Straightening track-dividing device for shrink film packaging bottles

A packaging bottle and heat shrinkable film technology, applied in the field of packaging, can solve problems such as the inability to realize automatic packaging, and achieve the effects of novel and reasonable structure, accurate and stable lane separation, and flexible and reliable actions

Inactive Publication Date: 2010-08-25

HANGZHOU WAHAHA GROUP

View PDF5 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Regardless of the packaging method, lane separation must be realized first. None of the various lane dividers can realize the lane separation of heat shrinkable film packaging bottles, so it is impossible to realize the automatic packaging of this product.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

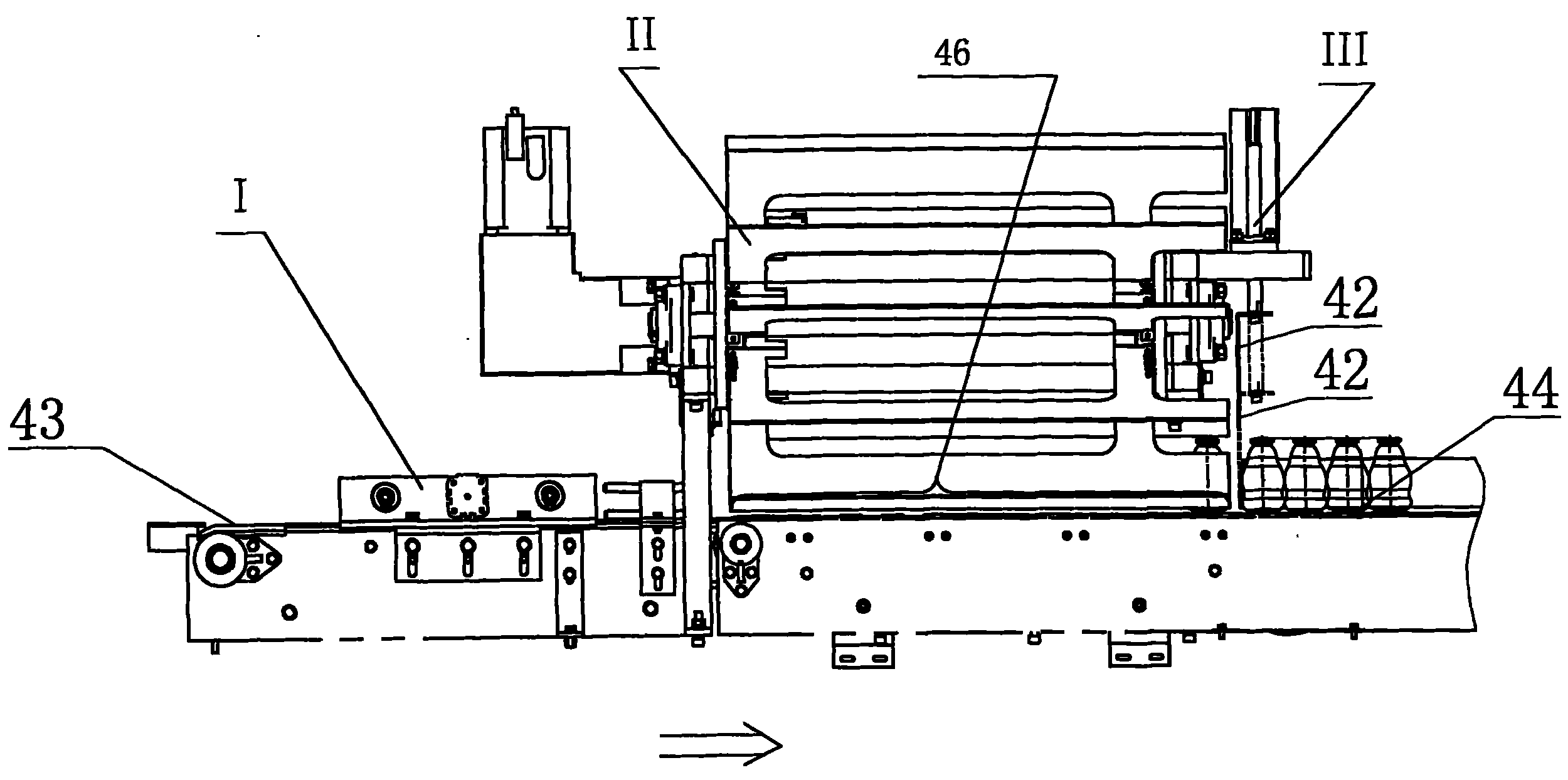

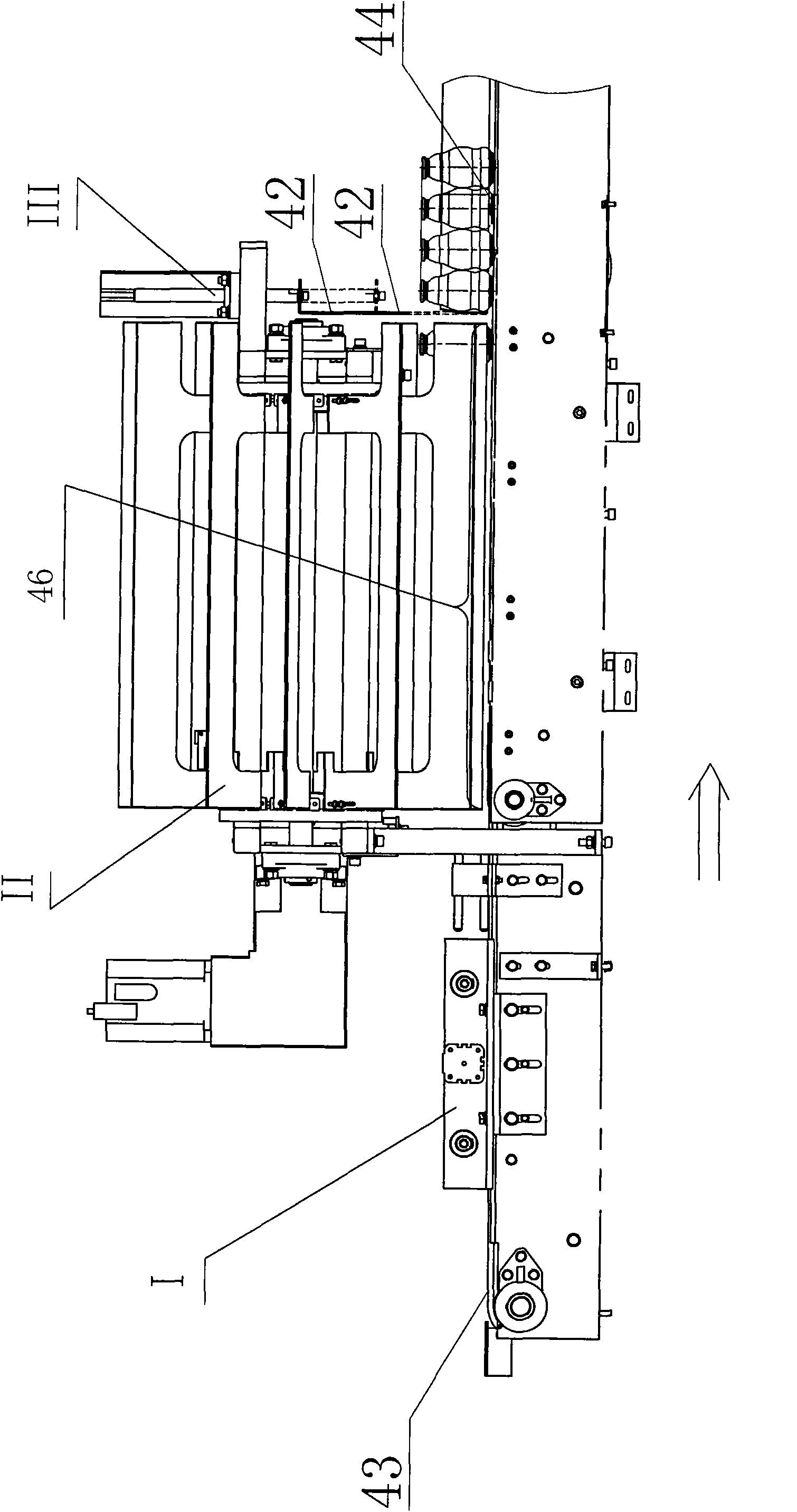

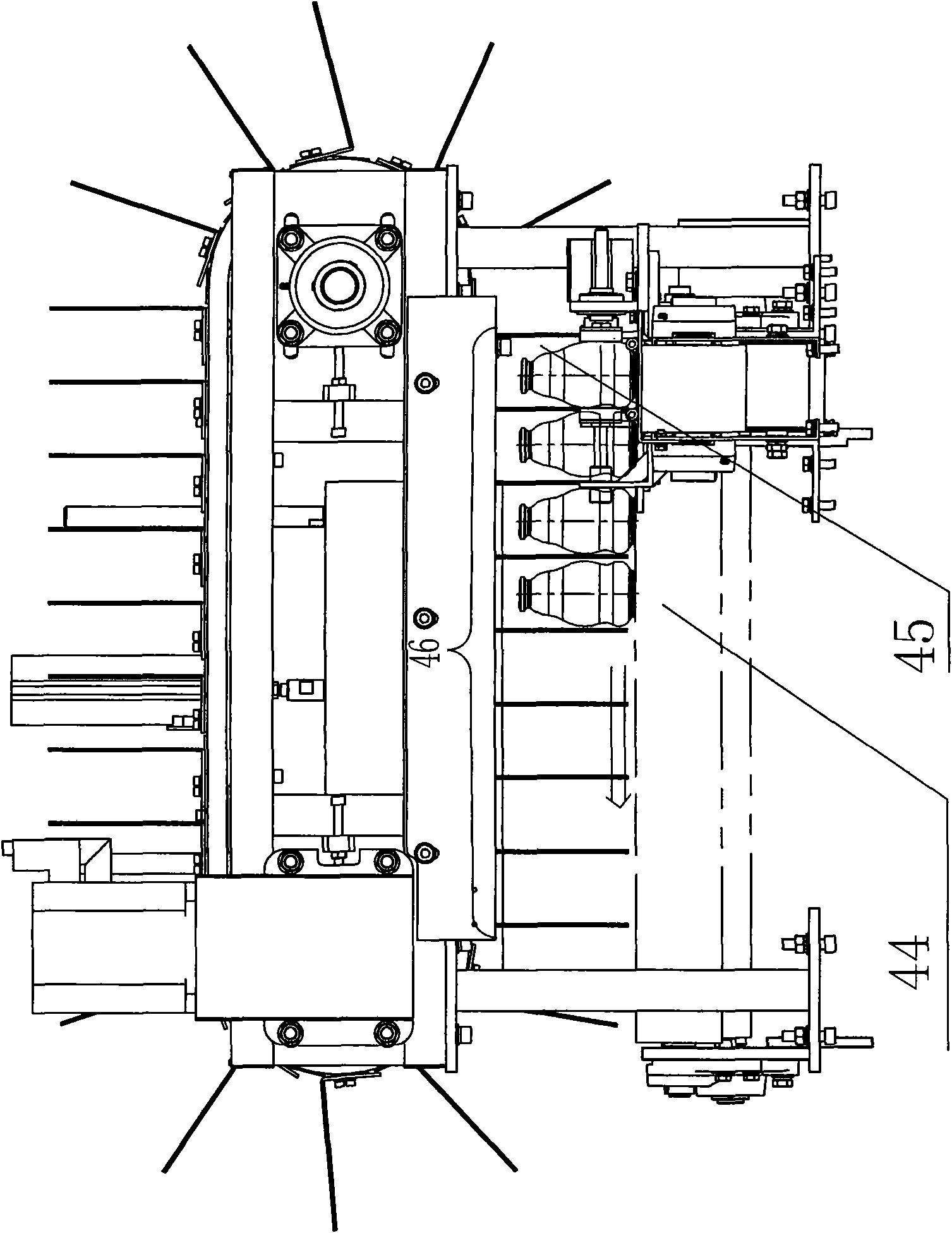

The invention relates to a straightening track-dividing device for shrink film packaging bottles. The invention aims to automatically separate shrink film packaging bottles which shrink into a row, thereby further realizing automatic boxing. The device has the characteristics of novel and reasonable structure, flexible and reliable motion, accurate track dividing, and high speed for changing varieties, thereby improving the work efficiency and avoiding bottle clamping. The invention has the technical scheme that the straightening track-dividing device for the shrink film packaging bottles is provided with a bottle feed conveyer belt and a buffer conveyer belt which are sequentially arranged in the motion direction of the bottles and move towards the same direction. The invention is characterized in that both sides of the bottle feed conveyer belt are provided with a counting and clamping mechanism; a bottle-poking track-dividing mechanism is hung above the buffer conveyer belt; and the outer side of the bottle-poking track-dividing mechanism is provided with a bottle blocking mechanism. The invention is suitable for manufacturing supplies before boxing in the industries of food, medication, daily health products and the like, and belongs to the technical field of packaging.

Description

Bottle unscrambling device for shrink film packaging bottles technical field The invention relates to a bottle unscrambling and lane-dividing device for heat-shrinkable film packaging bottles. It is suitable for production matching before packing in food, medicine and daily chemical industries, and belongs to the field of packaging technology. Background technique A number of HDPE bottles and straws are assembled into a unit through PVC film, and then become a relatively independent unit after being shrunk by electric heating. The packing of several units has been done by hand. The whole process includes removing the bottles from the conveyor chain of the large film shrinking machine and erecting them, combining them according to the packaging specifications, pushing them into the folded cartons by hand, and finally sealing the boxes by hand. Such products are not conducive to sorting during operation, and mechanical packaging has not been able to be realized. The packa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B65B21/06B65B57/20

Inventor 刘凤臣周东尤晨

Owner HANGZHOU WAHAHA GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com