A landscape garden pavement laying machine

A pavement laying and gardening technology, applied in the field of landscape gardening, can solve the problems of wasted laying man-hours, labor costs, and low laying efficiency, and achieve the effects of reducing workload, preventing warping or misalignment, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

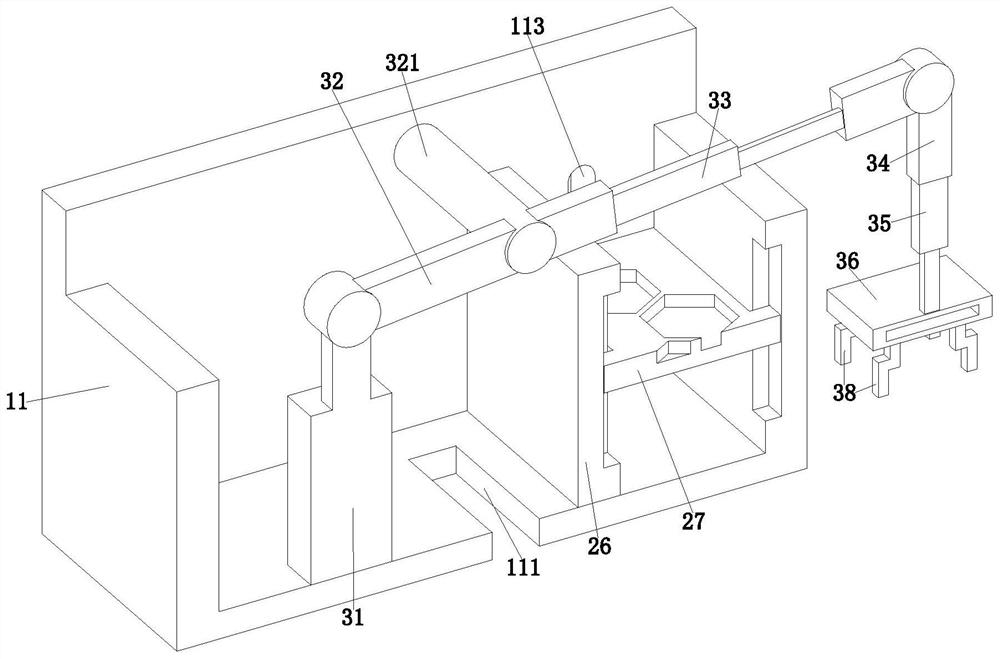

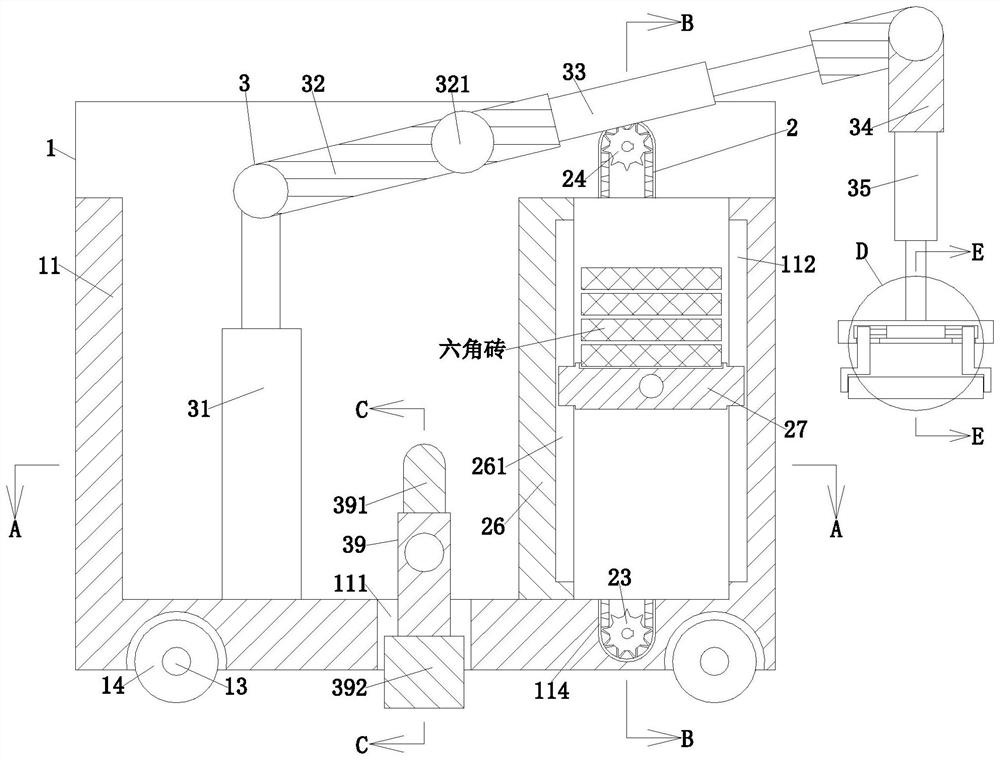

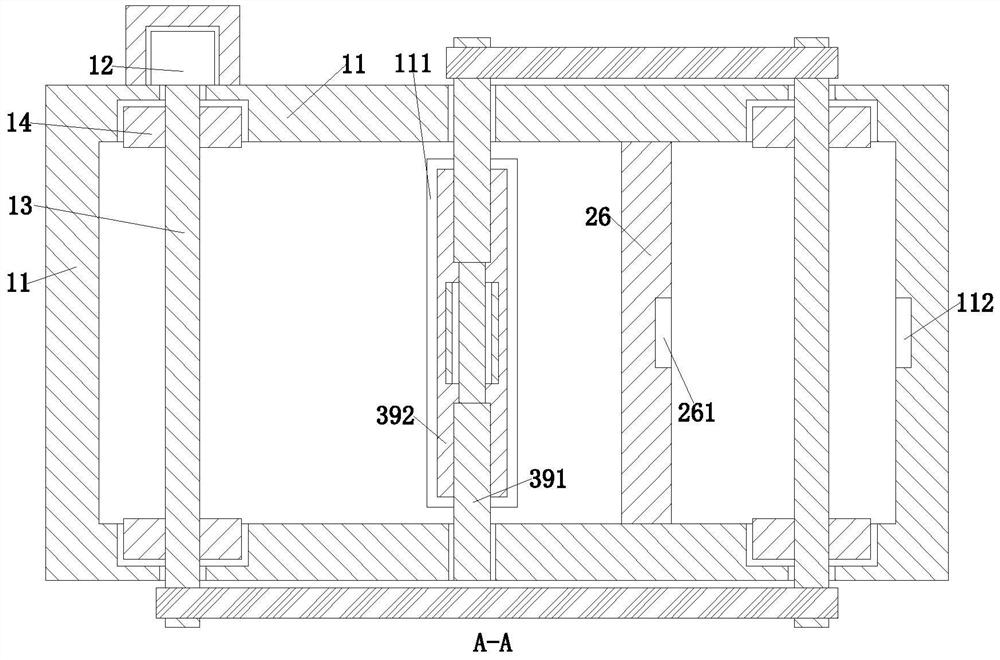

[0033] Such as Figure 1 to Figure 10 A landscape pavement paving machine shown includes a frame 1, a feeding unit 2 and an execution unit 3. The left view of the frame 1 is a concave structure, and a linkage hole 111 is opened in the middle of the lower end of the frame 1 for supplying The material unit 2 is set on the inner wall on the left side of the middle part of the lower end of the frame 1, and the execution unit 3 is set on the inner wall of the linkage hole 111 on the inner wall of the lower end of the frame 1, wherein:

[0034] The frame 1 includes a laying shell 11, a drive motor 12, a transmission shaft 13 and a moving roller 14, wherein: the laying shell 11 is a concave structure in a left view, and the middle part of the lower end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com