Heat radiation type packaging structure and its making method

A packaging structure and heat dissipation technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of high loss of stamping or cutting tools, inability to greatly improve production efficiency, and affect the appearance of packages, etc., to achieve Less wear and tear, good for cutting cost control, less prone to burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

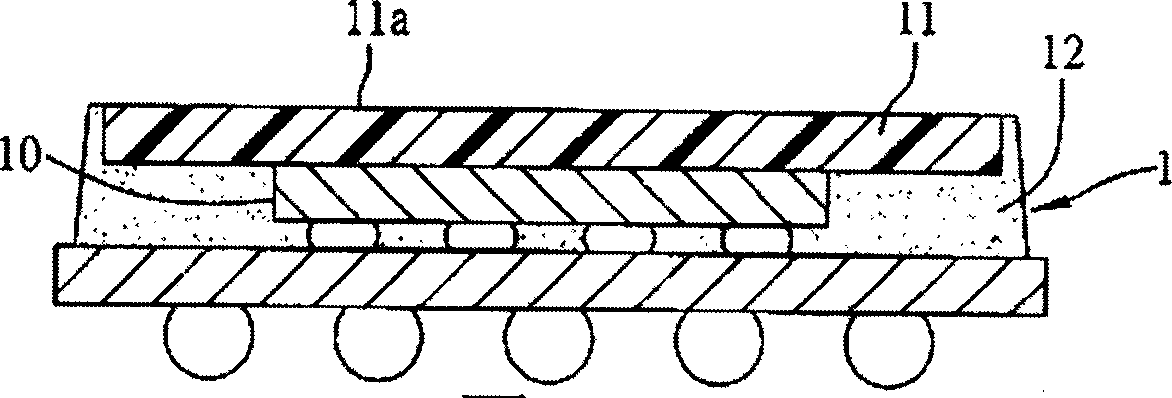

[0043] see Figure 4A to Figure 4F , which is a schematic diagram of the manufacturing process of Embodiment 1 of the heat dissipation packaging structure manufacturing method of the present invention.

[0044] Such as Figure 4A and Figure 4B As shown, first, a matrix substrate module sheet 40A is provided, and the substrate module sheet 40A is formed by arranging a plurality of substrate units 40 in an array. The substrate unit 40 has an upper surface 400 and a lower surface 401 respectively, and defines a through hole 402 . The substrate units 40 can be arranged in a straight strip besides being arranged in an array, and a single substrate unit can also be used if the process conditions permit.

[0045] Next, at a predetermined position on the upper surface 400 of each substrate unit 40, the active surface 41a of the chip 41 is placed on it through an adhesive layer 45 such as silver glue, and the chip 41 is made to close the hole 402. At one end, a plurality of bondin...

Embodiment 2

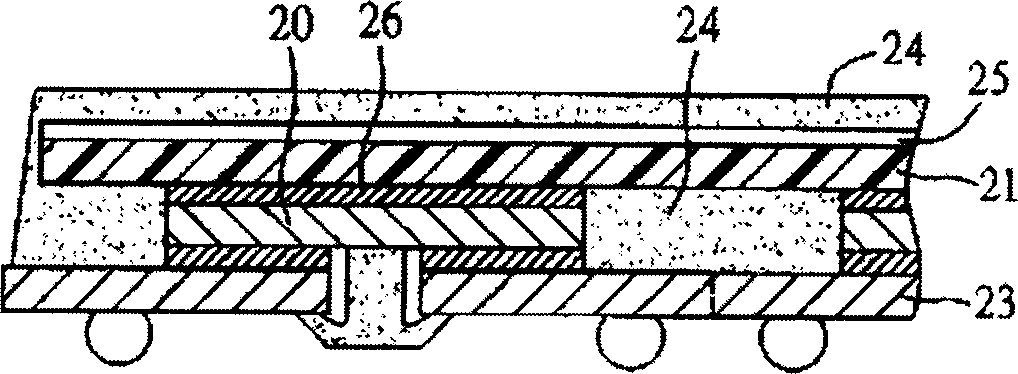

[0052] Please refer to FIG. 5A to FIG. 5G , which are schematic diagrams of the manufacturing process of Embodiment 2 of the heat dissipation packaging structure manufacturing method of the present invention. The manufacturing process of Embodiment 2 of the present invention is substantially the same as that of Embodiment 1, the main difference being that the semiconductor chip in Embodiment 2 is flip-chip connected and electrically connected to the substrate.

[0053] Figure 5A and Figure 5BAs shown, first, a matrix substrate module sheet 50A is provided, and the substrate module sheet 50A is formed by arranging a plurality of substrate units 50 in an array. The substrate units 50 each have an upper surface 500 and a lower surface 501 . Wherein, the substrate units 50 can also be arranged in a straight strip besides being arranged in an array, and a single substrate unit can also be used if the process conditions permit.

[0054] Next, at a predetermined position on the up...

Embodiment 3

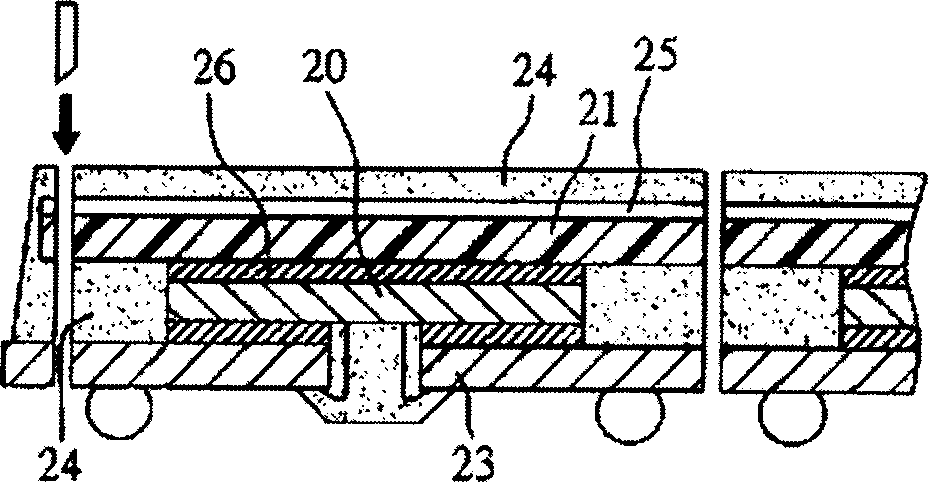

[0061] see Figure 6 As shown, it is a schematic cross-sectional view of Embodiment 3 of the semiconductor package structure manufactured by referring to the above heat-dissipating package structure manufacturing method of the present invention. The packaging structure of the present invention includes: a chip carrier, a semiconductor chip, a heat dissipation piece, and a packaging colloid. The semiconductor package structure of the present invention is made by a method similar to Preparation Example 1 and Example 2, the difference is that, in the semiconductor package structure of this embodiment, the heat sink connected to the semiconductor chip 61 63 is formed with an opening 63b at the position corresponding to the chip 61, that is, the metal thin layer 631 and the insulating core layer 630 part of the lower surface of the heat sink 63 are removed at the position of the chip 61, so that on the heat sink 63 Form the opening 63b that exposes the metal thin layer 631 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com