An integrated production process and production system of an annular thin-walled powder product

A production system, thin-walled technology, applied in the direction of manufacturing tools, grinding machine parts, and machine tools suitable for grinding workpiece planes, etc. Reduce the number of transfers and code discs, ensure efficient and reliable operation, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

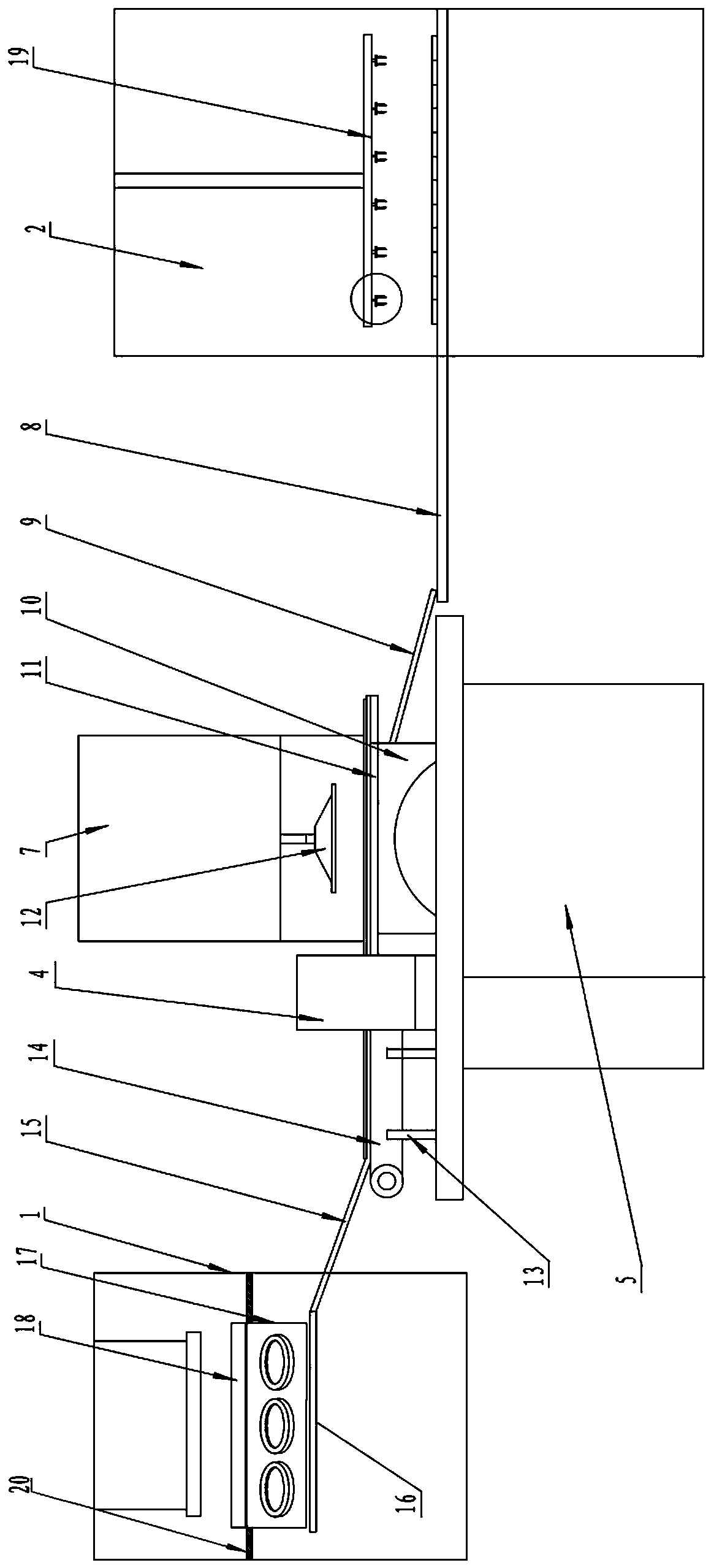

[0046] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

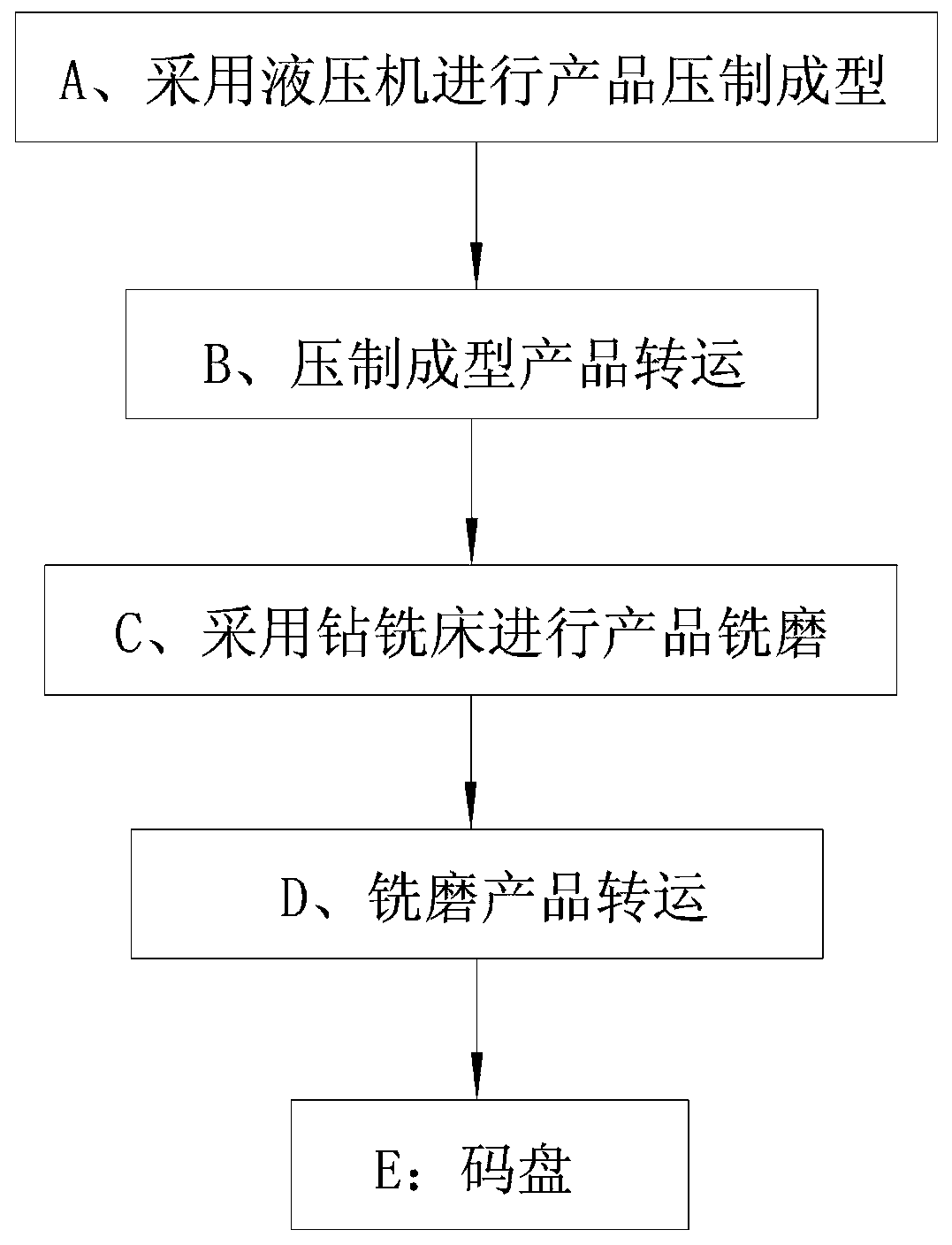

[0047] Such as figure 1 As shown, the present invention discloses an integrated production process and production system of an annular thin-walled powder product, comprising the following steps:

[0048] A. The product is pressed and formed by a hydraulic press;

[0049] B. Transshipment of pressed products:

[0050] A slideway A is arranged on one side of the workbench of the hydraulic press, a conveyor belt A is arranged at the lower end of the slideway A, and the end of the conveyor belt A is level with the workbench of the drilling and milling machine 7;

[0051] Use the push plate to push the pressed and formed product from the hydraulic press table to the slideway A, and the product is transported to the drilling and milling machine table through the slideway A and the conveyor belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com