Automatic secondary aluminum smelting aluminum and iron separation device

A separation device and aluminum melting technology, applied in the direction of improving process efficiency, etc., can solve the problems of single separation method, high production cost, low separation efficiency, etc., and achieve the effect of improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

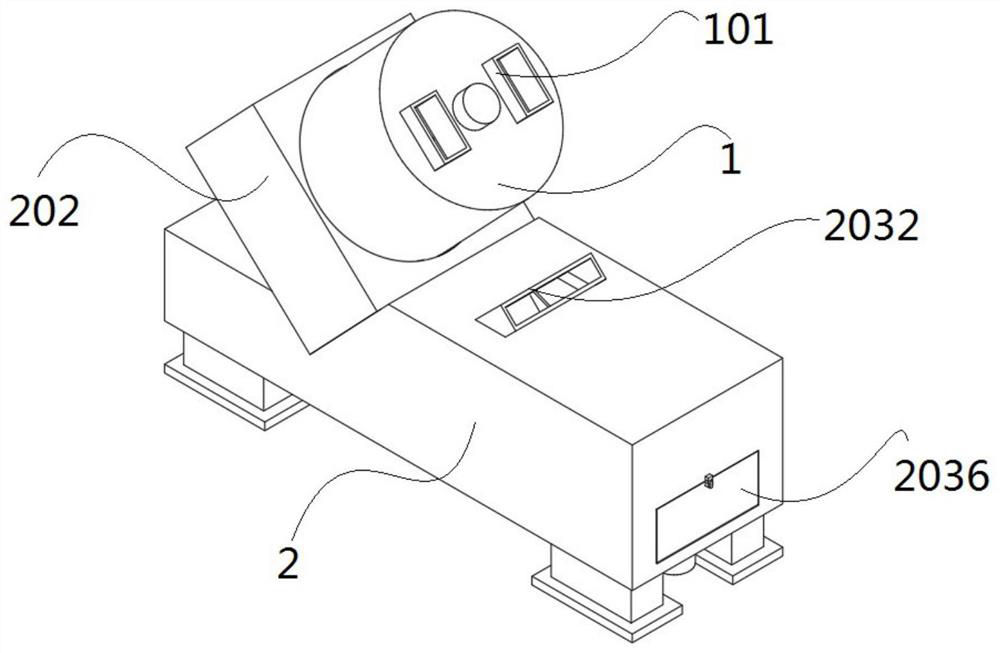

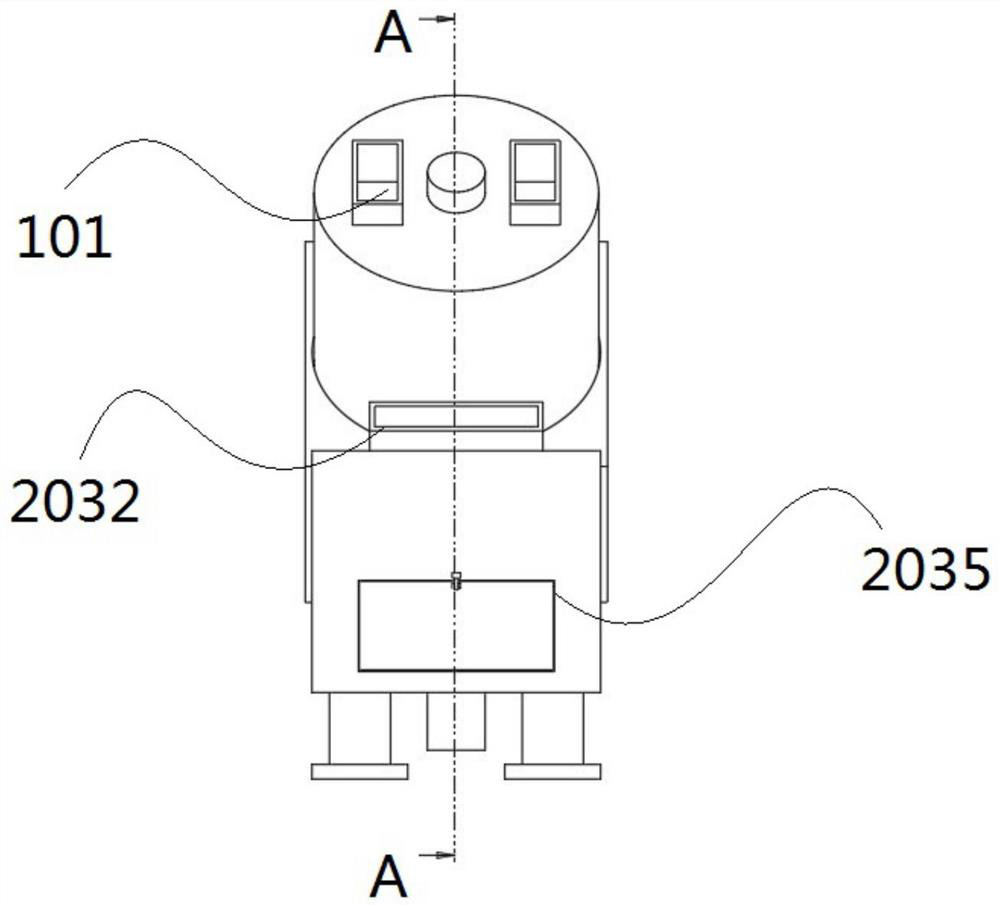

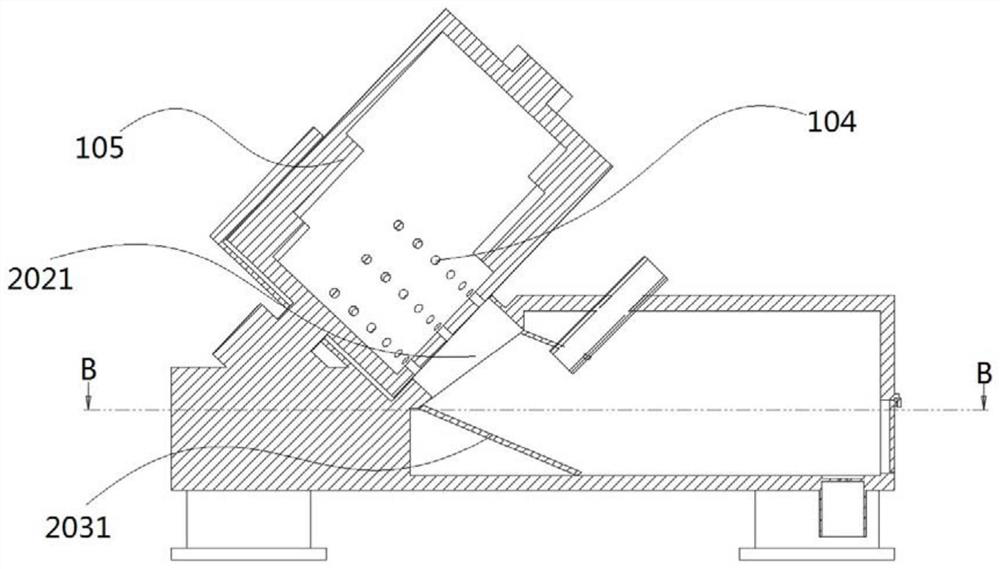

[0043] see Figure 1-6 As shown, this embodiment is an operation method and separation working principle of an aluminum-iron separation device for automatic melting of recycled aluminum:

[0044] The model of stirring motor 103 among the present invention is YCT400-4A speed regulating motor;

[0045] When using the aluminum-iron separation device of the present invention, at first the waste aluminum material is dropped into the smelting and separation furnace 1 through the feeding pipeline 101, and then the stirring motor 103 and the electric heating block 105 are turned on to heat and smelt the waste aluminum material in the furnace while stirring, so that Its smelting is more complete and thorough; the smelting temperature is controlled at 660 to 760 degrees Celsius to ensure that the state of aluminum and iron is significantly different, which is convenient for separation; At this time, the smelting separation furnace 1 and the auxiliary separation box 203 communicate with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com