Method for producing tubular knitwear items and products obtained thereby

A knitwear and tube-shaped technology, applied in the field of knitwear, can solve problems such as additional costs, technical difficulties, and manufacturing cost impacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

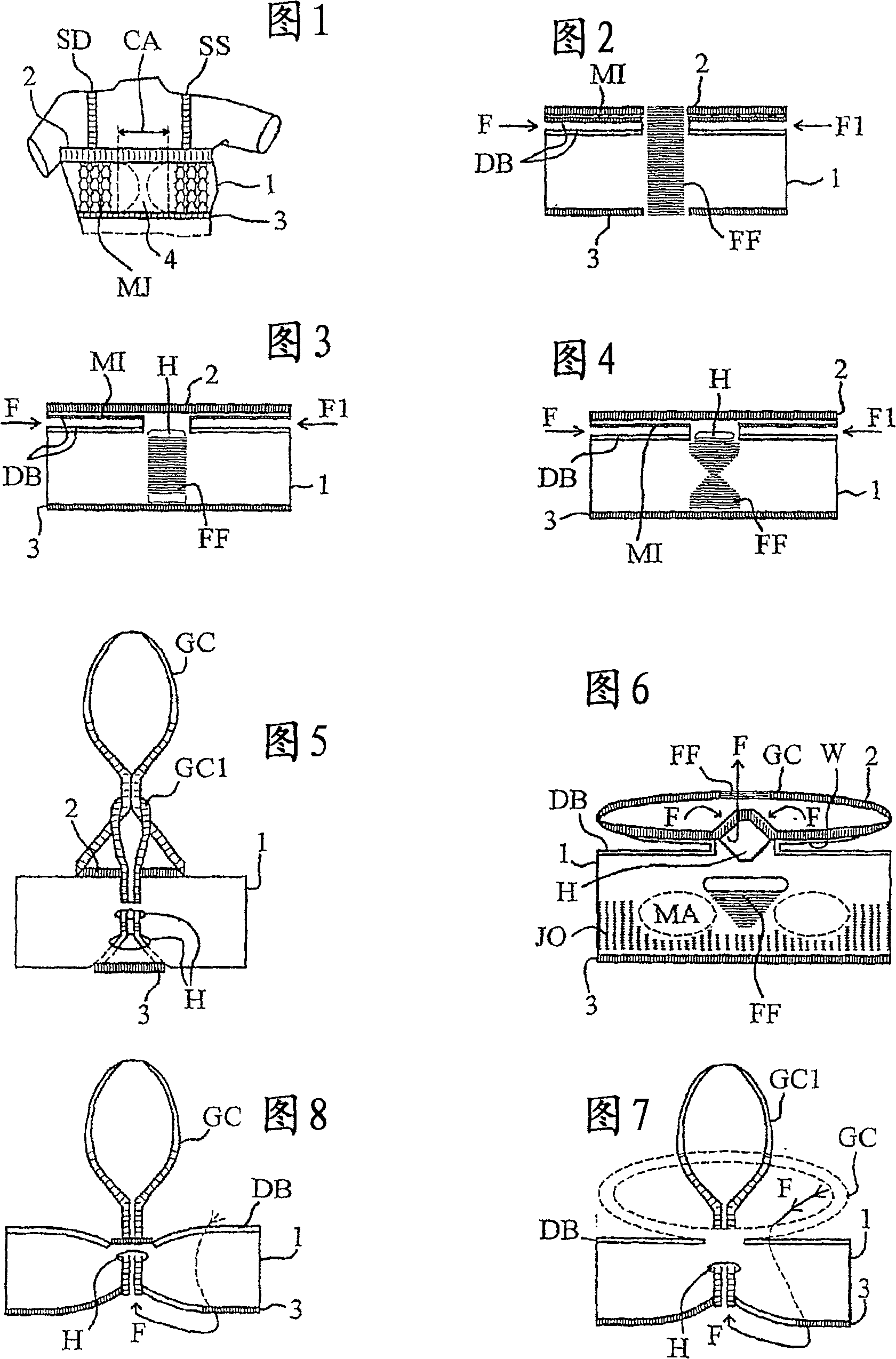

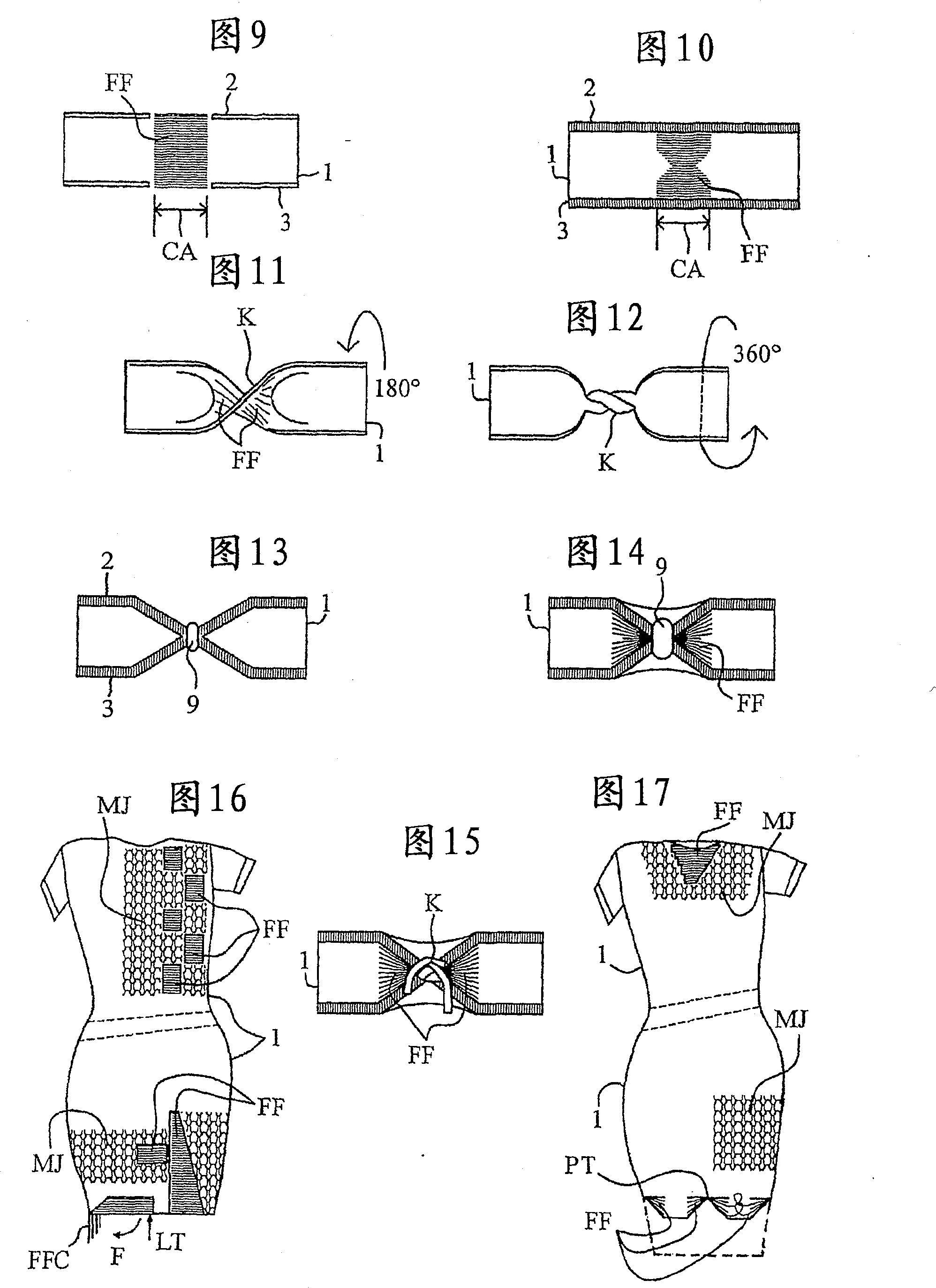

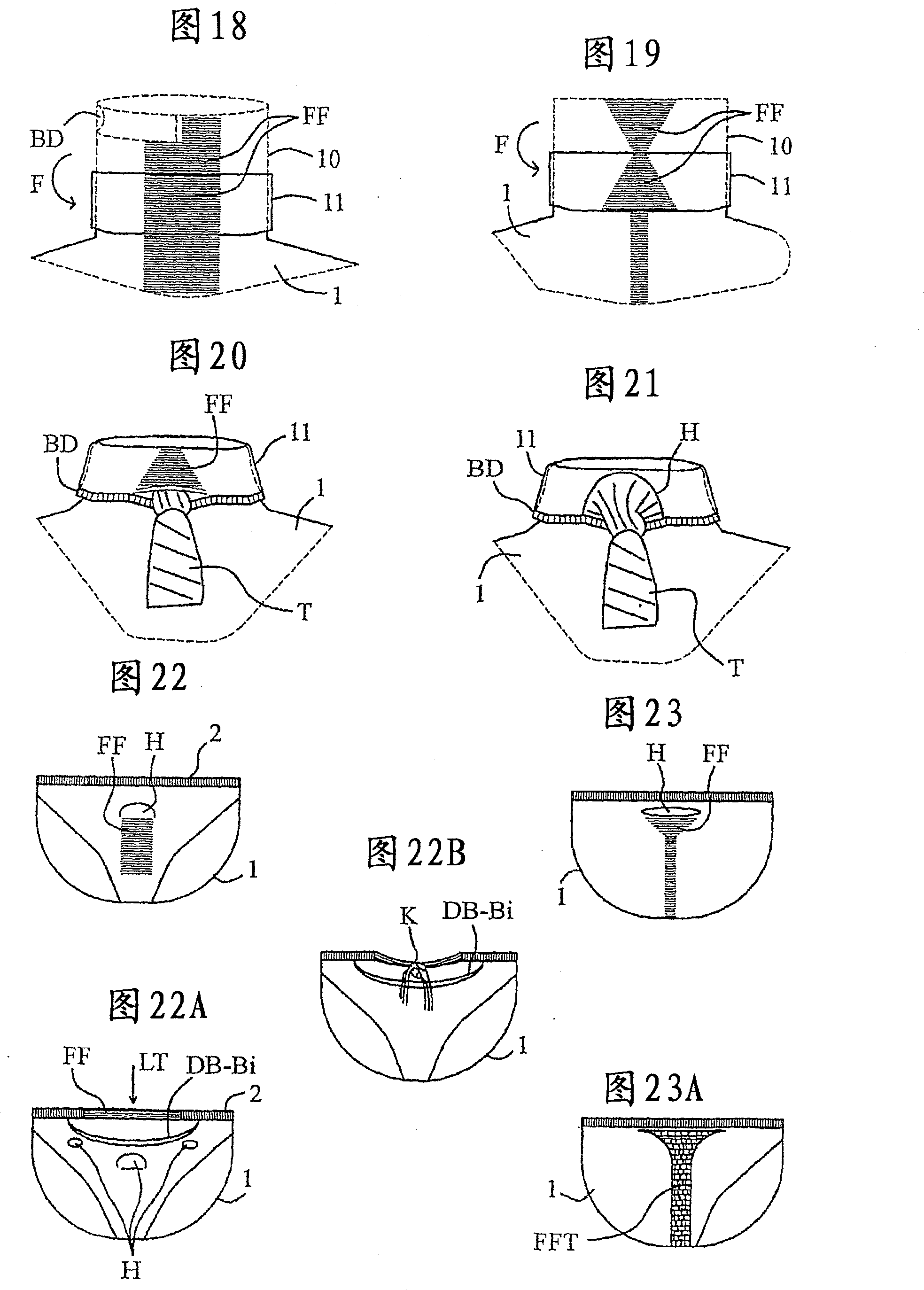

[0036]The following description will refer to, for illustrative and non-limiting purposes only, a circular knitting machine for the production of tubular knitwear, which generally comprises at least: a bed of needles or rotating needle cylinders with fixed cams, or On the contrary; a complete processing supply device, provided with one or more yarn feeders, which also moves the feeders; preferably an electronic needle selection device, used to control the knitting process during the knitting process according to the duty cycle and / or jacquard pattern. The elements involved; the cam for knitting, which can also be adjusted individually by the computer; the device for opening the latch under actuation; the fabric suction or push system; besides the usual yarn suction and shearing device, said The machine is also equipped with a turntable with selectable needles or jacks. In particular, most of the description will refer to "all electronic" single cylinder circular machines, such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com