Method for manufacturing bronze pipe

A tin bronze and copper tube technology, applied in the field of tin bronze tube preparation, can solve problems such as immature technology, unsatisfactory quality, and equipment precision defects, etc., and achieve the effect of strong operability and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

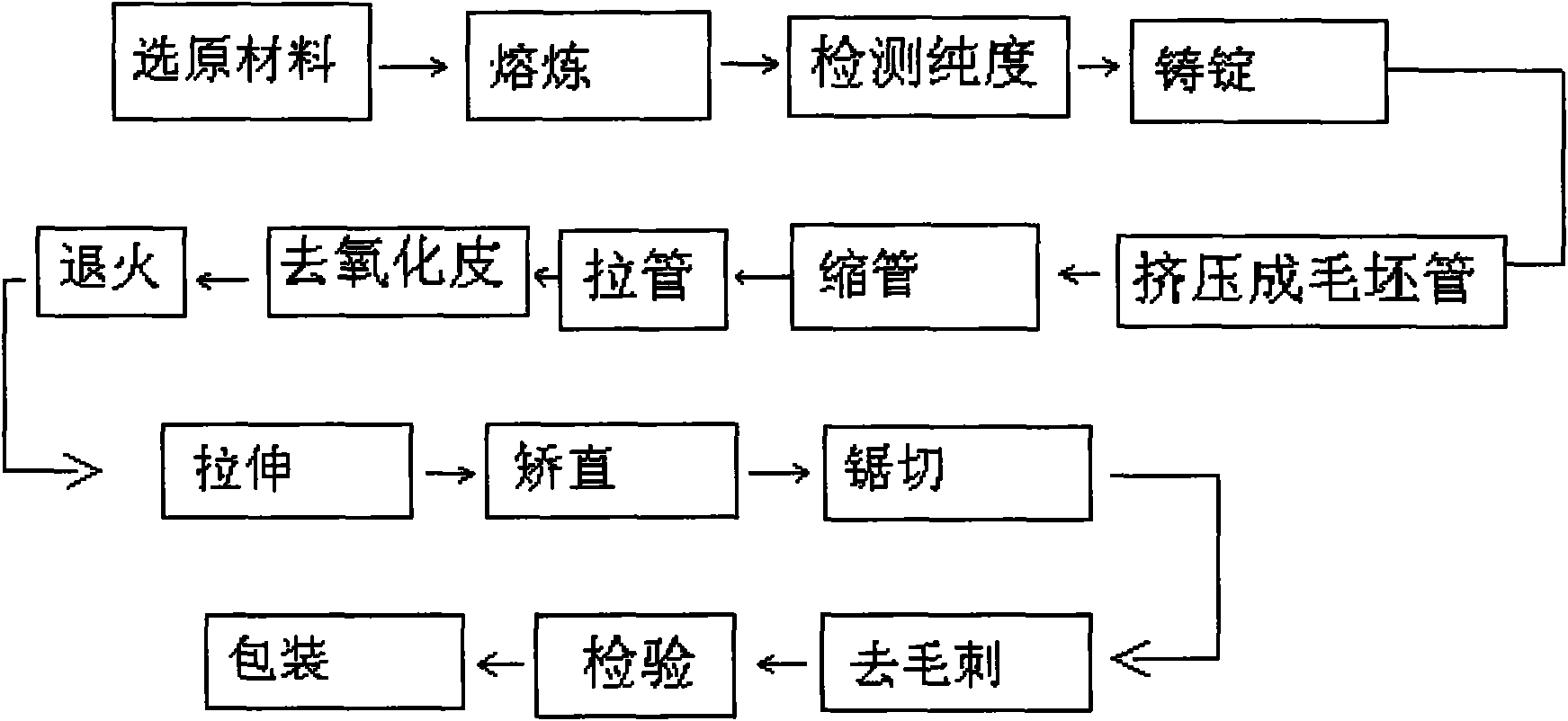

[0028] As shown in accompanying drawing, a kind of preparation method of tin bronze tube specifically comprises the following steps:

[0029] (1) Select electrolytic copper as the raw material for production, and use a power frequency induction furnace to melt the raw material. As a preferred solution, the electrolytic copper uses 1# electrolytic copper, and the power frequency induction furnace used is a high-power power frequency induction furnace that can be used in a short time Melt the raw material.

[0030] (2) Use the fully continuous horizontal dummy mechanism to cast copper water into copper ingots; using the fully continuous horizontal dummy mechanism can quickly and stably cast copper water into copper ingots;

[0031] (3) The copper ingots are shelled and extruded into various rough tubes by using a hydraulic double-action extrusion machine; the advanced hydraulic double-action extrusion machine can effectively and quickly shell the copper ingots and extrude them i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com