Patents

Literature

65 results about "Finished good" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Finished goods are goods that have completed the manufacturing process but have not yet been sold or distributed to the end user.

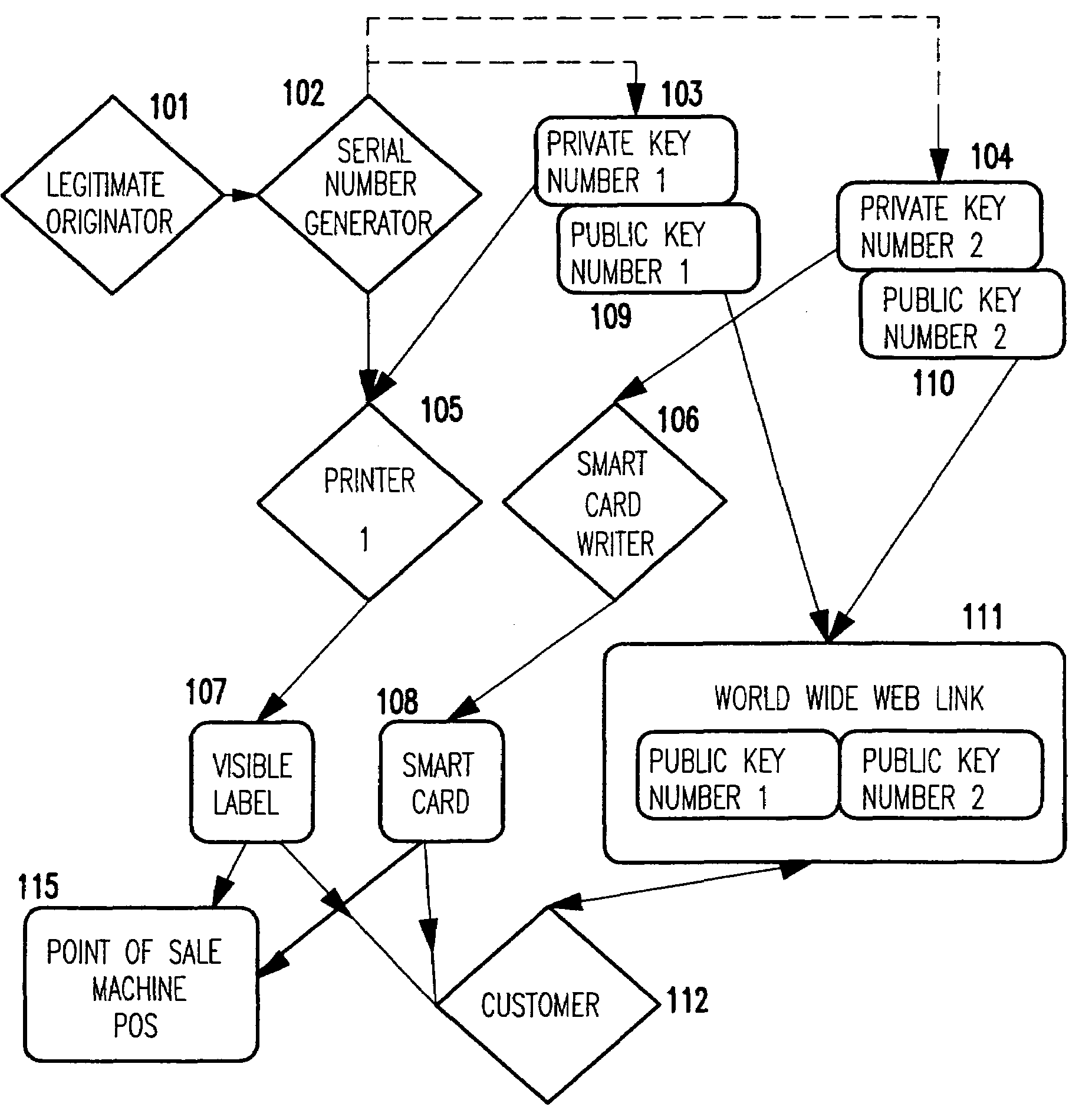

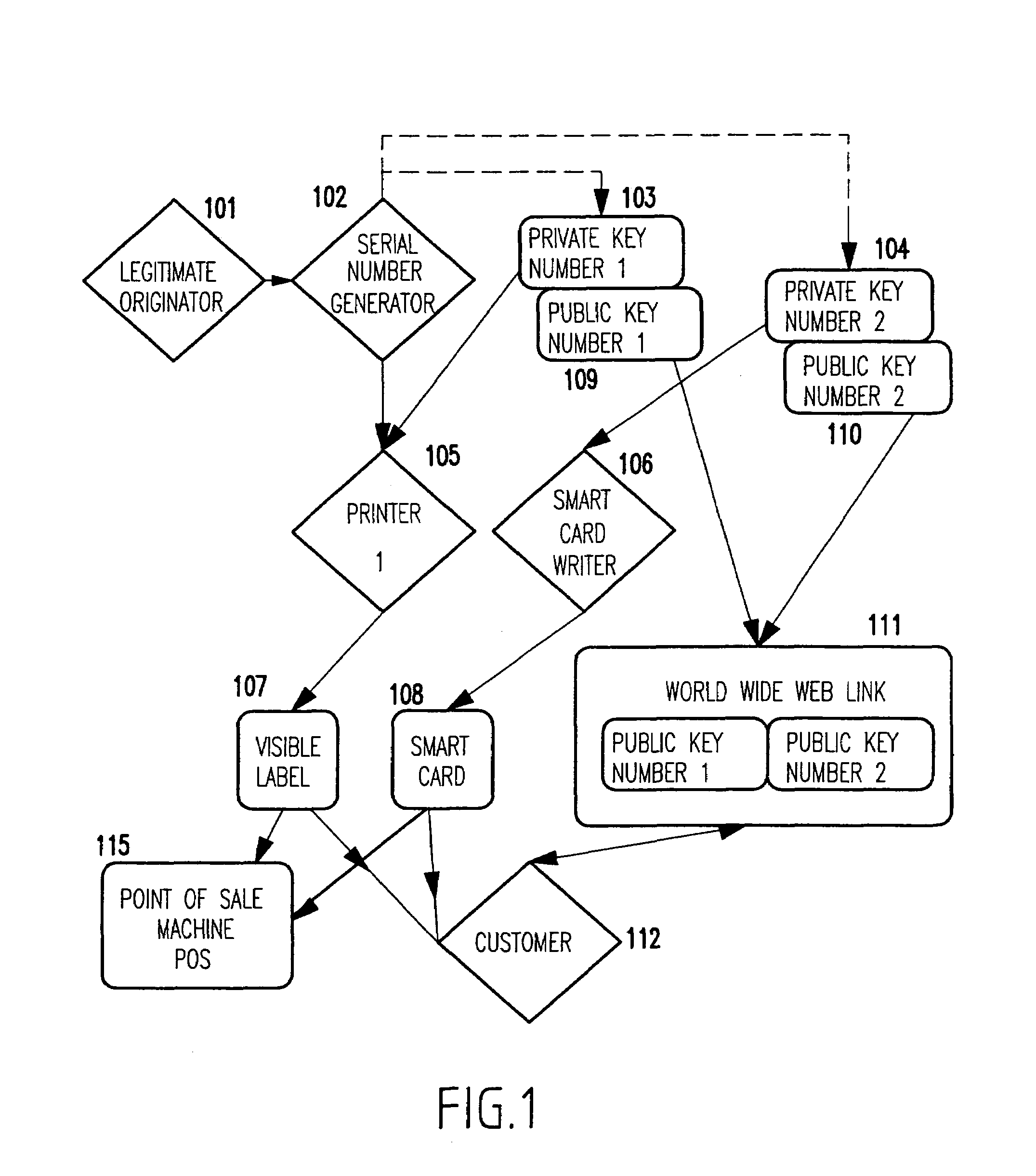

System for protection of goods against counterfeiting

InactiveUS6996543B1Fast informationQuick verificationOther printing matterUser identity/authority verificationPrint versionDigital image

In order to verify the authenticity of manufactured goods, a smart tag is attached to the goods containing encrypted authentication information, such as a serial number, a description of the good's physical appearance or chemical decomposition, its color, or digital images of the good etc. The encryption procedure comprises public / private key encryption with zero-knowledge protocols. Zero knowledge protocols allow a smart tag to be authenticatable and yet be duplication resistant by allowing the verifying agent to convince him / herself that the smart tag is authentic without revealing its authentication information. The verification procedure can be done using a reader at a point of sale (POS) machine equipped with the appropriate public key and zero-knowledge protocols to decrypt the authentication information. A printed version of the serial number or other authentication information may be placed on the goods in human readable form to quickly verify the information electronically read from the smart tag. With the present invention, only the manufacturer can create such smart tags with the associated data thus making it virtually impossible to pass off a counterfeit good as authentic. In addition to authenticating counterfeit goods, the present invention can be used to detect authentic goods being sold in a parallel market.

Owner:TOSHIBA GLOBAL COMMERCE SOLUTIONS HLDG

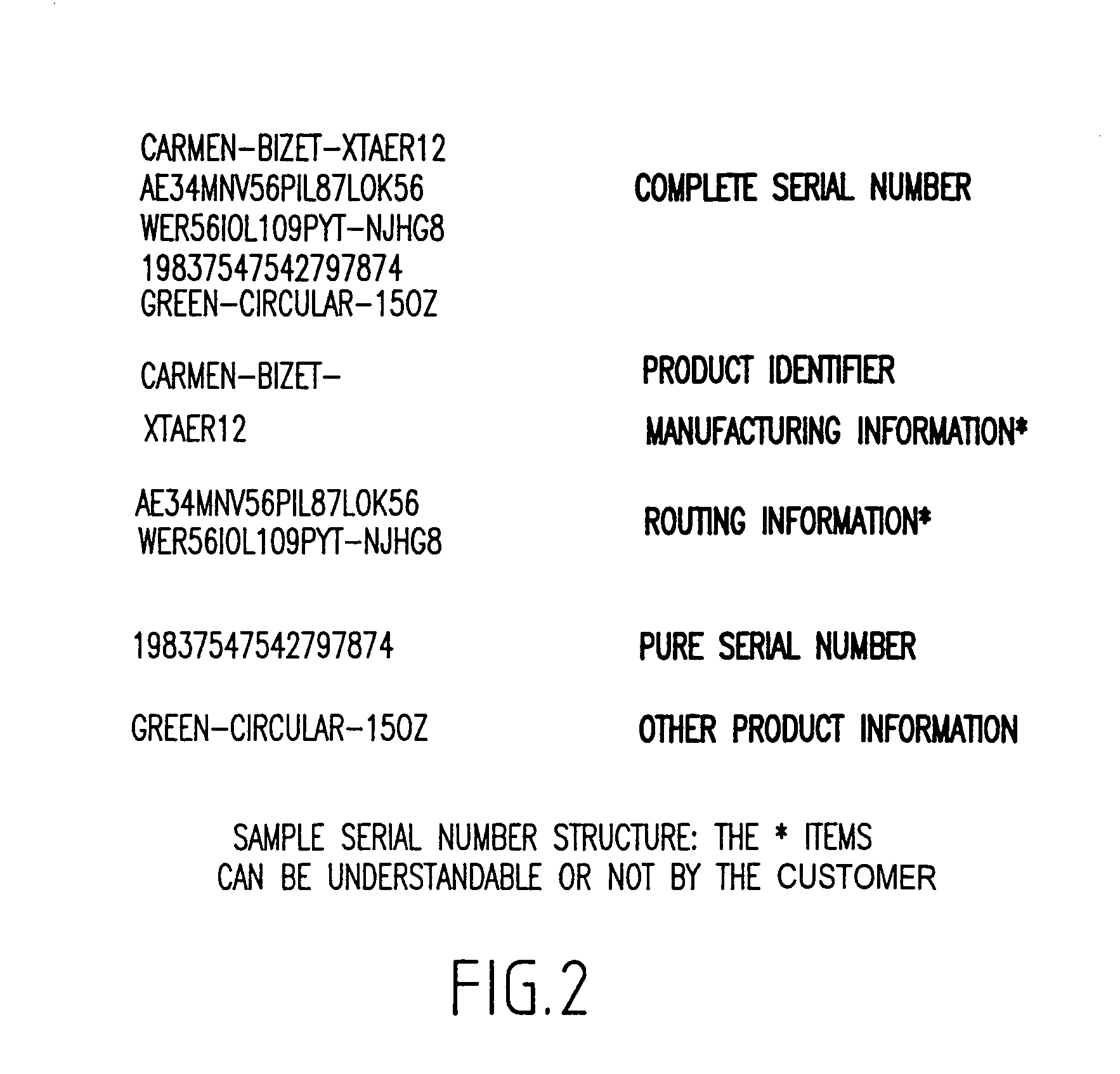

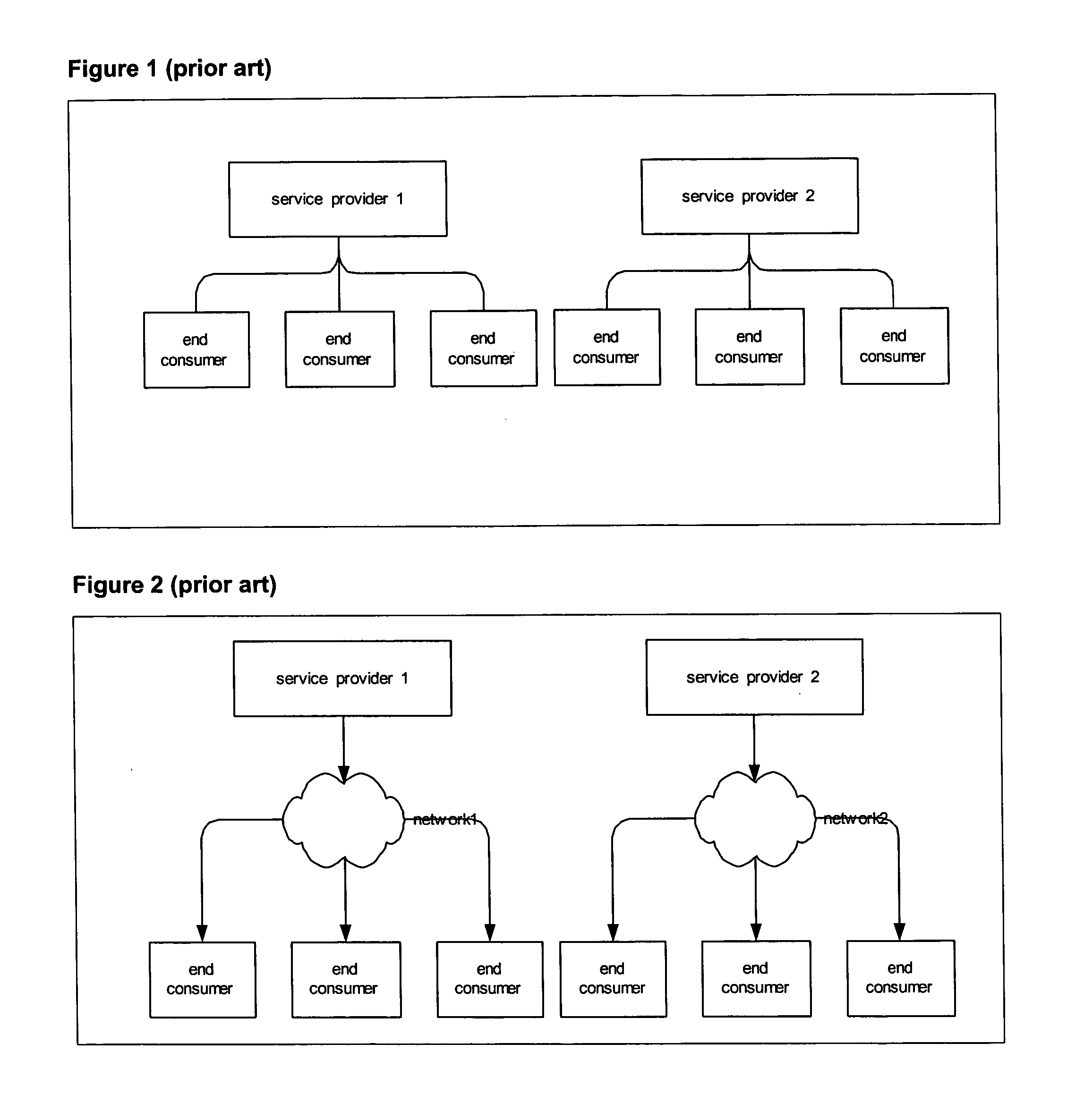

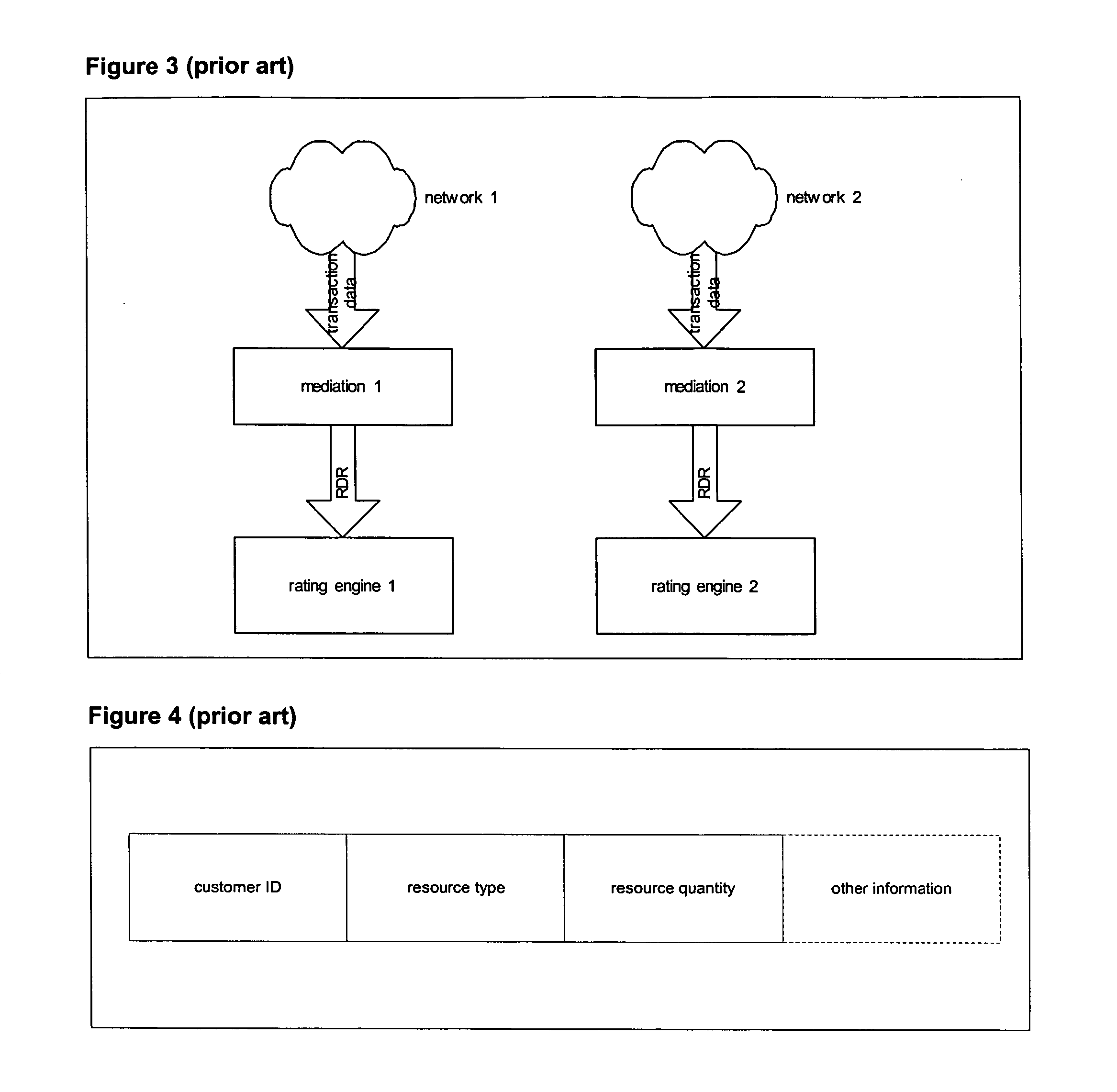

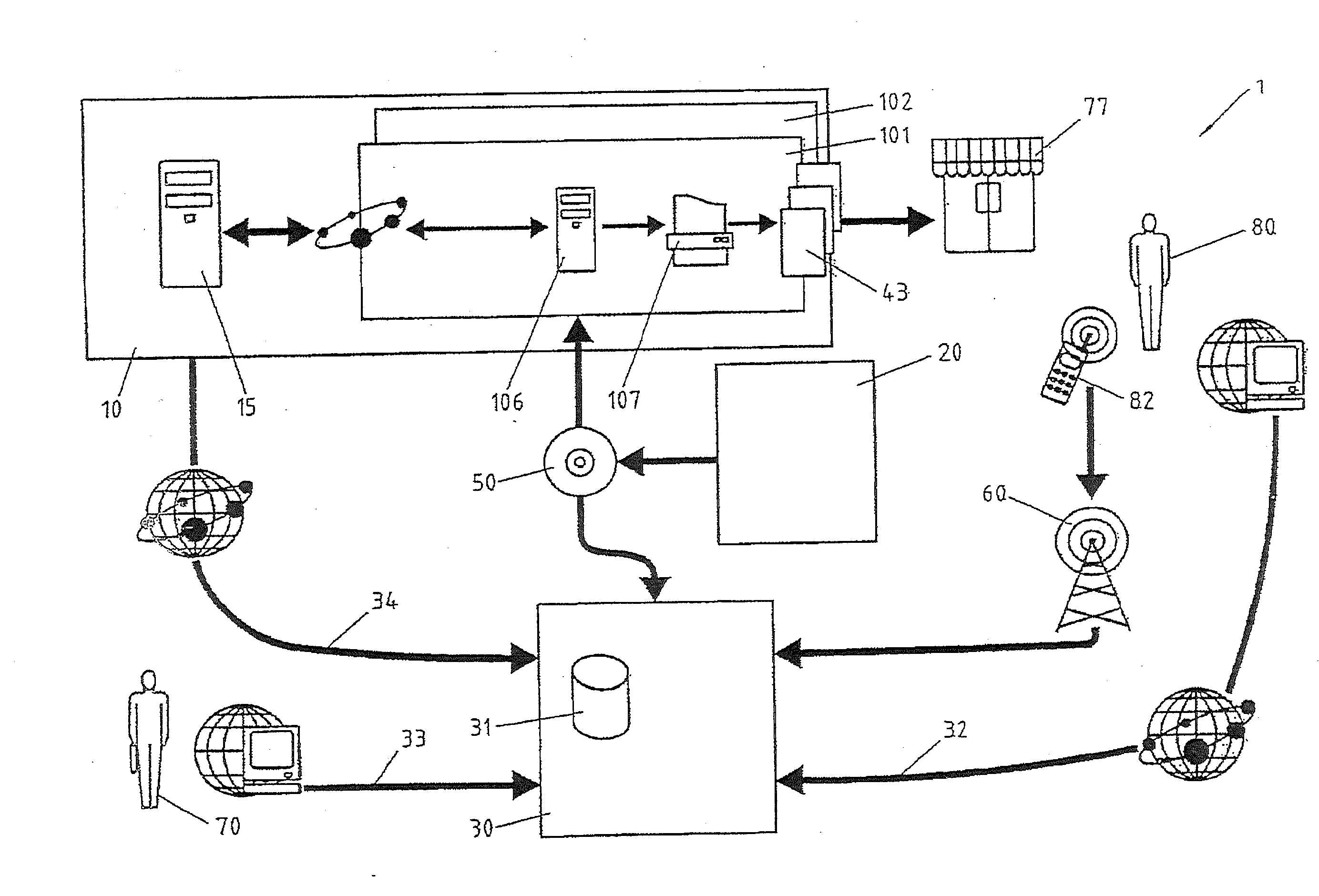

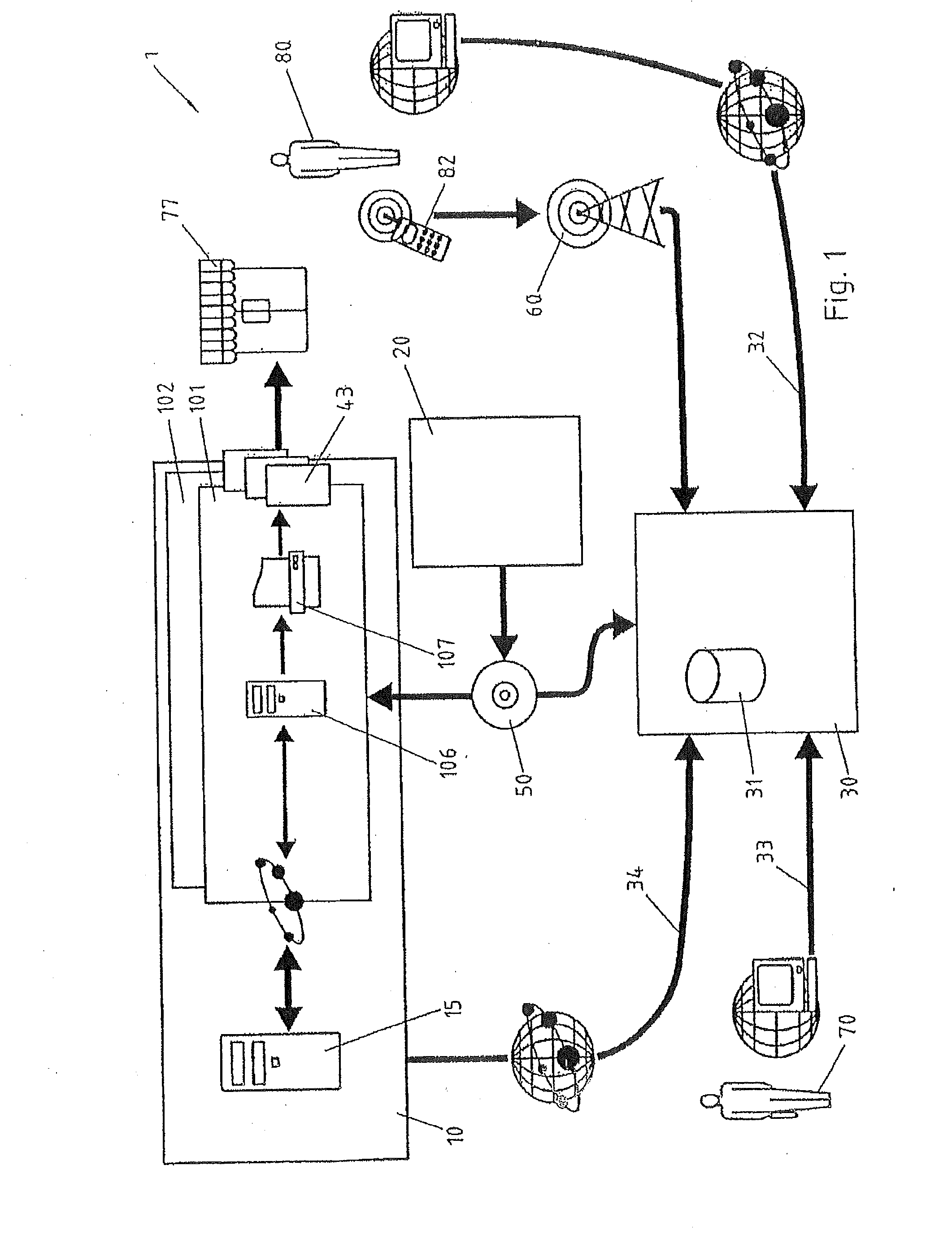

System for resource accounting for multiple entities in an arbitrary value chain

The inventive system includes a method to let participants in a value chain of digital and physical goods to package resources into sellable services and products, keep track of consumption of the resources and calculate charges to the end users and revenues to all participants. The participants to such supply chain include but not limited to resource suppliers, distributors, aggregators, resellers and service providers. The resources include but not limited to digital goods such as computing capacity, storage, content, software applications, data depository or special data acquisition instruments and physical goods such as commodity and manufactured items. Through this invention, resource supplies and consumptions and thus charges and revenues can be tracked and accounted for simultaneously. Any participants to the supply chain can host such system on behalf of itself and other participants. A participant can package resources into sellable units, track the resource supply by its suppliers and consumption by its customers, determine end users charges and revenues according to pricing structures and business rules including end user charges, loyalties, commissions, reseller fees, and roaming tariff, etc. When compared with the traditional methods, this invention tracks in real time all resource supplies and consumptions across the value chain simultaneously, in both actual resource unit and economic value. The invention can be realized in a combination of both hardware and software.

Owner:XCERIA

Methods and systems for making, tracking and authentication of products

ActiveUS20110093113A1Easy to manufactureUser identity/authority verificationCo-operative working arrangementsComputer hardwareThe Internet

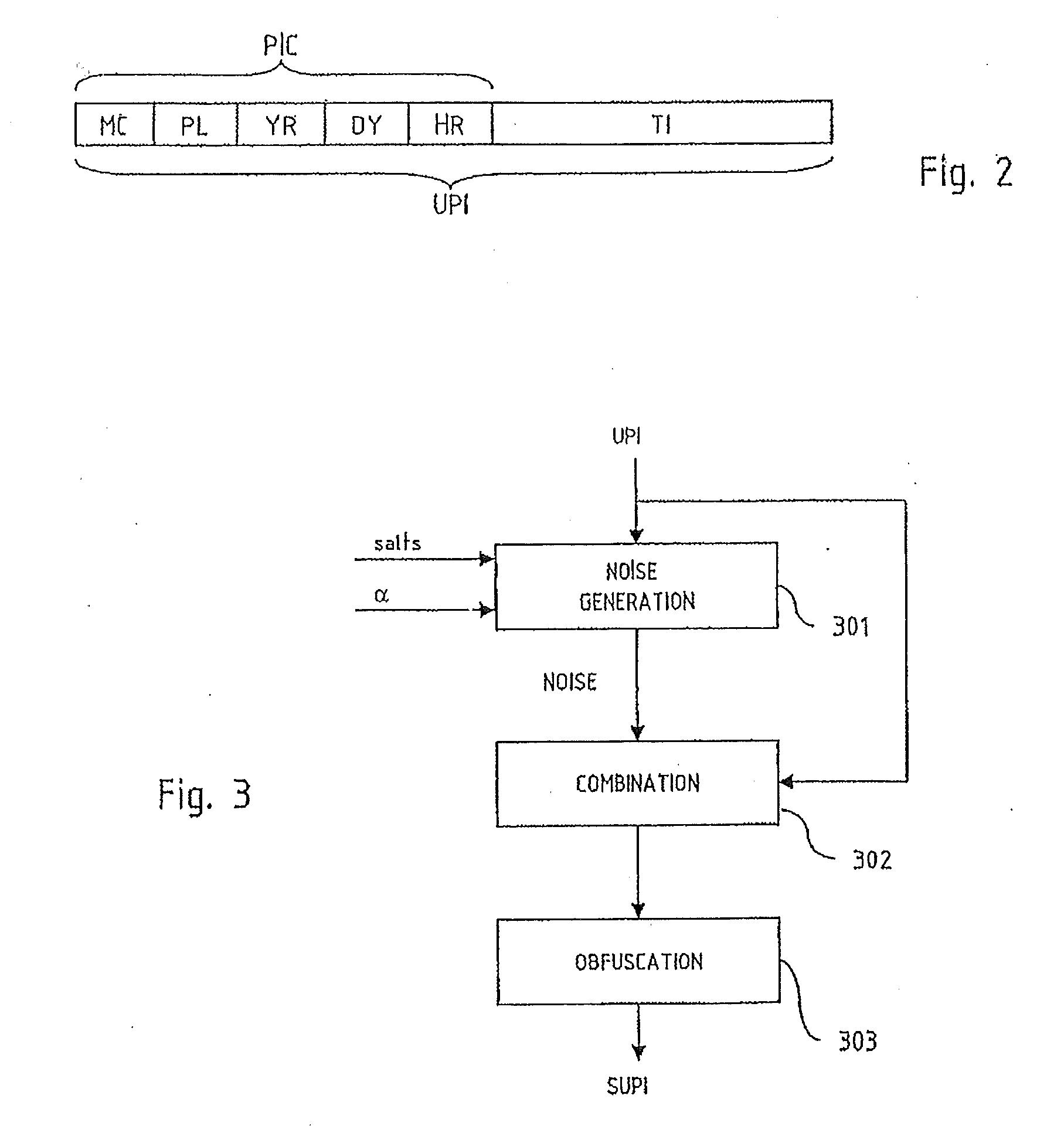

Manufactured goods are marked or labeled with a secure unique identifier. A central checking centre allows users to verify the authenticity of a particular good such as a cigarette pack or carton via any convenient interface such as the internet or a cell phone. A system of secret sharing allows secure authentication of each item and prevents code breaking or misuse.

Owner:PHILIP MORRIS USA INC

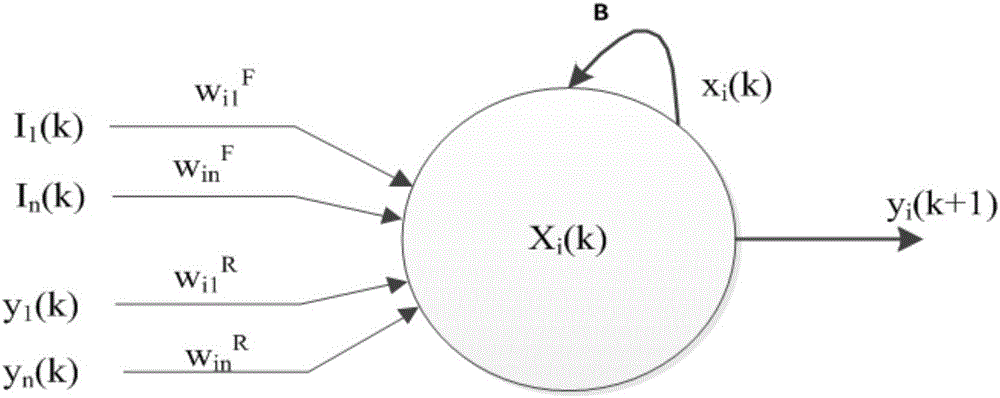

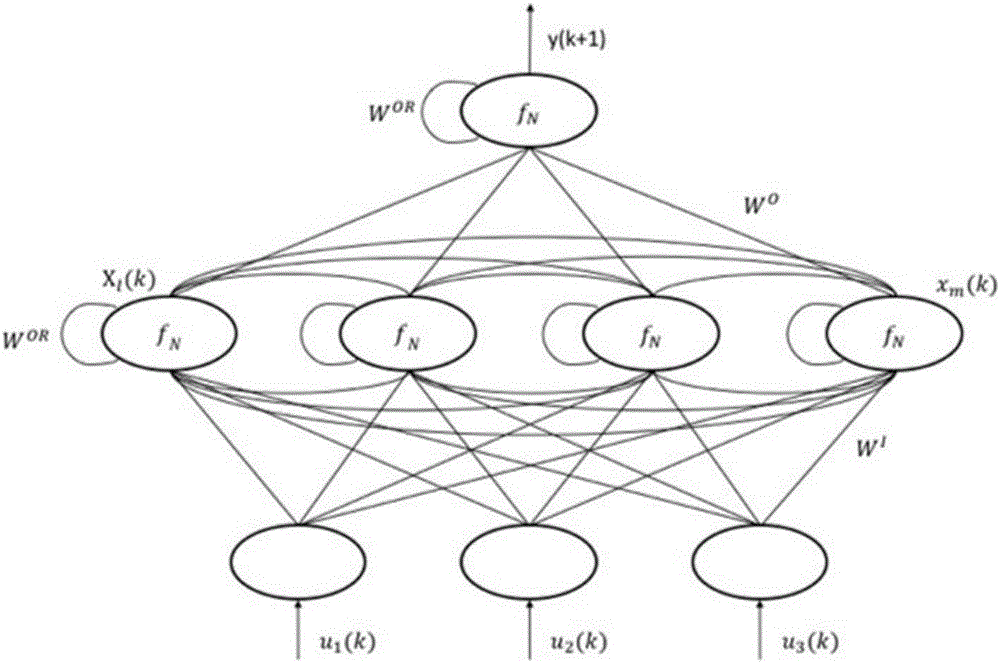

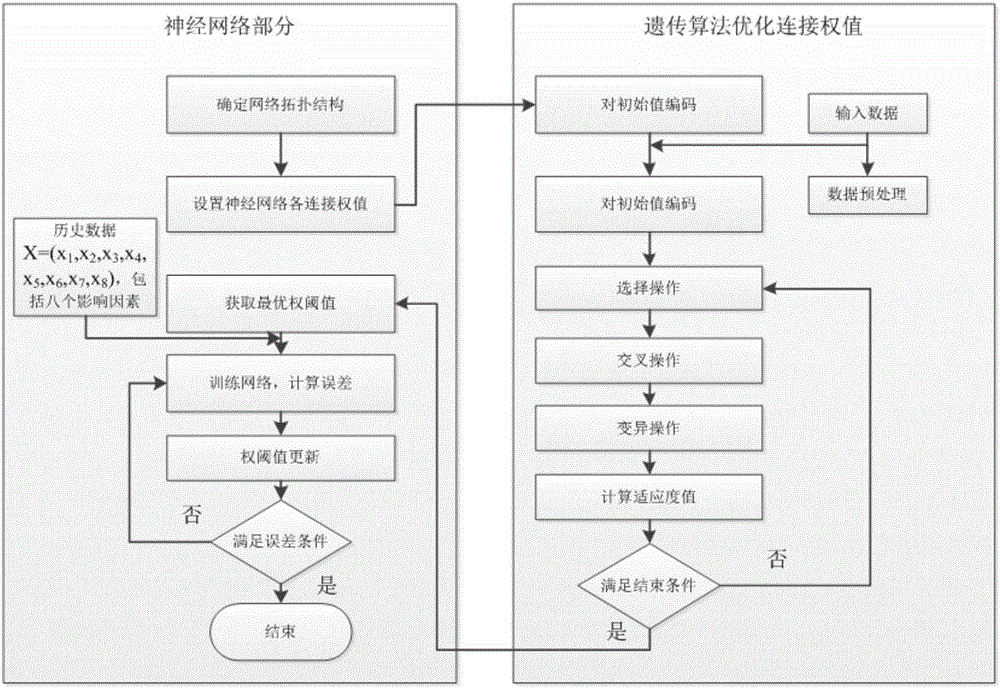

Chaotic neural network-based inventory prediction model and construction method thereof

InactiveCN105976049AUncover potential connectionsIncreased sensitivityForecastingChaos modelsWeight coefficientWaste product

An inventory forecasting model and its construction method based on chaotic neural network. The inventory of finished products is the key factor in precise distribution. If the inventory of finished products is sufficient, accurate delivery will be guaranteed, but the high inventory of finished products will bring a negative impact on the enterprise. The risk is high. On the one hand, it is difficult to process other materials after the original roll is processed into finished products. Once the user does not use it, it is likely to become a waste product. On the other hand, the finished product inventory takes up a large inventory space, which will make Limited storage capacity is getting tighter. The present invention divides the work into two phases. The first is the learning phase. The data of all the distribution users of the sample companies in the past three years are used as samples to establish a model, and these samples are used to learn and adjust the connection weight coefficients of the chaotic neural network, so that the network Realize the given input-output relationship; then the implementation stage, use the trained neural network to obtain the expected effect, establish a perfect calculation model, and realize the reasonable setting of the inventory.

Owner:WUHAN BAOSTEEL CENT CHINA TRADE

Method for continuously forming silicon carbide coating on surfaces of carbon fibers

InactiveCN102220621AImprove bindingSimple and fast operationElectrophoretic coatingsArtificial filament chemical after-treatmentFiberCarbon fibers

The invention provides a method for continuously forming silicon carbide coating on surfaces of carbon fibers, relates to the surface coating technology of the carbon fibers, and in particular relates to a technology for continuously forming silicon carbide coating on the surfaces of the carbon fibers by using an electrophoresis method. The technical problems to be solved are as follows: a methodcapable of continuously forming silicon carbide coating on the surfaces of the carbon fibers is provided, has simple equipment, and is convenient and fast to operate. The employed technical schemes are as follows: first step. preparing a silicon carbide electrophoretic fluid; second step. fixing a graphite tube and installing the carbon fibers in an electrophoresis tank; third step. switching on a power supply and carrying out silicon carbide electrophoretic deposition; and fourth step. blast-drying to obtain finished good carbon fibers. The method provided by the invention can continuously form silicon carbide coating on the surfaces of the carbon fibers, is simple and fast to operate, and has low cost; and the prepared carbon fibers with the silicon carbide coating have the characteristics of smooth surface, uniform coating and good binding between the coating and substrate, and the coating is not easy to fall off.

Owner:TAIYUAN XIKE NANO TECH

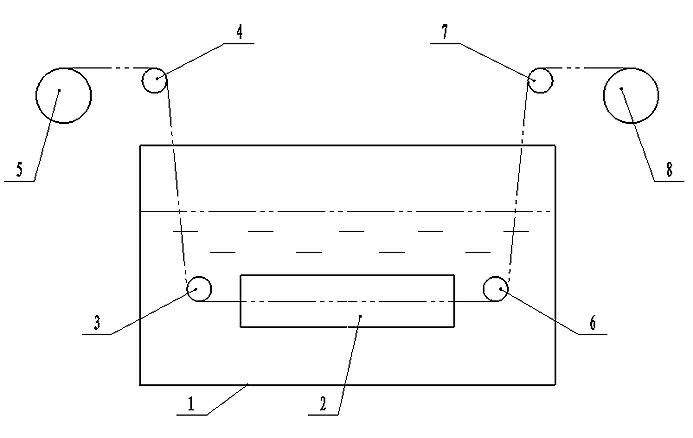

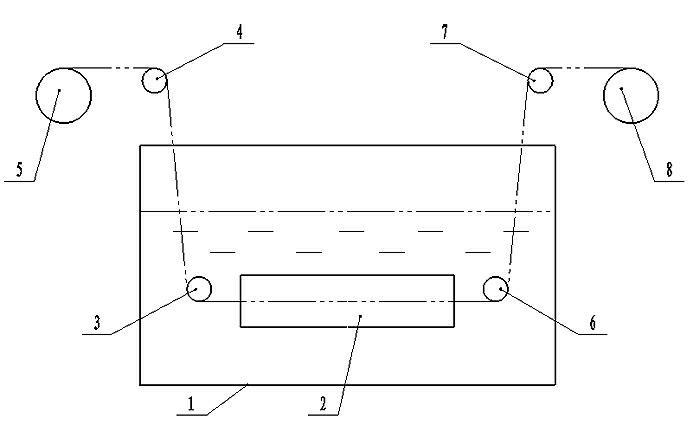

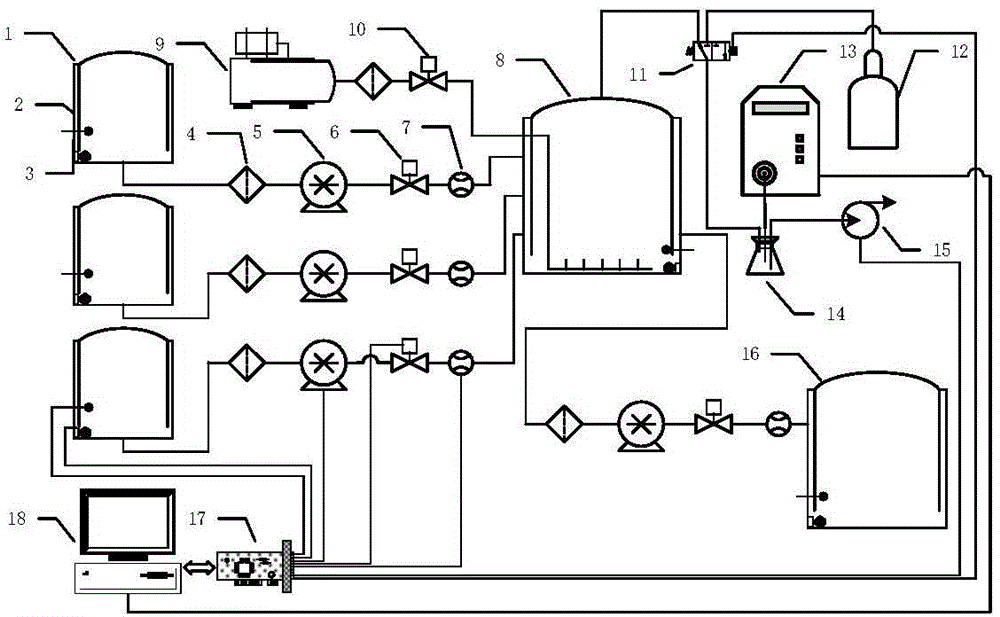

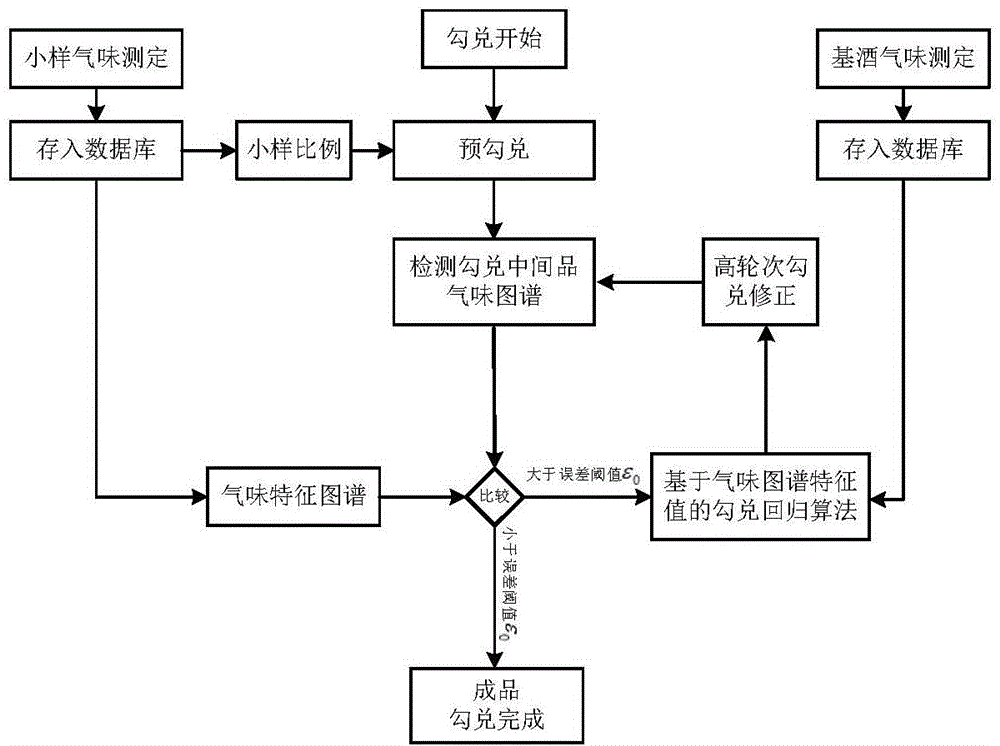

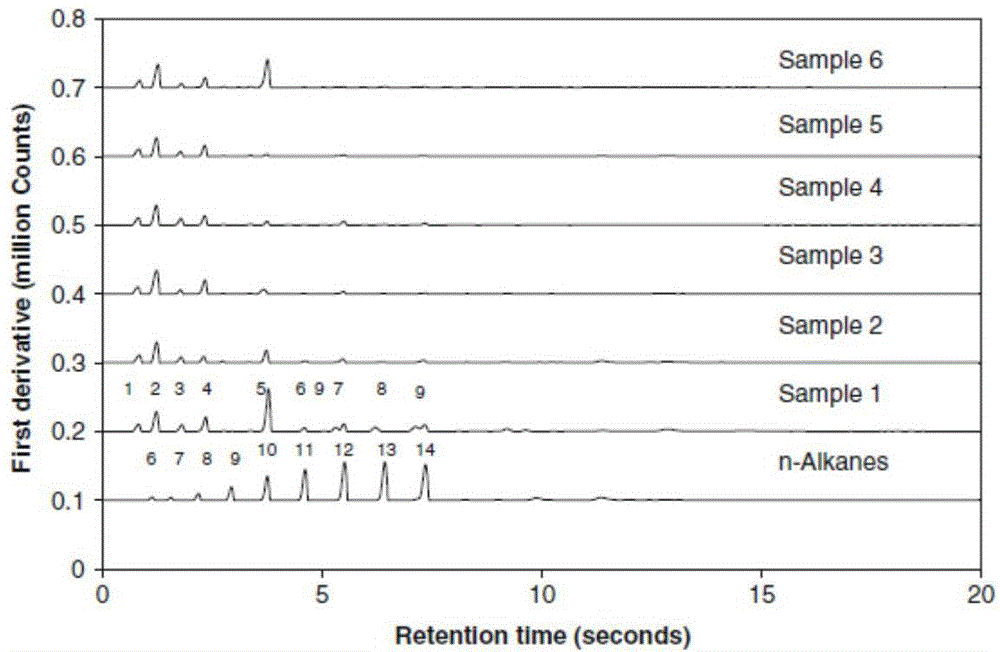

Automatic white wine blending system based on odour control

InactiveCN104450463AHigh blending efficiencyIncrease success rateComponent separationAlcoholic beverage preparationWine tasterEngineering

The invention relates to an automatic white wine blending system utilizing real-time odour detection and flow control; the blending proportion is controlled through an odour detection result, so that automatic blending of different flavoured wines and vintages is realized; blending of finished wine having special flavour can be rapidly completed by utilizing raw material wines of different batches without identification of wine tasters for many times; and the produced finished wine has the advantages of being precise in flavour and easy to adjust. The automatic white wine blending system based on odour control disclosed by the invention mainly comprises a raw material tank, a blending tank, a finished product tank, a pipeline system and an industrial computer control platform. The basic flow is as follows: measuring and demarcating odour of raw material wine, and recording in a database; demarcating odour characteristics of expectantly blended finished wine (sample), and determining a pre-blending proportion; blending by controlling the proportion of basic wine through a turbine flowmeter and an electromagnetic valve; sampling gas in the upper layer from the blending tank in real time in the blending process, and analyzing odour; and blending and correcting for many times in the later period so as to finally obtain expectant odour indexes, and storing in the finished good tank.

Owner:JIANGNAN UNIV

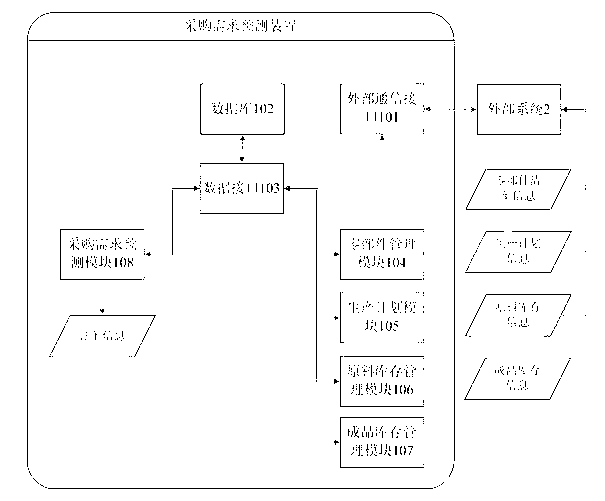

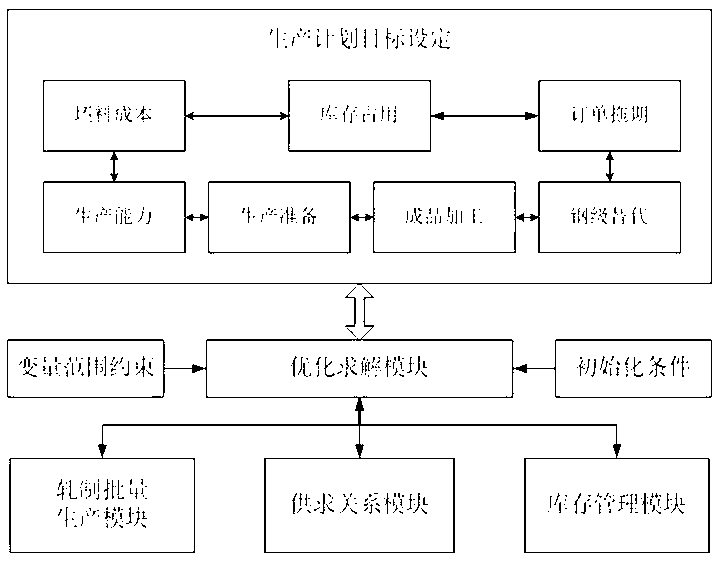

Device and method for forecasting steel product procurement demands

InactiveCN103106547AImprove turnaround speedImprove accuracyForecastingProgram planningInventory management

The invention discloses a device and a method for forecasting steel product procurement demands. A set of new forecasting models of the steel product procurement demands are built based on component and part information and combined with production plans and material inventory and finished goods inventory conditions. By means of the device and the method for forecasting the steel product procurement demands, inventory turnover speeds can be improved, forecasting accuracy can be improved, inventory management levels can be greatly improved, the business model of optimal inventory and minimum cost of supply chain service of steel product production enterprises can be achieved, and economical efficiency is excellent.

Owner:GUANGZHOU BAOSTEEL SOUTHERN TRADING

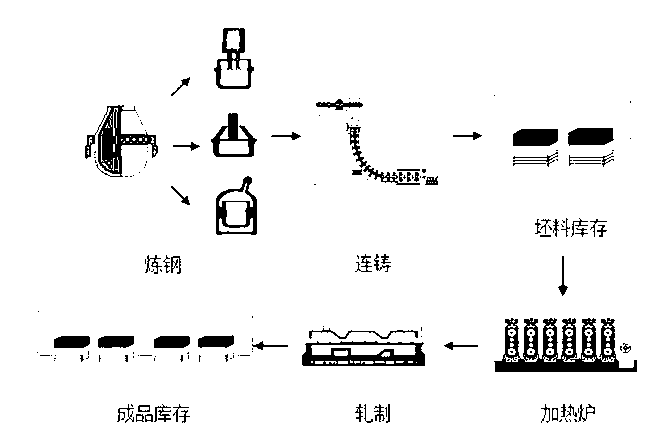

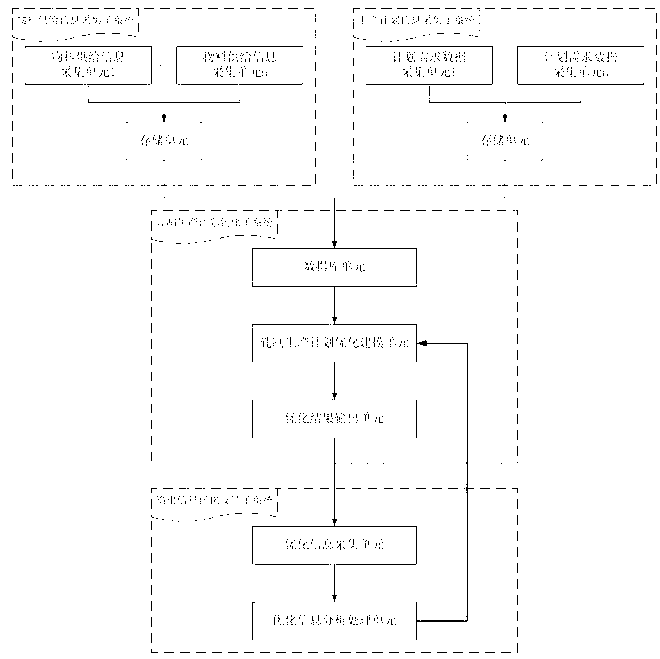

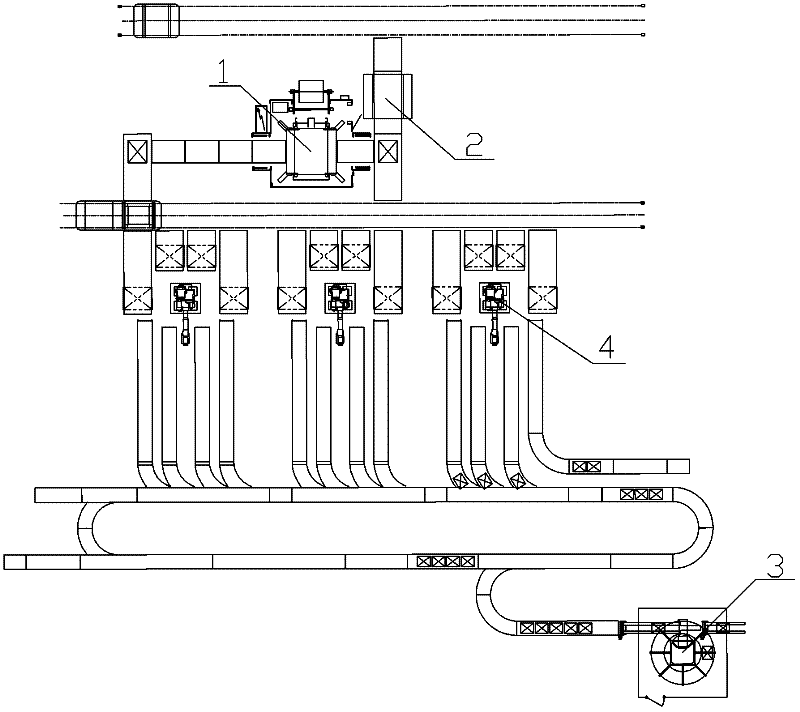

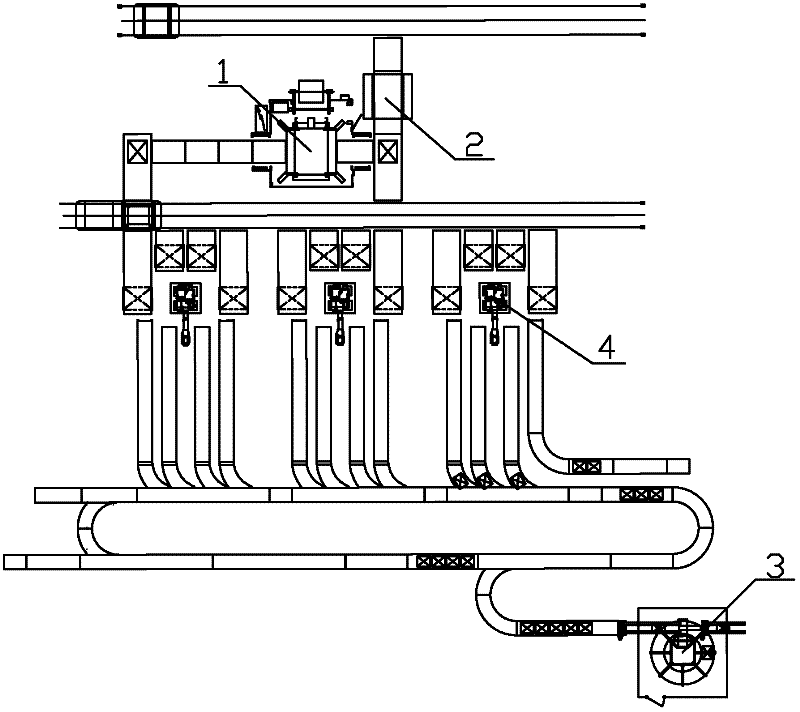

Multi-type steel batch rolling dynamic production planning system

The invention discloses a multi-type steel batch rolling dynamic production planning system which is composed of a production plan information collection subsystem, a material supply information collection subsystem, a rolling production plan optimization subsystem and an output optimization information feedback subsystem. An output result of the system is fed back to an upstream production plan optimization subsystem through the output optimization information feedback subsystem, and dynamic change of materials and orders in the production process is combined to conduct production plan adjustment to ensure operation of the production planning system under the condition of minimum production cost. According to the system, correlation between available capacity, replaceability of the steel materials, blank and finished goods inventory, blank and production cost, batch production, tardy production and other factors are comprehensively considered in the rolling process, flexibility is improved, and the system meets the production status and the requirements of modern steel enterprises for multiple types and small batch.

Owner:ZHEJIANG UNIV

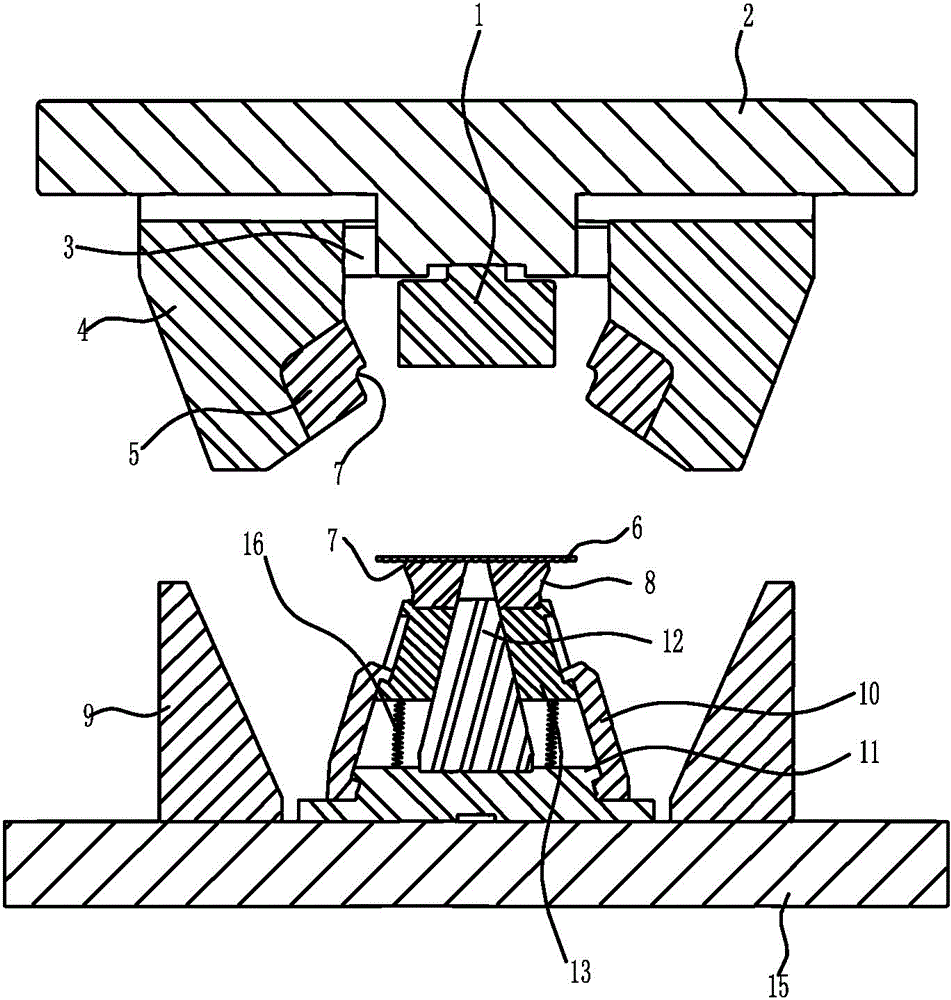

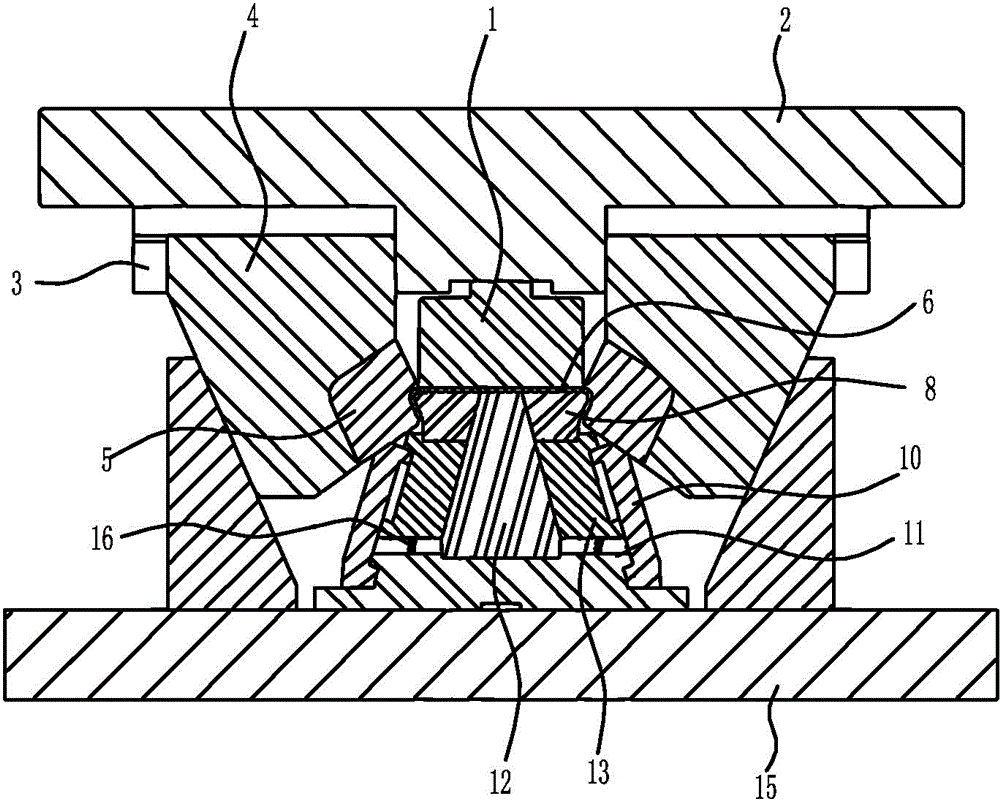

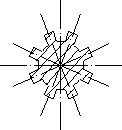

Punching machine for aluminium plate

The invention discloses machining shaping mould equipment, and particularly relates to a punching machine for an aluminium plate. The punching machine for the aluminium plate comprises an upper mould frame, an upper mould, a lower mould frame and a lower mould, wherein the lower mould comprises a frustum, a sliding frame and sliding blocks uniformly distributed on the periphery of the frustum in the circumferential direction; the frustum and the sliding frame are fixed on the lower mould frame; the frustum comprises a small upper end and a large lower end; an inclined sliding groove is formed in the sliding frame; the inclined sliding groove and an adjacent inclined surface or conical surface of the frustum face the same direction; the sliding blocks are arranged between the sliding frame and the frustum; the sliding blocks are propped against the inclined surface or the conical surface of the frustum; the sliding blocks are connected with the interior of the inclined sliding groove; the upper end face of the frustum and the upper parts of the sliding blocks together form a profile matched with the inner surface of a finished good in shape and provided with an inner turned edge. According to the punching machine for the aluminium plate, disclosed by the invention, the defects of low production efficiency and high manufacture cost in the prior art are overcome; therefore, the punching machine capable of manufacturing the aluminium plate with the inner turned edge in one step without an additional cylinder is provided.

Owner:SUIYANG COUNTY NAIHUAN ALUMINUM IND

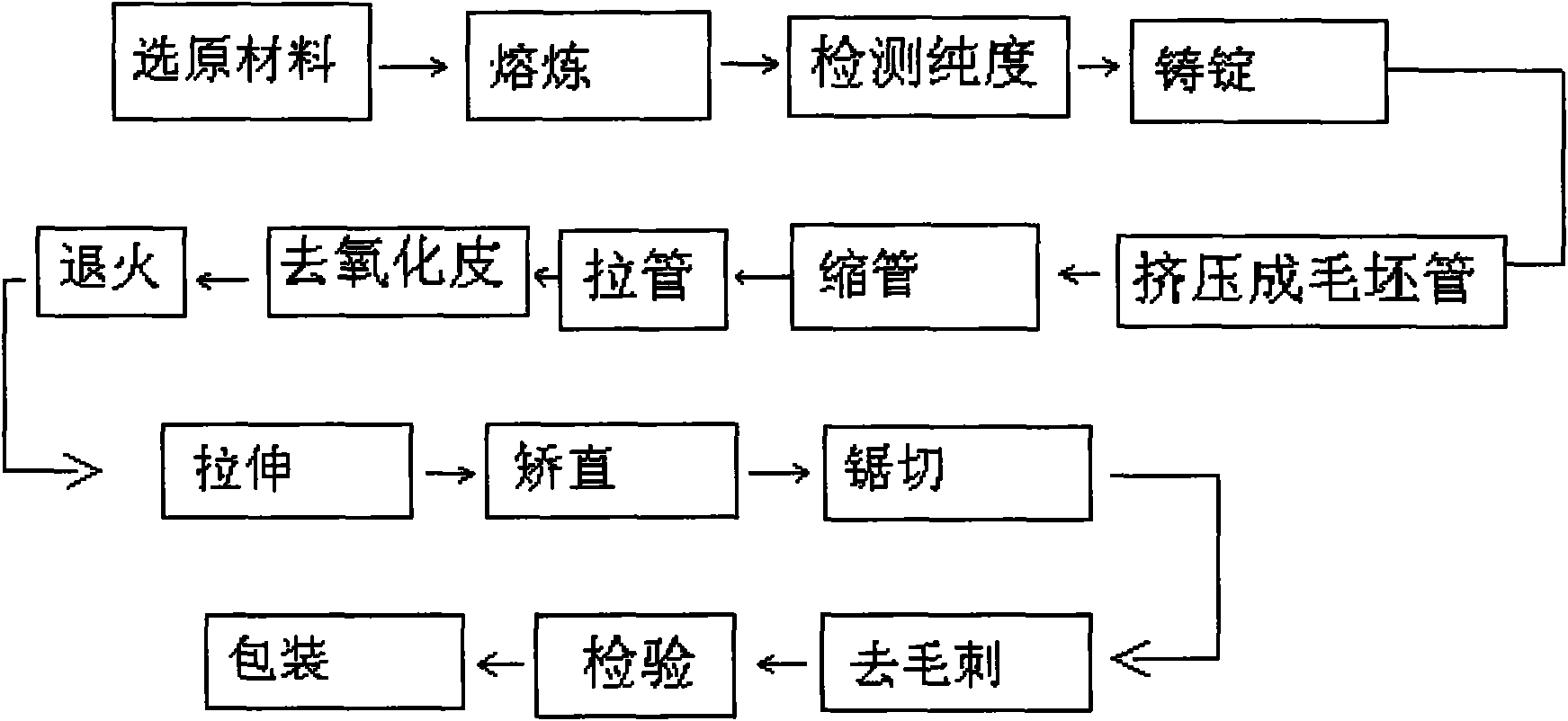

Method for manufacturing bronze pipe

InactiveCN101633011AEasy Shelling SqueezeMake sure you meet the requirementsColor/spectral properties measurementsFrequency conversionIngot

The invention discloses a method for manufacturing a bronze pipe, specifically comprising the following steps: selecting and melting raw materials; casting copper water into copper ingots; decladding the copper ingots and squeezing the copper ingots into various blank pipes; reducing one end of the blank pipe, removing oxide skins of the surface of the blank pipe; annealing the copper pipe to be softened; stretching the pipe materials to reach the requirement of customers through a frequency conversion stretcher; correcting the stretched copper pipe to the best straightness by a straightener; sawing the copper pipe into various lengths by a saw bit; removing burrs at two ends of the copper pipe; and testing to obtain finished goods. The method of manufacturing the bronze pipe provided by the invention has strong maneuverability, high efficiency, rational process design and high quality of the obtained bronze pipe.

Owner:SUZHOU JINCANG ALLOY NEW MATERIAL

Method for producing toona sinensis bud sauces

InactiveCN102919811AWhet the appetite and invigorate the spleenWith expelling wind and dampnessFood preparationAntioxidantBud

The invention discloses a method for producing toona sinensis bud sauces. The preparation process comprises the following steps of: (1) selecting high-quality toona sinensis buds, carrying out impurity removal, cleaning, segmented color-protecting, blanching treatment and drying on the selected high-quality toona sinensis buds so as to obtain a product for later use; (2) adding edible oil into a double-layer heating pan, after the temperature of the oil rises to 80-120 DEG C, adding an antioxidant, and stirring for about 10 minutes; (3) adding fresh garlic, fresh onions and 1 / 6 part of salt, decocting the obtained object for about 45 minutes; (4) adding red peppers, sesames and 1 / 6 part of salt, decocting the obtained object for about 50 minutes; (5) adding the spare toona sinensis buds, and decocting the obtained object for about 60 minutes; (6) adding special powder, self-made 'fengjiao' zanthoxylum oil and 1 / 6 part of salt; (7) continuously stirring, and decocting the obtained product for about 60 minutes, and then taking the obtained product out of the pan; (8) carrying out filling and sterilization; and (9) carrying out packaging on finished goods. According to the invention, the taste of toona sinensis buds is kept, so that the toona sinensis bud sauce both has the characteristics of flavored table pickles, and has the spicy taste of chilli sauces, therefore, the toona sinensis bud sauce has appetizing dietary-therapy and health-care functions.

Owner:陕西雨润椒业科技开发有限公司

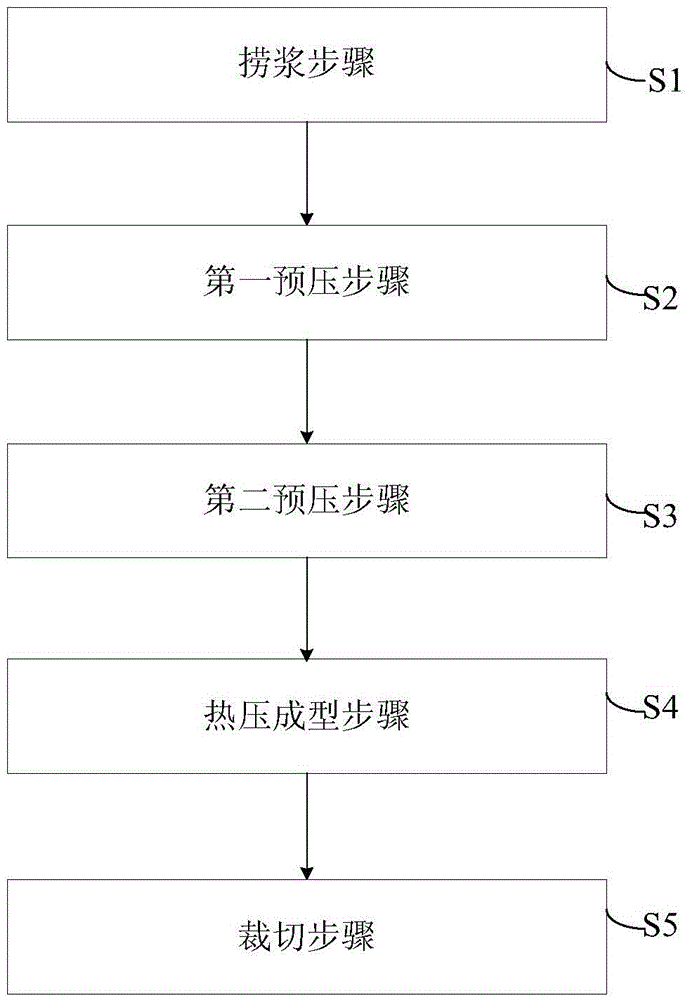

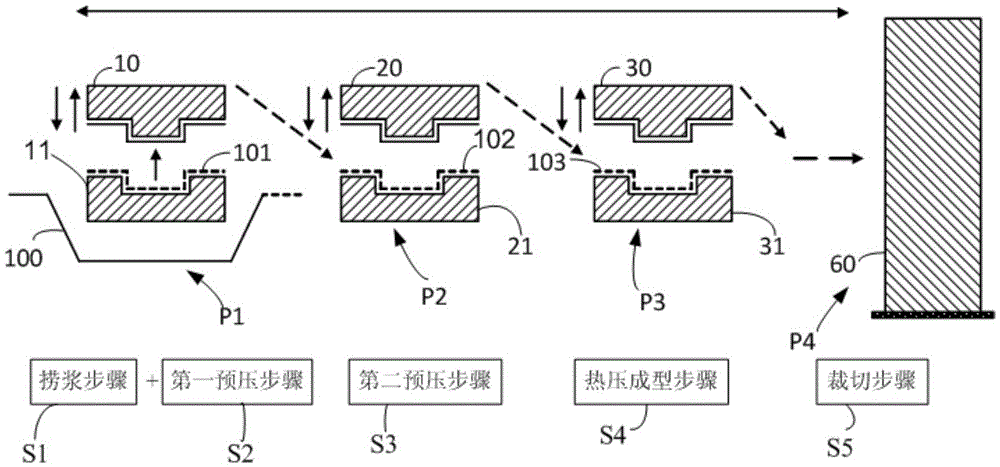

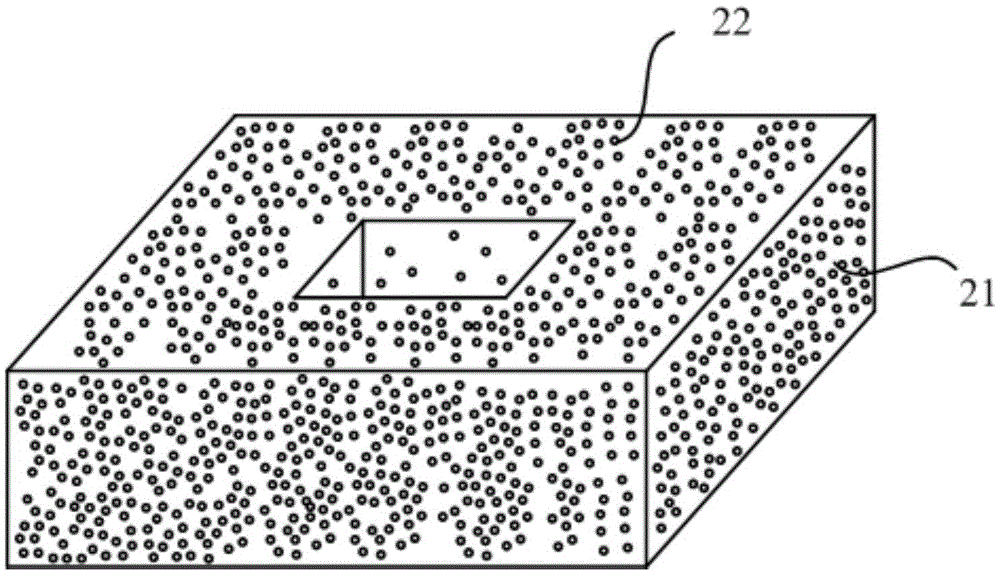

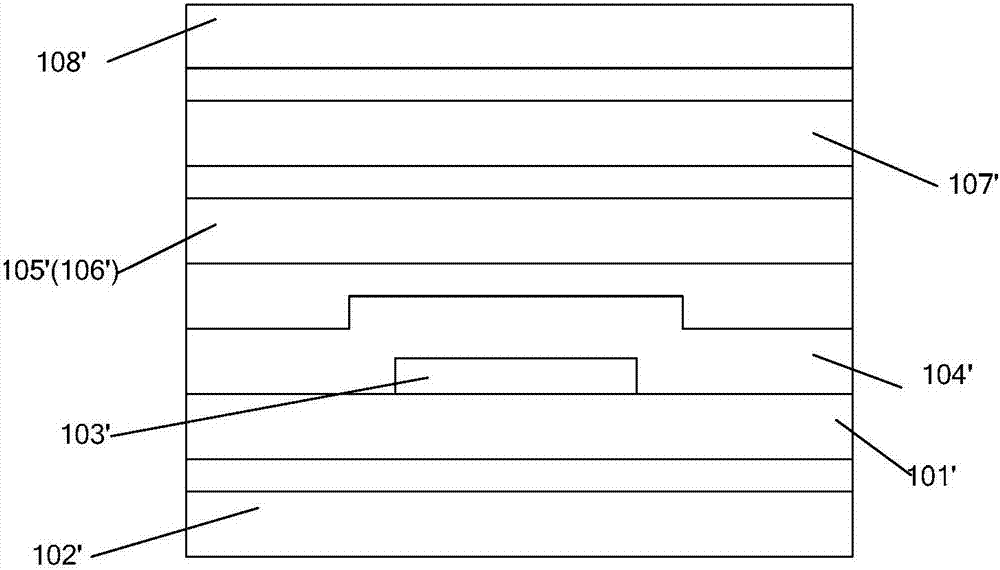

Wet paper molding method and paper plastic finished product

The invention provides a wet paper molding method and a paper plastic finished product, which are used for molding the paper slurry into a dried paper plastic finished good. The method comprises steps of a slurry taking step, a pre-pressing step, a second pre-pressing step, a thermal-pressing step, a thermal pressing molding step and a cutting step; the paper slutty is taken from the slurry tank of the mold to form a wet green by the first lower mold; the first lower mold and the first upper mold perform press fitting to perform the first pre-pressing step; the second upper mold and the second lower mold perform press fitting to perform second pre-pressing step; the third upper mold and the third lower mold perform hot press molding. The invention increases the drying degree of the wet green, and shortens the time spent on drying and molding of the paper plastic finished good. The paper plastic finished good are smooth on the inner surface and the outer surface, and the inner surface and the outer surface have the surface smoothness degree value which is greater or equal to 3Bekk second.

Owner:GOLDEN ARROW PRINTING

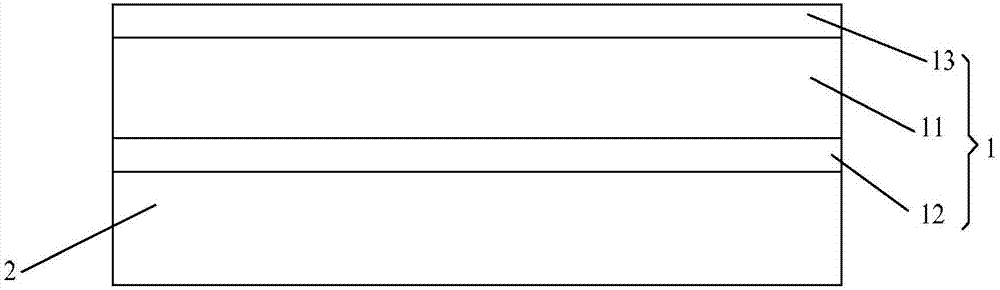

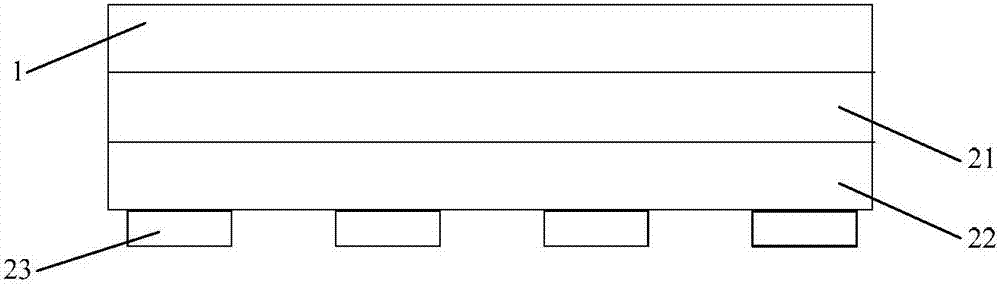

Water-oxygen-obstruction, touch-control and protection film, manufacture method for the same and OLED display panel

ActiveCN107204402ARealize integrationGuaranteed yieldSolid-state devicesSemiconductor/solid-state device manufacturingFinished goodControl function

The invention provides a water-oxygen-obstruction, touch-control and protection film, a manufacture method for the same and an OLED display panel. The water-oxygen-obstruction, touch-control and protection film comprises a flexible base material layer and a touch control film assembly. The flexible base material layer comprises a base material main body and a transition layer and a hardening protection layer, wherein the transition layer and the hardening protection layer are arranged on opposite surfaces of the base material main body; the hardening strength of the hardening protection layer is more than 5H of hardness of a pencil; the touch control film group having the obstruction function is in contact arrangement on the surface of the transition layer which is away from the base material main body; a touch control member in the touch control film group is arranged in a same function layer; because the transition layer and the hardening protection layer are arranged on the surface of the flexible base material layer and the hardness of the pencil of the hardening protection layer is more than 5H and thus the hardening protection layer can be used a cover lens for packaging; In the water-oxygen-obstruction, touch-control and protection film, the water-oxygen-obstruction function and the touch control function are integrated in the touch control film group and are in contact arrangement on the transition layer, which realize integration of the touch control film group and the cover lens, simplify the technology process and guarantee yield rate of the finished good.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Water pigment containing nano pigment for fine arts and manufacturing method thereof

InactiveCN101186782AHigh standardGood weather resistanceNatural resin coatingsArtist's paintsGlycerolChemical stability

The invention relates to esthetic gouache color containing nano-pigments and process for preparation, in particular belonging to the technical field of paints. The invention is characterized in that natural peach glue and acacia gum are taken to be added into formula distilled water to be heated, mixed, melted and made into adhesive glue solution. After being added with nano graining paste and pigment powder which are uniformly mixed with the adhesive glue solution, the adhesive glue solution is further added with lithopone, glycerol, sodium benzoate, and phenoxetol to be uniformly mixed, the mixture forms coarse paste which is added into a hopper of a three-roll grinder to be ground, and the ground slurry flows into a storage barrel, thereby achieving finished goods. The invention is powerful and bright in color, good in dyeing force and good in chroma, not only has good usability and bright color, but also has perfect weatherability and chemical durability, which meets the high demands of artists for the gouache color for art purposes.

Owner:宋健

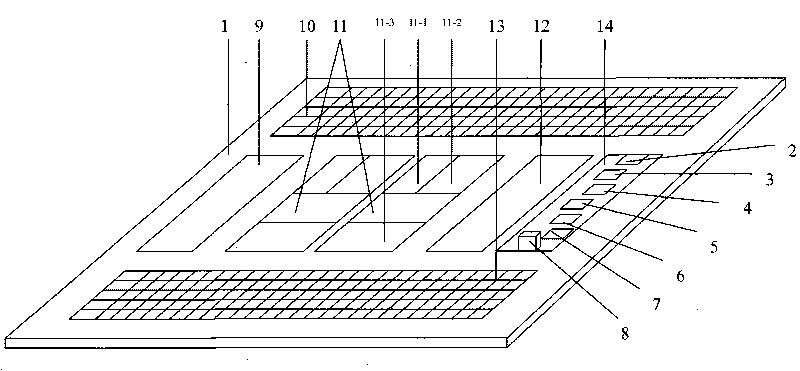

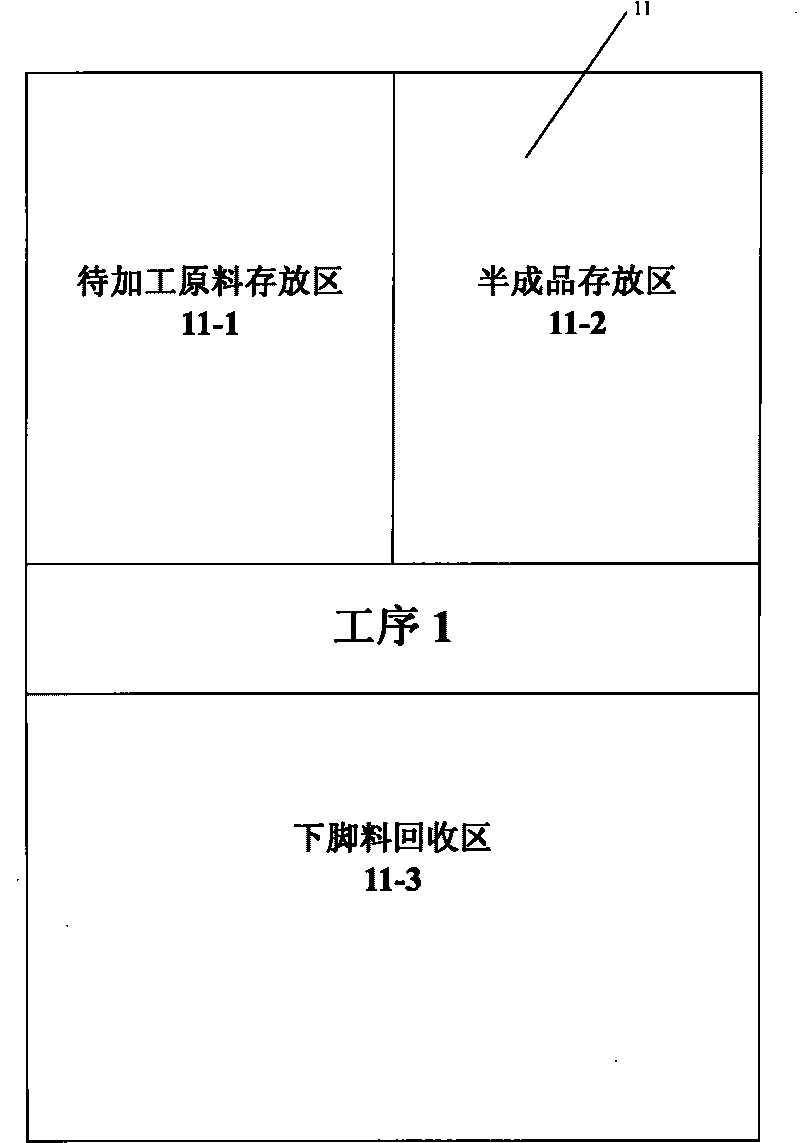

Teaching aids simulating production process and usage thereof

InactiveCN101707022AReproduce stock change statusReproduce the phenomenon of waiting in lineTeaching apparatusProcessing typeComputer science

The invention discloses teaching aids simulating a production process and a usage thereof. The teaching aids are composed of a teaching module and a display platform, wherein the teaching module is constituted by a raw material storehouse model, a simple production schedule model, a production manufacturing procedure model, a finished goods warehouse model, a simple financial reporting model and a tag card; the display platform is a magnetic plastic or wood plate, and the surface thereof is divided into a simple production schedule model storage area, a raw material warehouse model storage area, a production manufacturing procedure model storage area, a finished goods warehouse model storage area and a simple financial reporting model storage area; a teaching aids module and the tag card are both manufactured by thin resin or wood materials, and are pasted and / or tripped off with corresponding regions on the display platform through magnetism to represent the change of production and management conditions. The invention provides teaching aids to simulate the production process of processing type, assembling type and continuous type, thus being beneficial for students to comprehend the true meaning of production planning and production organization deeply.

Owner:吕明哲

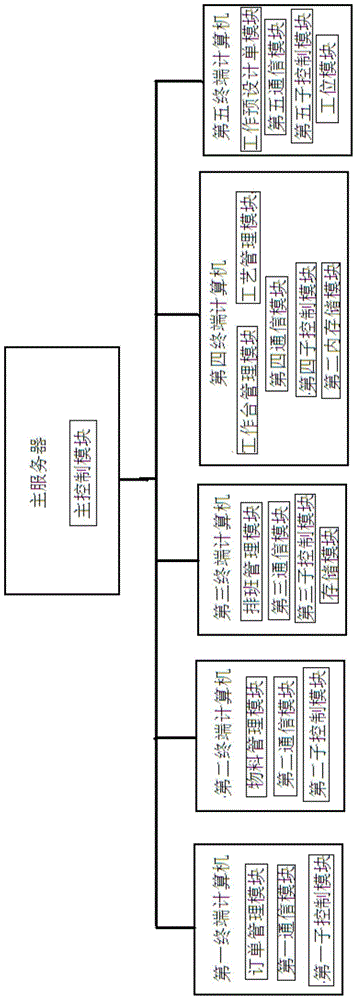

Radiopharmaceutical production management system

ActiveCN104318393AControllable information throughout the processImprove securityResourcesProcess informationMaterials management

The invention discloses a radiopharmaceutical production management system which comprises a main server. A main control module is arranged in the main server. The main control module is connected with an order management module, a material management module, a workforce management module, a workbench management module, a technology management module and a working pre-design single module respectively. The order management module sends order information to the main control module which check raw material inventory and finished good inventory information according to the order information through the material management module, production plan information is generated after comparing of the checking results and the order information, and then production personnel information in the workforce management module and production equipment information in the workbench management module are checked. The main control module sends production tasks to corresponding workbenches according to the production personnel information and the production equipment information, and production task manufacturing products in the production plan information are manufactured through the workbenches according to material getting information and technological process information provided by the technology management module and the working pre-design single module.

Owner:BEIJING ZHIBO BIO MEDICAL TECH +1

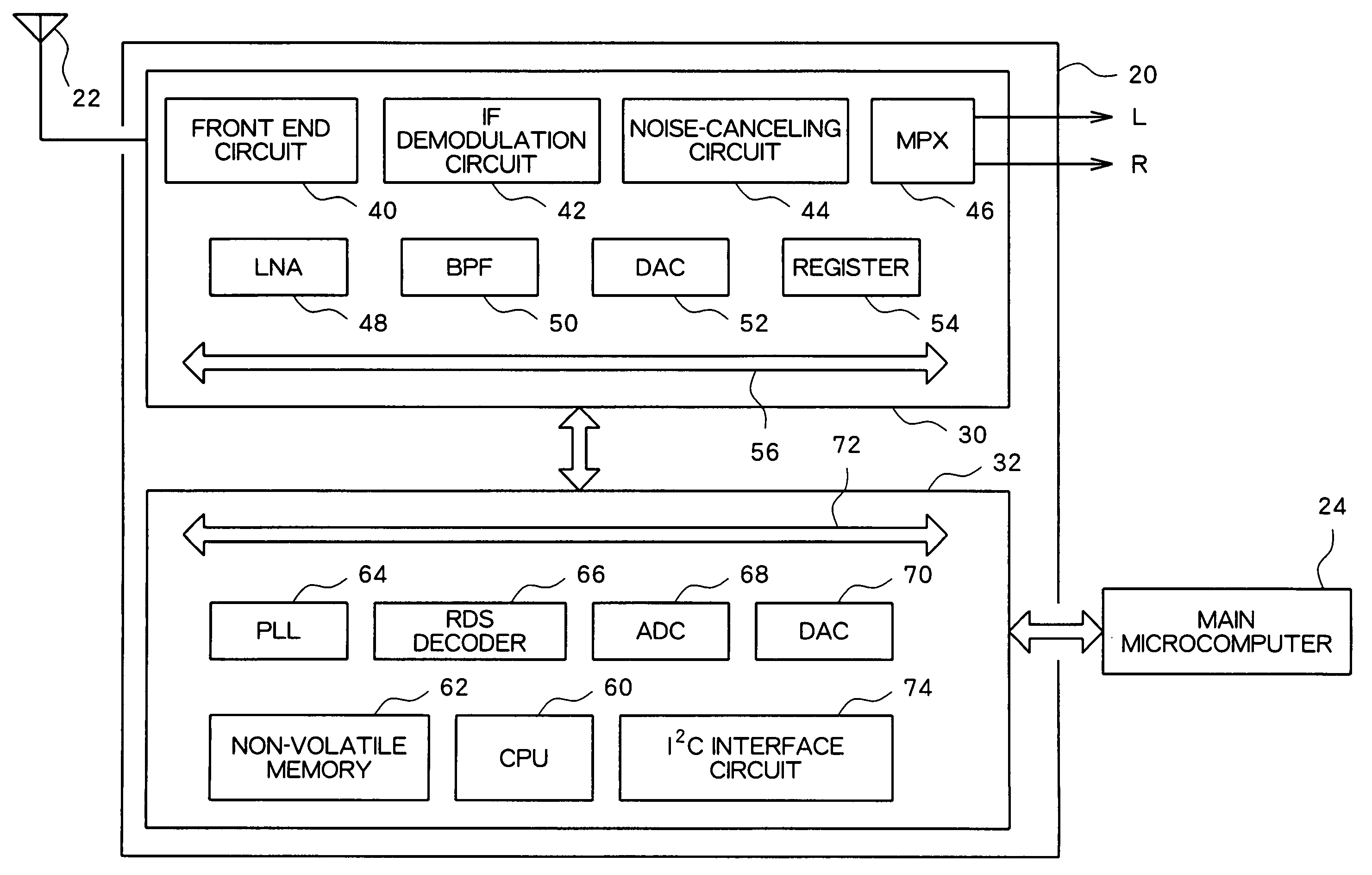

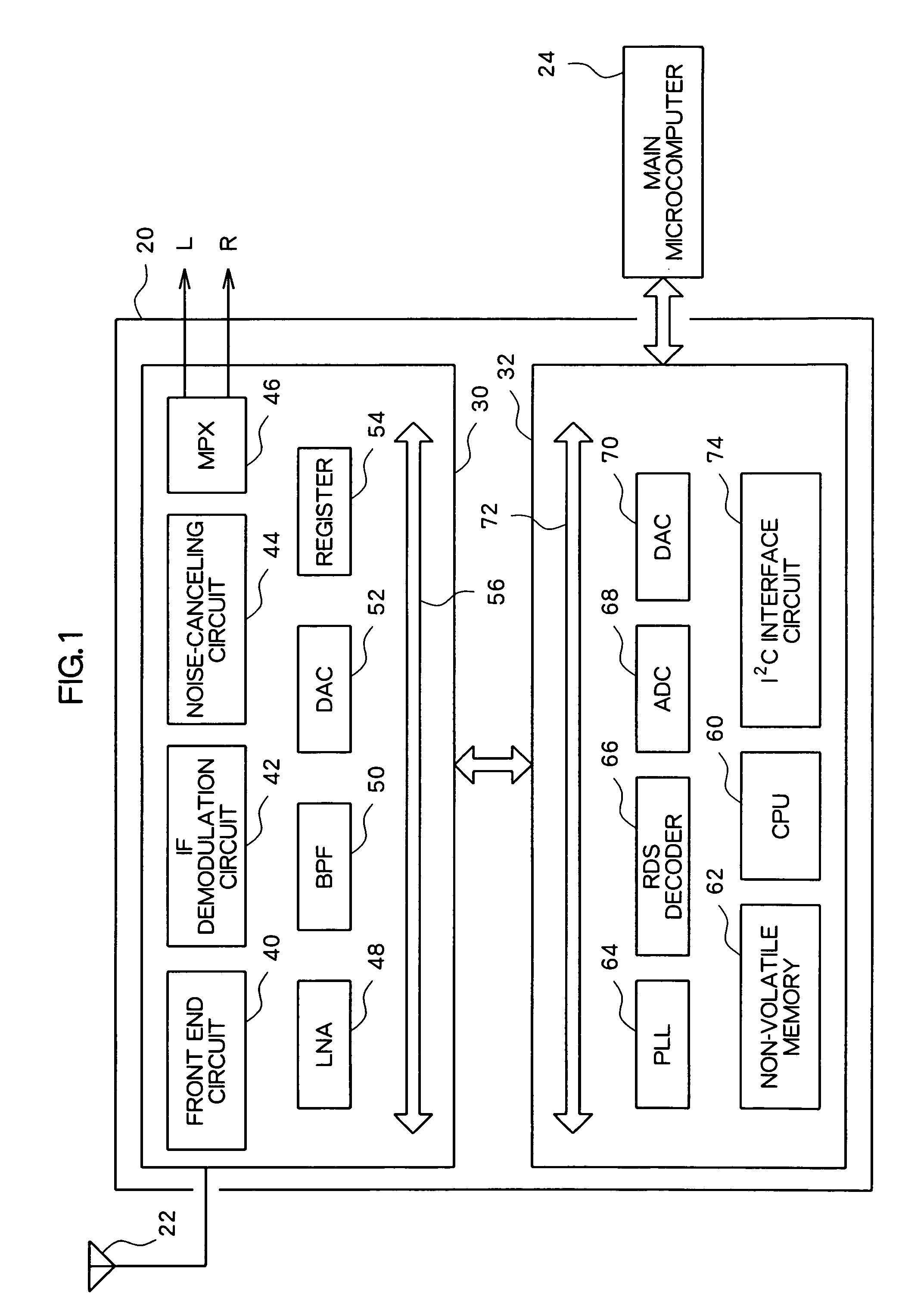

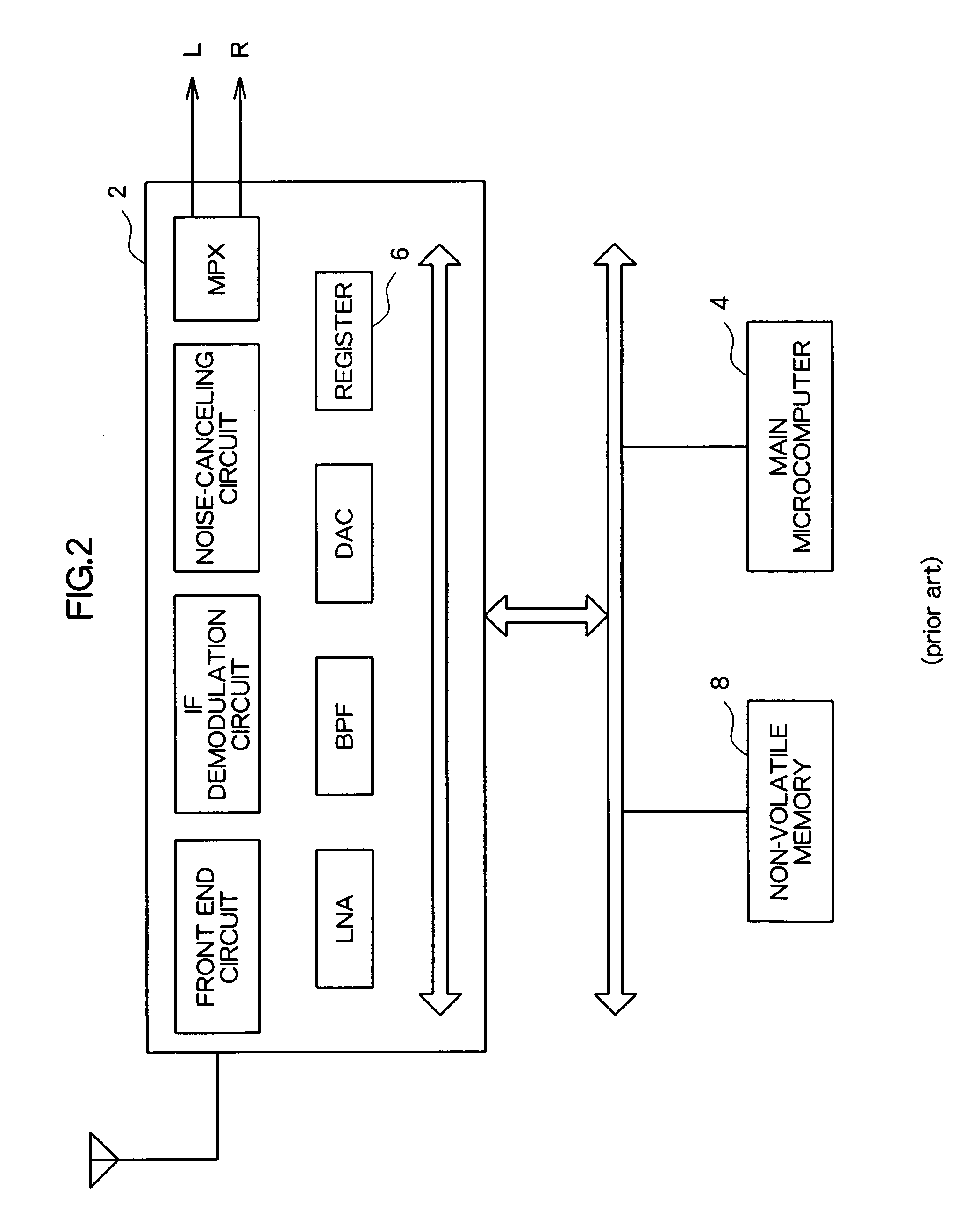

Semiconductor device for use in radio tuner and method for manufacturing the same

InactiveUS20090054022A1Low production costImprove productivityPulse automatic controlSolid-state devicesProcessor registerSemiconductor

Adjustment work for a radio tuner system IC is reduced. A radio tuner part 30 into which is built a register 54, and an electronic tuning control part 32 into which is built a nonvolatile memory 62 for storing an operation parameter preset in the register 54, are constructed to form a single tuner system IC 20. This structure enables data for the radio tuner part 30 of the same package to be written to the nonvolatile memory 62 at a step for manufacturing the tuner system IC 20. The work of adjusting the nonvolatile memory 62 is performed in conjunction with a finished goods inspection performed after packaging of the tuner system IC. High-speed semiconductor testers are generally used to perform such inspections, and the work of adjusting the nonvolatile memory 62 can also be performed at high speed.

Owner:SEMICON COMPONENTS IND LLC +1

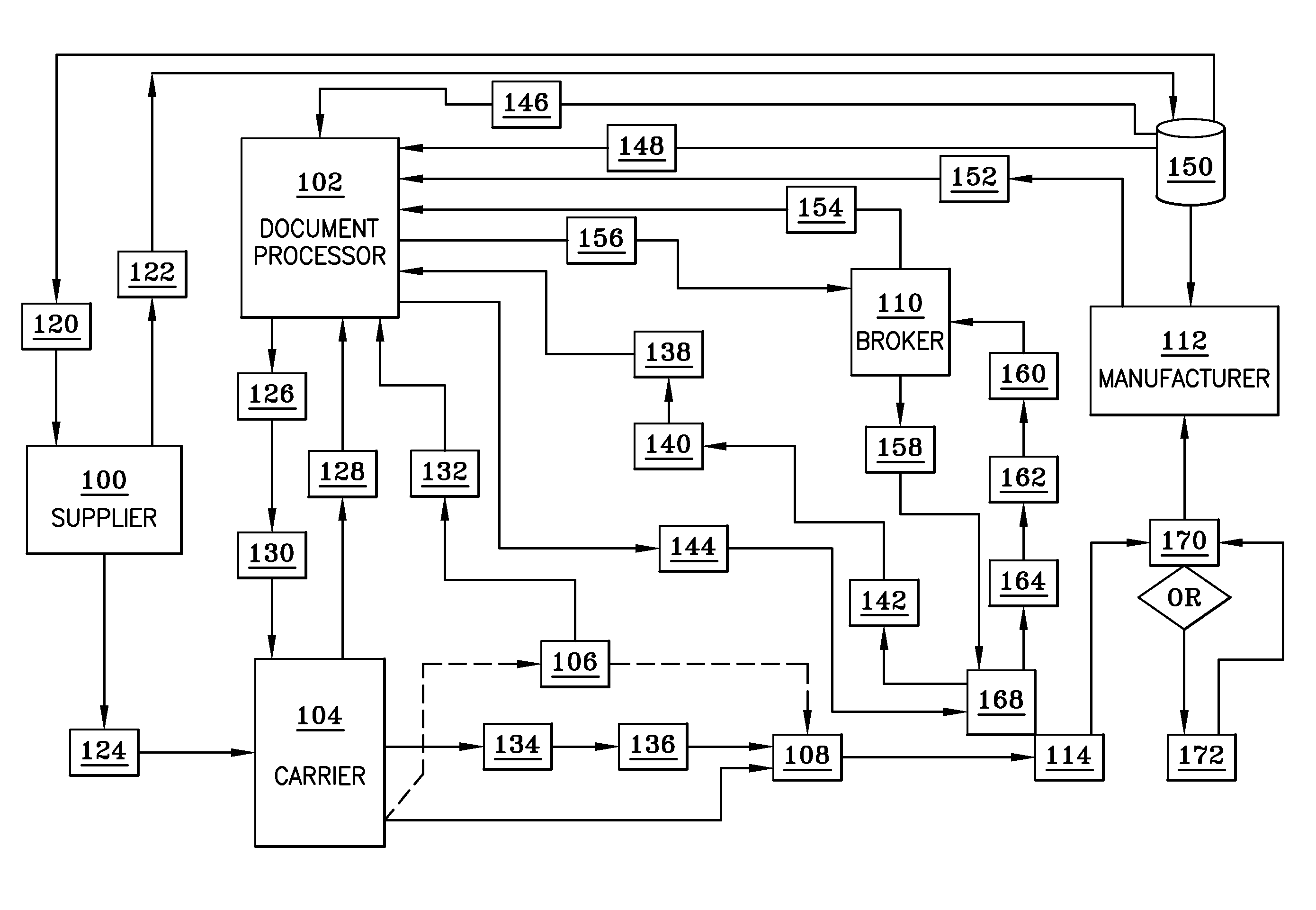

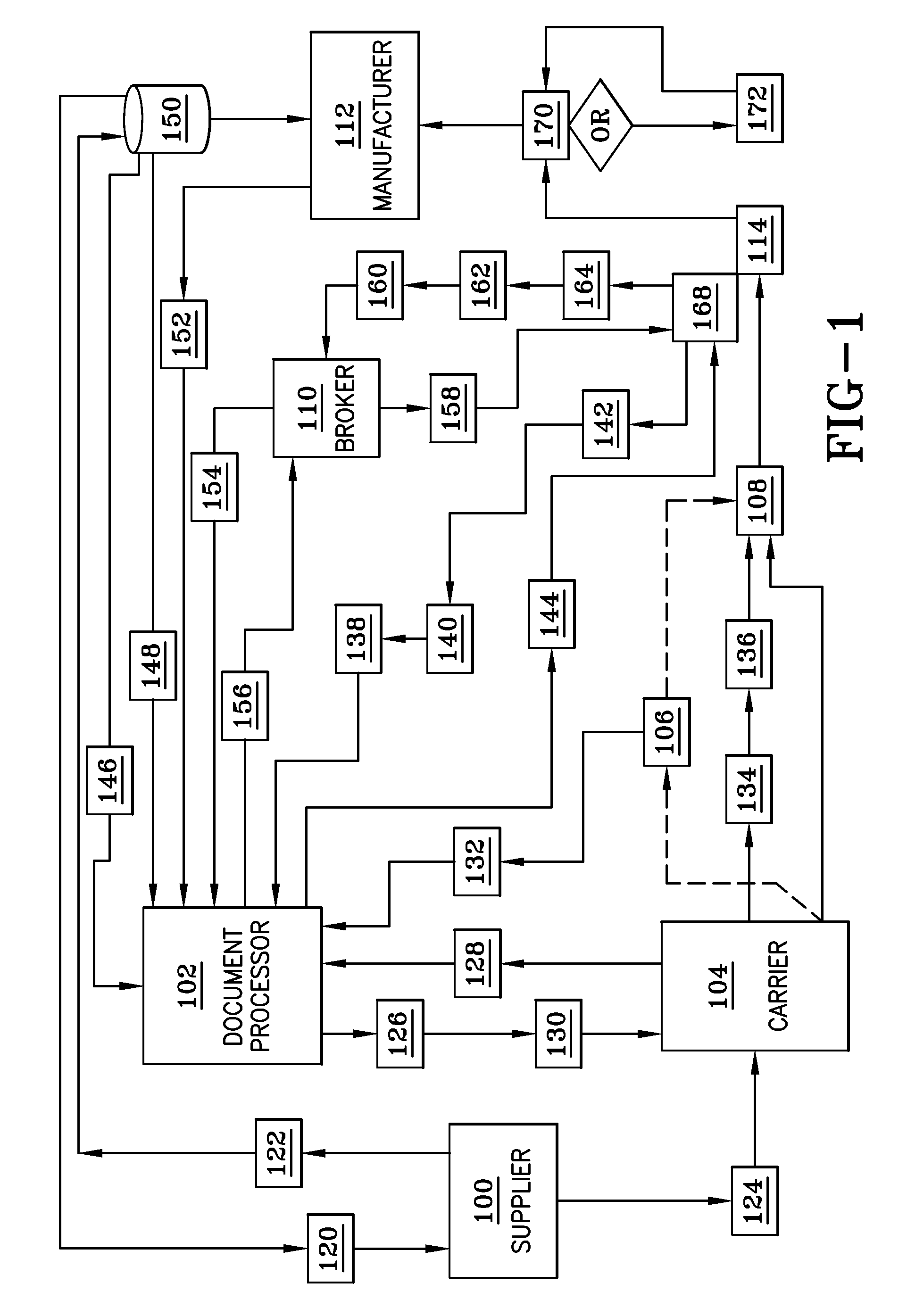

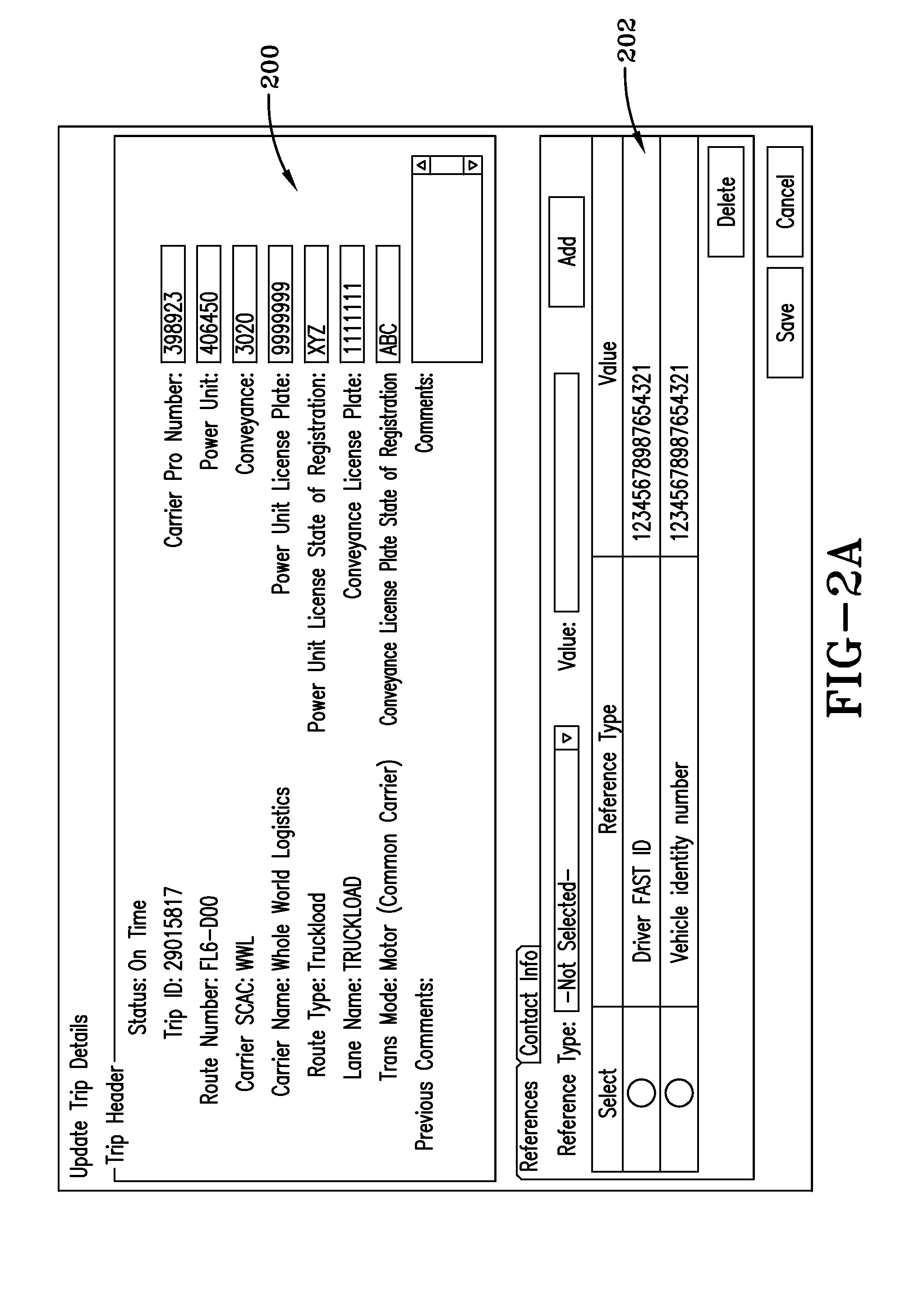

Electronically enabled clearance methodology for improved processing at border crossings

An electronically enabled clearance system and method for improved border crossings. The system and method generate and manage an electronic manifest (e-manifest) and an electronic commercial invoice (e-release) according to legal requirements as well as the requirements of a manufacturer that imports goods from other countries. A third party logistics provider may facilitate the interactions between an importer of manufactured goods, a supplier, a carrier, and a broker by serving as intermediary and hosting computer applications that manage the flow of information. A commercial invoice provides details about the goods in a shipment. A shipment control number (SCN) is associated with each commercial invoice. The e-manifest for a vehicle lists every SCN for the parts shipments loaded on the vehicle and therefore, provides a link to the commercial invoice data detailing information about the parts in the shipment.

Owner:HONDA MOTOR CO LTD

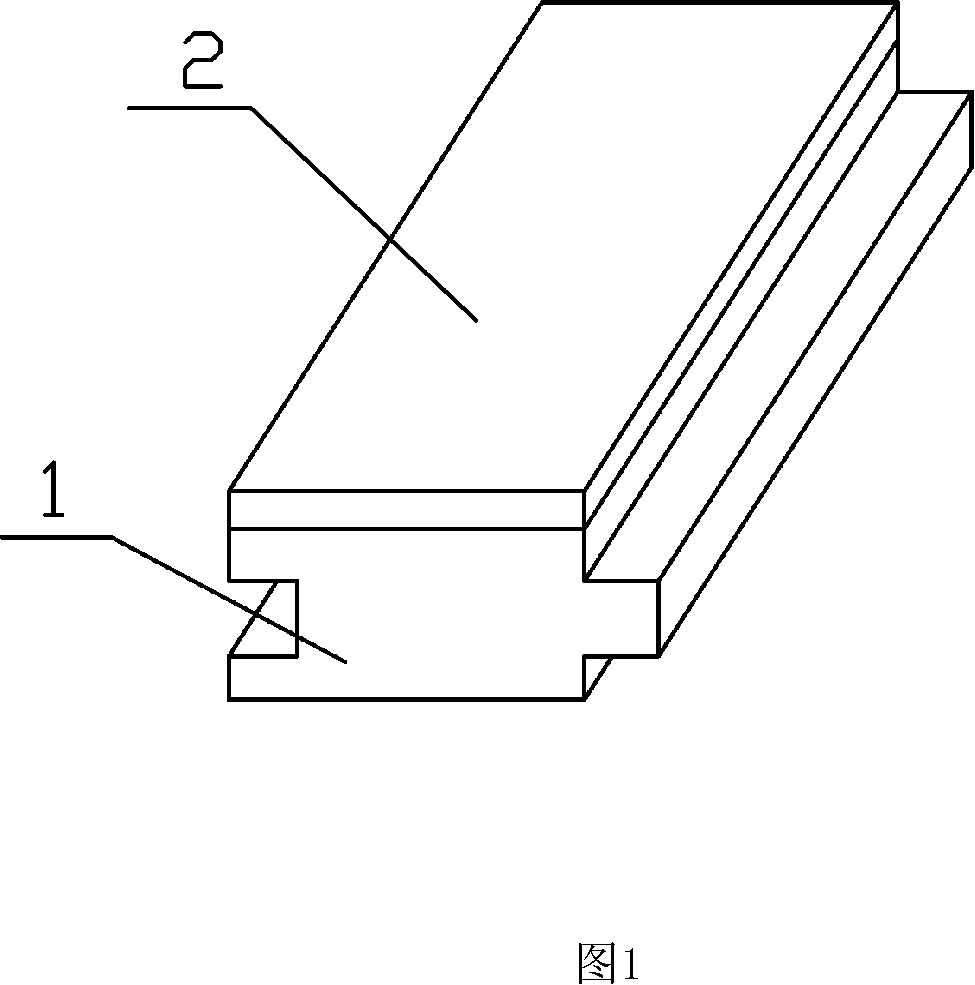

Production technology for wood-plastic water-proof outdoor floor and products produced thereby

ActiveCN101152760AHigh densityImprove waterproof performanceSynthetic resin layered productsFlooringMildewVolumetric Mass Density

The present invention discloses a wood-plastic waterproof outdoor floor production process and product. The steps are: wood is smashed into wood powder, 25 pieces to 40 pieces of wood powder and 60 pieces to 75 pieces of plastic powder are mixed and are blending modified in a blending machine to make a mixing powder. The mixing powder is added into an extrusion machine and is extruded. The extrusion temperature is from 20 DEG C to 150 DEG C, and the extrusion speed is from 130 to 170 revolutions per minute. The mixing powder is extruded by a module head and becomes a proximate matter. The proximate matter is cooled and formed. The cooled and formed proximate matter is added into a fixed-length cutting machine and is cut into finished goods. Products of the invention are formed through extrusion and are characterized in that the density is high. So the product is strong in waterproofing performance, bending resistant and stretching resistant, good in impact resisting, inflaming retarding, mothproof, mildew proof and rot proof. The product is suitable for outdoor use. The secondary processing performance of the product is good. The product has the wood processing performances of being lopped, nailed, drilled and planed and so on. The product is painting avoided and the foot sense is good. Little wood grade or quality requirement is needed in the production. The product can be completely recycled and the environmental protection effect is satisfying.

Owner:浙江永吉木业有限公司

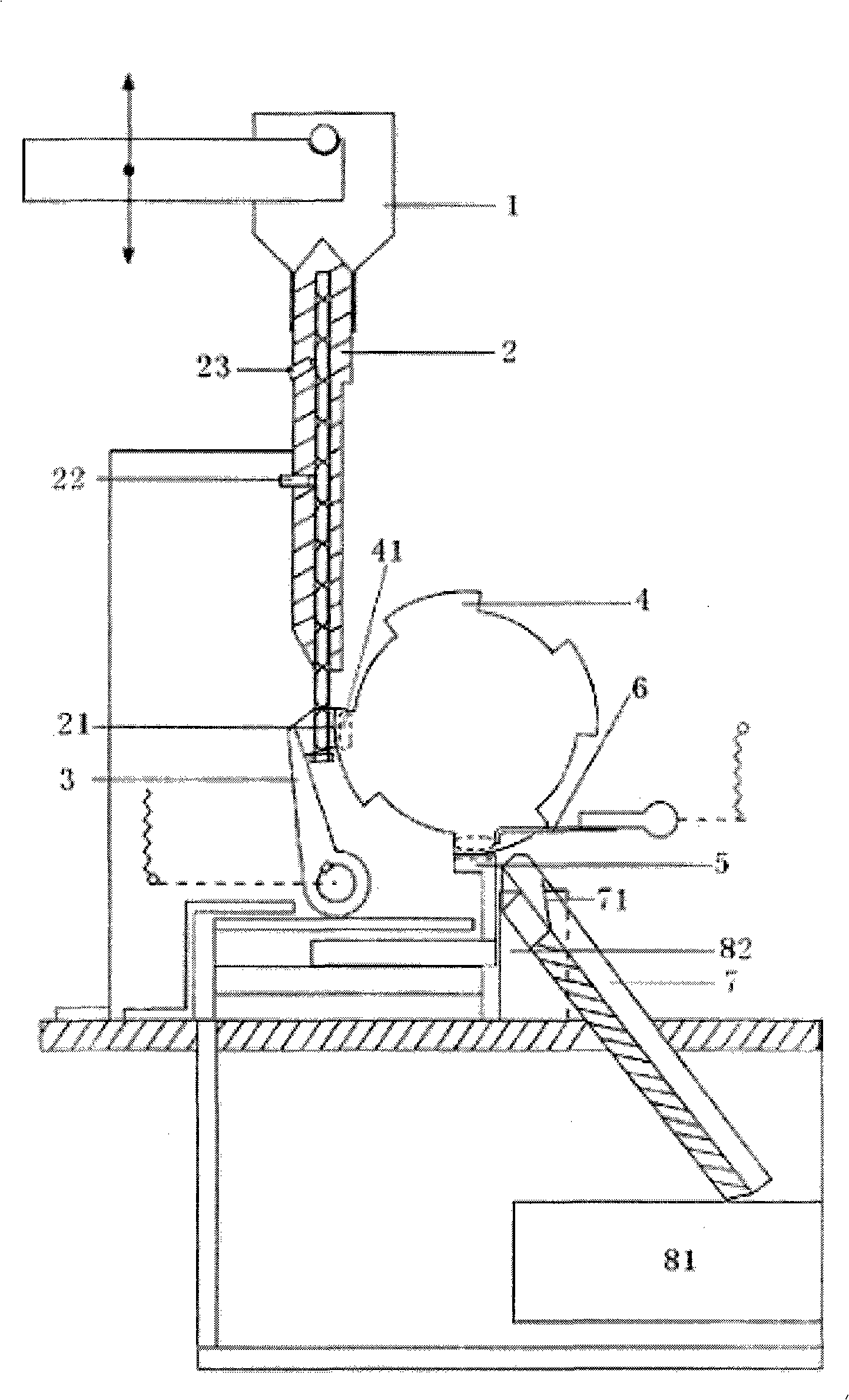

Device for rapidly checking capsules weight

InactiveCN101308041AReduce the problem of poor feedingImprove work efficiencyWeighing apparatus for materials with special property/formImpellerEngineering

The invention relates to a device for detecting weight of capsules rapidly, which comprises a feed bin, an upper channel, a feeding poke rod, a feeding impeller, a weighing platform, a feed-stopping baffle needle and a lower channel; capsules slide down the upper channel sequentially; and the lower end of the upper channel is provided with a discharging opening, two sides of which are respectively provided with the feeding poke rod that can extend into the discharging opening and the feeding impeller with the periphery surrounded by a storage chest; when the storage chest of the feeding impeller turns to the place corresponding to the discharging opening, the feeding poke rod pokes a capsule into the storage chest; once the storage chest turns to the lowest position along with the feeding impeller, the feed-stopping baffle needle pushes the capsule in the storage chest onto the weighing platform below the needle, the weighing platform detects weight of the capsule and judges whether the capsule is qualified; the follow-up storage chest pushes the weighed capsule into the lower channel when moving to the upper side of the weighing platform; and the qualified capsule slides down the lower channel into a finished goods warehouse, otherwise into a waster warehouse. The device works with high efficiency and maximally improves obstruction of capsule feeding.

Owner:SHANGHAI HENGYI PHARMA EQUIP

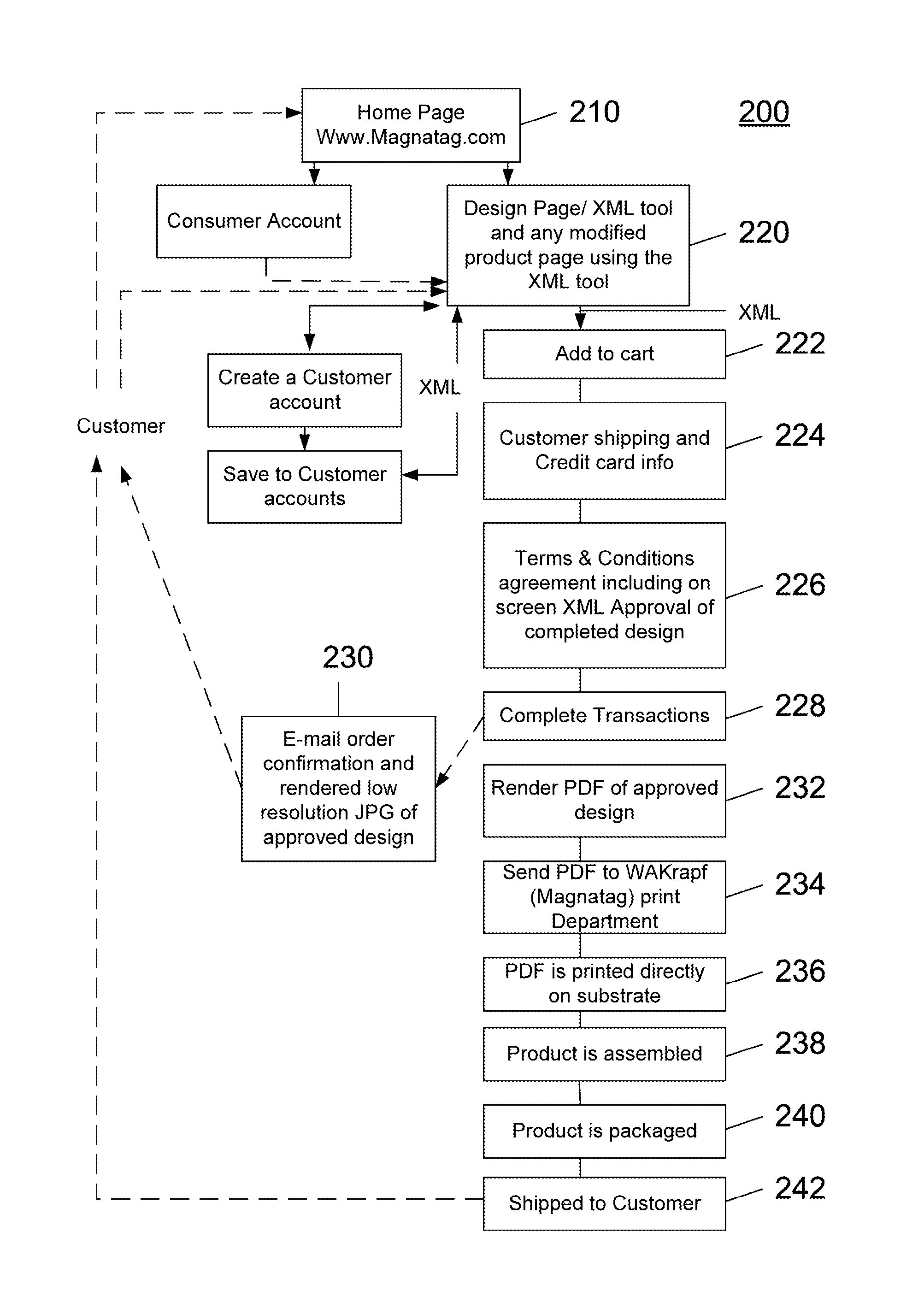

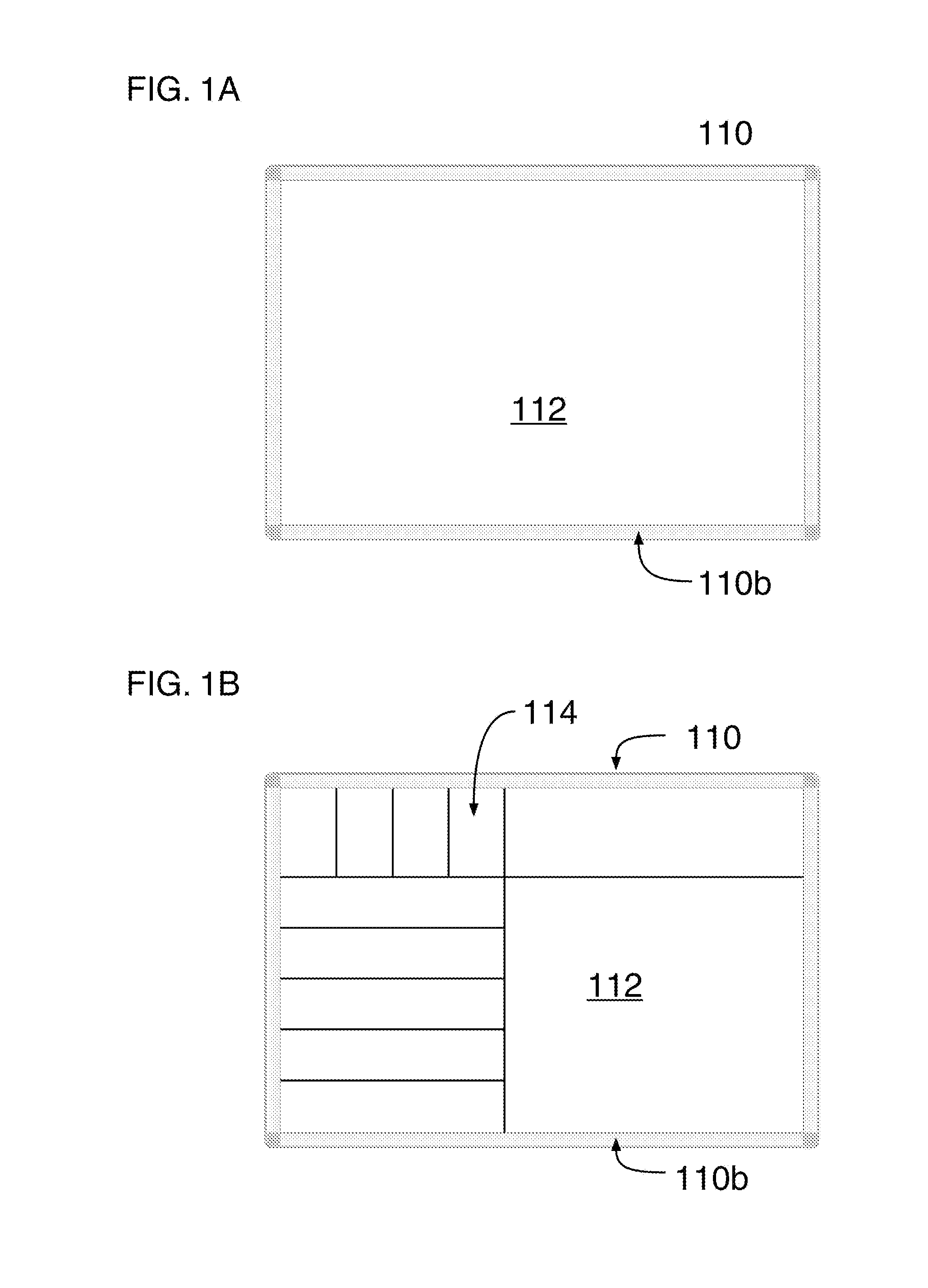

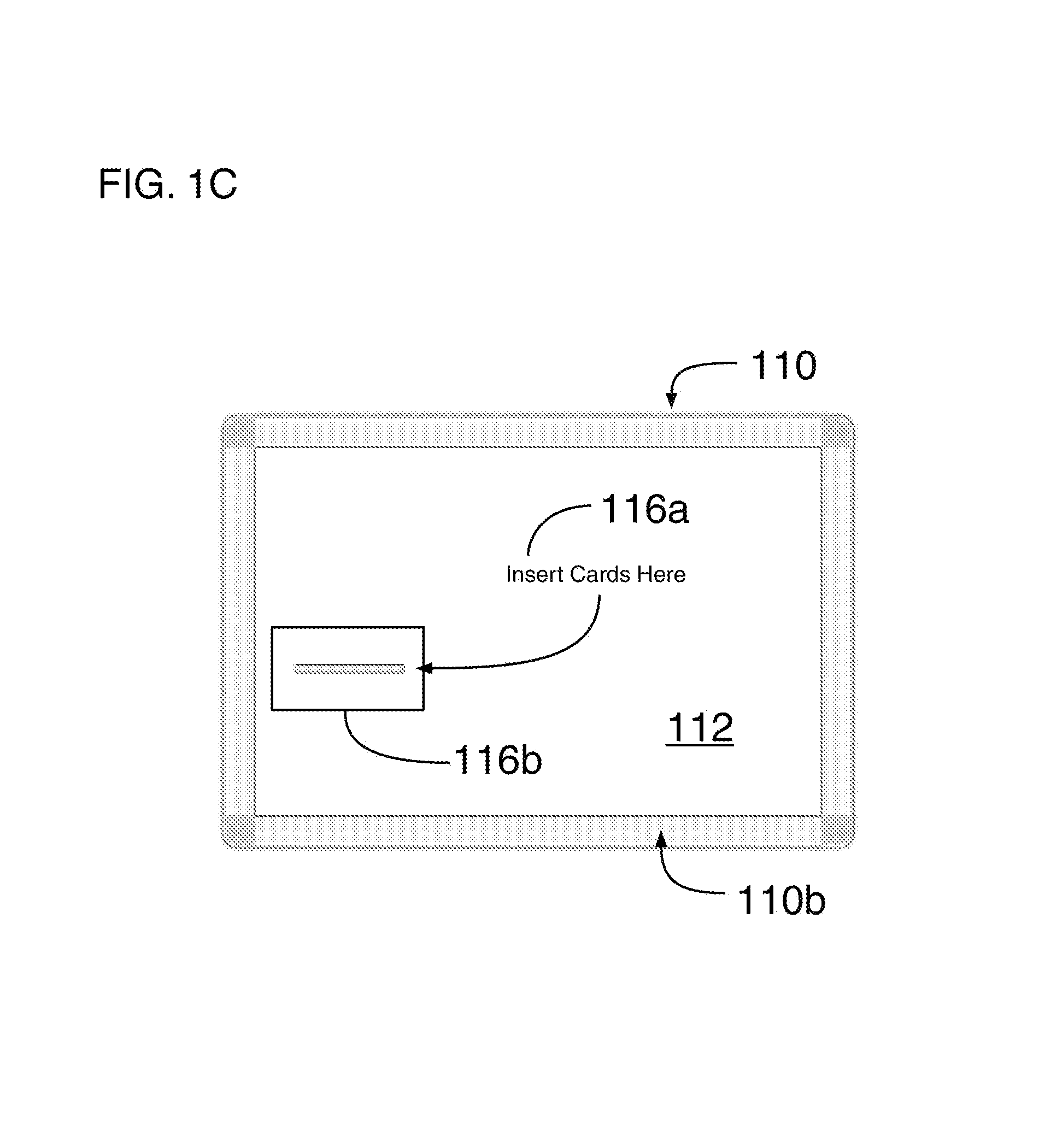

Customization of manufactured products

A system, apparatus and method for a person to communicate customized design information for an object, such as a product at a time prior to its manufacture. A network accessible communications channel and user interface is provided that enables the person to communicate design information, including a visual representation of the product, prior to its manufacture.

Owner:W A KRAPF

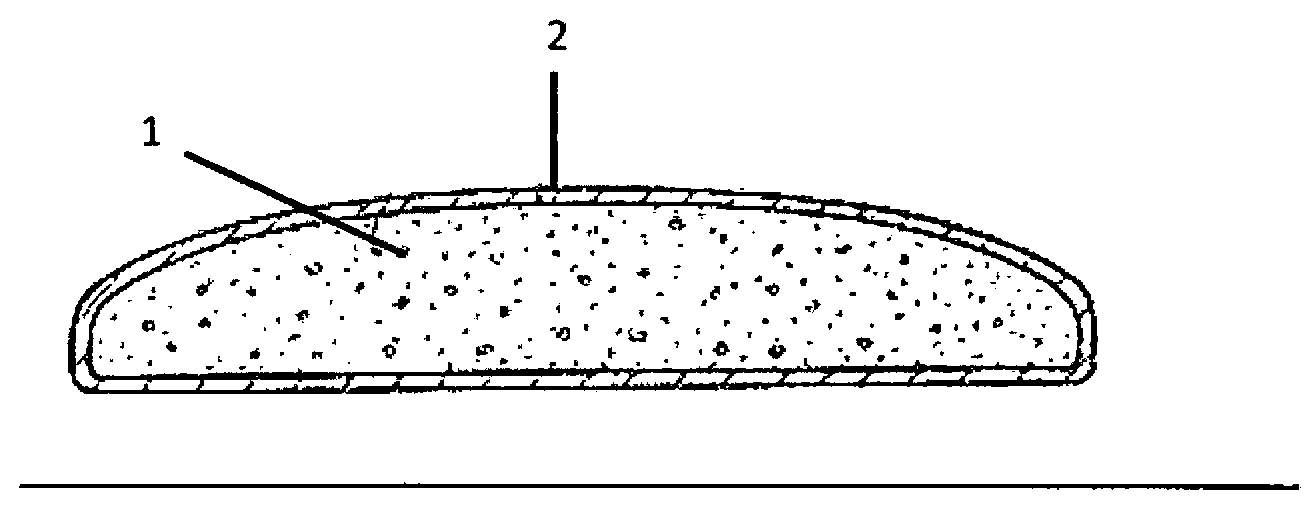

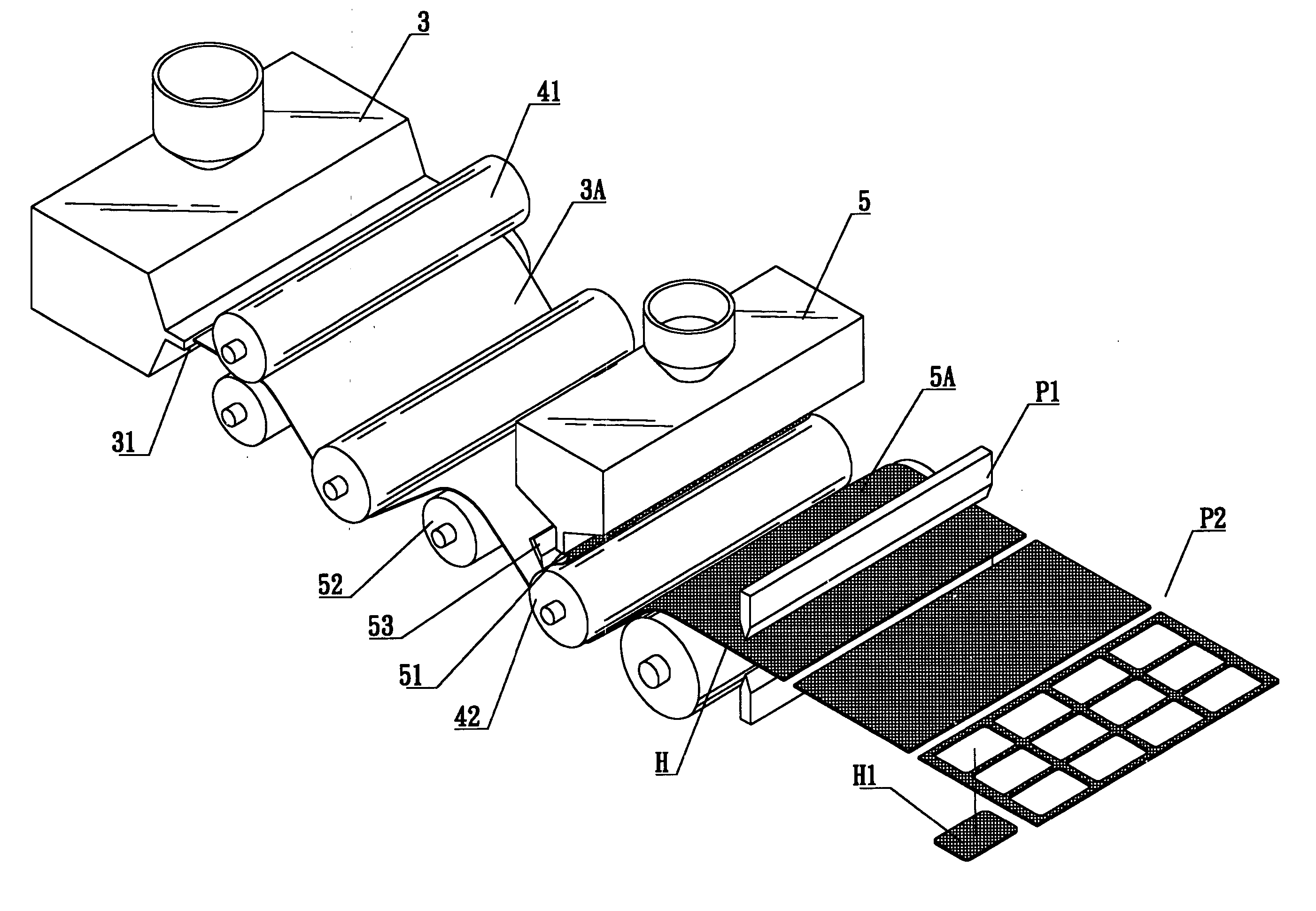

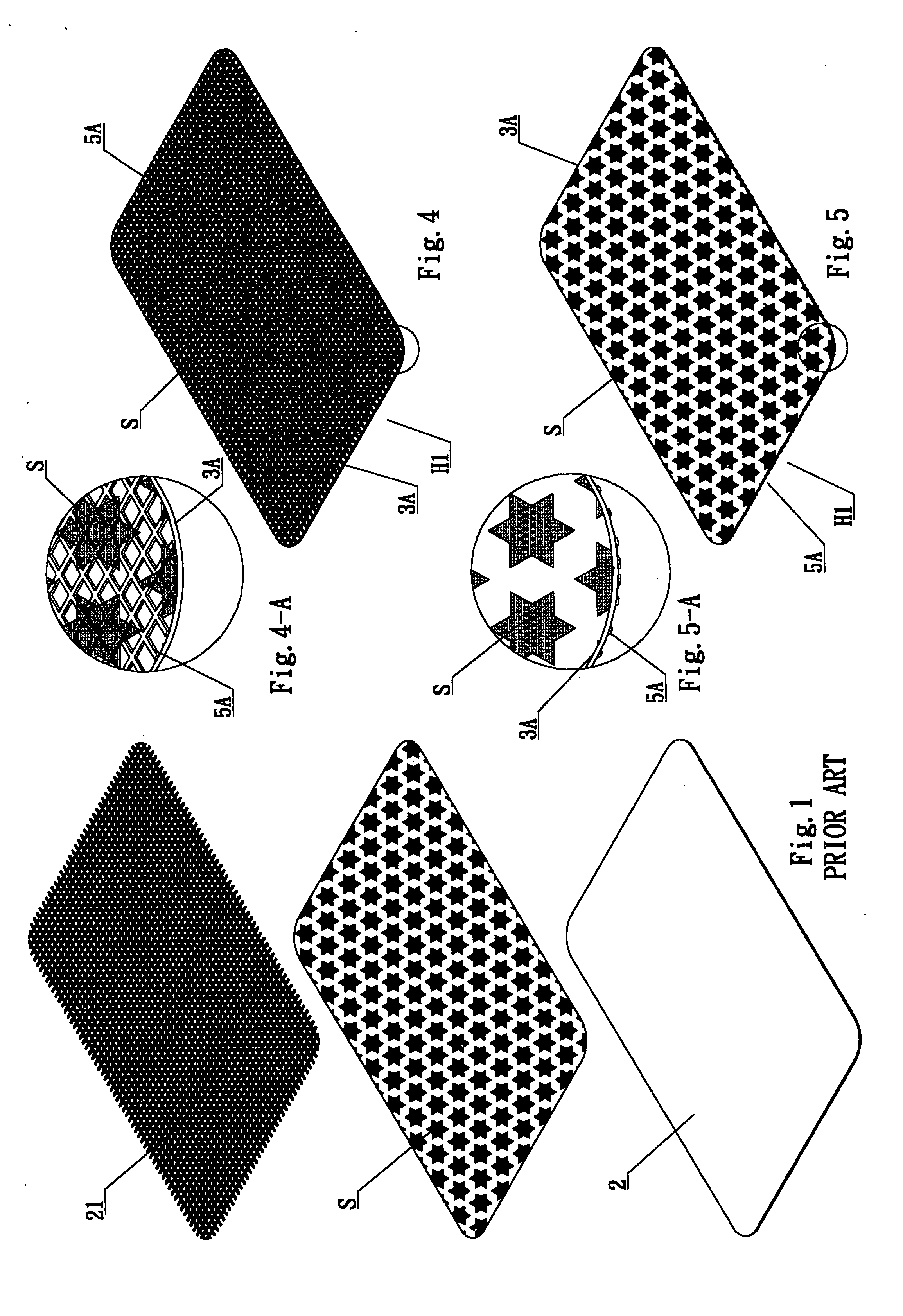

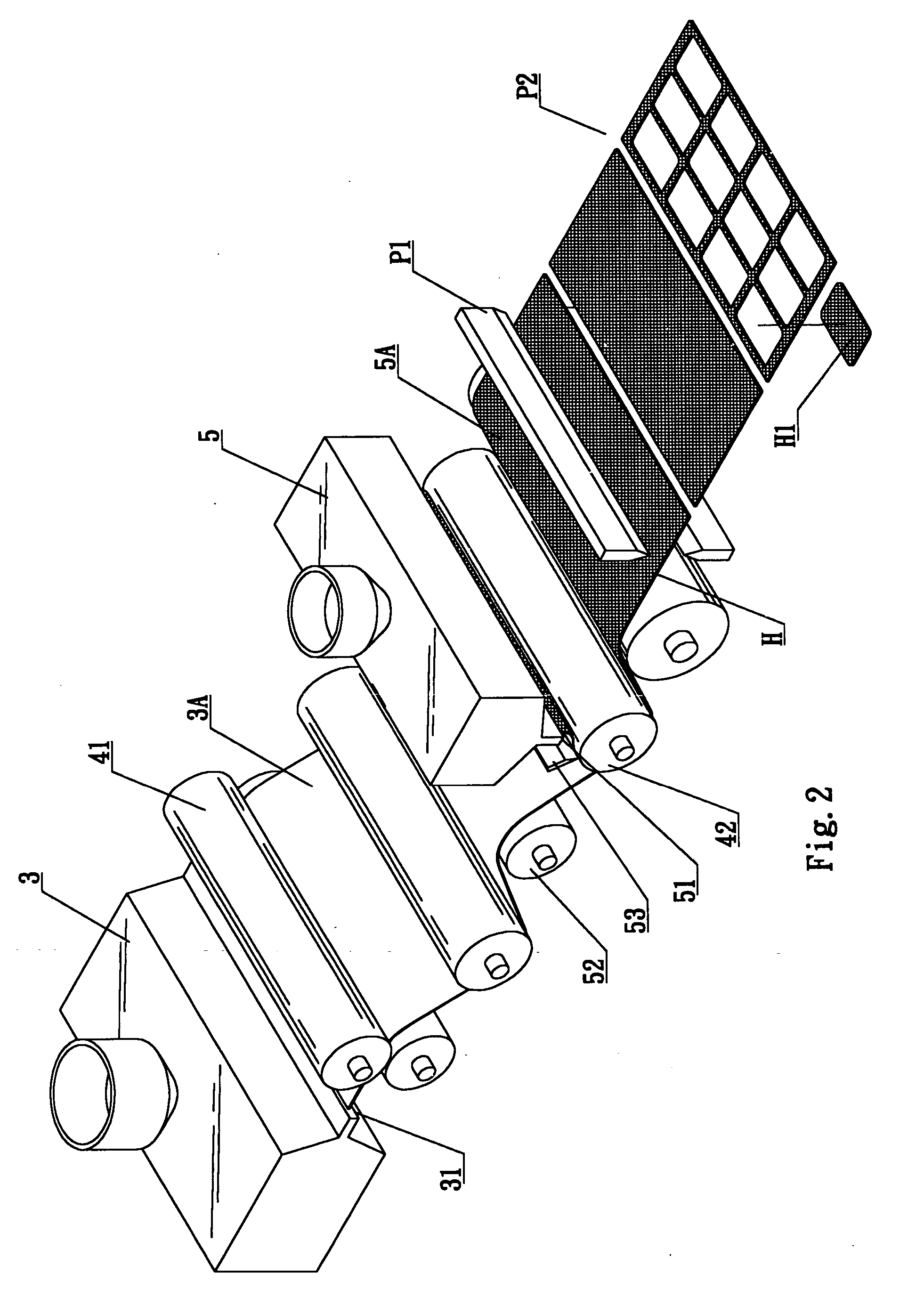

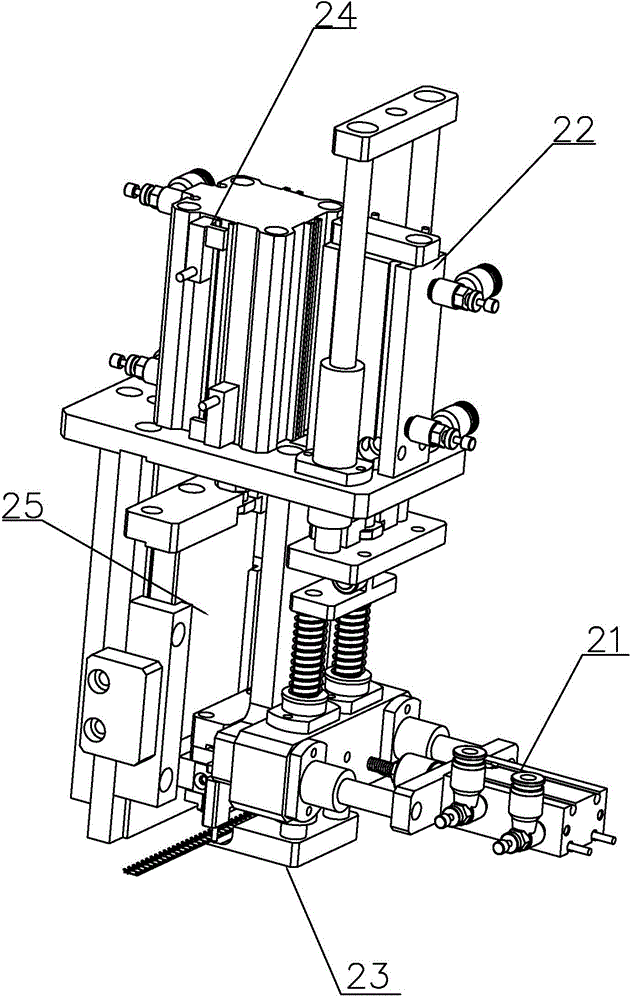

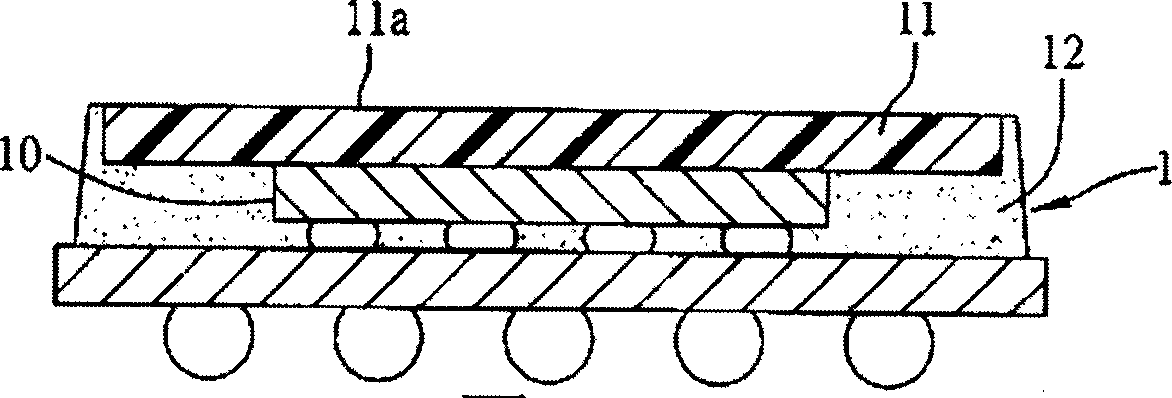

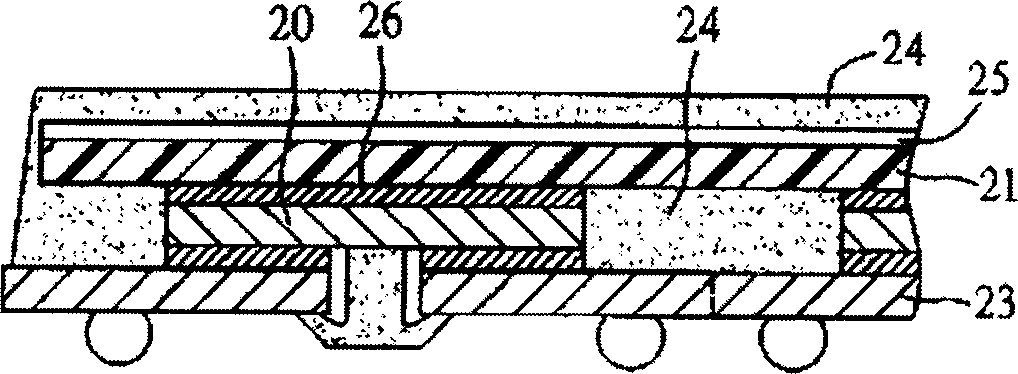

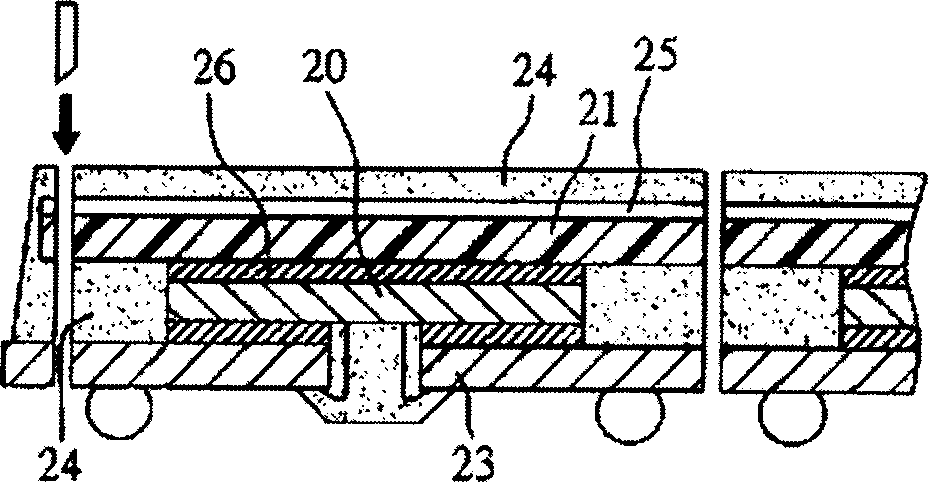

Method for coating a core of an arbitrary shape by thermoforming, automatic machine for the implementation thereof and finished product obtained by such a method

The invention relates to the coating of preformed objects with sheets of polymer material. More specifically, the invention relates to a method for coating a preformed core (1) having two faces and an edge around the periphery of the core, which edge links the two faces, said method comprising the thermoforming of a polymer material. The coating is formed by the heating, gluing and vacuum application of the two sheets of polymer material (20, 30) which are applied successively to the two faces of the core (1) in order to cover same completely. The invention also relates to an automatic machine for carrying out said method and to the resulting product. The invention can be used to produce finished products, in particular surfboards, furniture or display objects.

Owner:NEWTIS

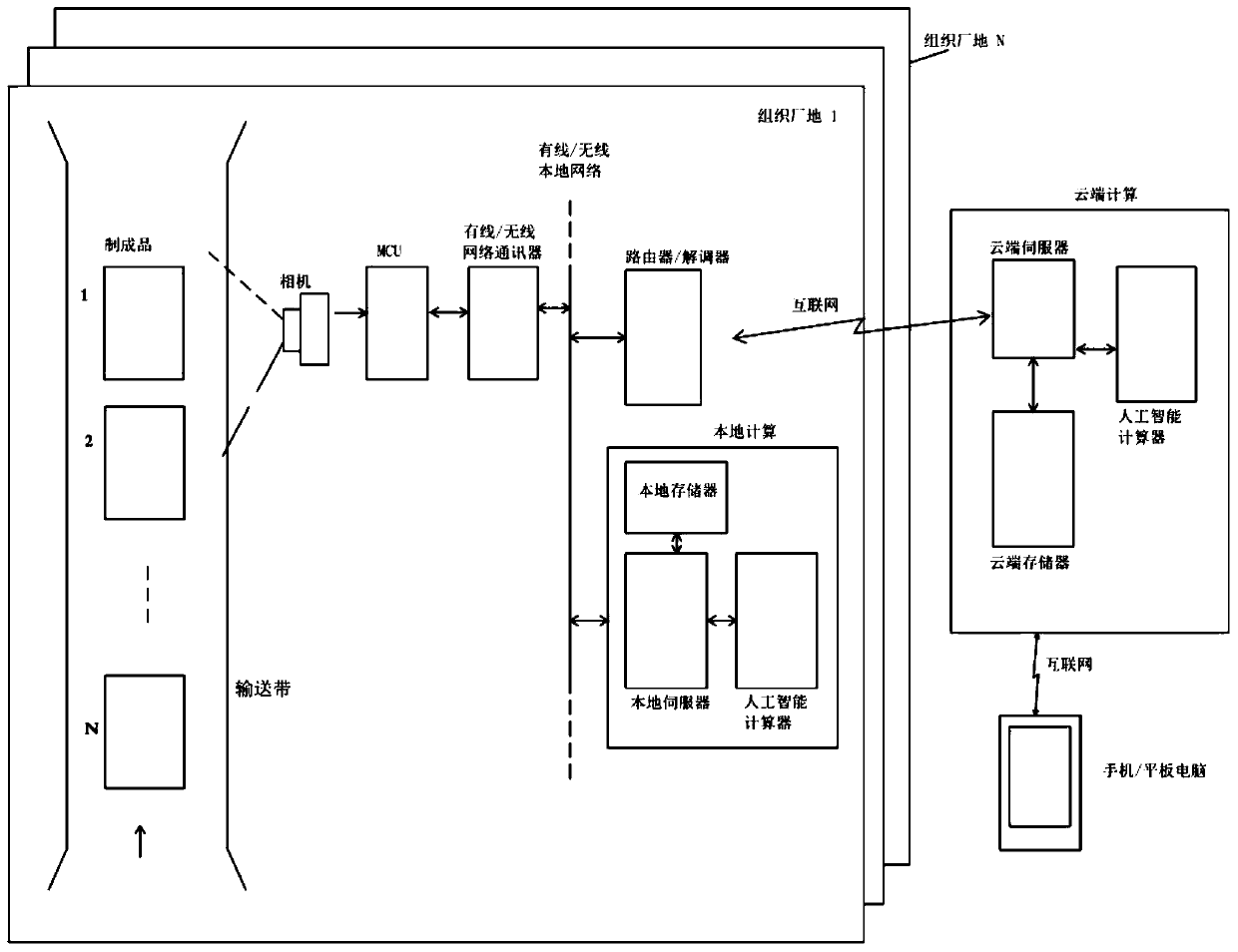

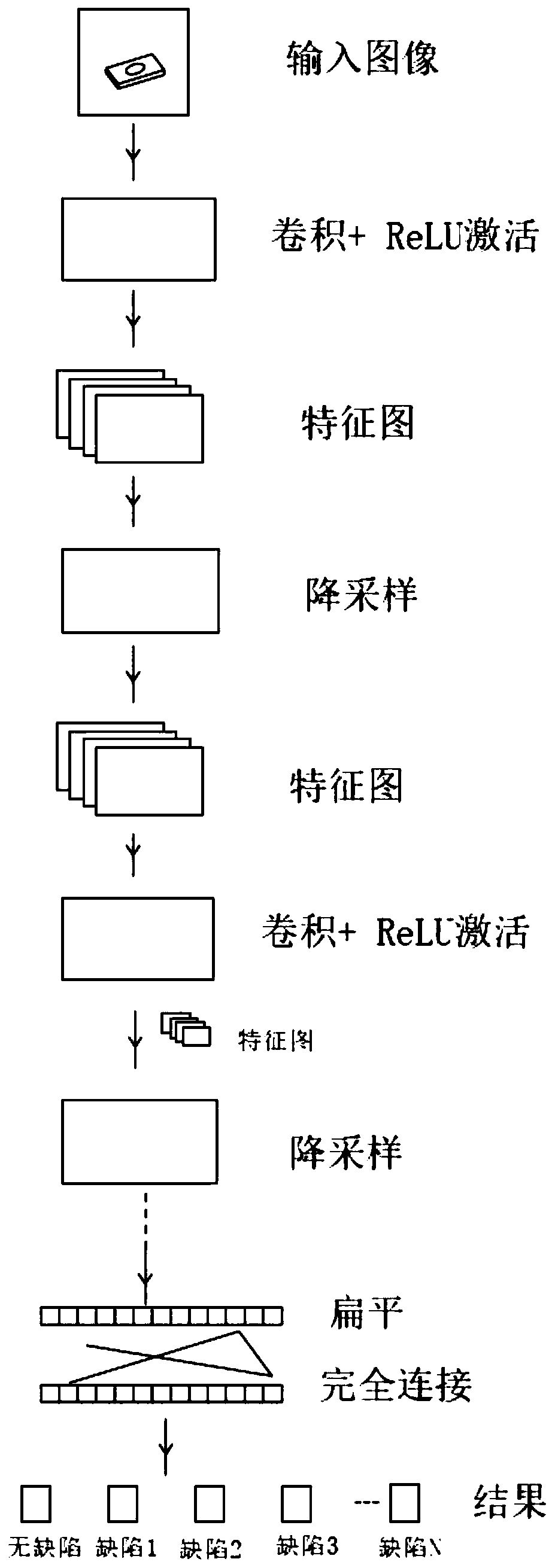

Method for carrying out non-invasive production defect identification and information communication on finished product by applying artificial intelligence cloud computing

InactiveCN110290203AIncrease productivityImprove product qualityClosed circuit television systemsResourcesGraphicsCamera image

The invention discloses a method for carrying out non-invasive production defect identification and information communication on a finished product by applying artificial intelligence cloud computing. An industrial camera is combined, and a micro-processing unit MCU is configured. After the arrangement, the camera can be used for capturing graphic images of finished products; through camera arrangement, a semi-finished product or a completely produced finished product does not need to be connected to a set of test software and hardware; the conveying belt can automatically bring a column of semi-finished products or finished products needing to be detected to the camera; the camera can capture images of the articles very quickly and easily; the micro-processing unit MCU sends a camera image obtained by a finished product passing through the conveying belt to the cloud computing server through a network; and the data is analyzed by artificial intelligence machine learning software in the cloud server, and the data from the cloud server can be directly sent to sites of other suppliers and clients through the mobile Internet connection and is connected to the mobile device for viewing.

Owner:东莞德福得精密五金制品有限公司

Method for continuously manufacturing anti-sliperry chopping boards

InactiveUS20060125141A1Good effectLow production costStretch-spinning methodsCooking vessel constructionsManufacturing technologyMaterial transport

A method for continuously manufacturing anti-slippery chopping boards, and the method uses a bottom mold pressing machine to provide a plastic mold board from the material output mold; the plastic mold board goes through a set of rollers for setting its thickness and is fed to the bottom of the mouth of an anti-slippery material pressing mold with the same width the after a preliminary setting is completed; a fixed-distance scraping board disposed at a material output position on a material transporting roller is used to produce rectangular anti-slippery meshes on the manufactured sheet anti-slippery material by intermittent scraping, so that the anti-slippery meshes can be formed and attached onto the surface of the plastic mold board simultaneously, while the plastic mold board is still not completely solidified. The finished good of the anti-slippery pad is seemingly an integral structure with one layer. After the plastic mold board and the anti-slippery mesh are integrally combined by the follow-up rollers, a thin pad with an anti-slippery bottom surface serving as a temporary chopping board is produced by cutting the plastic mold board into a fixed size, or the anti-slippery material is transferred onto the top surface or the bottom surface of the pad to produce an anti-slippery plastic mold board or an anti-slippery mesh placemat as to achieve a simple, convenient and cost-effective manufacturing process.

Owner:TSAU JU INT

Yarns for industry and fabrics made therefrom

InactiveCN101311397AReduced number of weaving stopsHypoventilation valueMonocomponent polyethers artificial filamentWoven fabricsYarnFiber

The invention discloses an industrial yarn and a fabric manufactured by the yarn. The yarn takes heat resistant fiber as raw material, and the diameter of the yarn at the knot is 0.8 to 2.5 times of that of the yarn at non-knot position. The fabric has small knots and high intensity. The invention provides a product for reducing broken end and machine halt due to big knots and low intensity of yarn when the fabric is weaved, thereby improving the weaving efficiency, the intensity of fabric and the stability of permeability value, and enhancing the combination property of finished goods.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

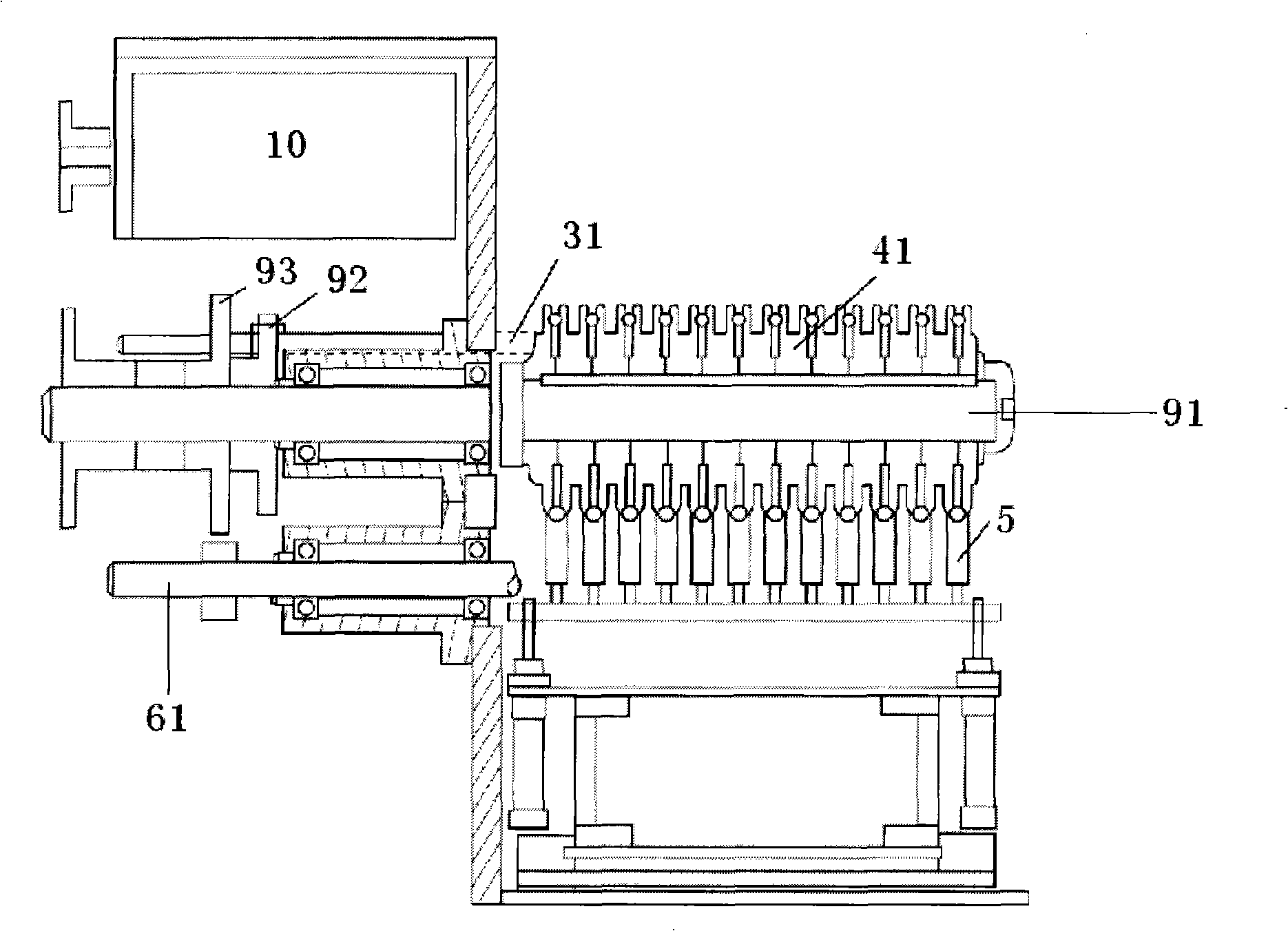

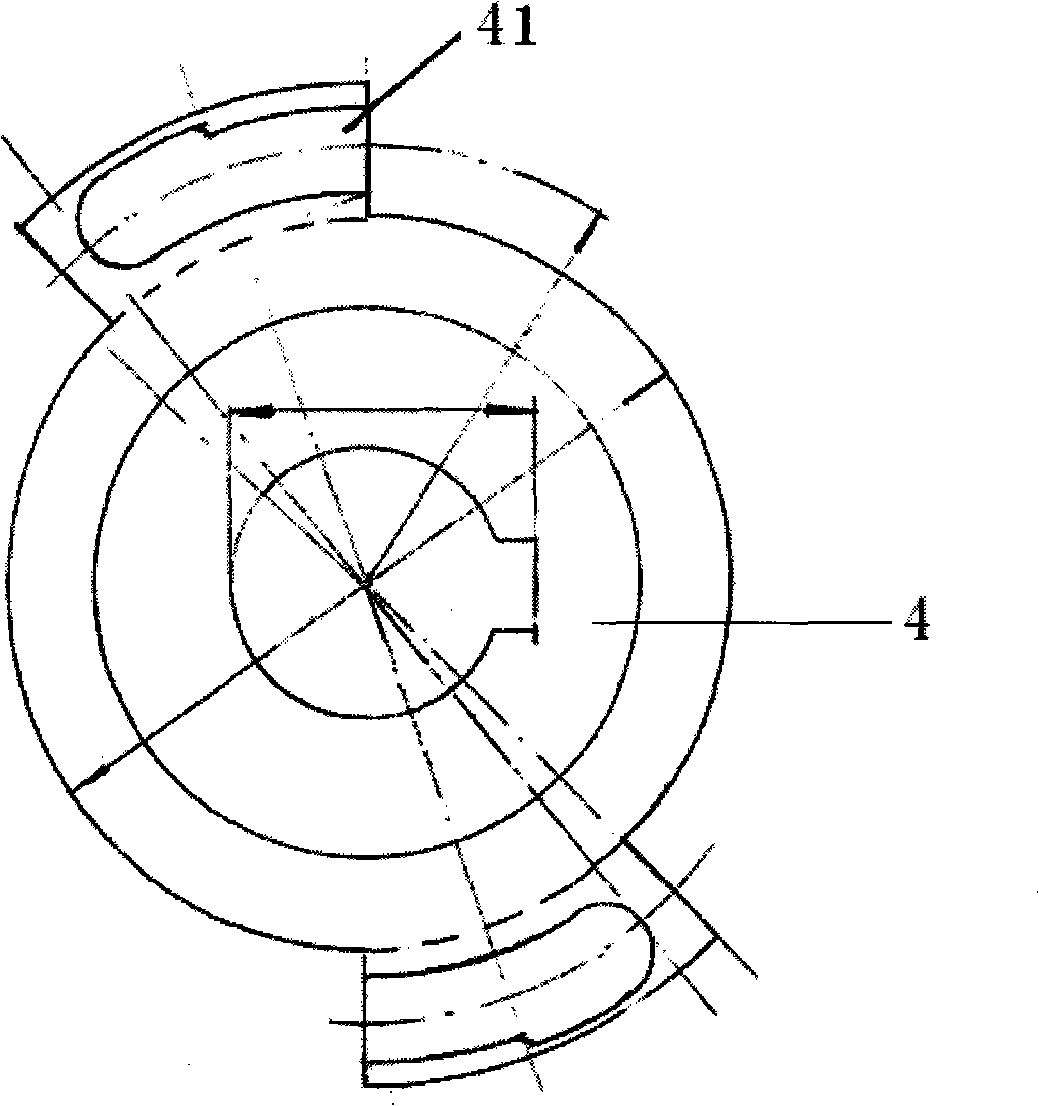

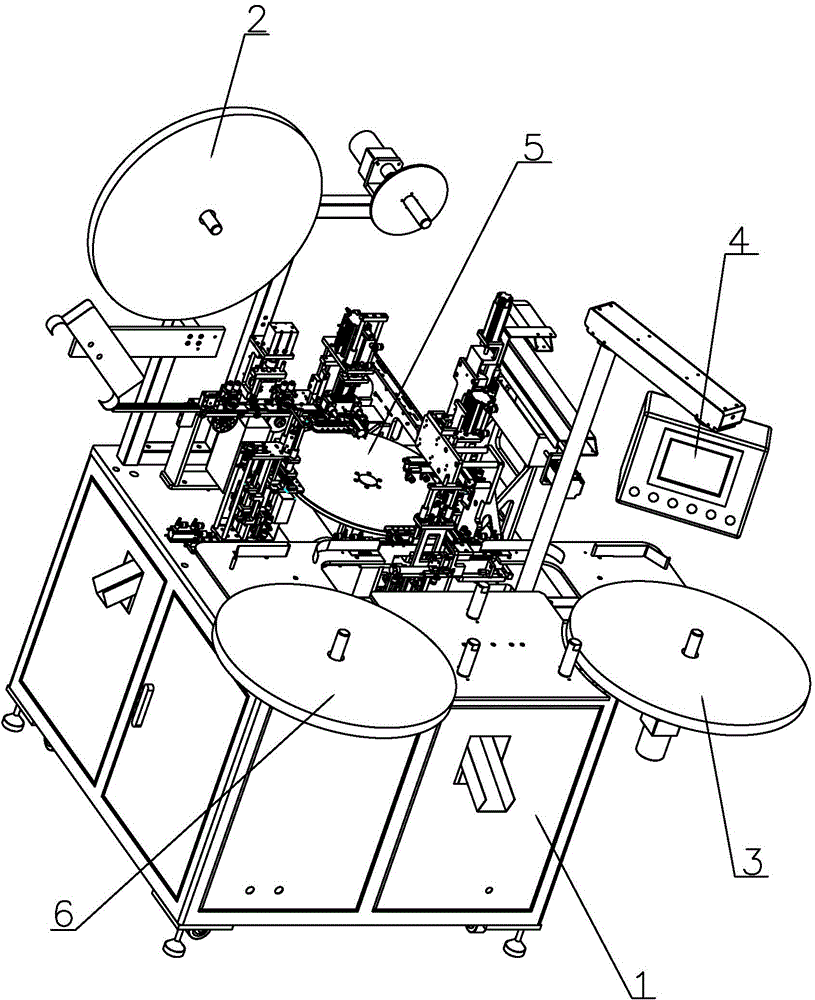

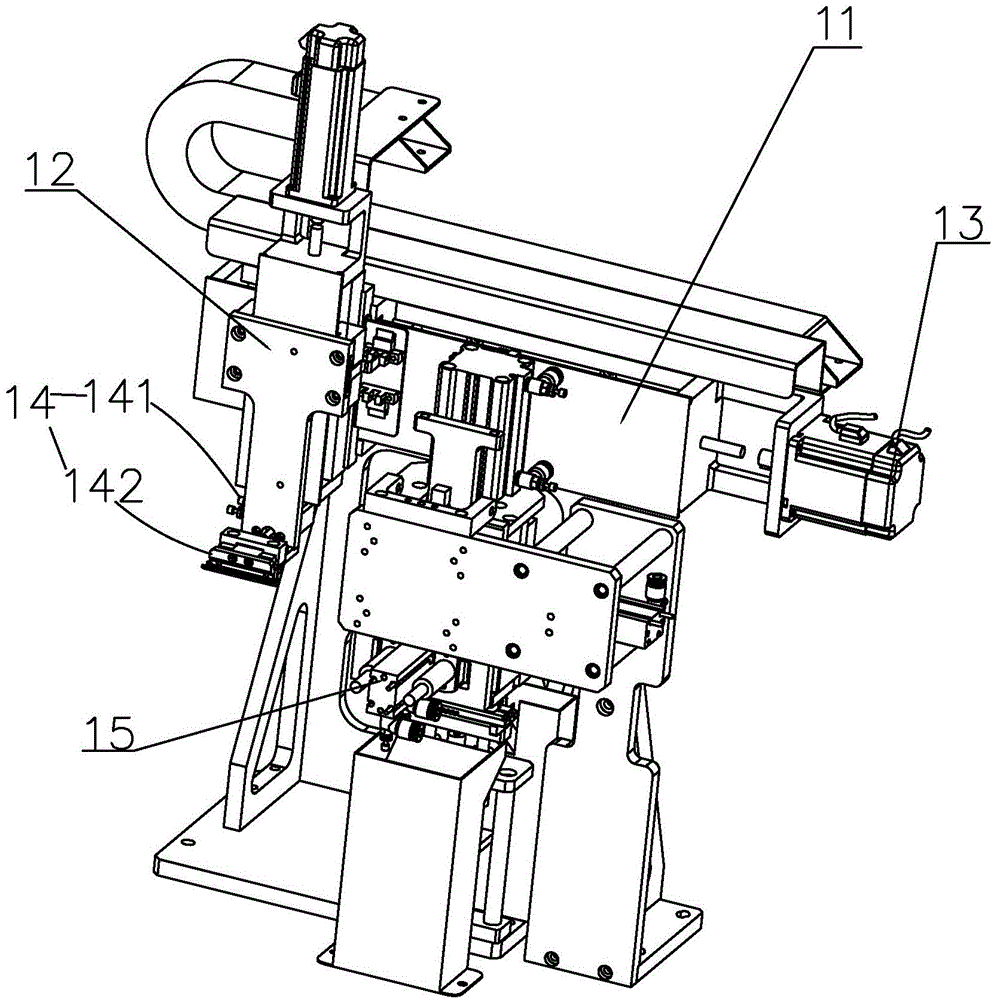

RF terminal assembly device

InactiveCN105024255ANo abnormalityIncrease productivityContact member assembly/disassemblyFinished goodManufacturing engineering

The invention discloses an RF terminal assembly device. Material grabbing mechanisms for grabbing plastic carriers, a material cutting mechanism for cutting material strips, a part assembly mechanism for assembling an RF combination part, a separation device for separating a material strip 1 and the RF combination part and a finished good assembly mechanism for assembling RF finished products are positioned on the circumference of a working table; and the center of the working table is provided with an index dial for conveying materials. The RF terminal assembly device adopts the mechanical production, and the whole product production process does not require manual processing, which improves production efficiency and the product quality.

Owner:KUNSHAN KANGSHUO ELECTRONICS TECH

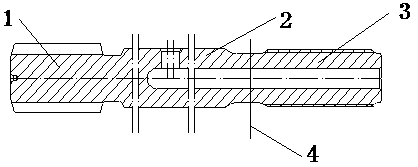

Bit shank manufacturing method

PendingCN110052794AHeat treatment process changesIncrease or decrease in lengthSolid state diffusion coatingFurnace typesFriction weldingSlag

The invention discloses a bit shank manufacturing method which comprises the following steps of regarding a bit shank as a divisible part, wherein the bit shank is divided into a left-side spline endand a right-side screw-thread male connector and is formed by combining a left part and a right part; (1) processing the screw-thread male connector; (2) processing the spline end; and (3) processingthe bit shank: A, selecting the spline end matched with a jackdrill, and the corresponding screw-thread male connector; B, using a friction welding machine for welding the spline end, the screw-threadmale connector and a middle cooperation end; C, removing internal and external welding trimmings, namely, welding slags; D, carrying out heat treatment on the welding part again; E, carrying out nondestructive inspection on the welding part; F, straightening and removing the straightening stress; G, feeding on a cylindrical grinding machine, grinding a middle part until the dimension meets the drawing requirement, polishing planes at two ends, and ensuring that the two end surfaces are parallel and perpendicular to a middle axis at the same time; and H, after passing inspection, coating anti-rust oil, packaging and storing. The spline end can be matched with multiple screwed joints, so that the material is saved; flexible and customized production can be realized; and the stock of finished goods in a warehouse is reduced.

Owner:刘艺纯

Method for warehousing cigarette cases via automatic logistics system

InactiveCN102530290AAvoid breakingRealize fully automated storageConveyor wrappingLogistics managementEngineering

The invention relates to a method for warehousing cigarette cases via an automatic logistics system, comprising the following steps: 1) transmitting stacked cigarette cases to an automatic film covering machine; 2) carrying out film covering on the cigarette cases by the automatic film covering machine; and 3) sending the film-covered cigarette cases to a finished goods warehouse for storage. By adopting the method of the invention, the breakage of the cigarette cases during the logistic transportation is basically prevented, the cost of human resource and the intensity of manual labor are reduced, and the danger of cigarette case strapping staffs operating on a conveyor belt is avoided. Before film covering is carried out on the cigarette cases by the automatic film covering machine, height detection can be firstly carried out on the cigarette cases, a film covering model preset in the system is called according to the height of the cigarette cases, and then cutting is carried out on a plastic film used for film covering. In such way, individualized film covering can be carried out according to the actual number and the sizes of the cigarette cases, and the flexible production demands of a factory can be satisfied.

Owner:SHANGHAI TOBACCO GRP CO LTD

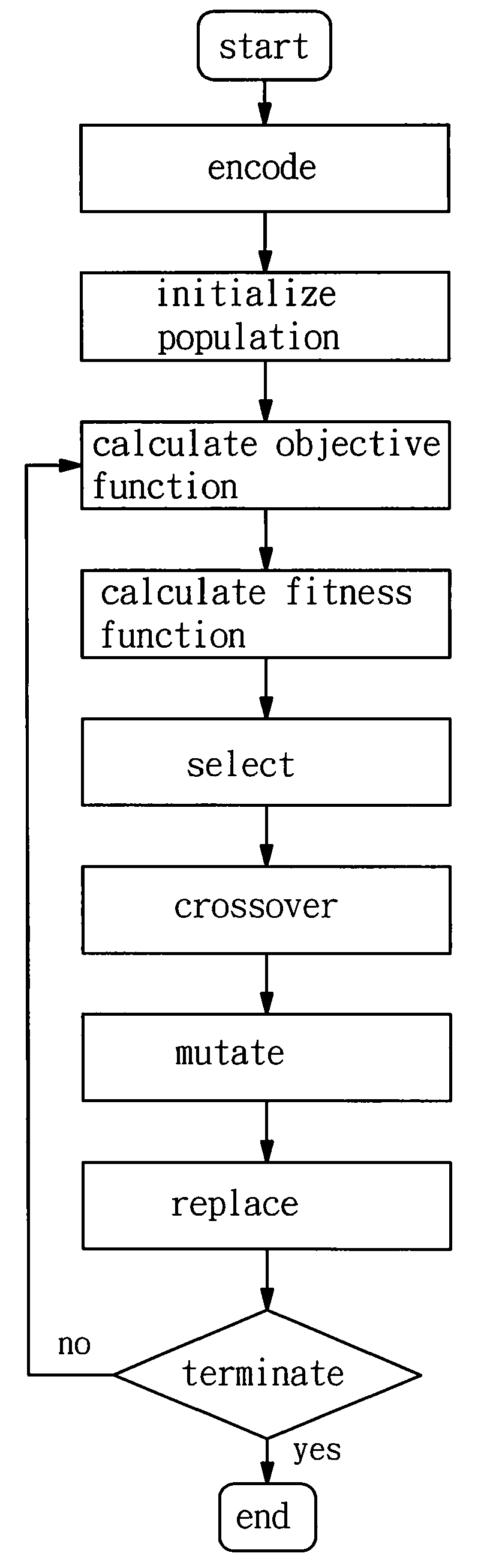

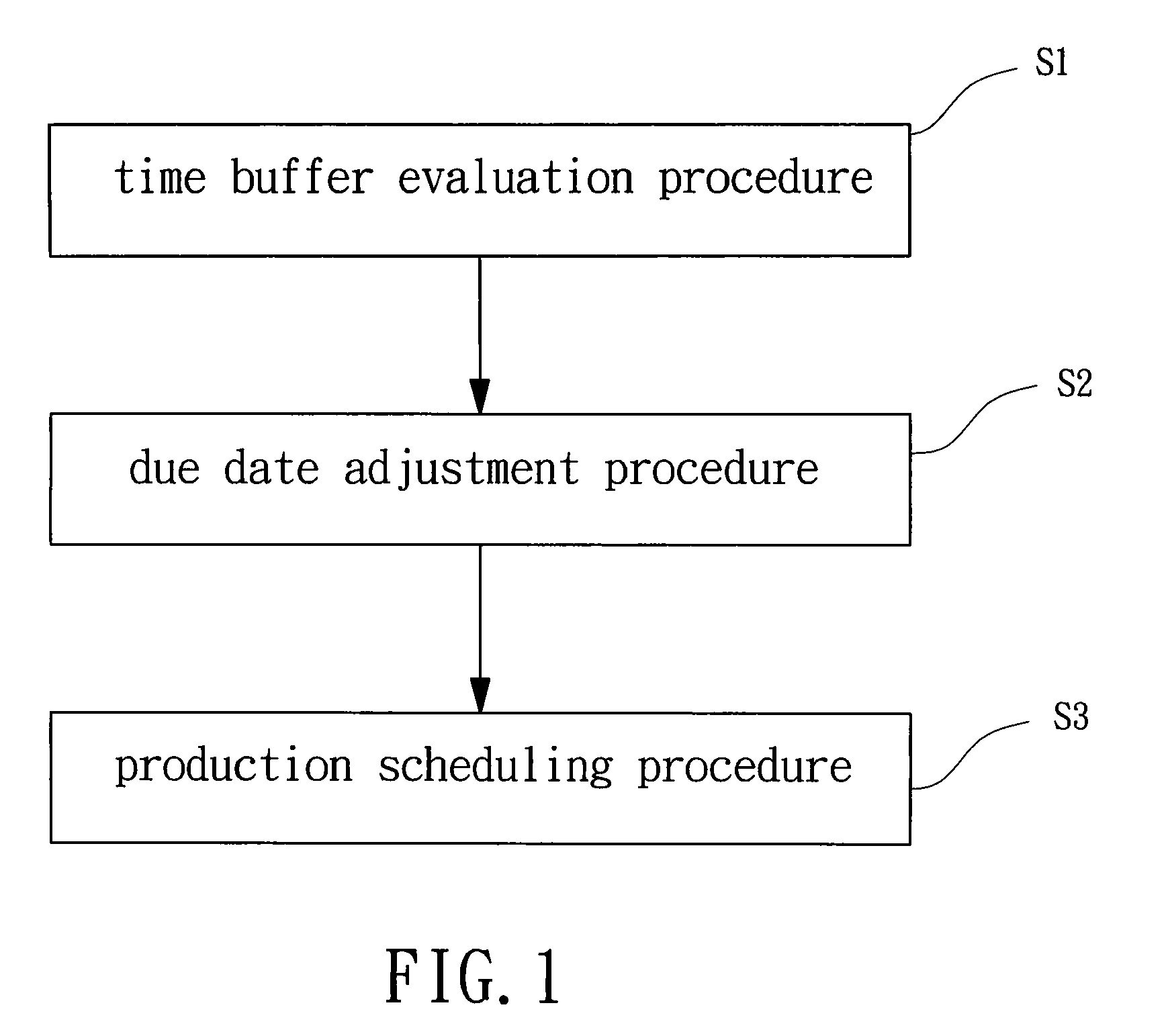

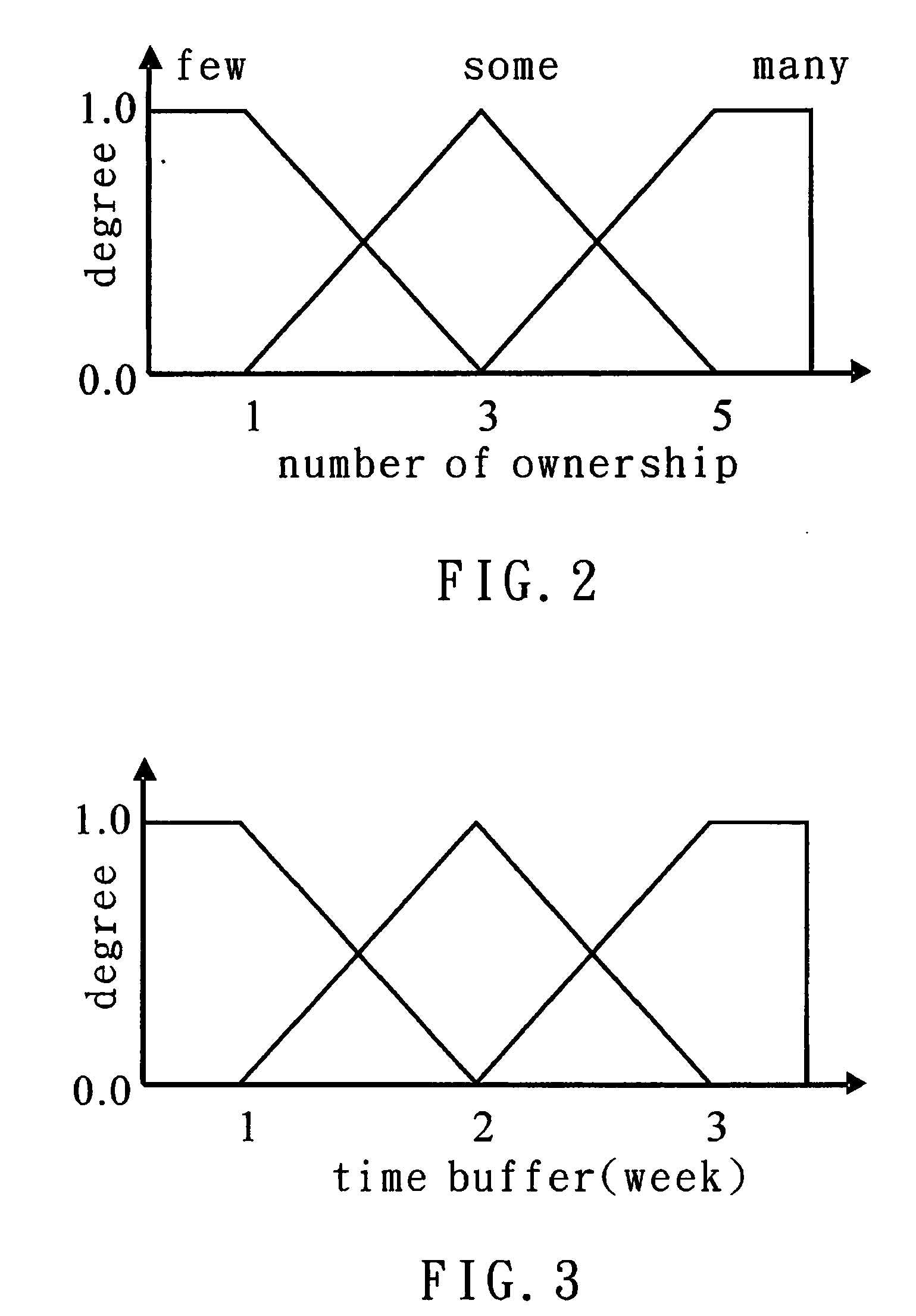

Method for reducing finished goods inventory for precast fabricator

A method for reducing finished goods inventory for a precast fabricator includes a buffer evaluation procedure to evaluate a time buffer via a fuzzy logic using customer characteristics, element characteristics, and building characteristics as parameters. A due date adjustment procedure is then carried out to adjust production due dates of the elements according to the time buffer and erection dates of the building. Finally, a production scheduling procedure is used to arrange a production sequence for fabricating the elements based on the adjusted production due dates.

Owner:NAT PINGTUNG UNIV OF SCI & TECH

Heat radiation type packaging structure and its making method

InactiveCN1828853ANot easy to produce burrsReduce wear and tearSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureSemiconductor chip

A heat radiation type packaging structure and method of preparation, said packaging structure includes chip carrier, semiconductor chip, heat radiation piece and packaging colloid. It contains connecting at least one semiconductor chip on chip carrier, connecting heat radiation piece on said chip, to proceed packaging moulding process, cutting packaging assembly to expose side of said heat radiation piece, removing out packaging colloid on metallic film of heat radiation piece to expose metallic film, said metallic film and heat conduction through hole for radiating heat in operation. The present invention avoids chip rhegma and spillover glue problem in moulding process, and then raising finished goods rate.

Owner:SILICONWARE PRECISION IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com