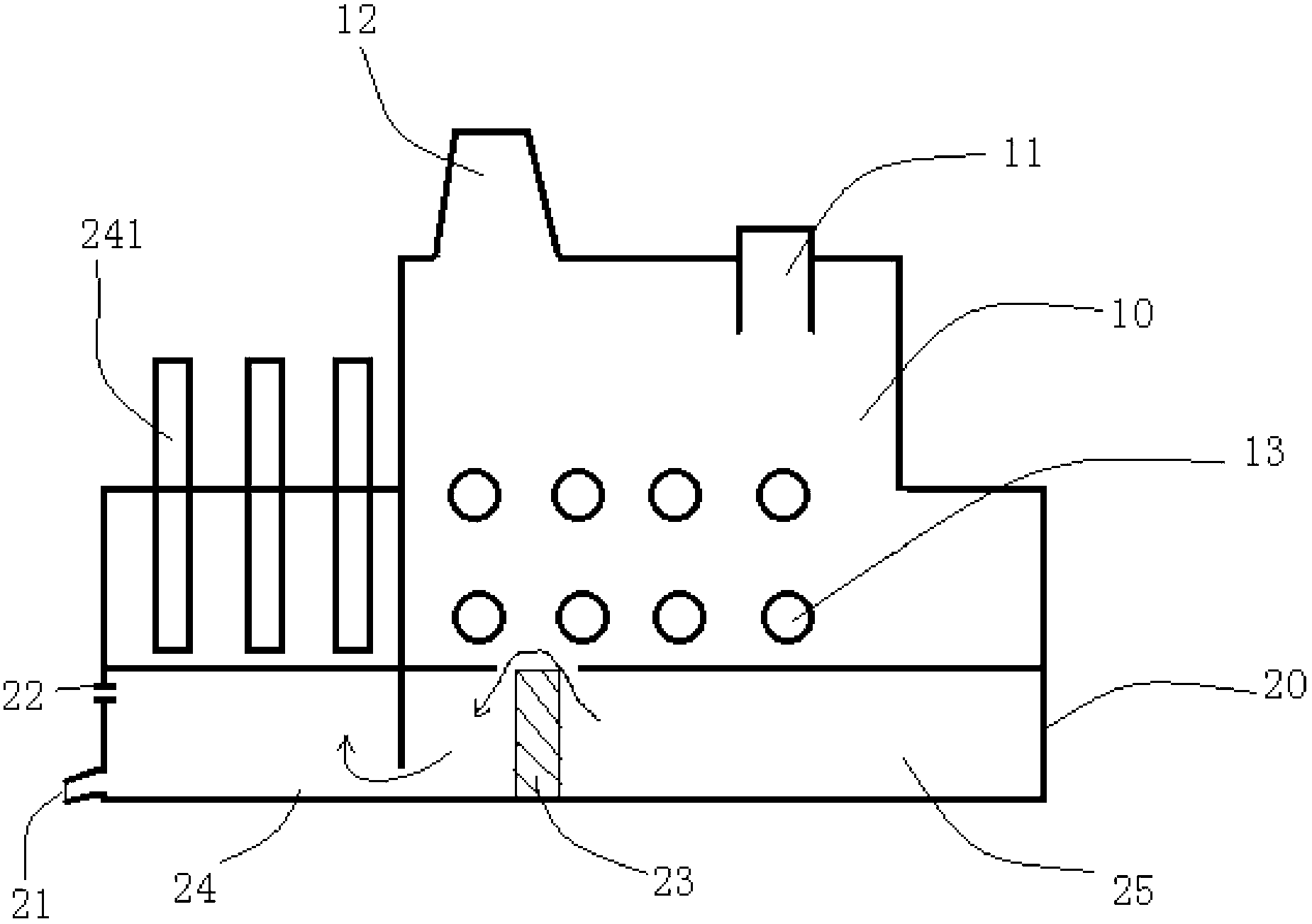

[0039] The dry laterite, reduced coal and sulfur are fed into the melting furnace through the material inlet 11, and the mixed gas composed of oxygen and natural gas is sprayed into the molten pool from the vent hole 13 by the side-blown lance, and the lance is immersed in the melt. The dry laterite ore completes ore melting, nickel-iron reduction reaction and nickel and iron sulfidation reaction in the smelting reduction sulfide zone 25 . A large amount of flue gas formed by the oxygen and natural gas injected by the side-blowing lance during the combustion process forms a violent agitation on the melt, and the nickel and iron metals in the melt are fully reduced and vulcanized under the action of the kiln chopping 23 installed at the bottom of the molten pool , and can promote the effective separation of slag and low-nickel matte mixed melt. The low-nickel matte is discharged from the product outlet 21, and the waste residue is discharged from the waste residue outlet 22.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com