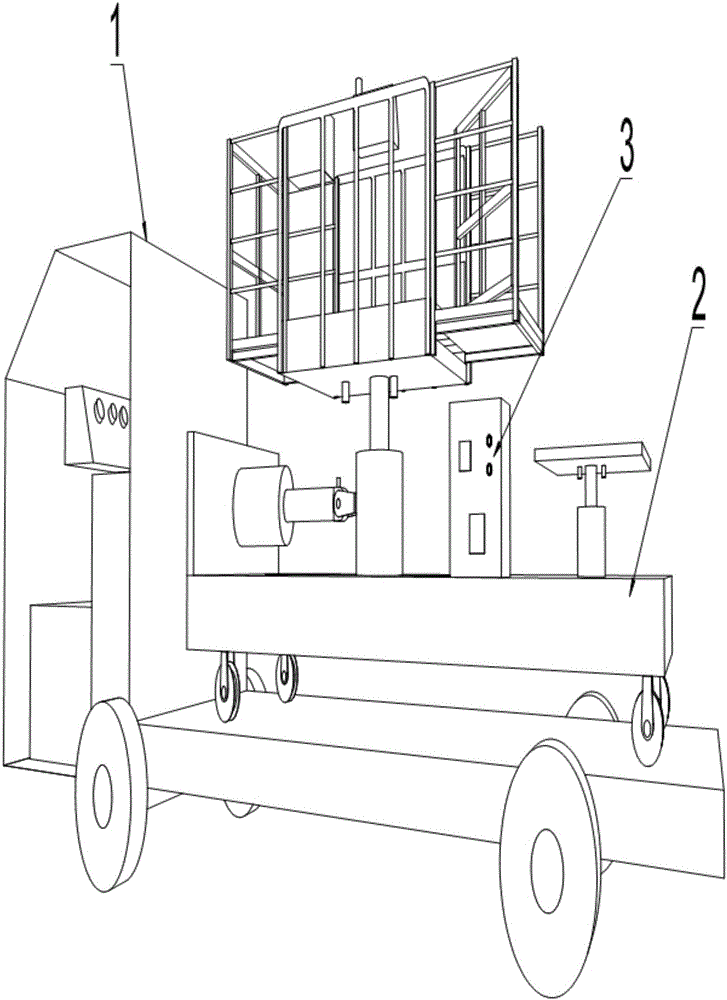

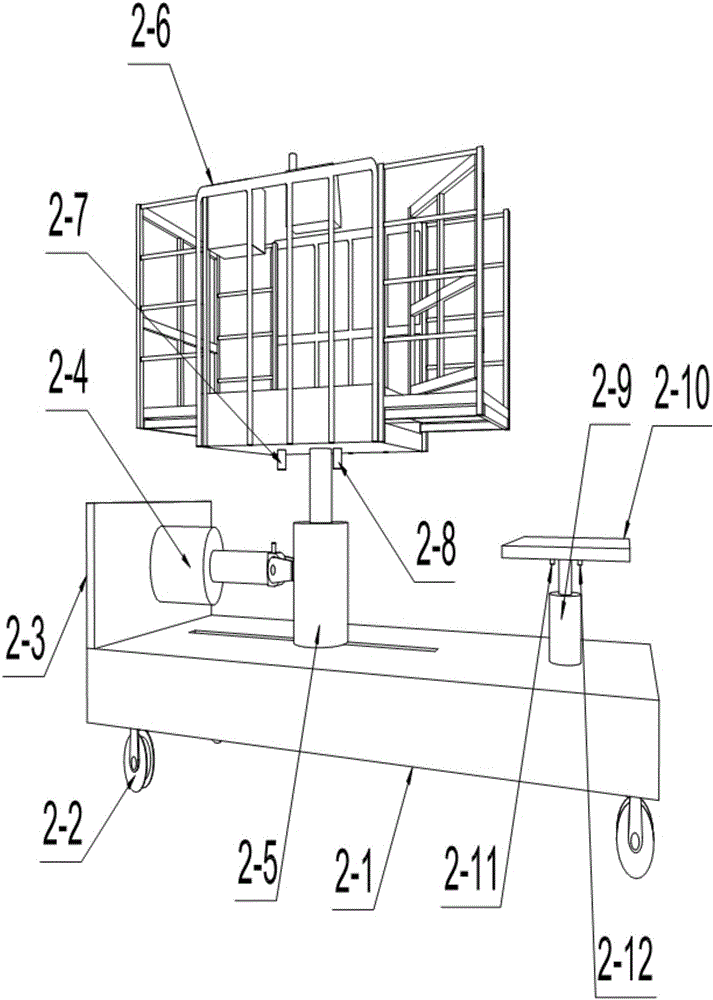

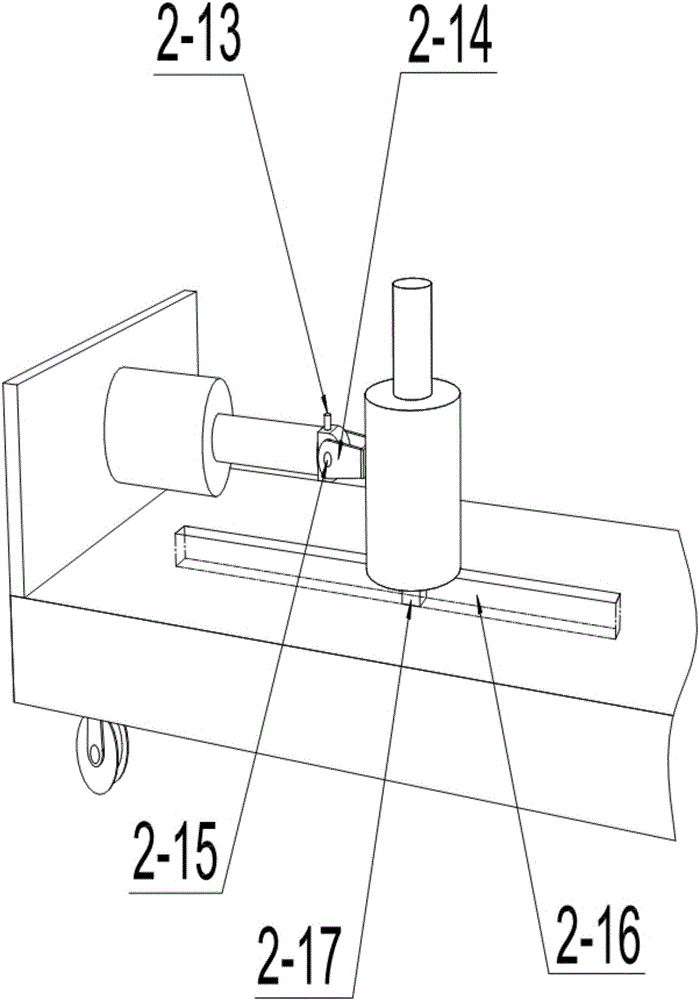

Automatic lifting control device for pruning garden trees and use method thereof

A technology for automatic lifting and manipulation of devices, applied in the direction of lifting devices, etc., can solve the problems of reduced mechanical work efficiency, complex control, and high processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Make load-bearing platform 2-6-1 of the present invention according to the following steps, and by weight fraction:

[0046] Step 1: Add 600 parts of ultrapure water with a conductivity of 0.8μS / cm into the reactor, start the stirrer in the reactor at a speed of 115rpm, start the heating pump, and raise the temperature in the reactor to 30°C; add in sequence (1R,2R)-N,N'-bis(5-tert-butyl-3-formyl-4-hydroxybenzoic acid methyl ester) 20 parts of hexamethylene diamine, (4S,5R)-4-(4 -Methoxyphenyl)-5-ethoxycarbonyl-1,3-dioxa-2-oxothiolane 19 parts, 3-methyl-4-butyrylamino-5-aminobenzoic acid 35 parts of methyl ester, stir until completely dissolved, adjust the pH value to 3.0, adjust the speed of the agitator to 145rpm, the temperature is 80°C, and the esterification reaction takes 14 hours;

[0047] Step 2: Take 125 parts of 4-(2,6,6 trimethyl-1-cyclohexen-1-yl)-3-buten-2-ol acetate, N-[4-[[4 -130 parts of -(dimethylamino)phenyl]phenylmethylene]-2,5-cyclo-hexadiene-1-yli...

Embodiment 2

[0052] Make load-bearing platform 2-6-1 of the present invention according to the following steps, and by weight fraction:

[0053] Step 1: Add 1100 parts of ultrapure water with a conductivity of 1.40μS / cm into the reactor, start the stirrer in the reactor at a speed of 200rpm, start the heating pump, and raise the temperature in the reactor to 55°C; add in order (1R,2R)-N,N'-bis(5-tert-butyl-3-formyl-4-hydroxybenzoic acid methyl ester) 65 parts of hexamethylene diamine, (4S,5R)-4-(4 -Methoxyphenyl)-5-ethoxycarbonyl-1,3-dioxa-2-oxothiolane 26 parts, 3-methyl-4-butyrylamino-5-aminobenzoic acid 78 parts of methyl ester, stir until completely dissolved, adjust the pH value to 9.5, adjust the speed of the agitator to 360rpm, the temperature is 140°C, and the esterification reaction takes 22 hours;

[0054] Step 2: Take 255 parts of 4-(2,6,6 trimethyl-1-cyclohexen-1-yl)-3-buten-2-ol acetate, N-[4-[[4 -270 parts of -(dimethylamino)phenyl]phenylmethylene]-2,5-cyclo-hexadiene-1-yli...

Embodiment 3

[0059] Make load-bearing platform 2-6-1 of the present invention according to the following steps, and by weight fraction:

[0060] Step 1: Add 645 parts of ultrapure water with a conductivity of 0.89μS / cm into the reactor, start the agitator in the reactor at a speed of 145rpm, start the heating pump, and raise the temperature in the reactor to 34°C; add in sequence (1R,2R)-N,N'-bis(5-tert-butyl-3-formyl-4-hydroxybenzoic acid methyl ester) 29 parts of cyclohexanediamine, (4S,5R)-4-(4 -Methoxyphenyl)-5-ethoxycarbonyl-1,3-dioxa-2-oxothiolane 21 parts, 3-methyl-4-butyrylamino-5-aminobenzoic acid 38 parts of methyl ester, stir until completely dissolved, adjust the pH value to 3.9, adjust the speed of the agitator to 154rpm, the temperature is 84°C, and the esterification reaction is 17 hours;

[0061] Step 2: Take 178 parts of 4-(2,6,6 trimethyl-1-cyclohexen-1-yl)-3-buten-2-ol acetate, N-[4-[[4 145 parts of -(dimethylamino)phenyl]phenylmethylene]-2,5-cyclo-hexadiene-1-ylidene]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com