A numerical control intelligent load cutting machine

A cutting machine and load technology, which is applied in the field of numerically controlled intelligent load cutting machines, can solve problems such as imperfections, and achieve the effects of reasonable structure, novel design, and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

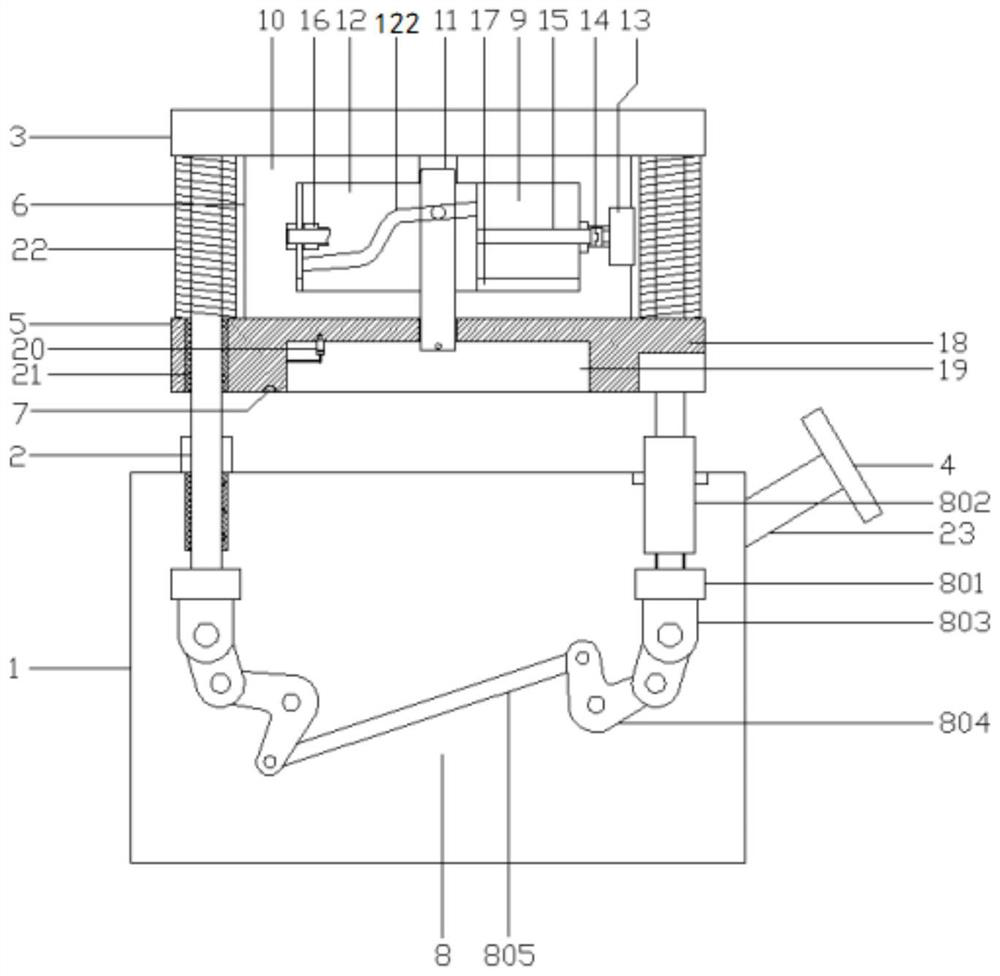

[0045] In actual use, the sound wave detector on the punching head sends the thickness signal of the material to be cut on the workbench of the body to the central control device, and displays it on the display screen. The material is input with the corresponding cutting program through the keyboard (in the processing of a single material, the corresponding cutting program is automatically set by the central control device according to the thickness of the material), and the control signal of the cutting program is sent to the hydraulic control system and buffer Cutting mechanism; when the hydraulic control system receives the control signal, it drives the oil cylinder on the transmission mechanism, and the punching head is driven by the oil cylinder to drop to 0-50mm above the material to be cut (or press on the material to be cut); the buffer cutting mechanism receives When controlling the signal, the drive controller sends a signal to the stepper motor, so that the spindle o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com