Patents

Literature

56results about How to "Make sure you meet the requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

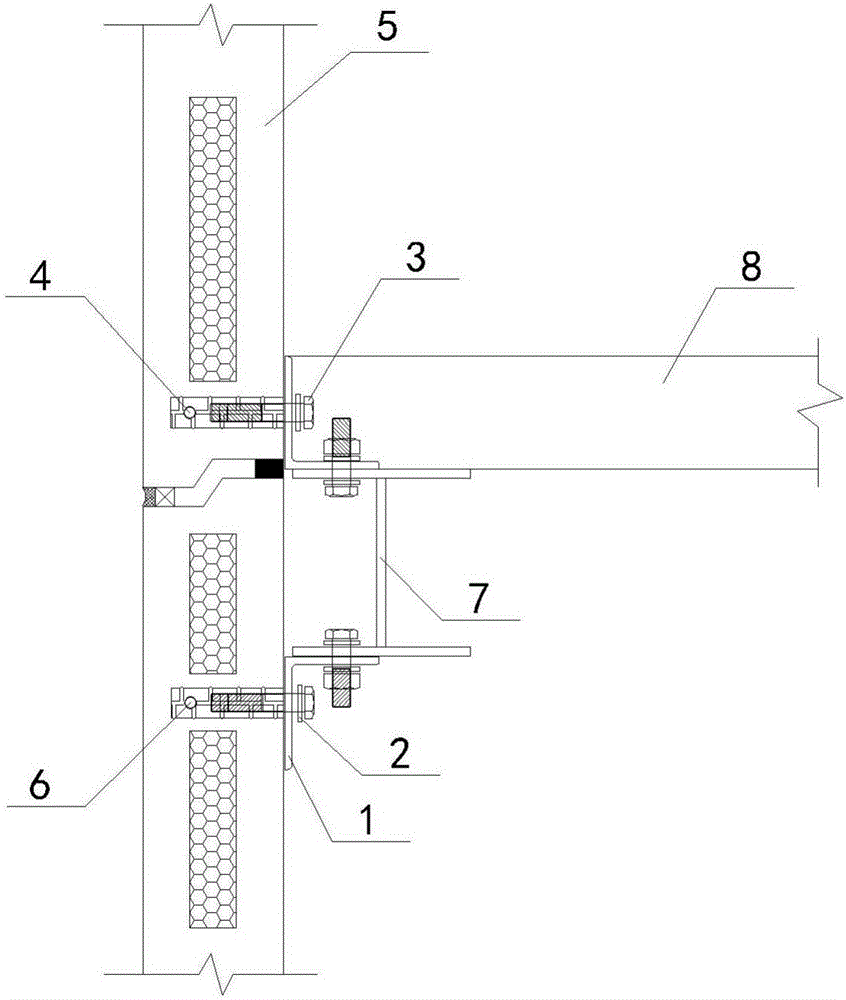

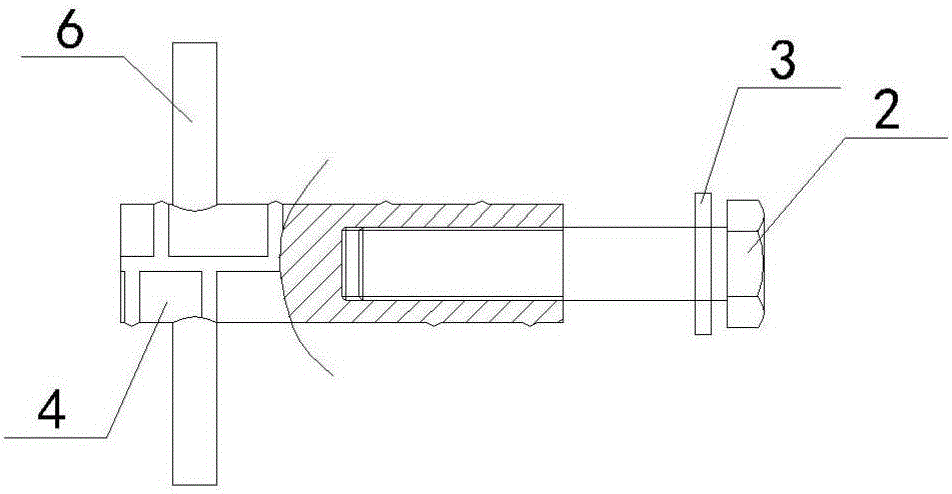

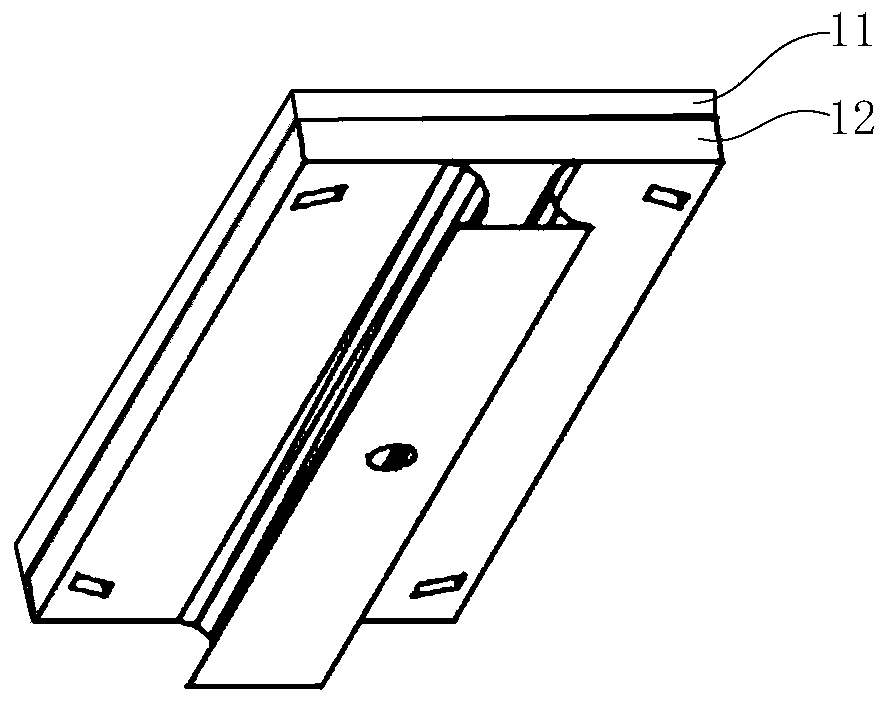

Moveable connecting structure of assembled steel structure outer hanging type wall slab

PendingCN106836514AImproved ability to resist sideways movementDissipate seismic energyProtective buildings/sheltersShock proofingWall plateFloor slab

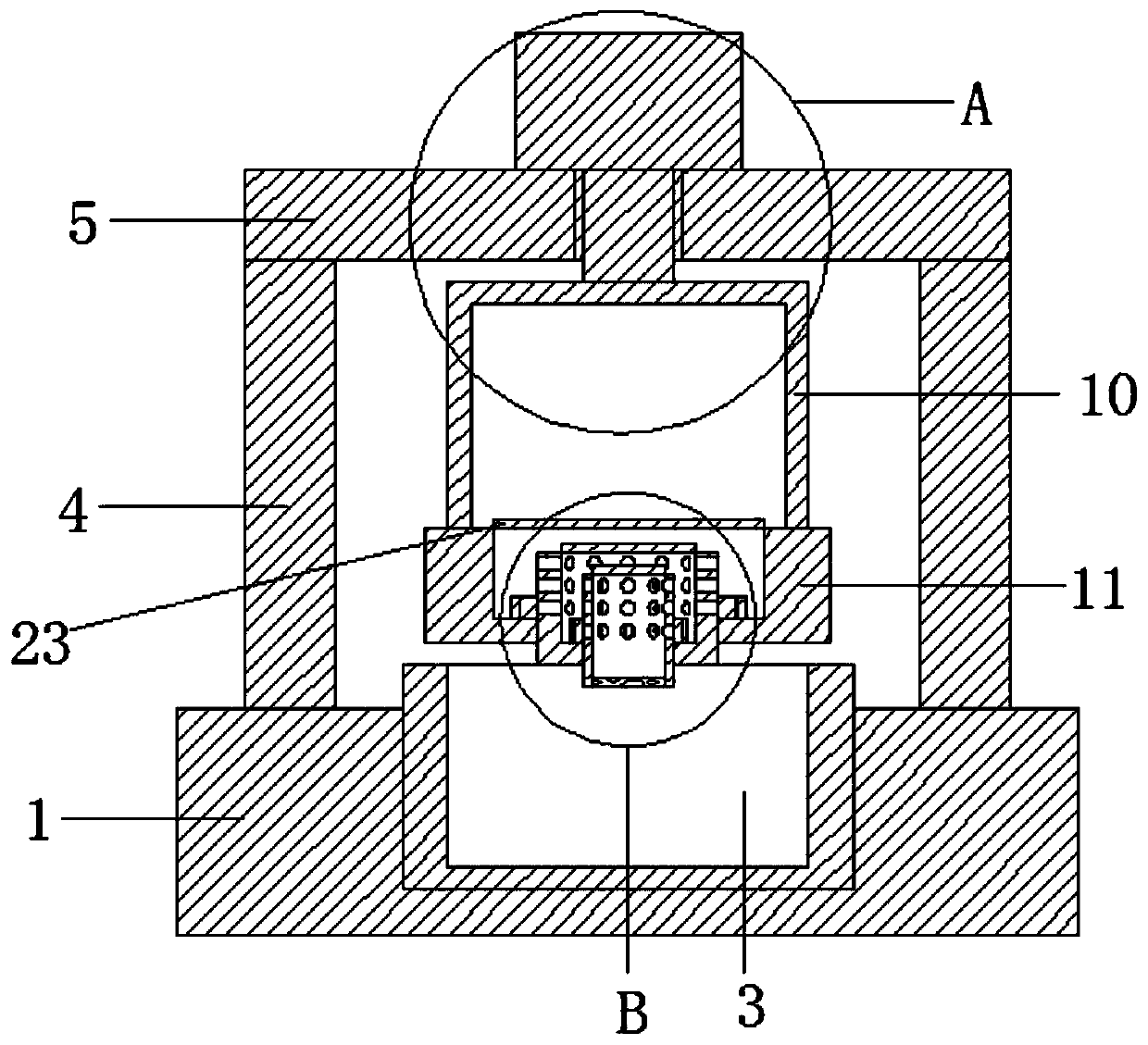

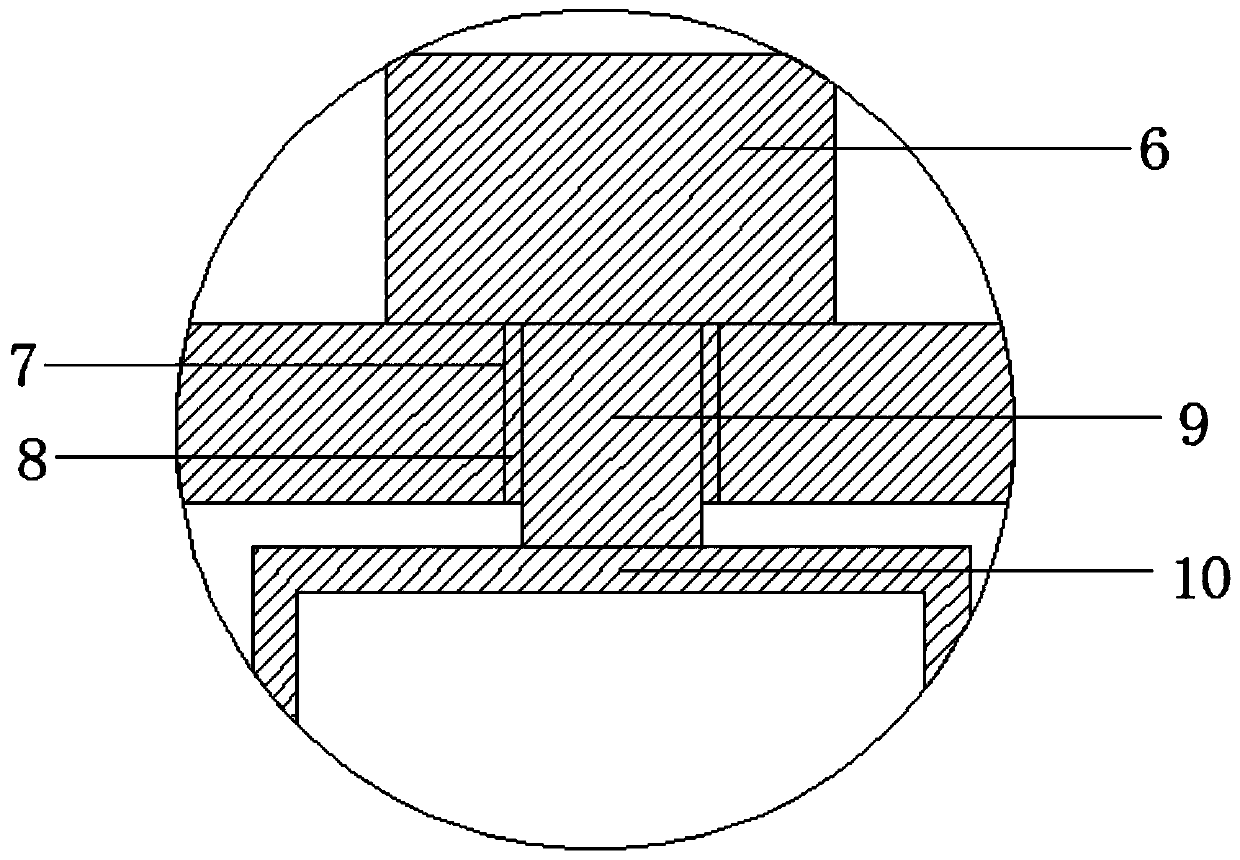

The invention discloses a moveable connecting structure of an assembled steel structure outer hanging type wall slab, and relates to the technical field of a building structure; an upper layer angle steel and a lower layer angle steel are in vertical frictional slipping connection with the upper layer angle steel and the lower layer angle steel; an upper wing and a lower wing of a H-type steel girder are in horizontal frictional slipping connection with the upper layer angle steel and the lower layer angle steel; the lower layer angle steel is hung at the lower part of the H-type steel girder to limit and adjust the upper layer wall slab; the upper layer angle steel is connected to the upper part of the upper wing of the H-type steel girder to limit and fix the H-type steel girder; a floor slab is arranged at the upper part of an upper wing of the H-type steel girder and supported by the H-type steel girder; through the frictional slipping connection structure, the structure can realize energy consumption and seismic mitigation and greatly improves the side migration resistance of the outer hanging wall slab; when the load is too big under the complex working condition, the structure can dissipate seismic energy and lighten function of the structure earthquake response; during the installation, the horizontal and vertical positions of the wall slab can be conveniently adjusted, so as to ensure that appearance of the whole wall slab meets requirement.

Owner:安徽富煌建筑设计研究有限公司

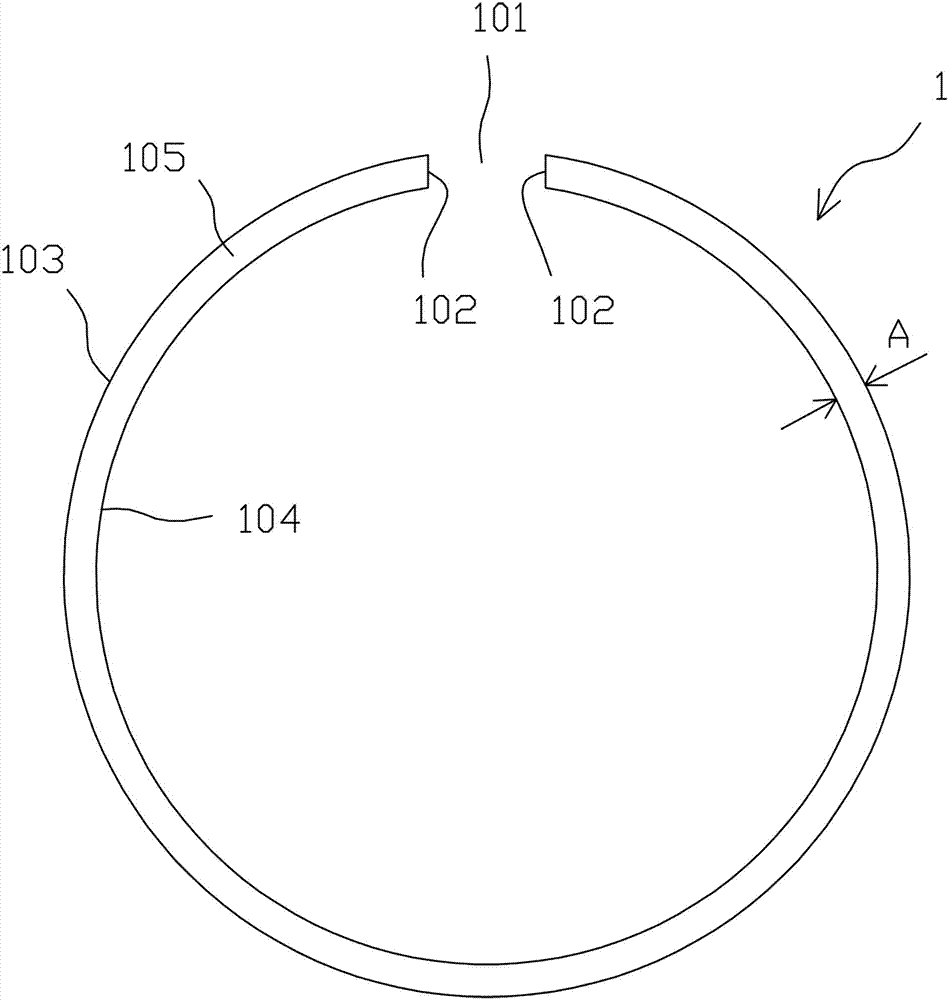

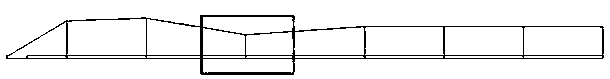

Method for machining sealing rings

InactiveCN104289871AAvoid it happening againSave raw materialsMachines/enginesEngine componentsResidual deformationUltimate tensile strength

The invention discloses a method for machining sealing rings. The method comprises the following steps of (1) carrying wiredrawing on metal bar materials, (2) carrying out heat treatment, (3) winding the wiredrawn metal bar materials into a spring shape, (4) cutting the metal bar materials into multiple twisted ring-shaped components with openings, (5) leveling the ring-shaped components, (6) carrying out quench tempering, (7) grinding the inner circumferential surfaces and the outer circumferential surfaces of the ring-shaped components so that the inner circumferential surfaces and the outer circumferential surfaces of the ring-shaped components can be regular arcs, (8) opening the openings of the ring-shaped components to a preset size and then carrying out heat shaping, (9) obtaining the formed sealing rings. According to the method for machining the sealing rings, material waste is quite low, the machined sealing rings are high in strength, toughness and elasticity and uniform in wall thickness, the thermal elastic loss and the residual deformation of the machined sealing rings are both small, latent defects of the sealing rings can be exposed in the early stage of machining, and the sealing rings with the latent defects can be picked out.

Owner:PINGXIANG DEBO TECH CO LTD

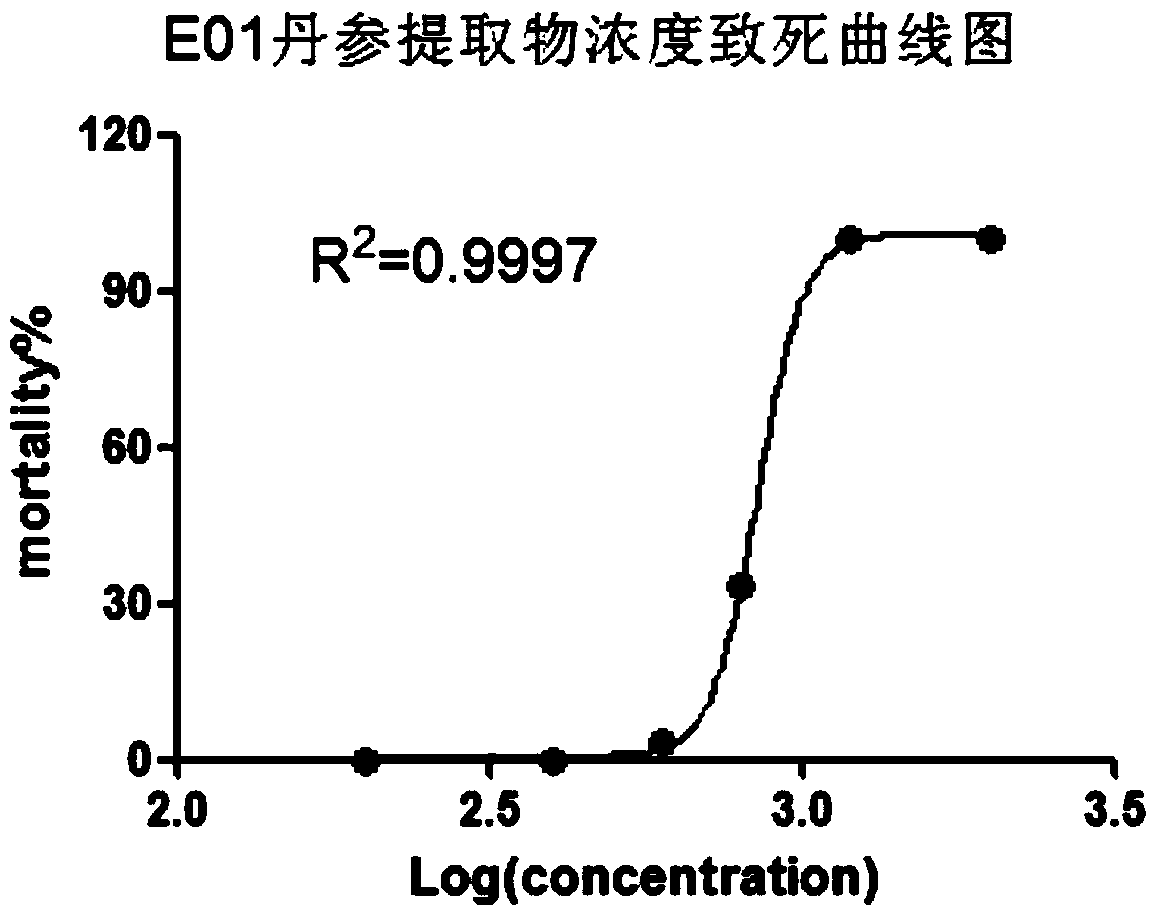

Preparation method of traditional Chinese medicine pellet

ActiveCN104224727AWith hypolipidemicImprove microcirculationOrganic active ingredientsPharmaceutical product form changeMoistureChinese drug

The invention relates to a traditional Chinese medicine pellet which is prepared from traditional Chinese medicine extractives or traditional Chinese medicine extracts and a base pellet according to the weight ratio of (1:5)-(5:1); and the traditional Chinese medicine pellet has the bulk density of 0.6-1.3g / ml, the specific surface area of 0.005-0.05m<2> / g and the particle size of 0.5-1.8mm. The invention also provides a preparation method of the pellet, so that the problems that traditional Chinese medicines or vegetable drugs easily absorb moisture and are unstable are solved; and the preparation method is simple, feasible and suitable for industrial production.

Owner:TIANJIN TASLY PHARMA CO LTD

Electrochemistry wastewater treatment device

InactiveCN103193300AQuickly cut and disintegratedMake sure you meet the requirementsWater/sewage treatmentElectrochemistryPower flow

The invention discloses an electrochemistry wastewater treatment device. The electrochemistry wastewater treatment device comprises a set of ultrastrong oxidoreduction wastewater treatment devices, wherein a high-frequency direct-current electric cabinet is arranged on one side of the ultrastrong oxidoreduction wastewater treatment device; an ultrasonic unit connected with the electric cabinet through a lead is arranged at the bottom of an electrolytic cell; leads are respectively connected between the high-frequency direct-current electric cabinet and the electrolytic polar plates of the wastewater treatment device; and the high-frequency direct-current electric cabinet is capable of generating high-frequency direct-current electric field of over than 20,000 hertz. The conventional pulse direct-current electric cabinet can be replaced by the high-frequency direct-current electric cabinet, so that the high-frequency direct-current electric field of over than 20,000 hertz can be generated on the plate electrode; the current intensity can be regulated based on the wastewater condition, macromolecules and long molecules in the wastewater can be cut and disintegrated rapidly to generate ultrastrong oxidoreduction function; and all indexes can meet the requirement through multiple reactive tanks and secondary deep filtration.

Owner:梁凤鸣

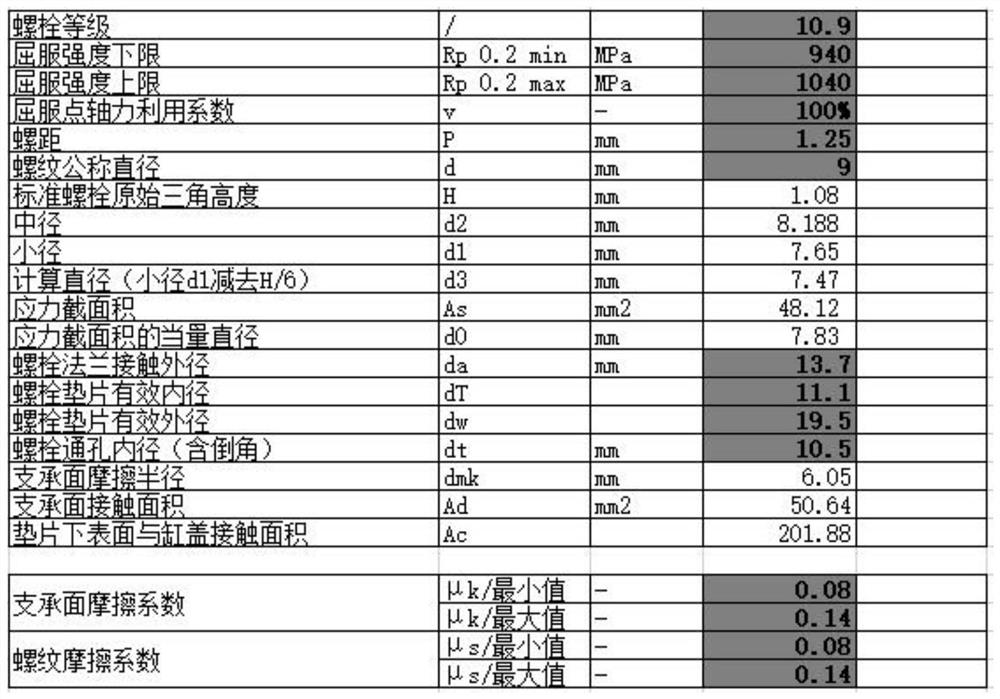

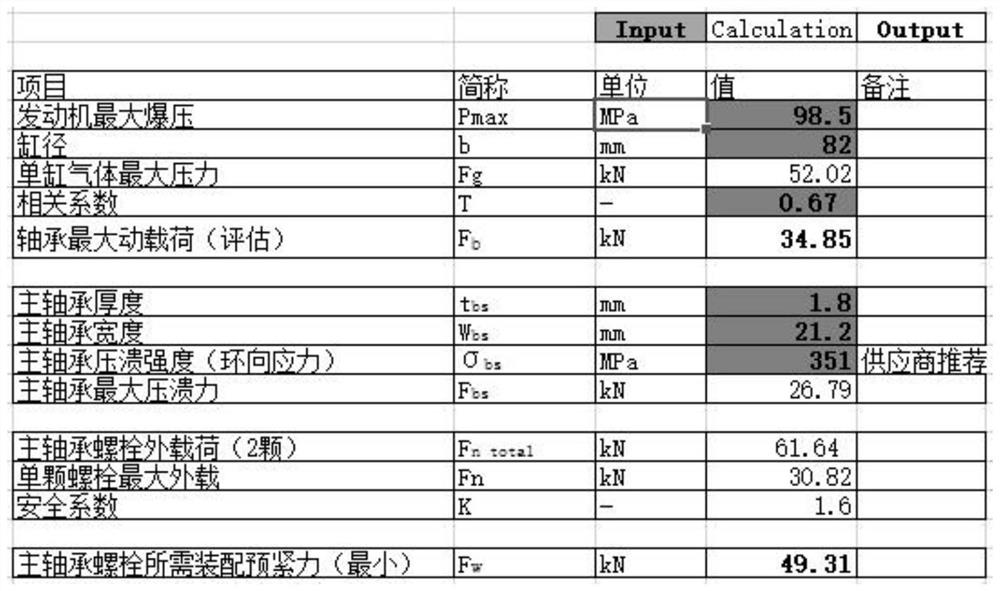

Gasoline engine cylinder cover bolt model selection and checking method

ActiveCN112580156AThe force model is simpleImprove design safety marginGeometric CADDesign optimisation/simulationGasolineControl theory

The invention relates to a gasoline engine cylinder cover bolt model selection and checking method, and belongs to the technical field of vehicle manufacturing. The maximum working load of the engineis obtained through the maximum explosion pressure of the engine, the maximum external load of the single bolt of the air cylinder cover is further obtained, the preset safety coefficient determined according to axial force attenuation is finally simplified to the pre-tightening force required for sealing the air cylinder cover through the single bolt, then forward model selection is conducted onthe bolt. The specifications and sizes, the friction coefficient dispersion differences, the yield strength dispersion differences and the actual conditions of the bolts in the mass production state are are considered to accurately obtain the actual maximum pre-tightening force and the actual minimum pre-tightening force of the bolts, and finally perform checking. By means of the method, forward model selection can be accurately conducted on the gasoline engine air cylinder cover bolts, the invention is simpler and more convenient, consideration is complete, and the selected bolts can better meet the actual running situation of a gasoline engine.

Owner:DONGFENG MOTOR CORP HUBEI

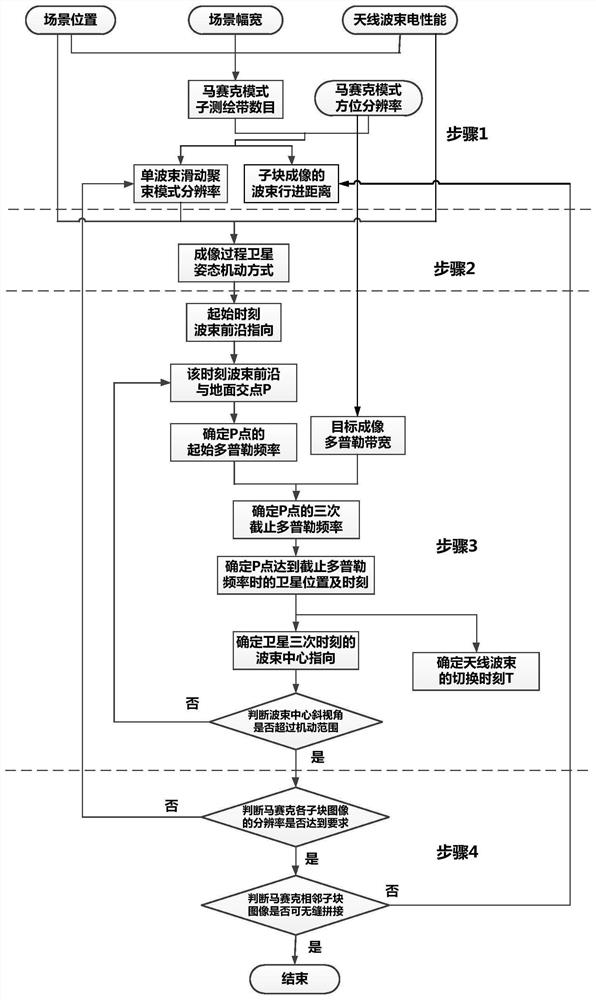

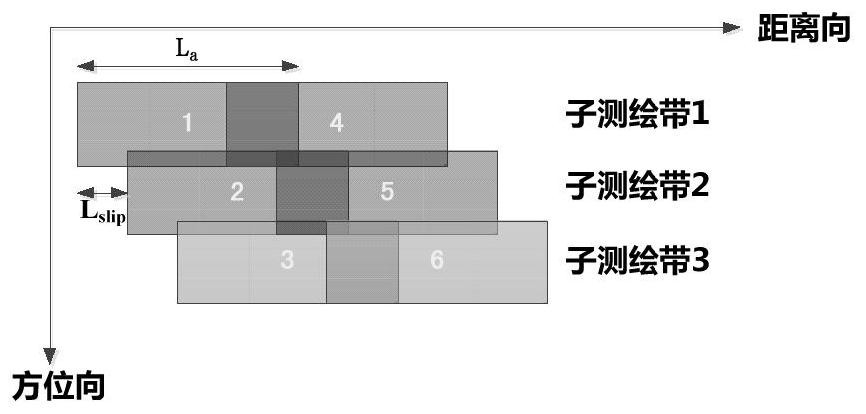

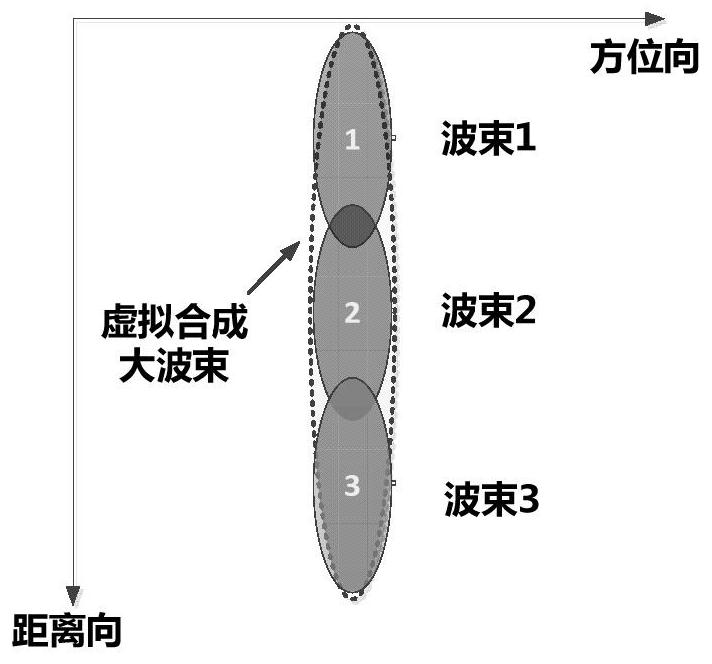

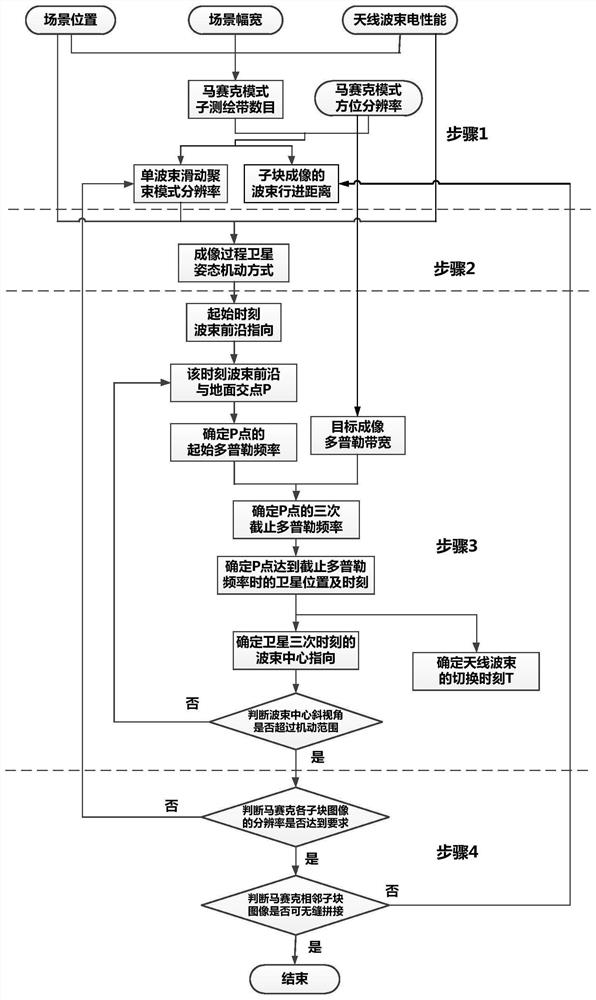

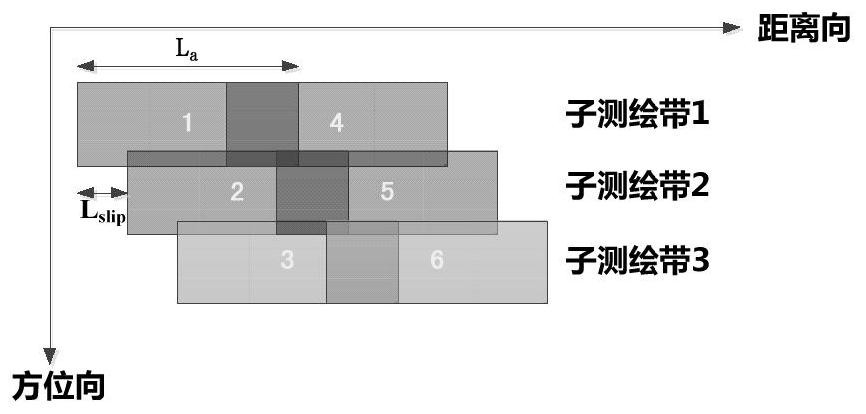

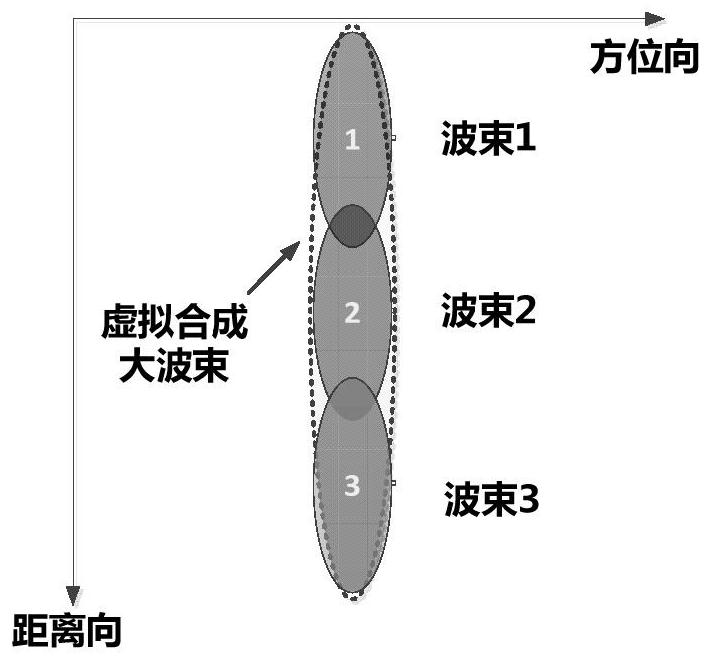

On-orbit implementation design method for satellite-borne SAR mosaic mode

ActiveCN112014840AMake sure you meet the requirementsImprove processing efficiencyGeometric image transformationRadio wave reradiation/reflectionImage resolutionAzimuth direction

The invention relates to an on-orbit implementation design method for a satellite-borne SAR mosaic mode. According to the method, a design constraint condition of a mosaic mode is built according to geometric resolution and scene breadth to be achieved by the satellite-borne SAR image and the number of needed pitching beams; an attitude maneuver mode of a satellite platform is designed in a mosaicmode imaging process according to constraint conditions; according to a resolution requirement, the squint angle of an antenna beam at a starting moment and the maneuvering curve of the satellite attitude along with time, each moment when the antenna beam is switched in the pitching direction is solved; and finally, according to the designed attitude maneuvering curve and the beam switching moment, analysis is performed to confirm the conditions that: 1) the azimuth resolution reaches a technical index, and 2) adjacent sub-block images in the mosaic can be effectively spliced in the azimuth direction to ensure the integrity of a whole scene image.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

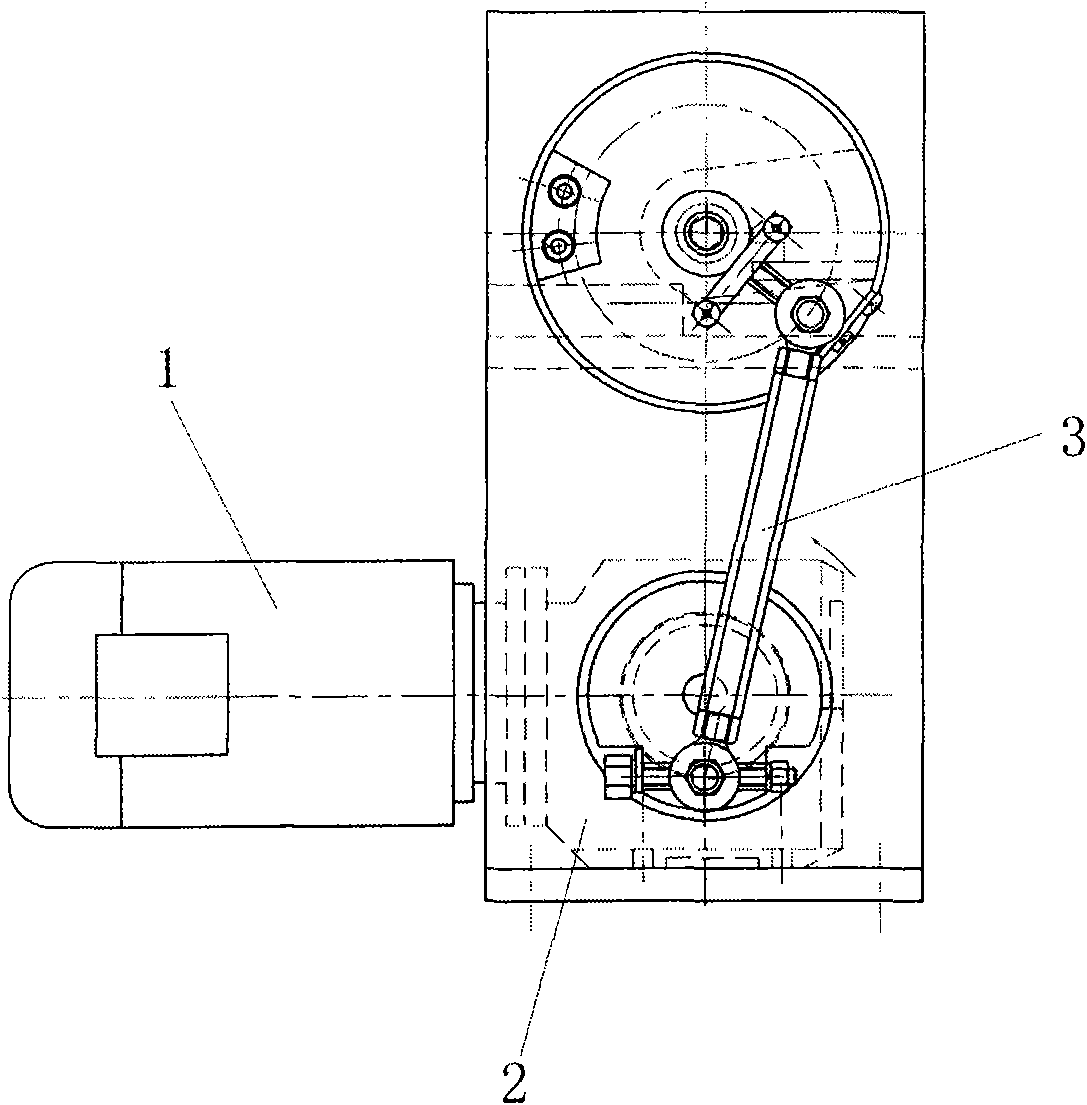

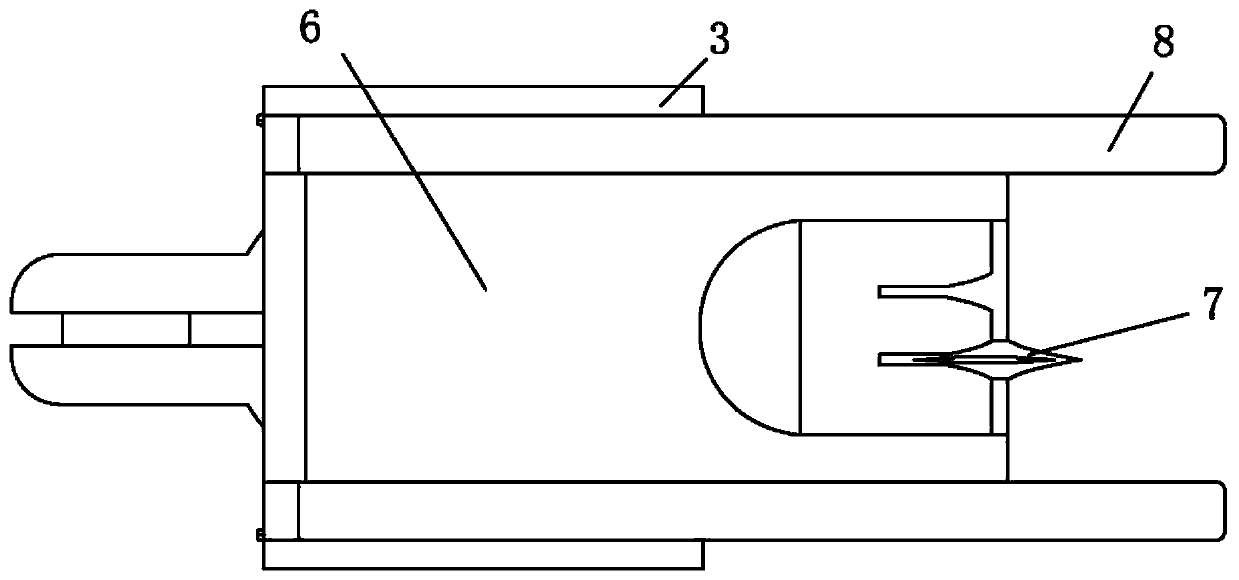

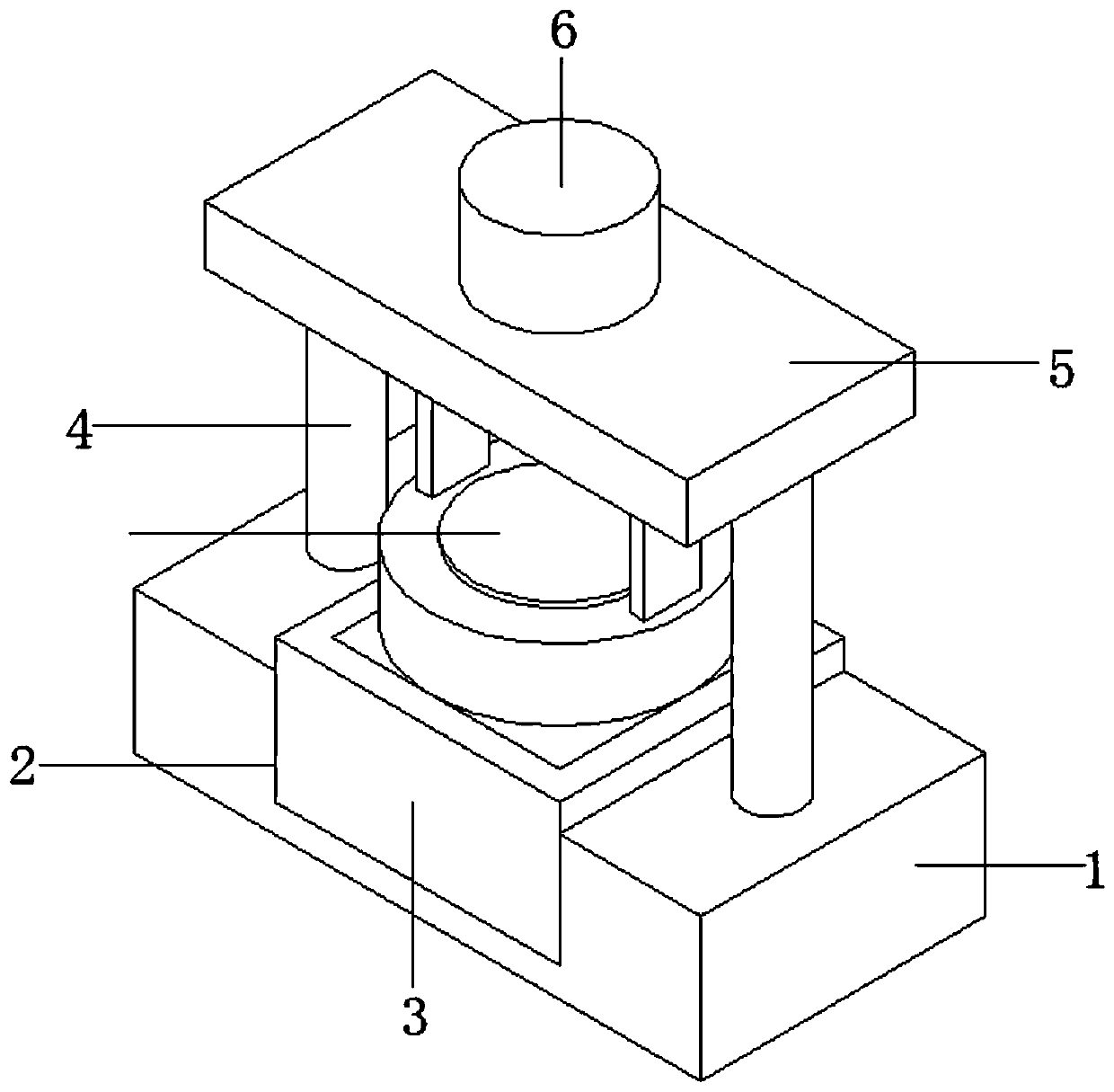

Fatigue strength detecting machine of trundle brake sheet

InactiveCN101819116AMake sure you meet the requirementsImprove securityUsing mechanical meansMaterial strength using repeated/pulsating forcesElectric machineryEngineering

The invention relates to a fatigue strength detecting machine of a trundle brake sheet, which is characterized comprising a stand. The lower end of the stand is transversely provided with a motor which is connected with an electronic counter, and the electronic counter is connected with an inductive switch; the output shaft of the motor is connected with a retarding mechanism; one end of a rocker in a crank and rocker mechanism is connected with the retarding mechanism and the other end is connected with one end of a rotating shaft positioned above the rocker; and the other end of the rotating shaft is connected with a brake sheet driving mechanism. The brake sheet driving mechanism is provided with a driving arm and a trundle fixing mechanism, wherein the driving arm is fixed on the rotating shaft through a flat key and provided with a groove for blocking the front end of a brake handle of a trundle, the groove is positioned at one side of the rotating shaft, and the axial direction of the groove is parallel to the rotating shaft; and the trundle fixing mechanism is fixed on one side of the rotating shaft of the stand and positioned at the side opposite to the groove of the driving arm. The invention can detect the fatigue strength of the trundle brake sheet so as to ensure that the trundle brake sheet meets the requirement and improve the use safety of the trundle brake sheet.

Owner:圣路机械(嘉兴)制造有限公司

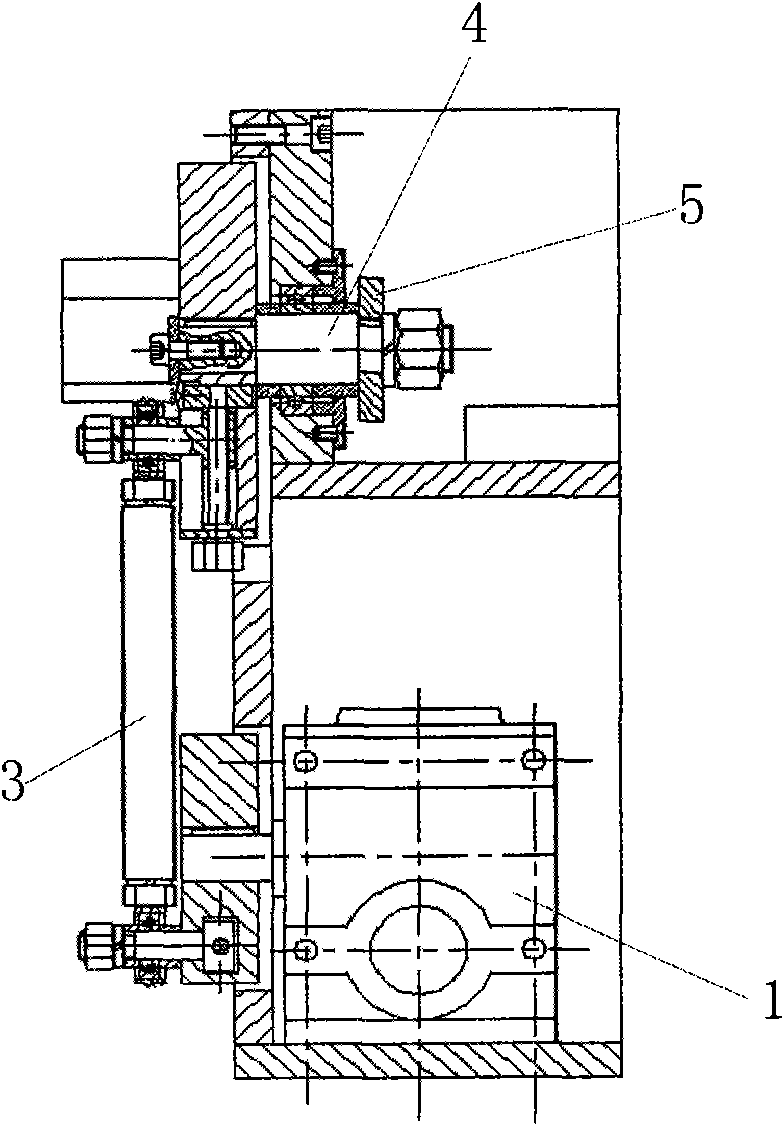

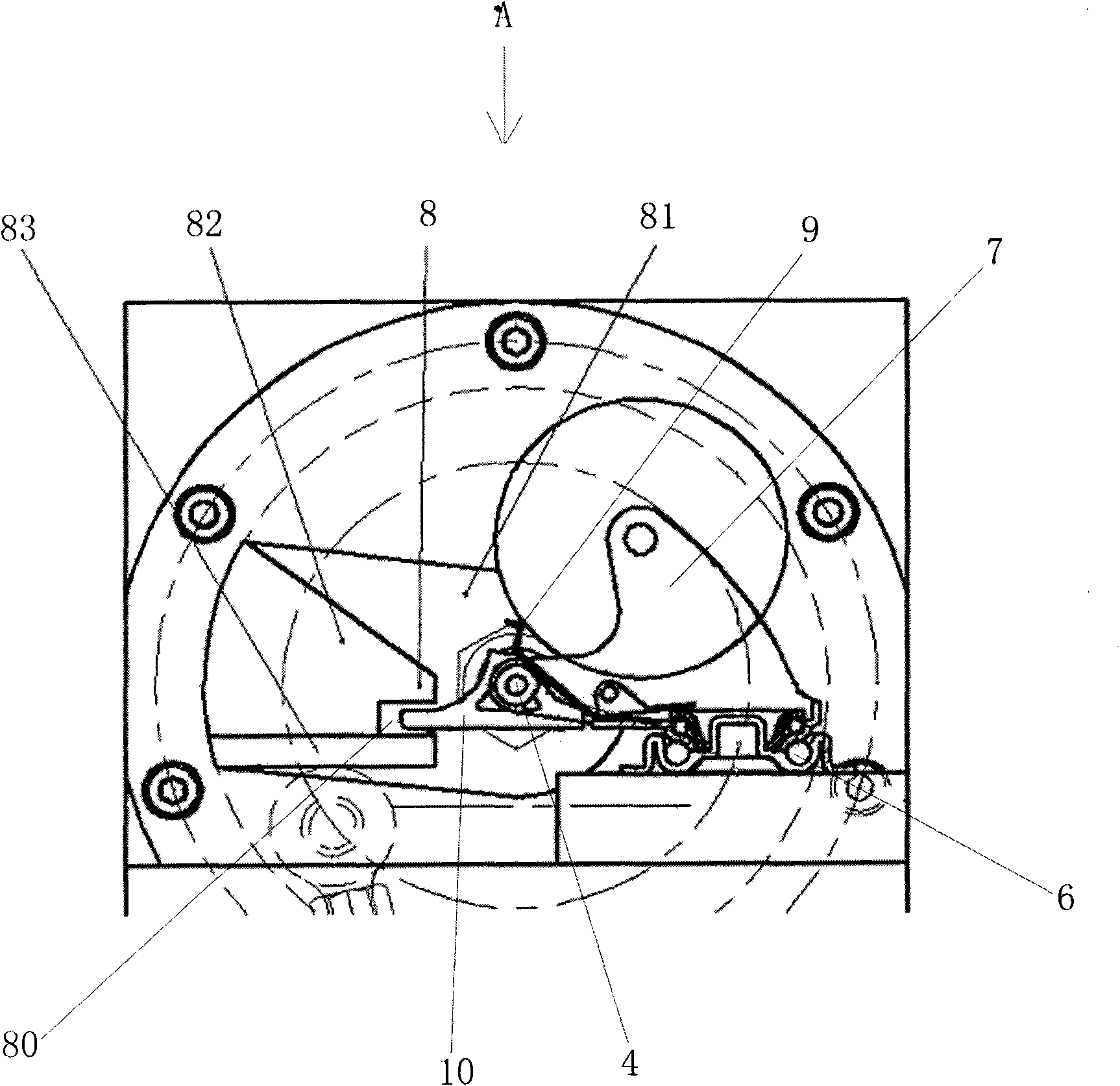

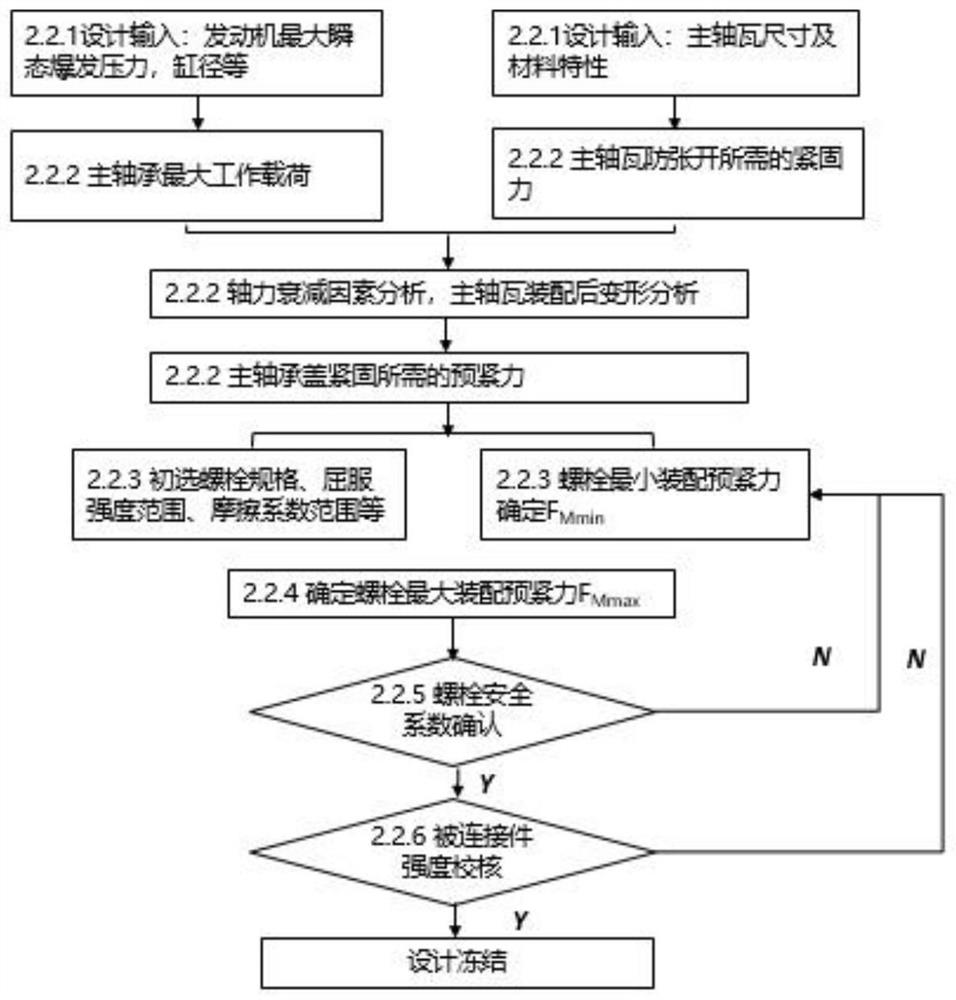

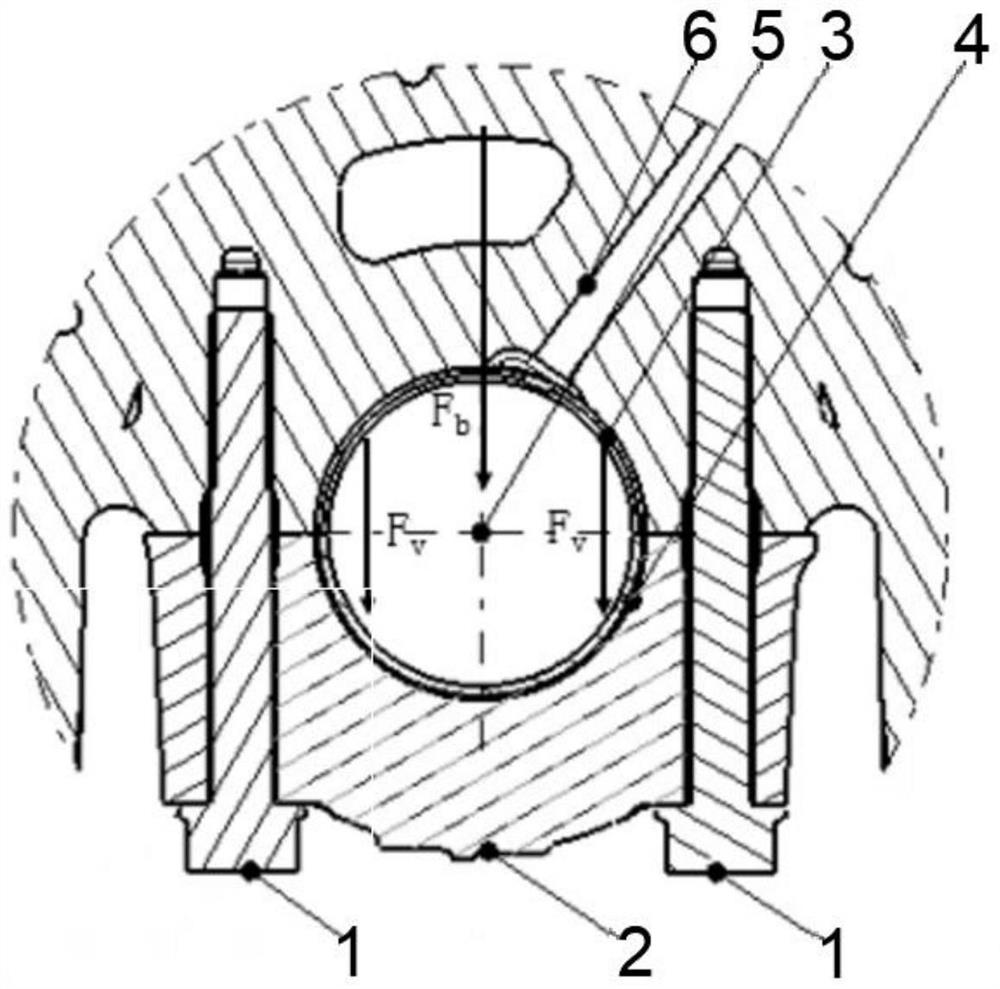

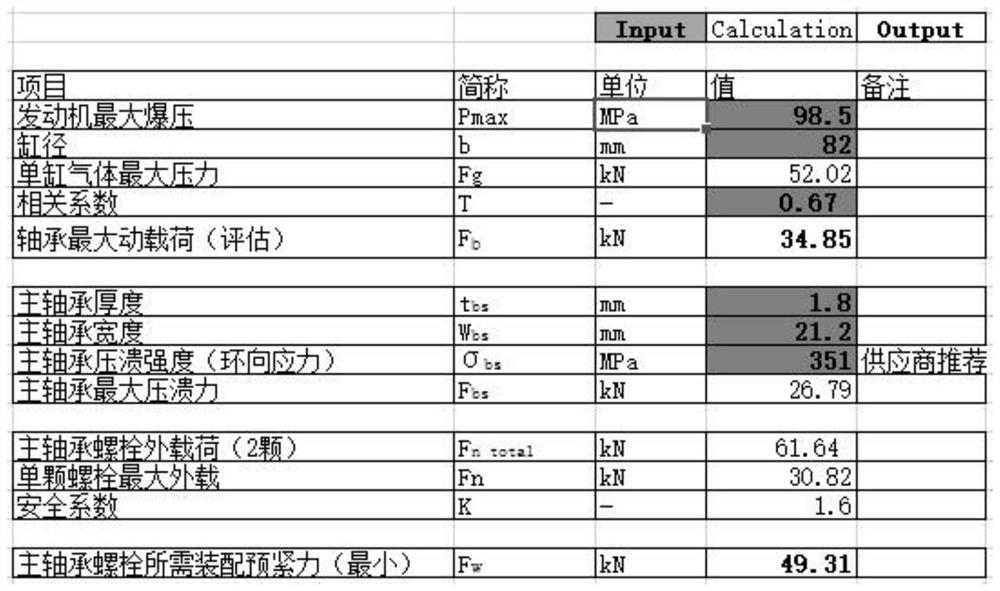

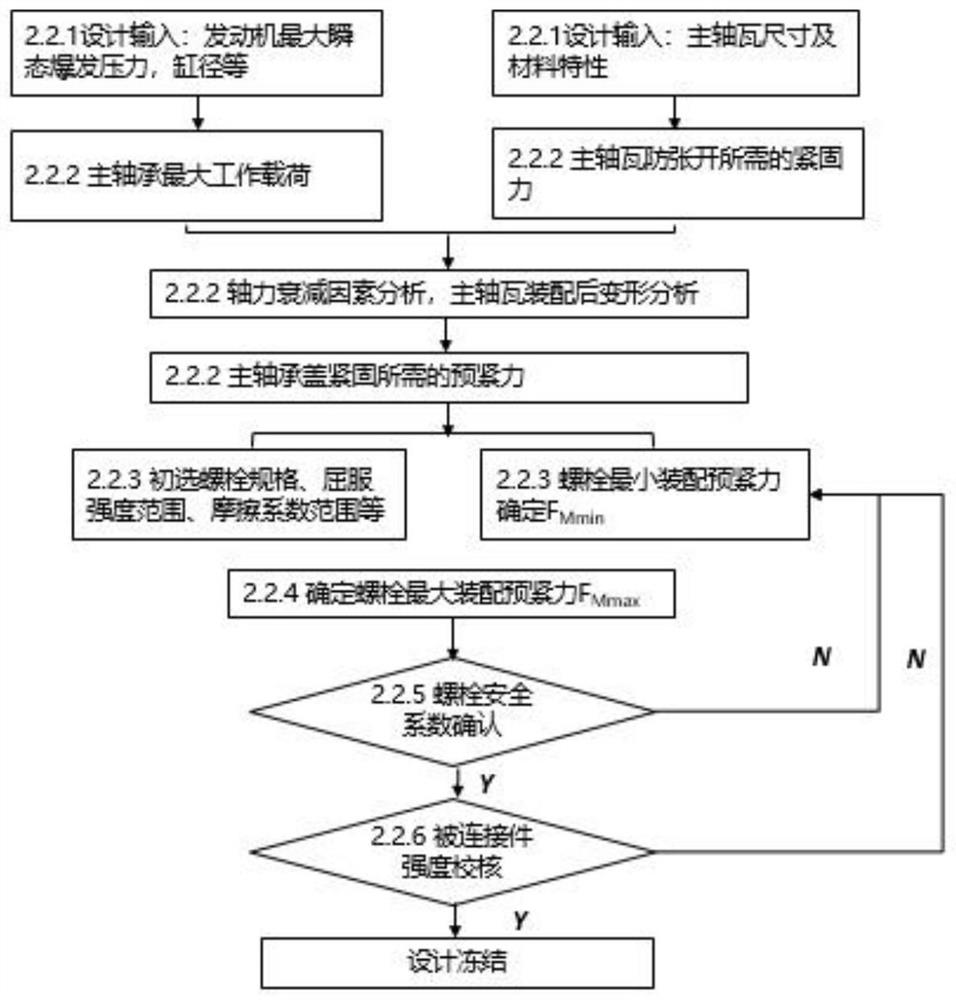

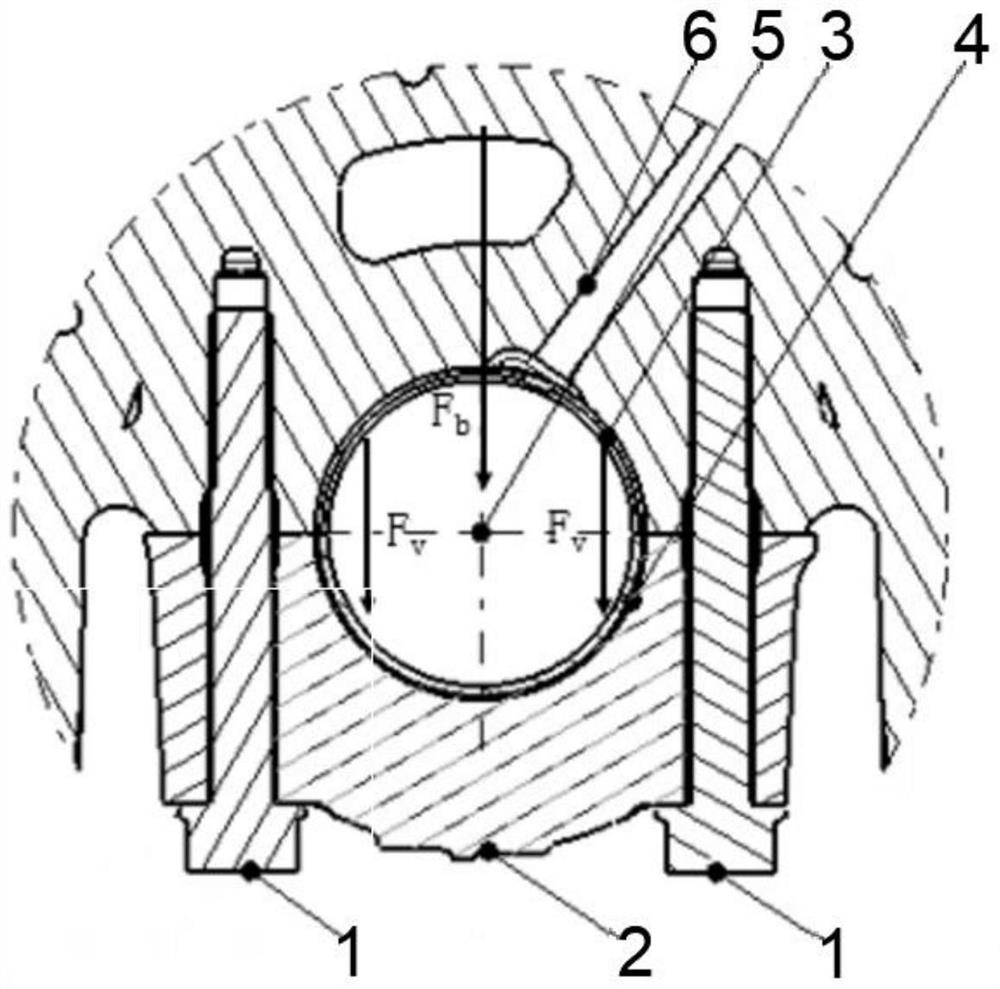

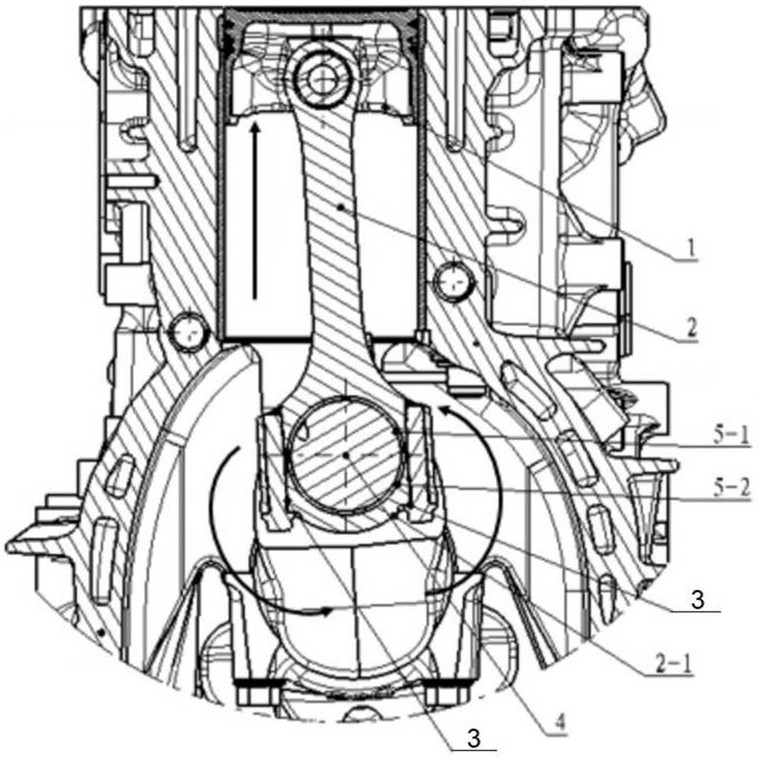

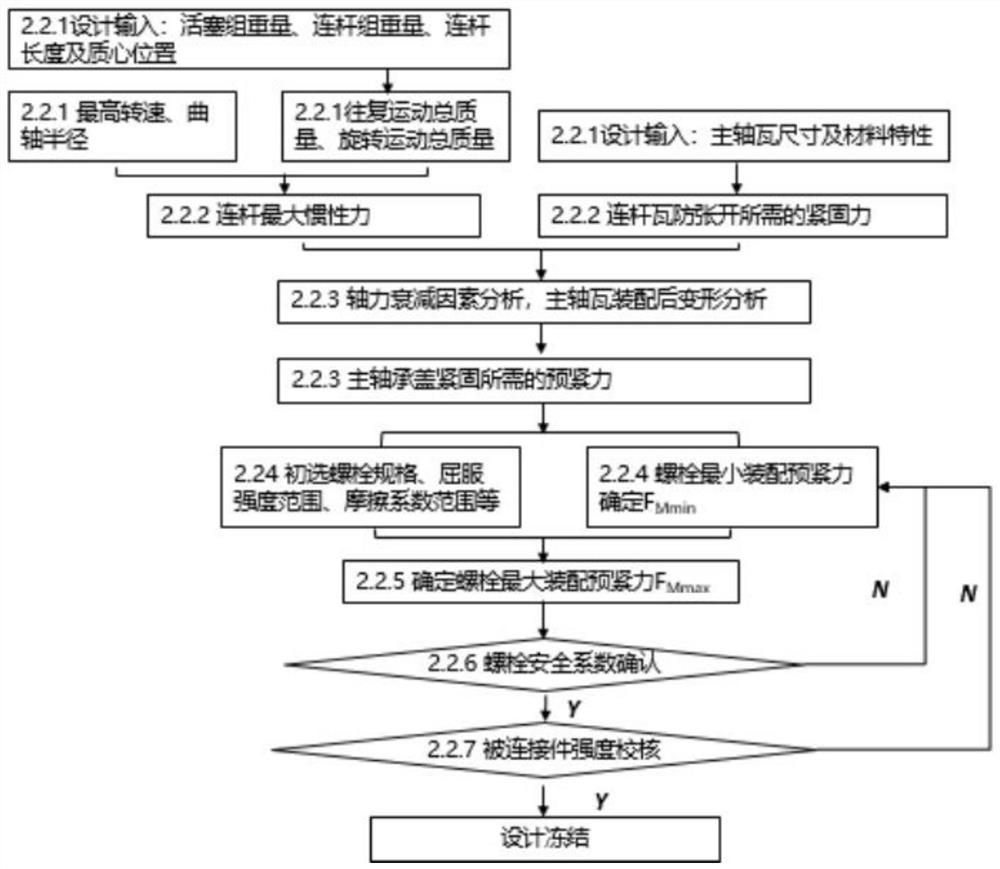

Automobile engine main bearing cap bolt model selection and checking method

ActiveCN112528425AImprove design safety marginImprove work efficiencyGeometric CADSpecial data processing applicationsAxial forceIndustrial engineering

The invention relates to an automobile engine main bearing cap bolt model selection and checking method, and belongs to the technical field of automobile manufacturing. According to the method, the maximum working load of the engine is obtained through the maximum explosion pressure of the engine, the maximum dynamic load of the bearing bush of the main bearing cover is further obtained, the pre-tightening force needed for preventing the main bearing bush from being opened under the static assembling condition is considered, and the preset safety coefficient is determined according to axial force attenuation; simplifying is performed to obtain a pre-tightening force required to be provided for fastening a bearing bush by using a single bolt, forward model selection is performed on the bolt, and the actual maximum pre-tightening force and the actual minimum pre-tightening force of the bolt is accurately calculated by considering the specification, the size, the friction coefficient dispersion difference, the yield strength dispersion difference and the actual condition among multiple batches of bolts in a mass production state of the bolt. and finally checking is carried out. According to the method, forward model selection can be accurately carried out on the automobile engine main bearing cap bolt, the method is simple, convenient and perfect in consideration, and the selectedbolt better conforms to the actual running condition of an automobile engine.

Owner:DONGFENG MOTOR CORP HUBEI

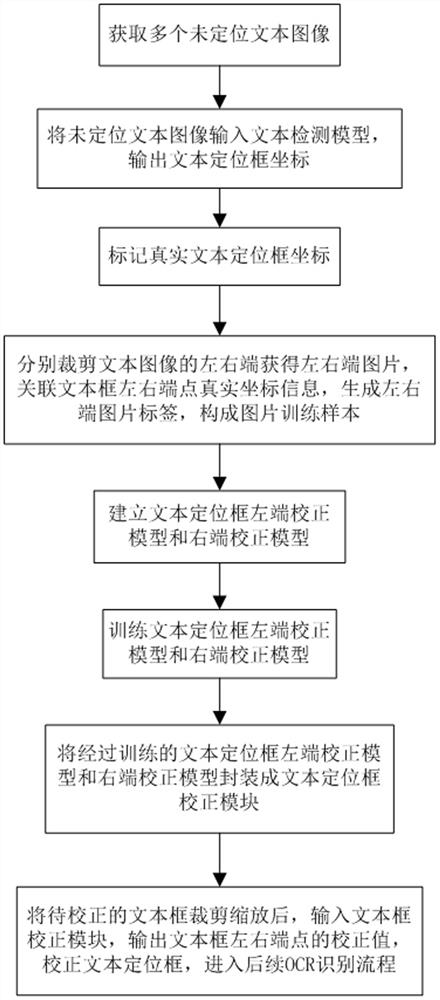

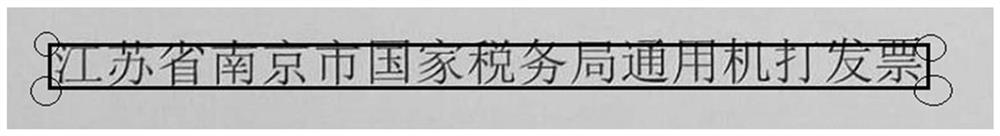

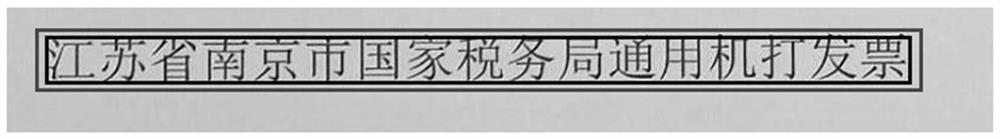

Text positioning box correction method and system based on convolutional neural network

PendingCN111783763AHigh precisionFast efficiencyNeural architecturesCharacter recognitionText boxText detection

The invention relates to a text positioning box correction method and system based on a convolutional neural network, and the method comprises the steps: building a neural network for text positioningbox correction, carrying out the independent training of the left and right ends of a text positioning box, setting a subsequent verification step for verifying a result, and guaranteeing that a trained model meets the requirements. Compared with the prior art, the text box correction model obtained by training is used for correcting the text positioning box in the text picture, so that the positioning precision of the text detection method can be effectively improved, a more accurate text positioning box is obtained, and the accuracy of picture text recognition and the practicability of a text detection and recognition system are improved.

Owner:厦门商集网络科技有限责任公司 +1

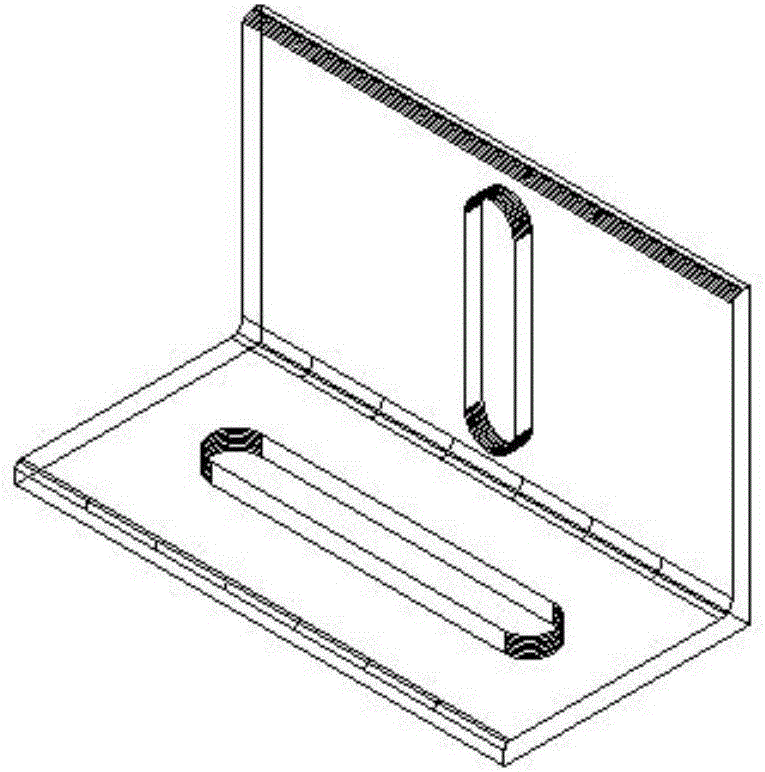

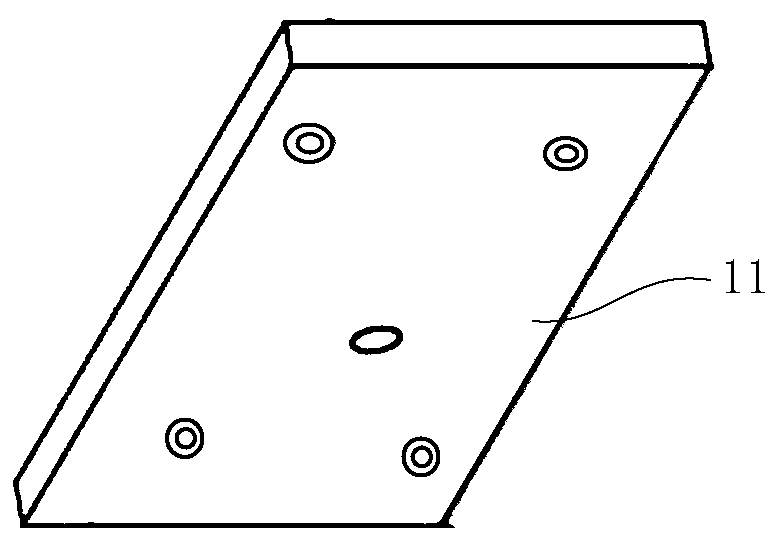

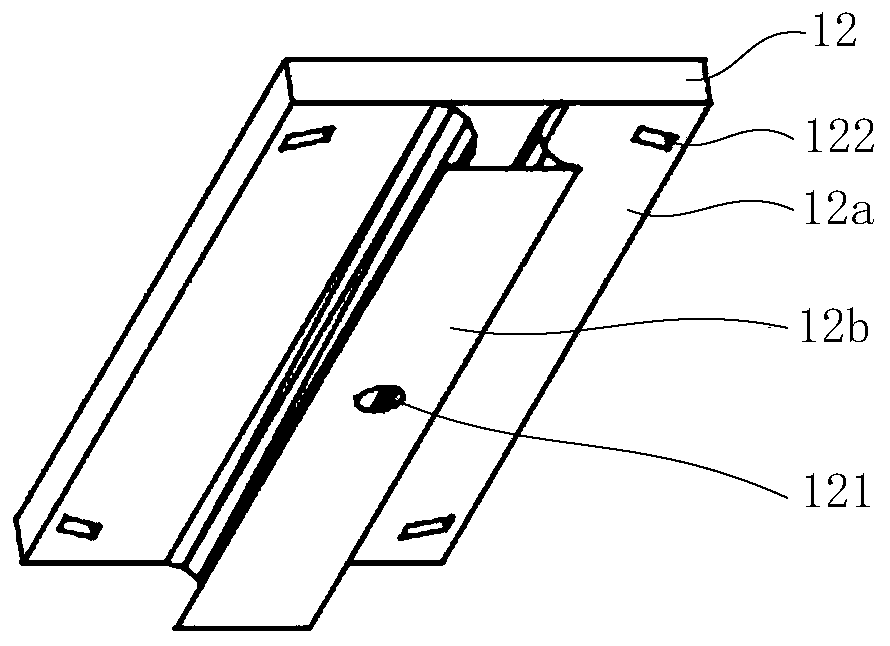

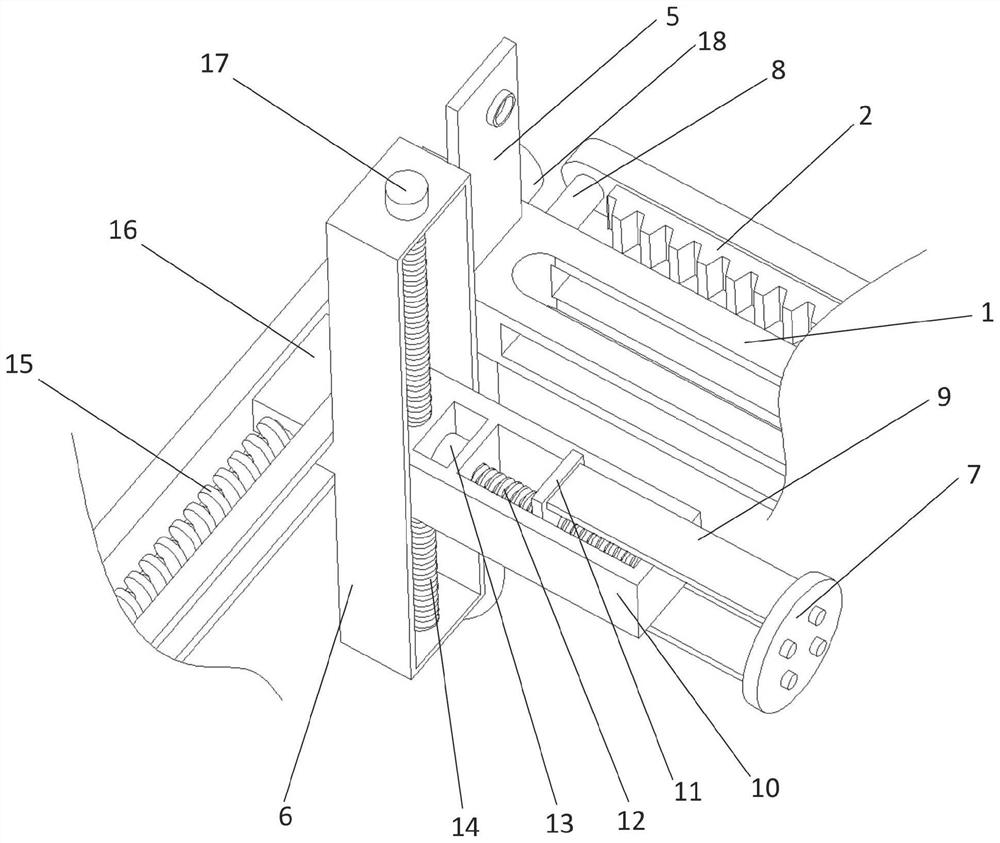

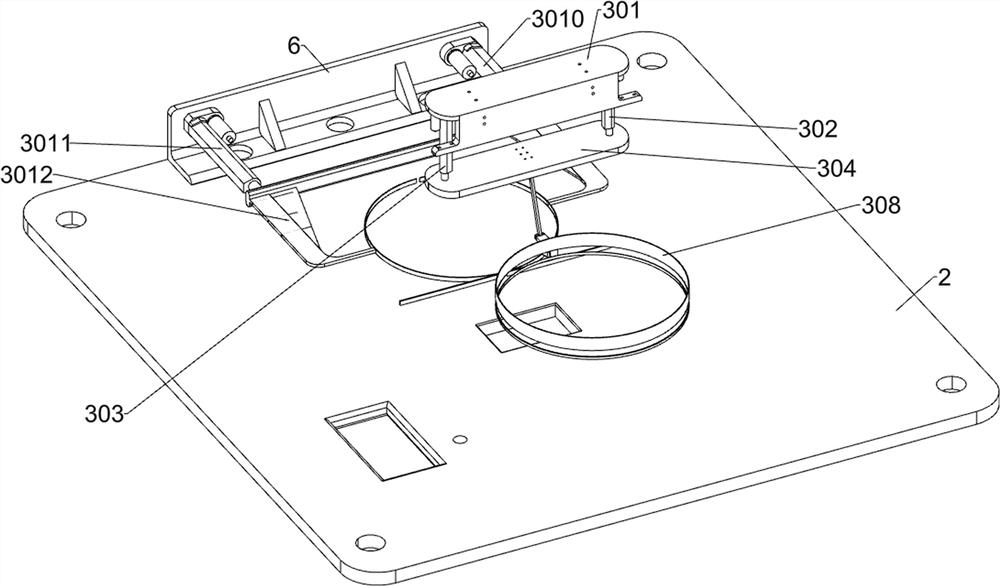

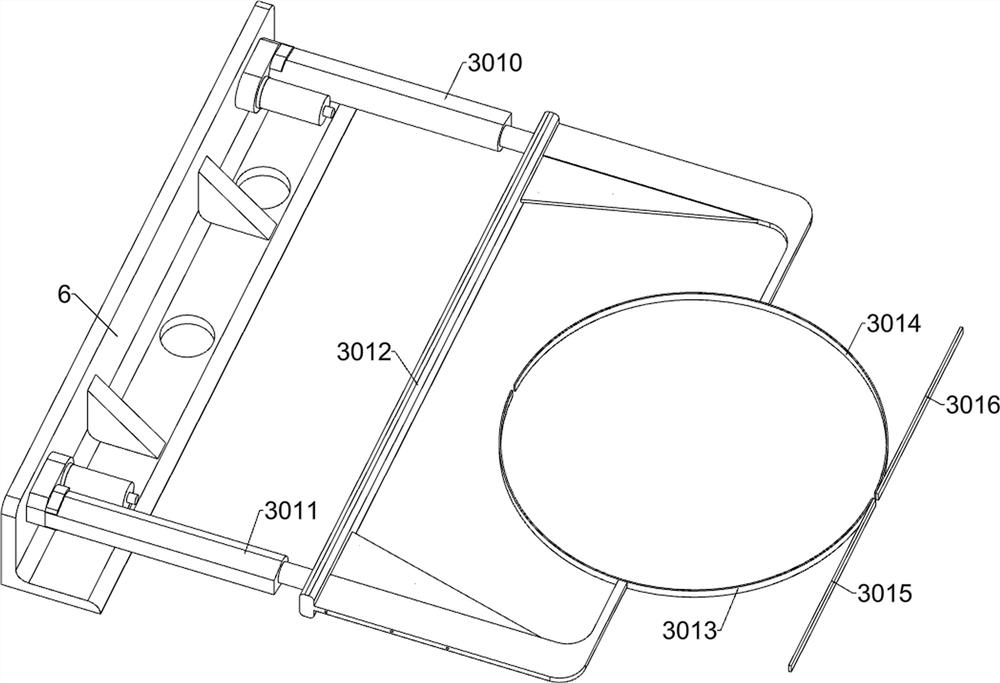

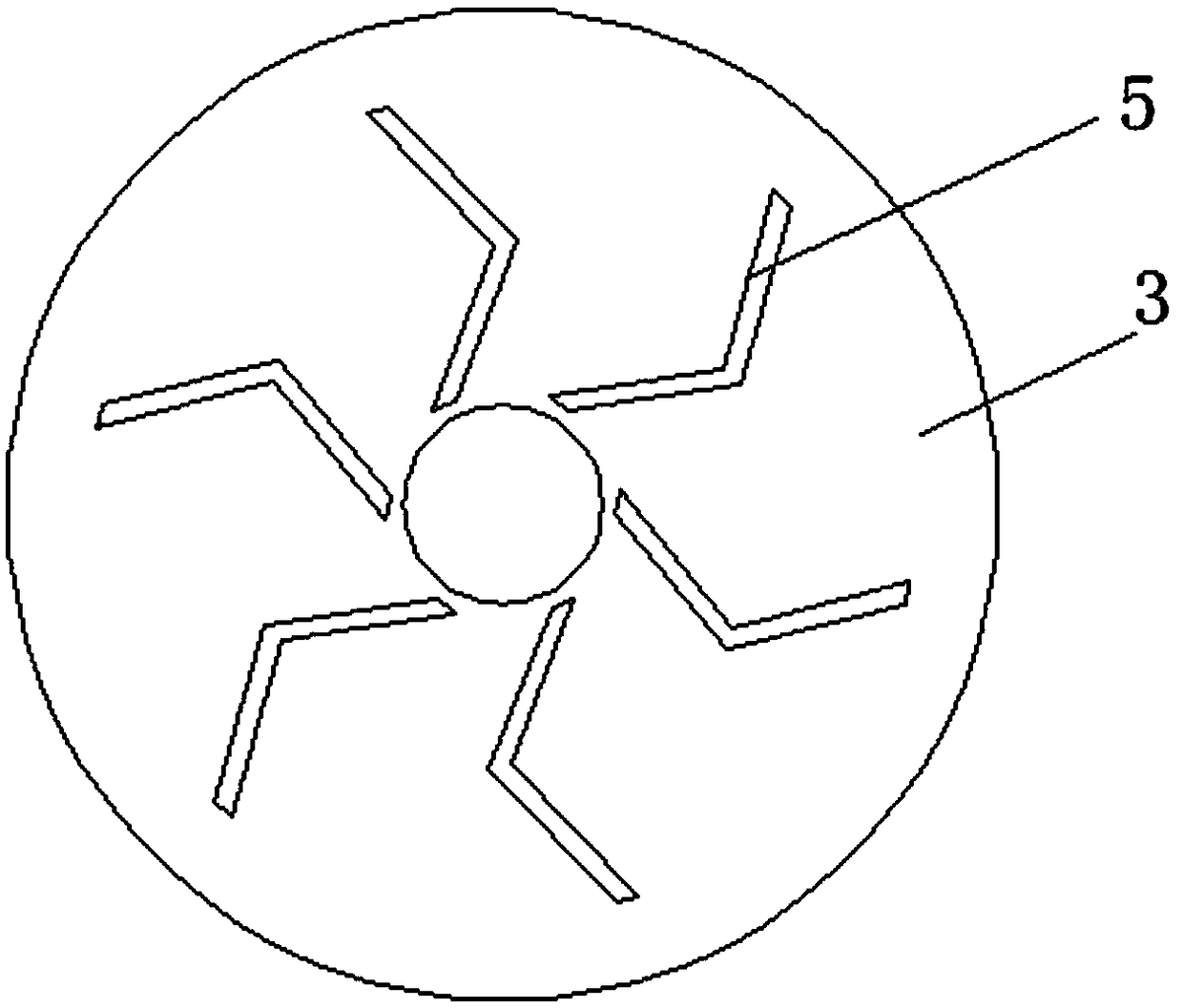

Crystal bar workpiece plate, and crystal bar cutting device and cutting method

InactiveCN110625836AMake sure you meet the requirementsAvoid damageWorking accessoriesFine working devicesCrystal orientationEngineering

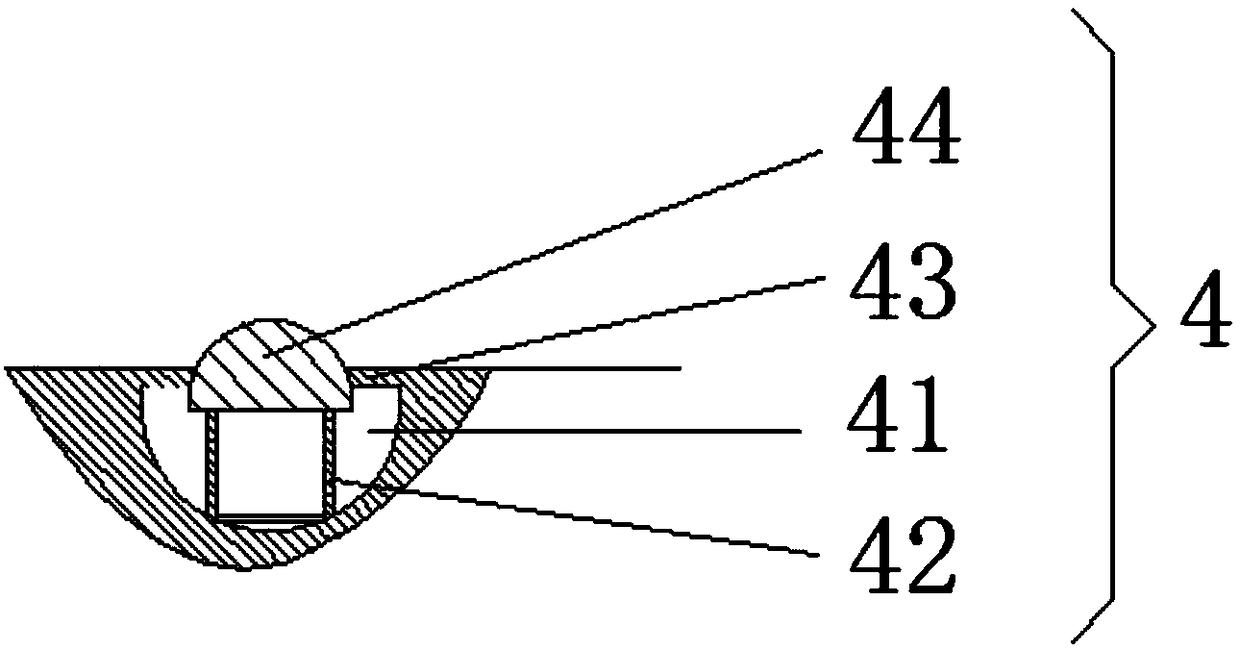

The invention provides a crystal bar workpiece plate, and a crystal bar cutting device and method. The crystal bar workpiece plate comprises a fixed plate and an adjustment plate, wherein the fixed plate is used for placing a crystal bar; the adjustment plate is located on a surface away from the crystal bar, of the fixed plate, a circle center hole and a plurality of waist-shaped through holes are formed in the adjustment plate, the circle center hole is located in the middle of the adjustment plate, and the plurality of waist-shaped through holes are located in the periphery of the circle center hole; and the fixed plate is connected with the adjustment plate through bolts located in the circle center hole and the plurality of waist-shaped through holes, and the bolts in the waist-shapedthrough holes are capable of moving in the waist-shaped through holes to adjust the relative positions of the fixed plate and the adjustment plate, so that adjustment for a crystal orientation deflection angle of the crystal bar is realized. According to the crystal bar workpiece plate, and the crystal bar cutting device and method, position adjustment for the crystal bar is realized through thestructural design that the fixed plate and the adjustment plate are cooperated, and by adjusting the position of the adjustment plate relative to the fixed plate, and the crystal orientation deflection angle of the crystal bar is adjusted to be in an expected range, so that a finally-cut wafer can meet the requirements. With the adoption of the crystal bar workpiece plate, and the crystal bar cutting device and method, the quality of the cut wafer can be increased, and the production efficiency can be increased.

Owner:ZING SEMICON CORP

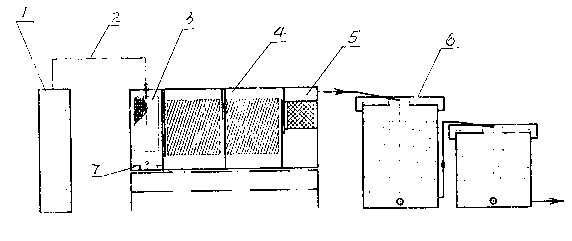

Carbonate eater high-molecular polymer two-stage indirect drying system and drying process

ActiveCN107685404AEasy disposalSmall amount of gasGranular material dryingDrying gas arrangementsExhaust fumesExhaust gas emissions

The invention relates to a carbonate eater high-molecular polymer two-stage indirect drying system. The system comprises a paddle dryer, a steam pipe dryer and an alkali washing tower. The paddle dryer is provided with a feed port, a tail gas exhaust port, a second-grade dried tail gas input pipe, saturated steam input pipes I and II, steam condensed liquid discharge pipes I and II, and a dried material discharge port; the tail gas exhaust port is connected with a cloth bag dust remover I; the alkali washing tower is connected with a water sealing tank, and is provided with a spraying pipe, awaste gas exhaust pipe I and a waste water discharge pipe; the dried material discharge port is connected with a cloth bag dust remover II; one end of the steam pipe dryer is connected with a feedingcyclone, and a saturated steam input pipe III, a steam condensed liquid discharge pipe III, a product discharge pipe and a steam inlet are arranged at the other end; the steam inlet is connected witha steam heater and the second-grade dried tail gas input pipe; and the steam heater is provided with the saturated steam input pipe III and a steam condensed liquid discharge pipe IV, and one side isconnected with a fine filter and a rough-effect filter. The invention further discloses a drying process of the system. The system is excellent in drying effect and free of pollution.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

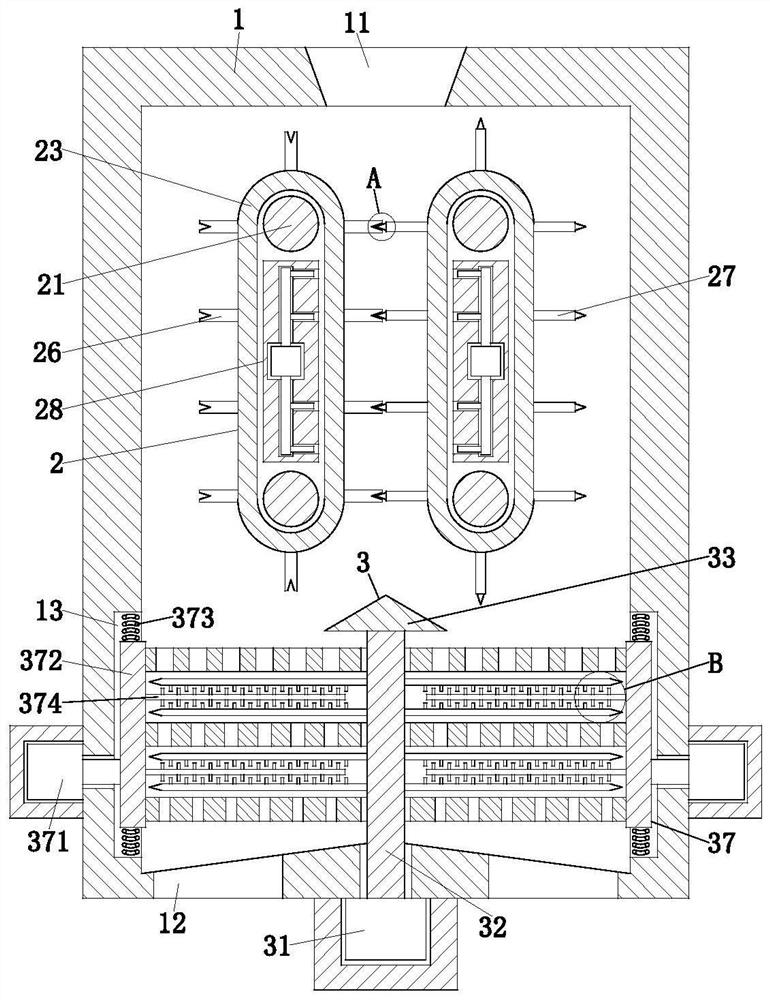

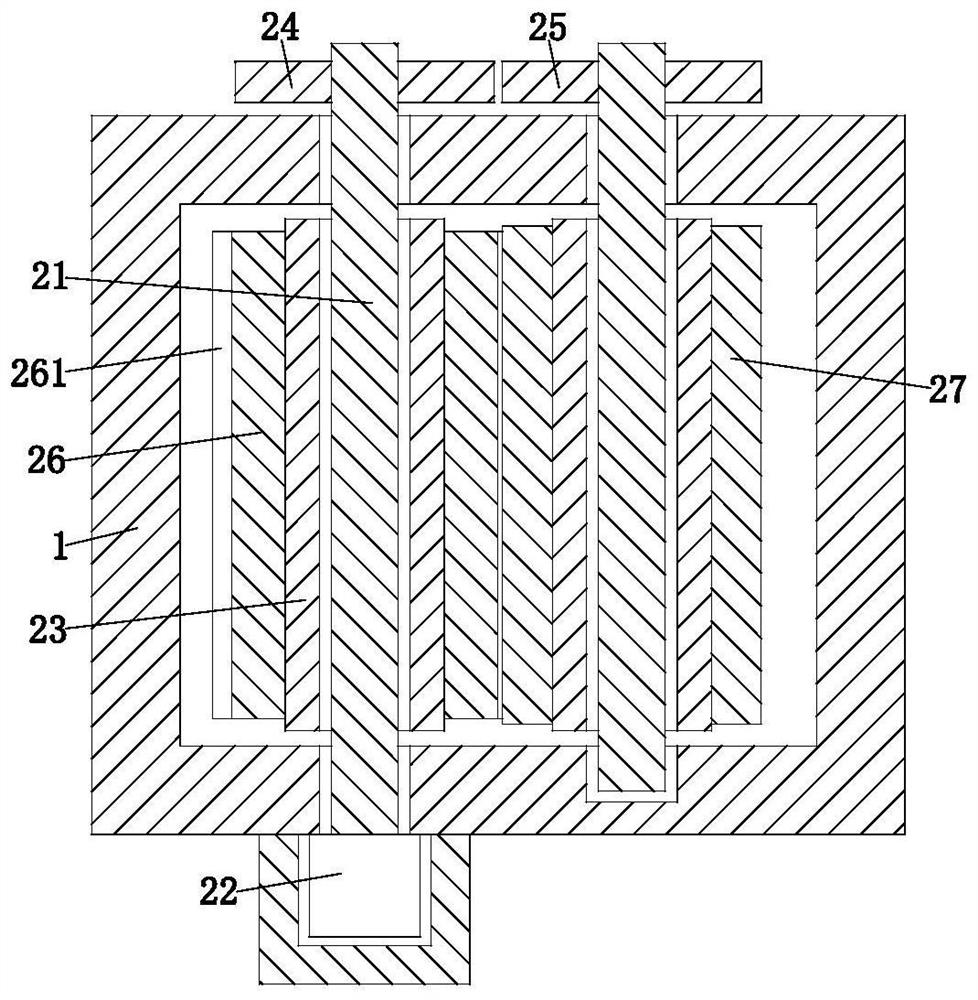

Method for preparing organic fertilizer from straws

ActiveCN112778028AEasy to processImprove cutting effectSievingBio-organic fraction processingAgricultural engineeringOrganic manure

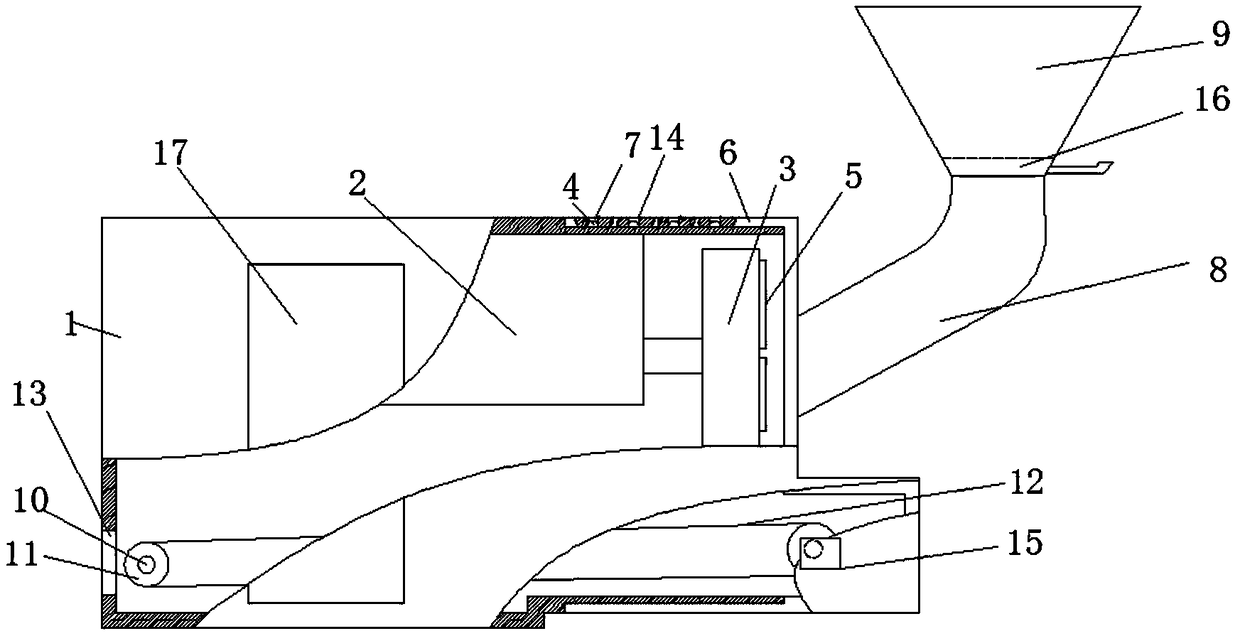

The invention provides a method for preparing an organic fertilizer from straws. According to the method for preparing the organic fertilizer from the straw, a device for preparing the organic fertilizer from the straw is adopted. The device for preparing the organic fertilizer from the straw comprises a processing shell, a slitting unit and a smashing unit, wherein the slitting unit is arranged on the upper side of the inner wall of the processing shell, and the smashing unit is arranged on the inner wall of the lower end of the processing shell. By means of the device, the method of the invention can overcome the problems that straw is mostly processed in a manual cutting mode when being cut at present, the straw needs to be cut step by step in the manual cutting mode, residual water in the straw cannot be removed, later straw processing is affected, cutting efficiency is affected, and the labor cost is consumed; and the method of the invention can also overcome the problems that it cannot be guaranteed that the smashed straw meets processing requirements and secondary smashing processing needs to be conducted on the straw since straw is generally and directly smashed through a smashing machine and multi-stage smashing cannot be achieved through the smashing machine in the prior art.

Owner:山东宝瑞生物科技有限公司

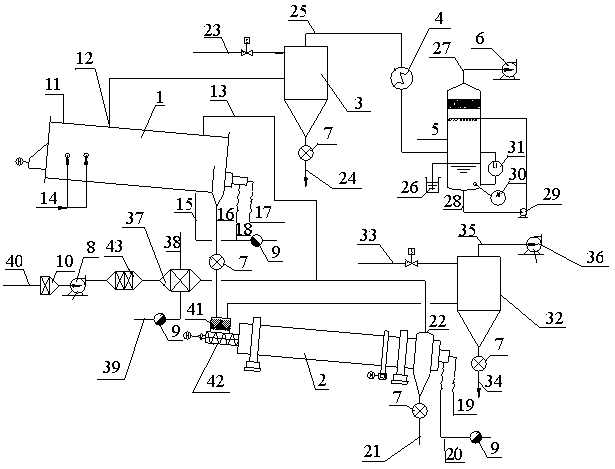

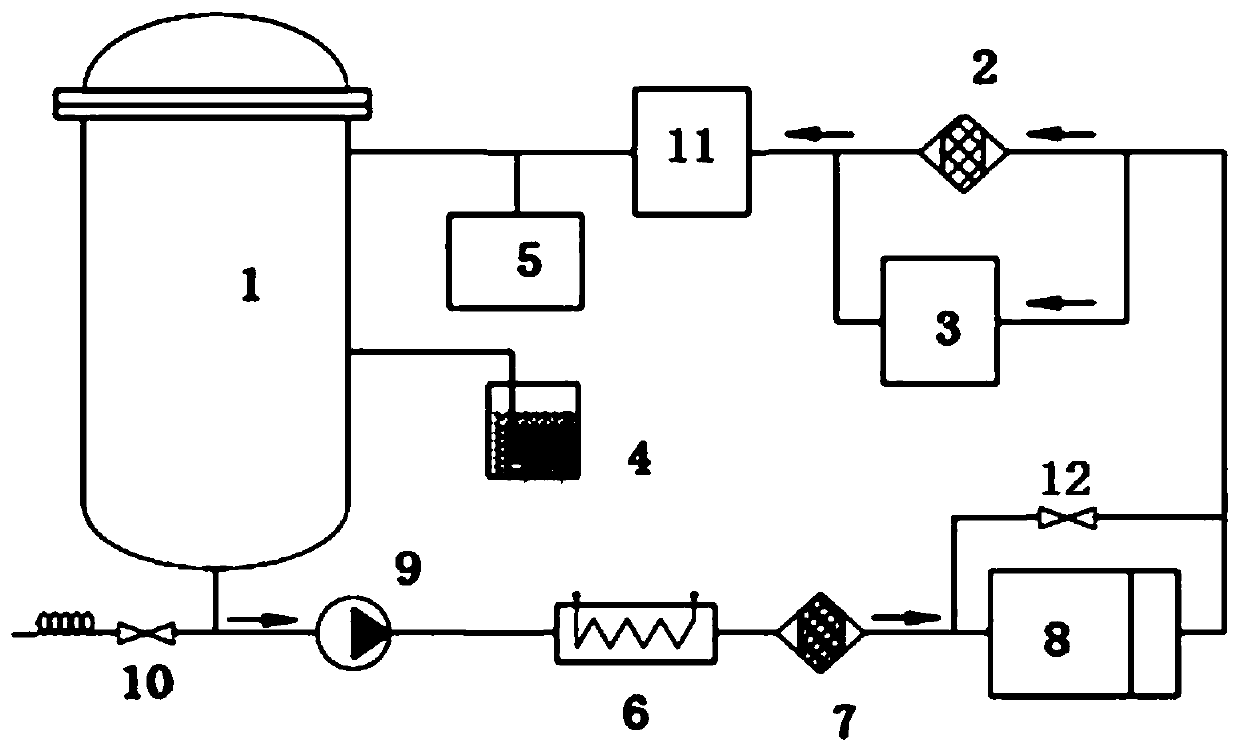

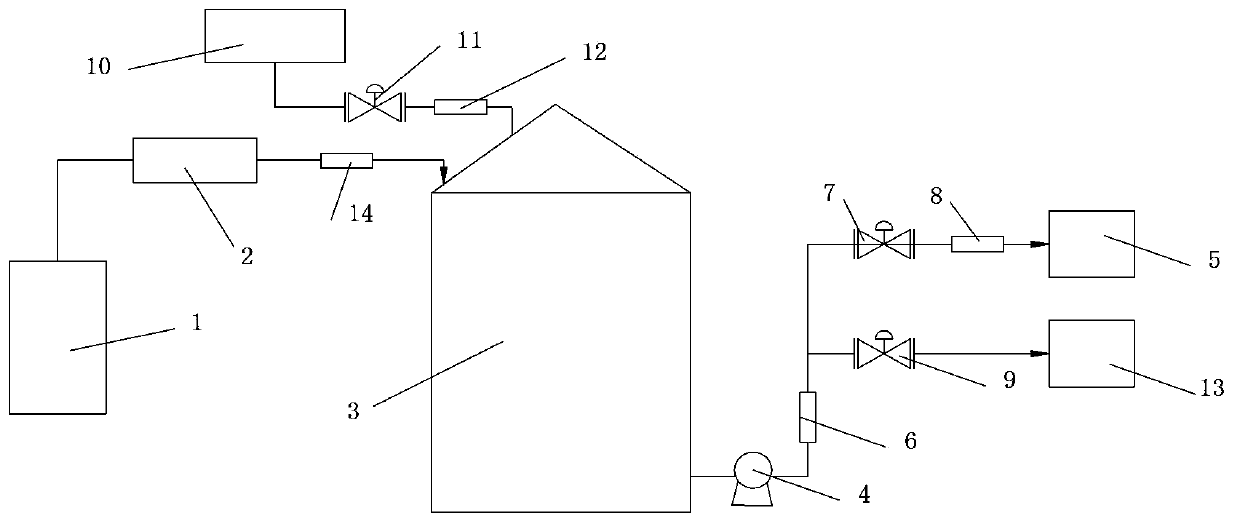

Wind generator gear lubricating oil on-site regeneration treatment system and method

PendingCN110252024AEfficient and fast regenerationMake sure you meet the requirementsFiltration circuitsLubricant compositionFilter systemMonitoring system

The invention relates to a wind generator gear lubricating oil on-site regeneration treatment system and method. The system includes a vacuum dehydration system, a regeneration system, a filtration system, a heating system, an additive automatic replenishing system, an oil quality on-line monitoring system, a cleaning and filling system, a magnetic filtration system, a circulating oil pump and an oil suction valve. Waste oil is sucked into a vacuum tank of the vacuum dehydration system, the circulating oil pump pumps the oil out from the bottom of the vacuum tank, after passing through the heating system, the magnetic filtration system, the regeneration system and the filtration system, the treated oil is returned to the vacuum tank from the vacuum tank top. The on-line monitoring system monitors the oil product parameters in real time during regeneration, after removal of degradation products from the oil product, an additive is added according to the index parameters of recovered oil, the cleaning and filling system performs repeated flushing on a waste oil drum and loads the qualified oil obtained by regeneration treatment into the cleaned oil drum. The replaced waste gear oil is subjected to regeneration treatment and on-line quality monitoring on site, thus ensuring that the oil subjected to regeneration treatment meets the standard requirements.

Owner:XIAN THERMAL POWER RES INST CO LTD

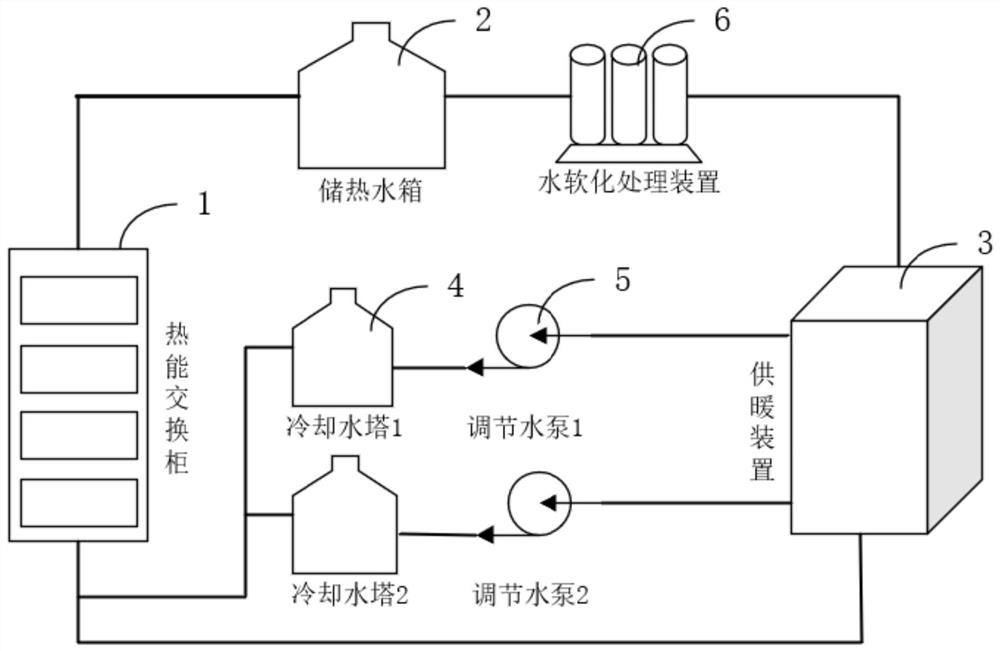

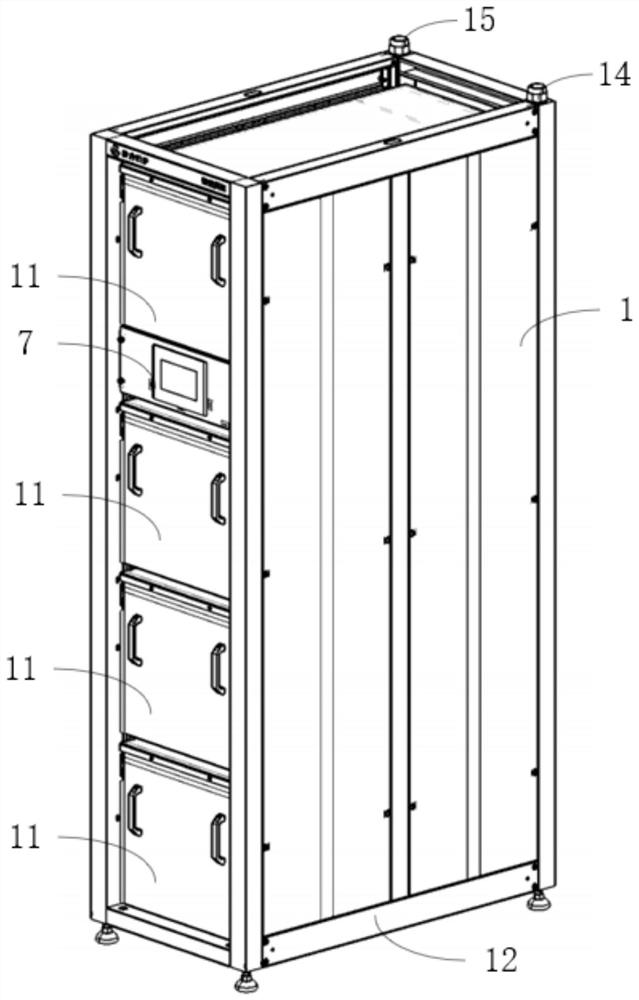

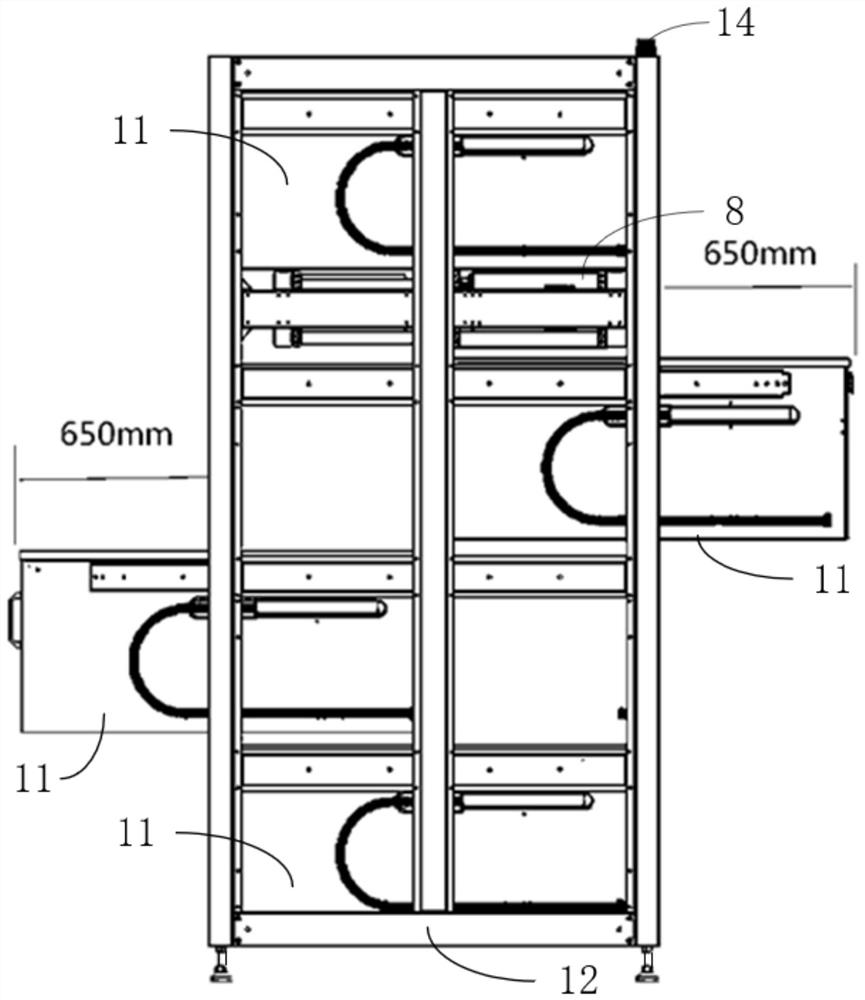

Digital server heat energy efficient recovery system and control method thereof

PendingCN113503578AGuaranteed cooling effectAchieve recyclingEfficient regulation technologiesSpace heating and ventilation detailsThermodynamicsCooling effect

The invention provides a digital server heat energy efficient recovery system and a control method thereof. The system comprises a heating device, a heat storage water tank and at least one heat energy exchange cabinet, and a server is arranged in the heat energy exchange cabinet; the heat storage water tank is connected with the heating device and used for exchanging heat with the heating device; the heat energy exchange cabinet is provided with a water inlet pipe and a water outlet pipe, and the water outlet pipe is connected with the heat storage water tank, and the water inlet pipe is connected with the heating device; and the system further comprises a cooling water tower, and the cooling water tower is connected with the heating device and the water inlet pipe and used for conducting secondary cooling on heating return water and transferring the heating return water subjected to secondary cooling to the heat energy exchange cabinet. According to the digital server heat energy efficient recovery system provided by the invention, the heat energy generated in the operation process of the server is transmitted into the heating device, and the heat energy is recycled by establishing a heat energy circulation system. The PUE value of the system is close to 1, the cooling effect of the server is guaranteed, meanwhile, cyclic utilization of energy is achieved, and the operation cost is reduced.

Owner:易链科技(深圳)有限公司

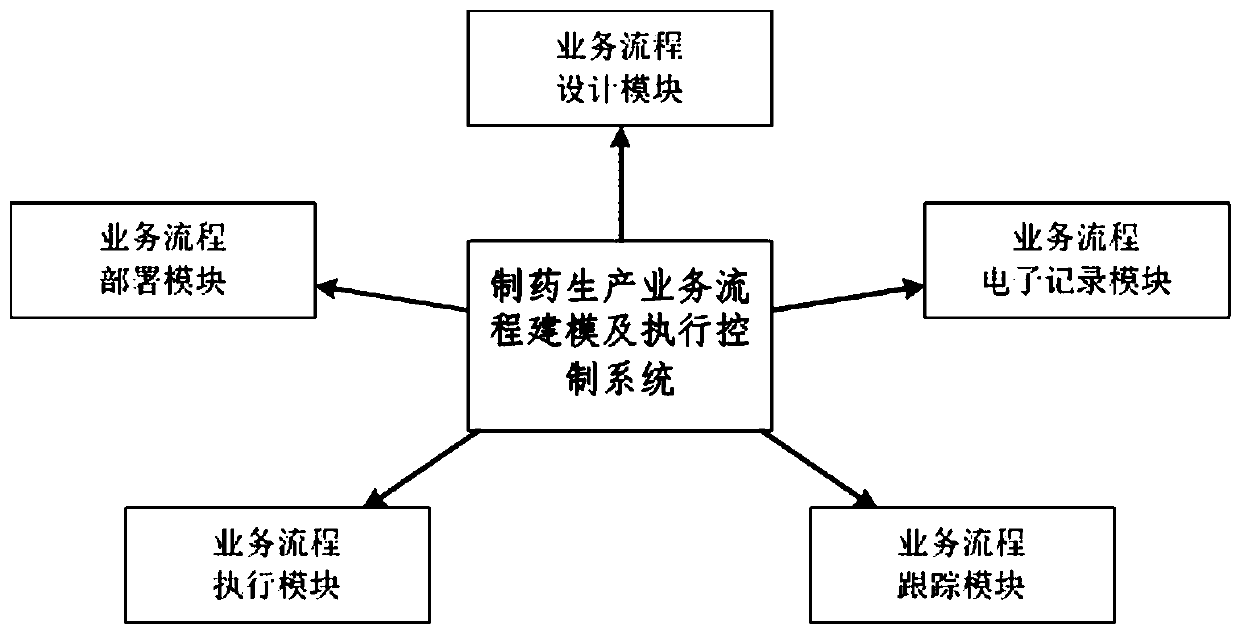

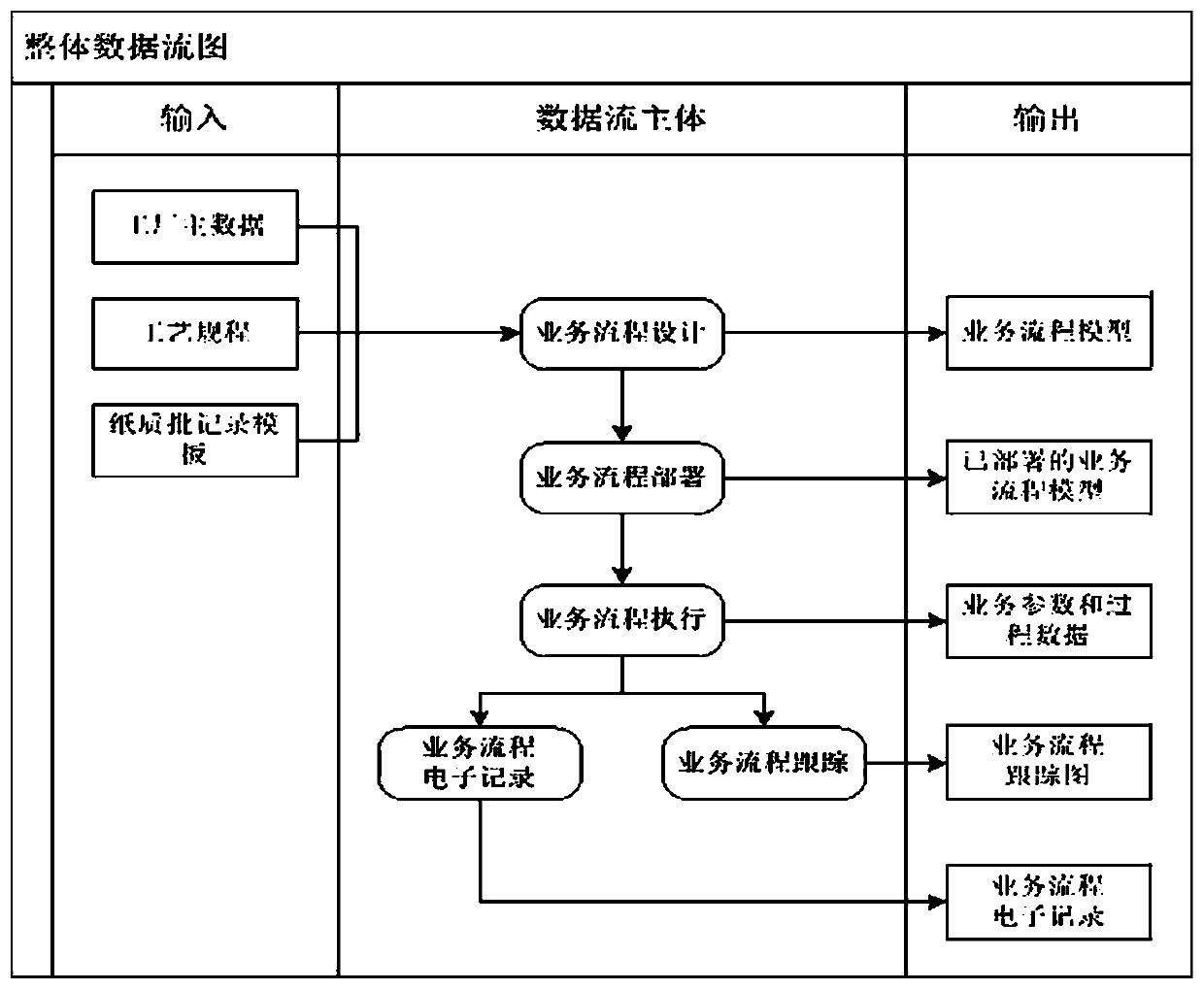

Pharmaceutical production business process control system and method

The invention provides a pharmaceutical production business process control system and method, wherein the method comprises the steps: recognizing a standard model library according to a production standard, building a production business process based on the standard model library, and setting the information of each process node of the production business process; carrying out version control onthe production business process to obtain a controlled business process, and deploying the controlled business process to obtain a deployed business process; executing the deployed business process in a step-by-step navigation mode, and recording process parameters in the execution process; recording an execution result obtained by executing the deployed business process to obtain a production record, and processing and storing the production record; and carrying out graphical tracking on the execution process, and displaying process parameters. According to the invention, pharmaceutical enterprises can be helped to better meet the requirements of laws and regulations, the working efficiency is improved, the process is continuously improved, the product quality is optimized, and informationized means support is provided for the increasingly strict supervision requirements of the government on the production of the pharmaceutical enterprises.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

Condensed water recycling system for evaporation process

ActiveCN103388157AEfficient recyclingMake sure you meet the requirementsElectrolysis componentsSaline waterElectrolysis

The invention relates to the field of industrial sewage recycling and particularly relates to a condensed water recycling system for an evaporation process. The condensed water recycling system comprises an evaporation device, a condenser, a process condensed water tank and an electrolyzer cathode chamber which are connected sequentially; condensed water generated by the evaporation device and the condenser is conveyed to the electrolyzer cathode chamber to serves as a diluting medium, so that process condensed water is recovered effectively; a first pH meter and a first flowmeter are arranged on a pipeline which connects the process condensed water tank and the electrolyzer cathode chamber together, so that the flow and pH value of the condensed water entering the electrolyzer cathode chamber are monitored; and since a pipeline leading to a primary brine refining unit is connected with a pipeline between the first pH meter and a first control valve, the process condensed water is discharged to the primary brine refining unit and used for desalting when the pH value of the process condensed water does not meet the requirement, so that the process condensed water is treated and utilized effectively, and further the comprehensive and efficient utilization of the process condensed water is realized.

Owner:内蒙古君正化工有限责任公司

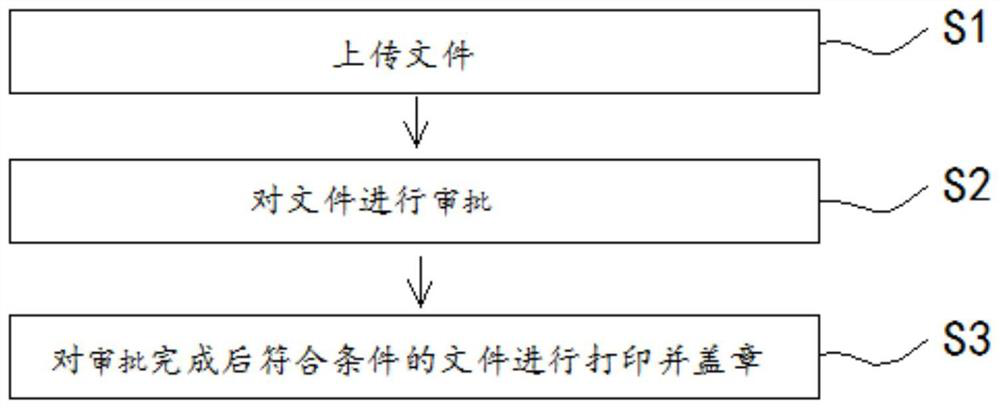

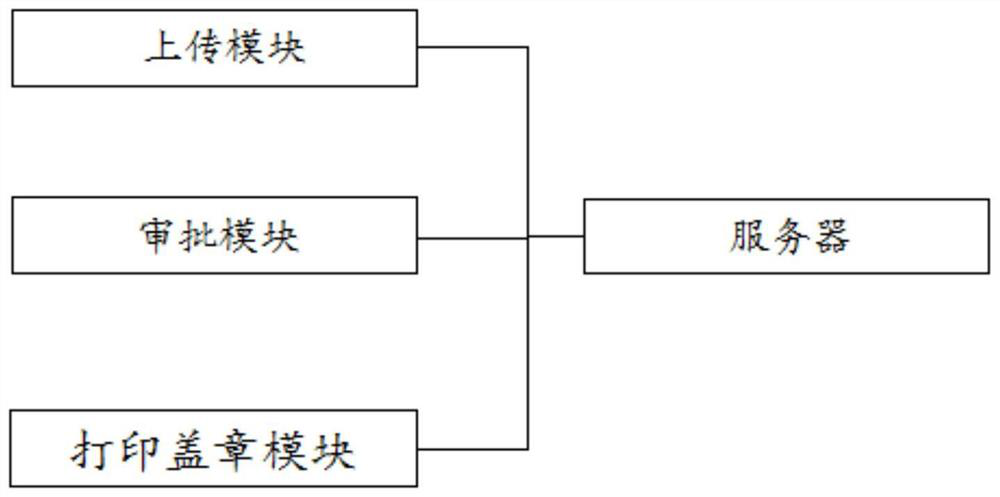

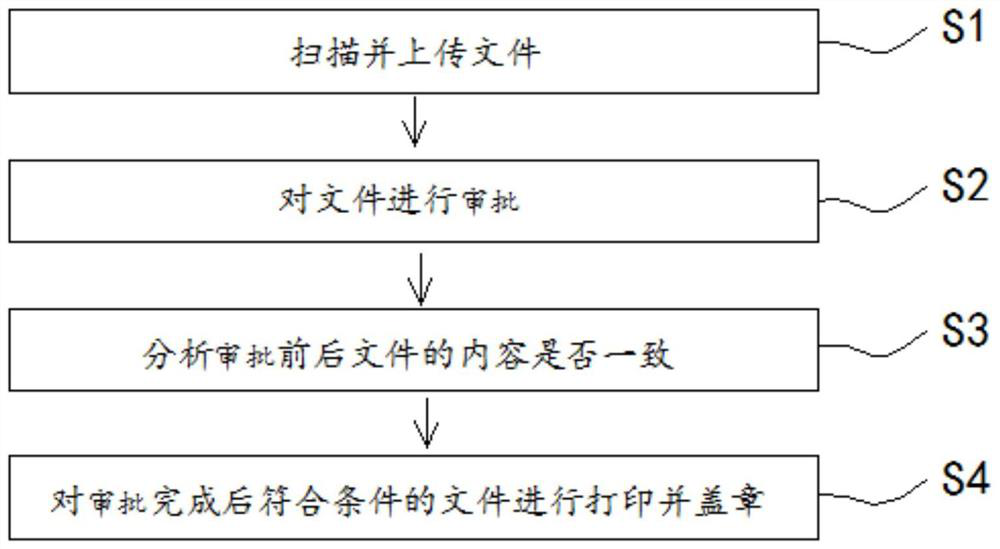

File sealing permission monitoring method and system

PendingCN113642983ARealize online approvalAvoid hidden dangers of stampingOffice automationSoftware engineeringDatabase

The invention relates to a file sealing permission monitoring method and system, and the method comprises the following specific steps: uploading a file, confirming and marking a seal using position of the file, and examining and approving the uploaded electronic file; and analyzing whether the contents of the files before and after examination and approval are consistent, and automatically stamping the paper files which are consistent before and after identification or directly printing and stamping the electronic files. The automatic stamping machine has the beneficial effects that the whole-course online approval, automatic printing and stamping and automatic authentic identification and automatic stamping of the file are realized, the paper file stamping hidden danger caused by human factors and management vulnerabilities is avoided, and the paper file stamping efficiency and safety are improved.

Owner:深圳承章科技有限公司

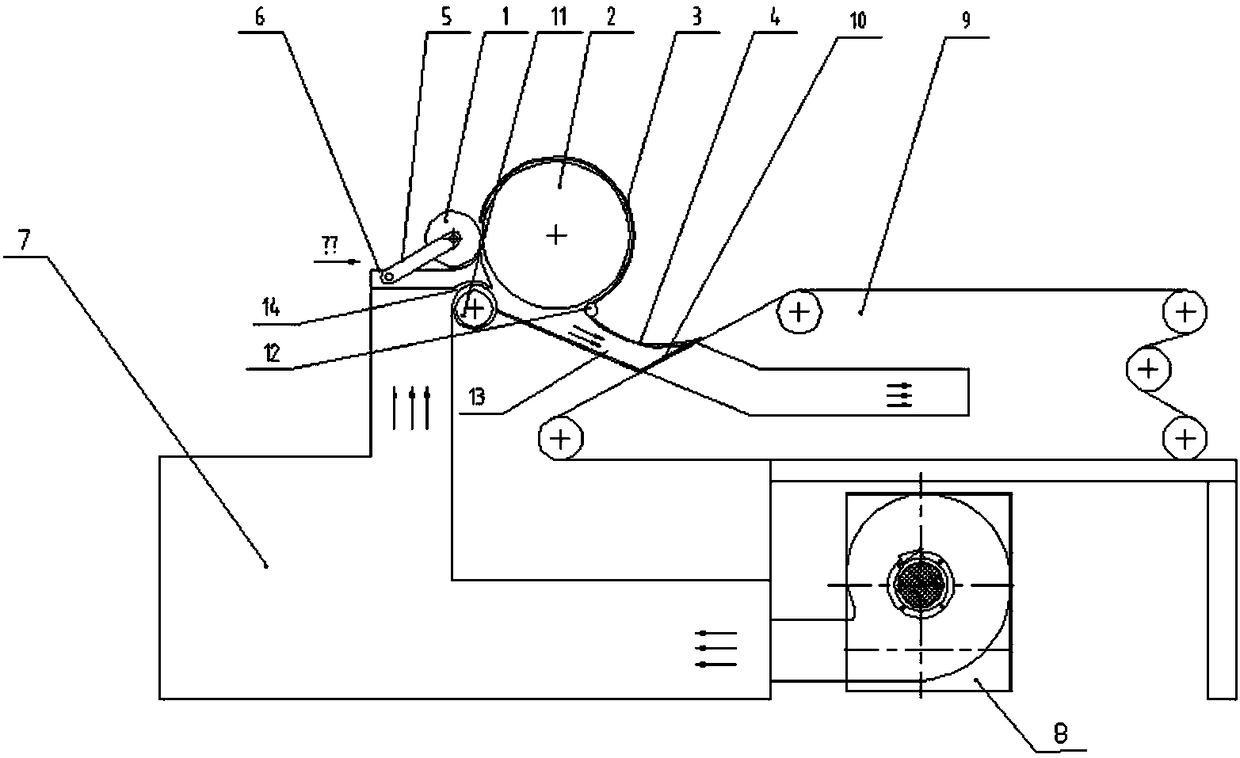

Air-laid web-forming machine for glass fibers

PendingCN108456994AMake sure you meet the requirementsSolve the problem that the glass staple fiber cotton net cannot be madeNon-woven fabricsFiberGlass fiber

The invention discloses an air-laid web-forming machine for glass fibers. The air-laid web-forming machine comprises a cotton feed plate, a feeding roller, a beater roller and a web forming trolley, wherein the feeding roller is arranged on the cotton feed plate, the beater roller is arranged at the right side of the feeding roller, a cotton conveying chamber is arranged below the beater roller, an eccentric roller is arranged below the cotton feed plate, an air inlet communicating with the cotton conveying chamber is formed by the cotton feed plate and the eccentric roller, and the cotton conveying chamber is connected with an upper curtain net of the web forming trolley. According to the air-laid web-forming machine for the glass fibers, provided by the invention, the problem of ordinaryair-laid web forming that glass staple-fiber cotton webs cannot be produced is solved; the condition that formed webs are satisfactory is ensured in a plurality of adjusting modes; due to a mobile web-forming mechanism, the routine maintenance can be conveniently carried out.

Owner:苏州九一高科无纺设备有限公司

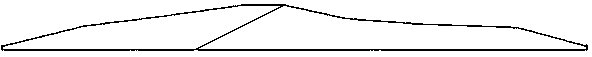

Ultra-high performance ultra-large sized tyre and preparation process thereof

ActiveCN102935788AEnsure performance meets requirementsSimple internal structureTyresPneumatic tyre reinforcementsFinite elemente analyseMechanical engineering

The invention discloses an ultra-high performance ultra-large sized tyre and a preparation process thereof. The specification of the ultra-high performance ultra-large sized tyre is 305 / 25R32108W, the rim diameter is 32 inches, the rim width is 11J, the outer diameter is 965mm, the section width is 313mm, and the load is 1000kg. The tyre contour designed by high-performance tyre contour design software and subjected to finite element analysis is adopted, and the advanced structural design means and the stable process control can be adopted, the volume production of the tyre with the specification is realized, simultaneously all aspects of performances of the tyre can meet the requirements, product development risks are effectively reduced and the product development period is reduced.

Owner:QINGDAO SENTURY TIRE CO LTD

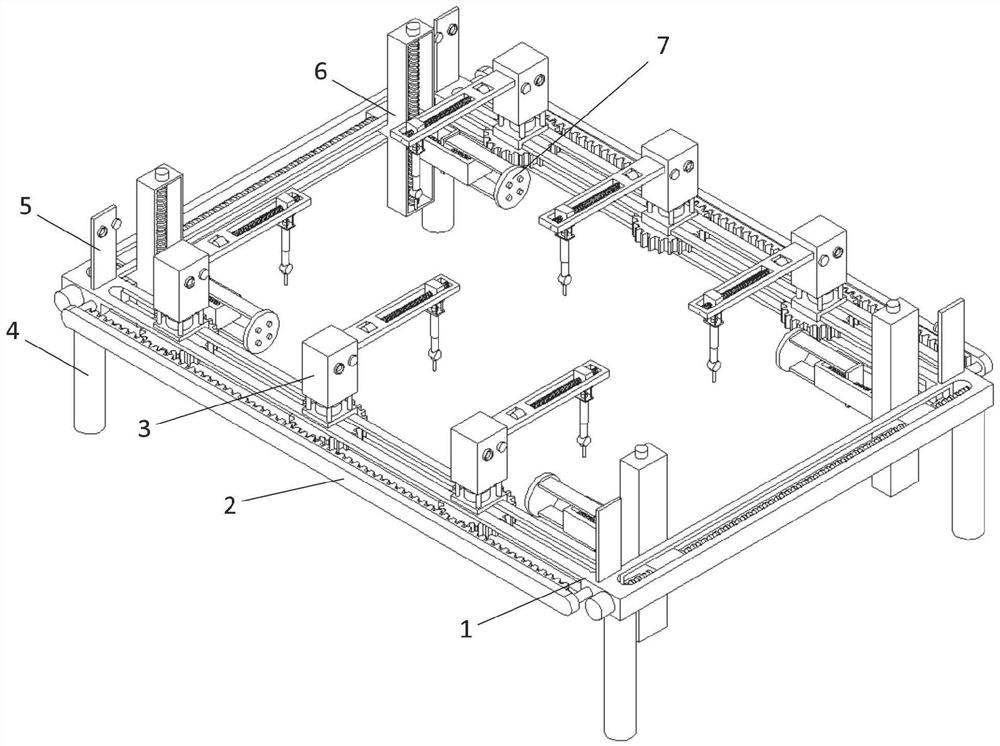

Automatic electronic testing fixture for battery case of new energy automobile

InactiveCN114838640AMake sure you meet the requirementsImprove test efficiencyUsing optical meansMechanical measuring arrangementsAutomotive batteryElectrical battery

The invention provides an automatic electronic testing fixture for a new energy automobile battery case. The automatic electronic testing fixture comprises a concentric-square-shaped frame; the two groups of clamping units are symmetrically arranged on the frame edges of the two ends of the concentric-square-shaped frame respectively and are used for clamping the battery shell; the multiple groups of detection platforms are erected on the two sides of the concentric-square-shaped frame; each group of detection platform comprises a mobile driving device arranged on the concentric-square-shaped frame; the measuring table is erected at the top of the movable driving device and is driven by the movable driving device to move in the length direction of the frame edge on one side of the concentric-square-shaped frame; the horizontal driving assembly is erected on one side of the measuring table, faces the interior of the concentric-square-shaped frame and drives a moving table to move front and back; the rotation driving assembly is erected at the bottom of the moving table; the electric telescopic rod is driven to rotate through the rotation driving assembly; and the test rod is connected with the end part of the electric telescopic rod through a lever meter. The device can quickly detect the holes and the mounting grooves in the battery shell in batches, and whether the positions of the holes and the mounting grooves in the battery shell meet requirements or not is measured.

Owner:HUAIAN COLLEGE OF INFORMATION TECH

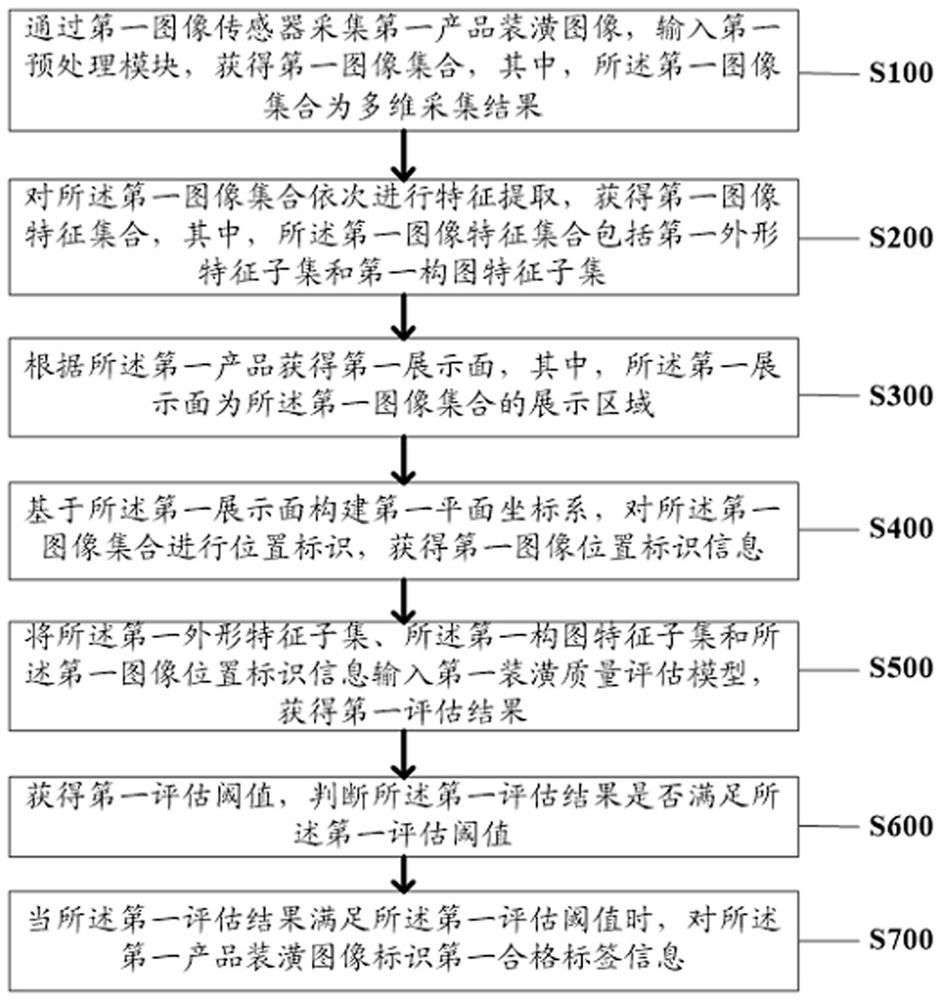

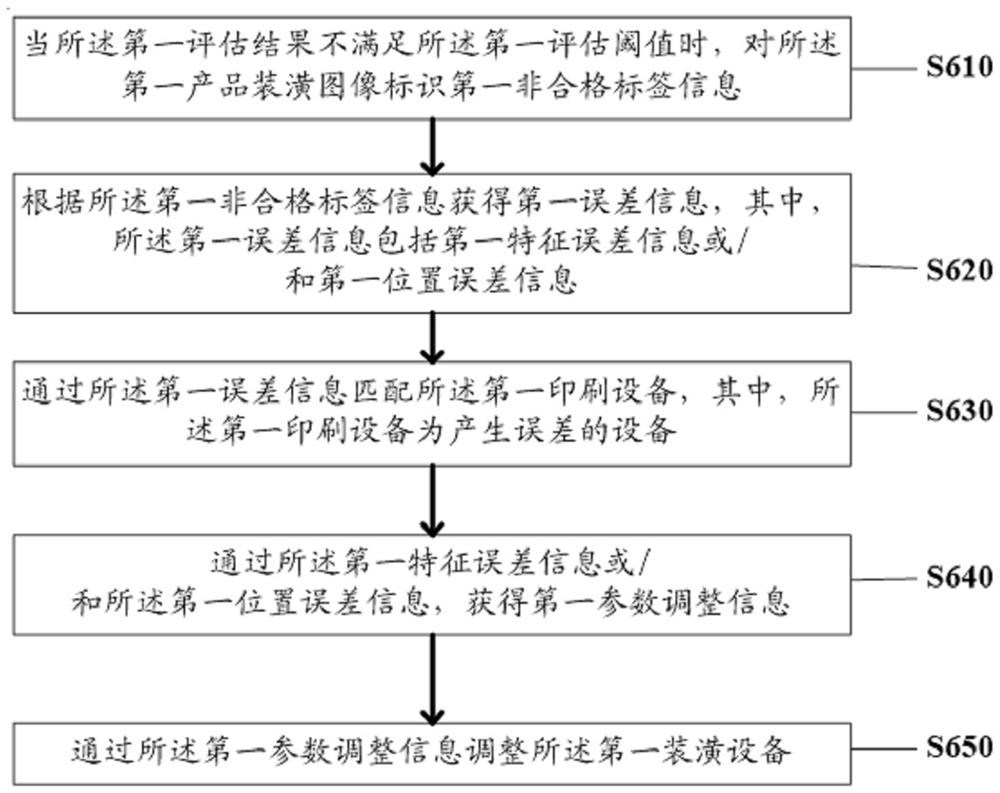

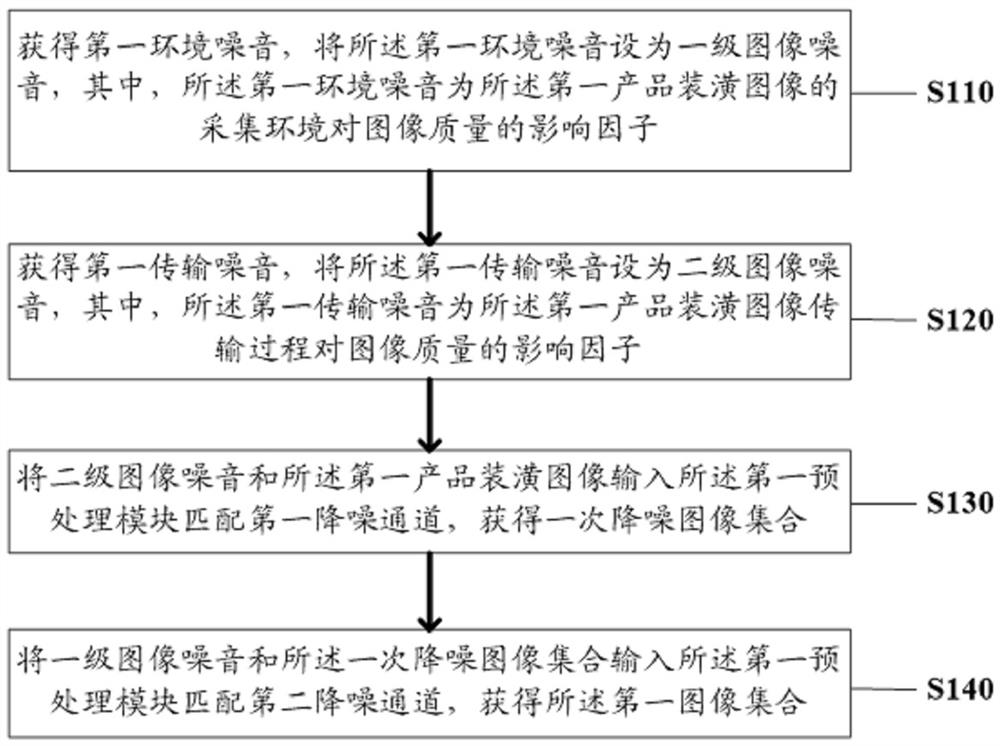

Packaging decoration quality inspection method based on machine vision

ActiveCN113610851AQuality real-time monitoringImprove quality inspection efficiencyImage enhancementImage analysisEvaluation resultFeature extraction

The invention discloses a packaging decoration quality inspection method based on machine vision, and the method comprises the steps: collecting a first product decoration image through a first image sensor, inputting the first product decoration image into a first preprocessing module, and obtaining a first image set; sequentially performing feature extraction on the first image set to obtain a first image feature set; obtaining a first display surface according to the first product; constructing a first plane-coordinate system based on the first display surface, and obtaining first image position identification information; obtaining a first evaluation result based on the first decoration quality evaluation model; obtaining a first evaluation threshold value, and judging whether the first evaluation result meets the first evaluation threshold value or not; and when the first evaluation result meets the first evaluation threshold value, marking first qualified label information on the first product decoration image. The technical problems that in the prior art, the inspection efficiency of product packaging materials and printing decoration quality is low, and meanwhile mistaken inspection and missing inspection exist are solved.

Owner:武汉平桥兄弟包装材料有限公司

A type selection and checking method of the main bearing cap bolts of an automobile engine

ActiveCN112528425BImprove design safety marginImprove work efficiencyGeometric CADSpecial data processing applicationsAxial forceControl theory

The invention relates to a method for selecting and checking bolts of a main bearing cap of an automobile engine, and belongs to the technical field of vehicle manufacturing. The method provided by this application obtains the maximum working load of the engine and further obtains the maximum dynamic load of the bearing pad of the main bearing cap through the maximum explosion pressure of the engine, and considers the preload force required to prevent the main bearing pad from opening under static assembly conditions, According to the predetermined safety factor determined by the attenuation of the axial force, it is simplified to the pretightening force provided by a single bolt to fasten the bearing pad, and then the bolt is positively selected, and then the bolt is in the state of mass production. According to the specification and size, friction coefficient dispersion, yield strength dispersion and the actual situation, the actual maximum pre-tightening force and the actual minimum pre-tightening force of the bolts are calculated accurately, and finally checked. The method can accurately select the bolts of the main bearing cap of the automobile engine. The method is simple and well considered, and the selected bolts are more in line with the actual situation of the operation of the automobile engine.

Owner:DONGFENG MOTOR CORP HUBEI

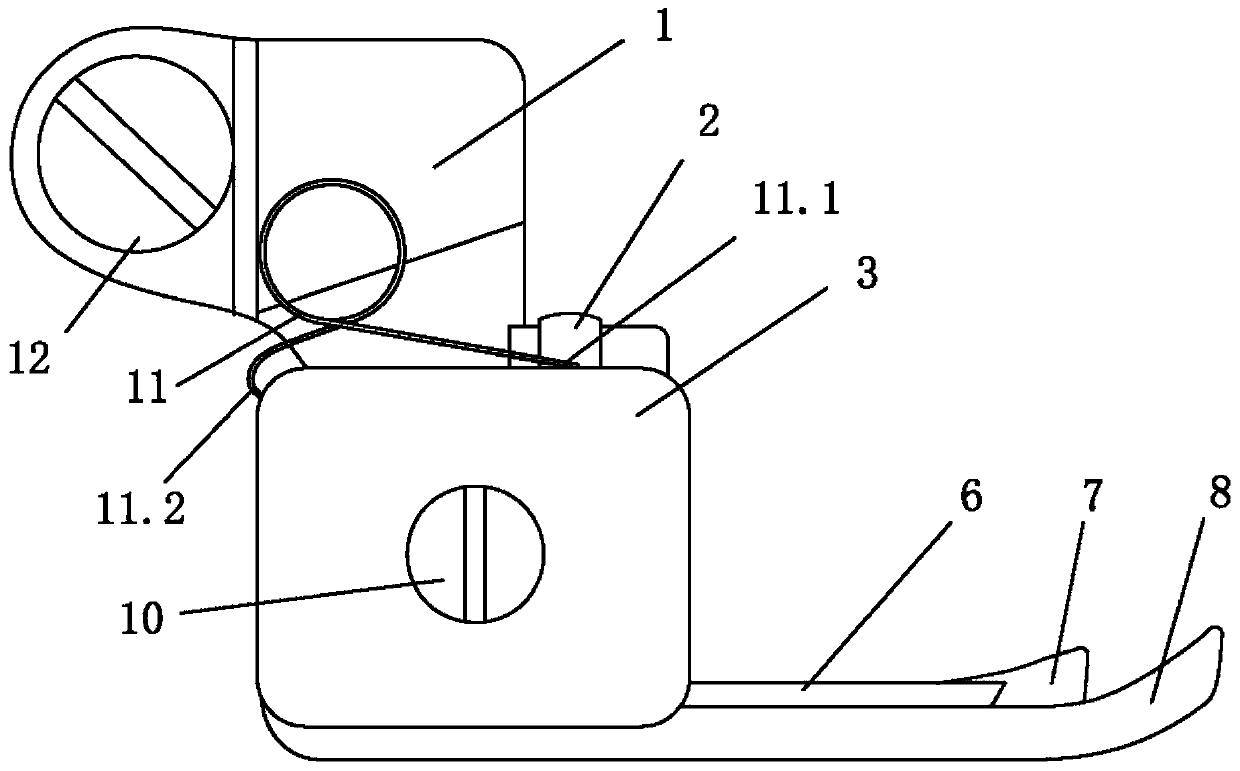

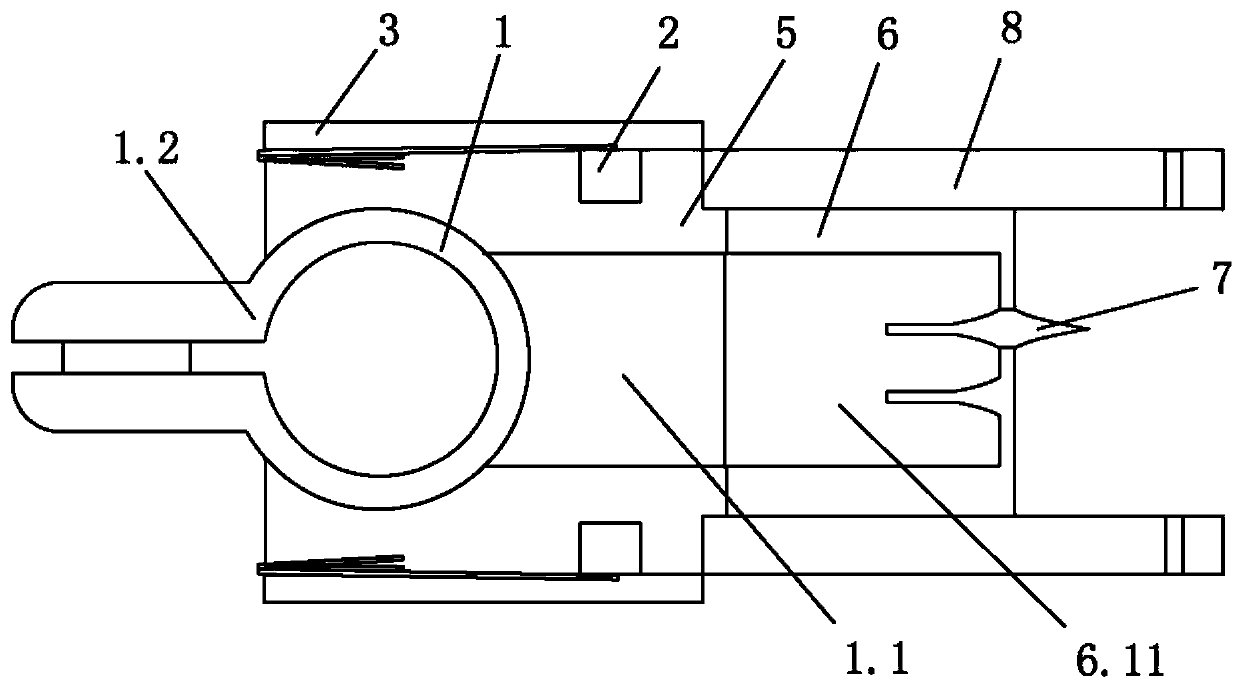

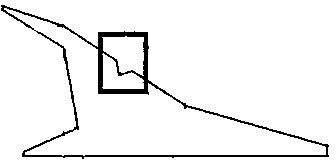

Middle dividing presser foot provided with ultrashort seam allowance knife

PendingCN109706633AGuarantee product qualityEnsure stability and improvePressersEngineeringSewing machine

The invention relates to a textile sewing machine component and aims to provide a middle dividing presser foot provided with an ultrashort seam allowance knife. The middle dividing presser foot can ensure that the quality of a sewed middle dividing pressing line meets the requirements. According to the technical scheme, the middle dividing presser foot provided with the ultrashort seam allowance knife comprises a connector, a pressing plate and a first elastic element, wherein the connector is fixedly connected with the bottom of a pressing rod, the pressing plate is hinged to the connector through two hinging lugs on the upper part of the pressing plate and provided with a pinhole, and the first elastic element applies force to the connector and the pressing plate separately. The middle dividing pressure foot is characterized in that the pressing plate is also provided with the seam allowance knife which is embedded into a seam during sewing; the seam allowance knife is positioned onthe front side of the pinhole of the pressing plate and protrudes forwards and downwards by a certain distance.

Owner:HIGH FASHION CHINA CO LTD

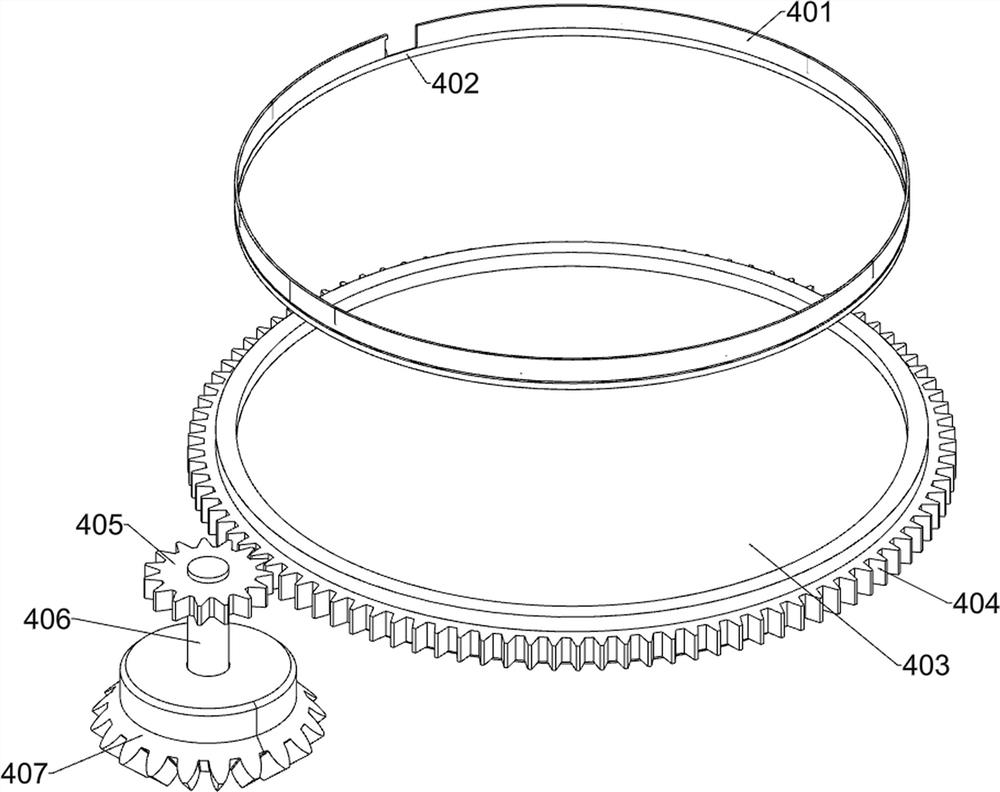

Instrument for bi-directionally and uniformly adding graphite powder before crack detection of stainless steel watch case

ActiveCN113731761AAvoid flyingReduce wasteLiquid surface applicatorsPreparing sample for investigationGraphiteMaterials science

The invention relates to the field of watches, in particular to an instrument for bi-directionally and uniformly adding graphite powder before crack detection of a stainless steel watch case, and aims to solve the technical problem that the adding thickness of the graphite powder is required, and the thickness of the graphite powder is difficult to control when the graphite powder is added, so that the graphite powder is too thick and too thin, and the thickness cannot reach the standard. According to the technical scheme, the instrument for bi-directionally and uniformly adding the graphite powder before crack detection of the stainless steel watch case comprises a discharging assembly and an inner ring processing assembly; the inner ring processing assembly used for processing the inner ring graphite powder on the surface of the watch case is installed on the discharging assembly. The graphite powder is added in a bi-directional mode in the graphite powder adding process, in the adding process, the graphite powder can be prevented from flying around, waste of the graphite powder is reduced, in addition, during adding, the thickness of the graphite powder on the inner ring of the watch case can be effectively guaranteed, the thickness of the outer ring of the inclined surface of the watch case can also be guaranteed, it is guaranteed that the graphite powder meets the requirement, and later detection of the stainless steel watch case is facilitated.

Owner:深圳市宇珀黄金钟表科技有限公司

A Design Method for On-orbit Implementation of Spaceborne SAR Mosaic Pattern

ActiveCN112014840BMake sure you meet the requirementsImprove processing efficiencyGeometric image transformationRadio wave reradiation/reflectionImage resolutionAzimuth direction

A design method for on-orbit implementation of a spaceborne SAR mosaic pattern. The present invention firstly establishes the design constraints of the mosaic pattern according to the geometric resolution to be achieved by the spaceborne SAR image, the scene width, and the required number of elevation beams. ;Secondly, the attitude maneuvering mode of the satellite platform in the mosaic mode imaging process is designed according to the constraint conditions; Thirdly, according to the resolution requirements, the oblique angle of the antenna beam at the initial moment, and the maneuver curve of the satellite attitude over time, the antenna beam is calculated at the pitch to each moment of switching. Finally, according to the designed attitude maneuvering curve and beam switching time, it is confirmed that: 1) the resolution in azimuth direction has reached the technical index; integrity.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

Chromium ore grinding collection environment-friendly equipment

The invention belongs to the field of chromium ore grinding, and discloses chromium ore grinding collection environment-friendly equipment which comprises a base and a multi-stage grinding cylinder. Aplacement rectangular groove is formed in the center of the top end of the base, a collection box is placed in the placement rectangular groove, two sets of supporting rods are symmetrically and fixedly connected to the centers of two edges of the top end of the base, an installation plate is fixedly installed at the top ends of the supporting rods, a servo motor is fixedly connected to the center of the top end of the installation plate, an installation through hole is formed in the center of the top end of the installation plate, a bearing is arranged on the inner wall of the installation through hole, the output end of the servo motor is connected with a rotating shaft, the end of the rotating shaft rotationally penetrates through the bearing and is connected with a right-angle-n-shaped frame, the multi-stage grinding cylinder is arranged at the bottom end of right-angle-n-shaped frame, and the multi-stage grinding cylinder comprises a first-stage grinding cylinder, a second-stagegrinding cylinder, a third-stage grinding cylinder, a first-stage cylinder plug, a second-stage cylinder plug and a third-stage cylinder plug.

Owner:ANHUI HANSHAN COUNTY TIANSHUN ENVIRONMENTAL PROTECTION EQUIP

Food mechanical potato slicing equipment

The invention discloses food mechanical potato slicing equipment. The food mechanical potato slicing equipment comprises a box body, wherein one side, away from an electric motor, of a cutting base isequipped with a plurality of cutters; the position, on the box body, of the top of a movable material sleeve base is provided with a plurality of limiting holes; the positions, in the limiting holes,of the top of box body are equipped with a plurality of blocking ball devices; the position, on the cutting base, of the outer wall of the right side of the box body communicates with a charge tube;one end, away from the box body, of the charge tube communicates with a material pocket; the positions, close to the two sides of the bottom of the box body, of the inner cavity of the box body are rotatably connected with rollers through rotary shafts; and the outer surfaces of the rollers are in mutual transmission through a transmission belt. The invention relates to the food processing mechanical field, in particular to the food mechanical potato slicing equipment which solves the problem that mouth feel is affected by material deterioration as existing used slicing equipment cannot freelyregulate thickness of a to-be-sliced potato, cannot timely convey out sliced potato slices after slicing is completed, and the potato slices are accumulated for a long time.

Owner:刘宇豪

Ultra-high performance ultra-large sized tyre and preparation process thereof

ActiveCN102935788BEnsure performance meets requirementsSimple internal structureTyresPneumatic tyre reinforcementsElement analysisSoftware design

The invention discloses an ultra-high performance ultra-large sized tyre and a preparation process thereof. The specification of the ultra-high performance ultra-large sized tyre is 305 / 25R32108W, the rim diameter is 32 inches, the rim width is 11J, the outer diameter is 965mm, the section width is 313mm, and the load is 1000kg. The tyre contour designed by high-performance tyre contour design software and subjected to finite element analysis is adopted, and the advanced structural design means and the stable process control can be adopted, the volume production of the tyre with the specification is realized, simultaneously all aspects of performances of the tyre can meet the requirements, product development risks are effectively reduced and the product development period is reduced.

Owner:QINGDAO SENTURY TIRE CO LTD

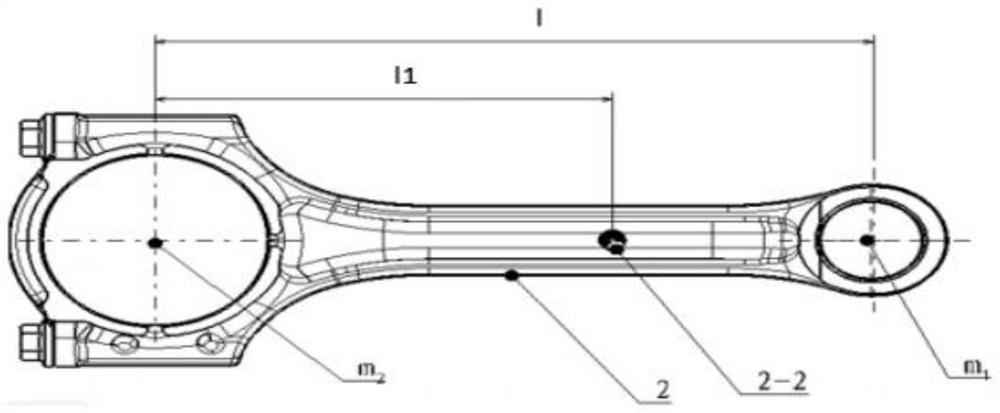

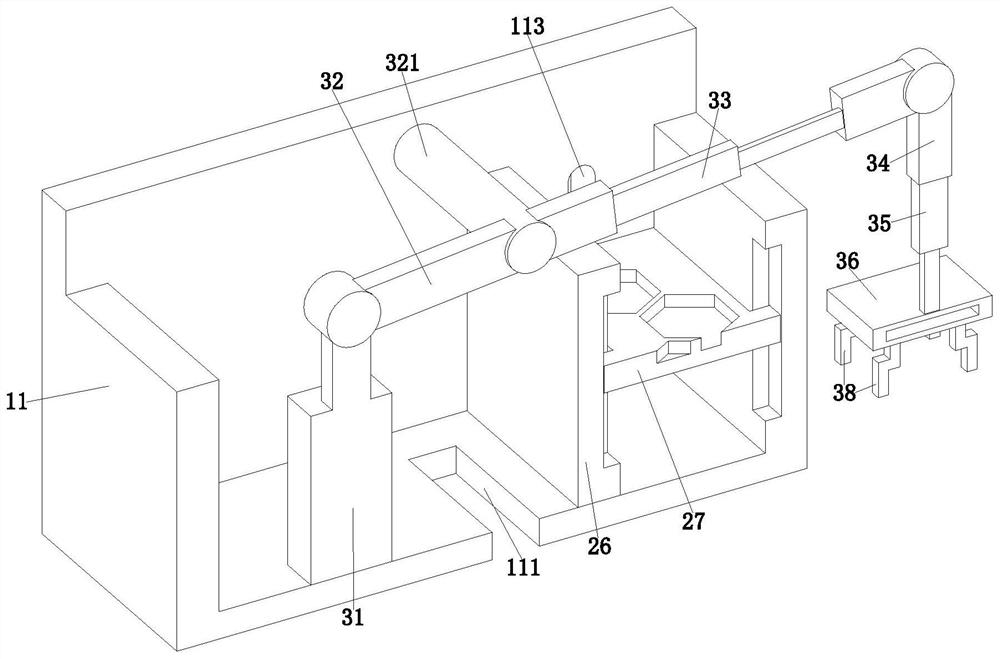

Automobile engine connecting rod bolt model selection and checking method

ActiveCN112528394AImprove design safety marginImprove work efficiencyGeometric CADDesign optimisation/simulationReciprocating motionIndustrial engineering

The invention relates to an automobile engine connecting rod bolt model selection and checking method, and belongs to the technical field of automobile manufacturing. According to the method, the connecting rod is divided into the rotary motion part and the reciprocating motion part, so that the maximum inertia force of the connecting rod is accurately obtained, the pre-tightening force needed forpreventing the main bearing bush from being opened under the static assembly condition is considered, and the preset safety coefficient is determined according to axial force attenuation; and finally, simplifying is performed to obtain a pre-tightening force required to be provided for fastening the bearing bush by a single bolt, then forward model selection is carried out on the bolt, and the actual maximum pre-tightening force and the actual minimum pre-tightening force of the bolt is accurately calculated by considering the specifications and sizes, the friction coefficient dispersion difference, the yield strength dispersion difference and the actual conditions of multiple batches of bolts in a mass production state of the bolt. Finally, checking is carried out. According to the method, forward model selection can be accurately carried out on the automobile engine connecting rod bolt, the method is simpler and more convenient and complete in consideration, and the selected bolt can better meet the actual running condition of the automobile engine connecting rod.

Owner:DONGFENG MOTOR CORP HUBEI

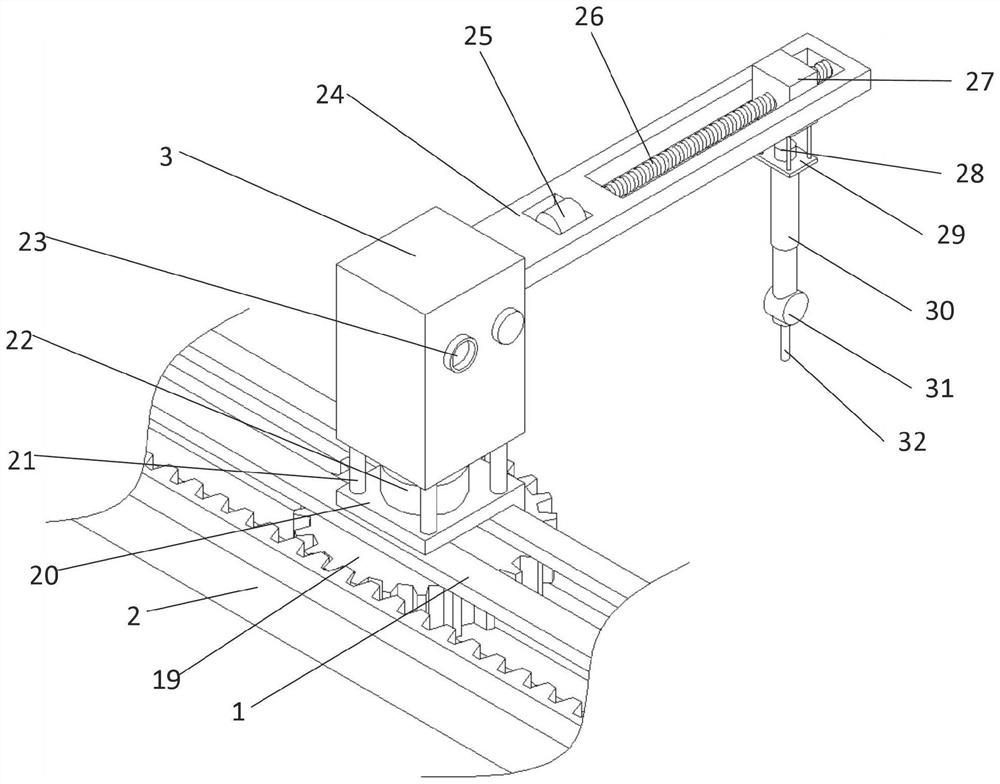

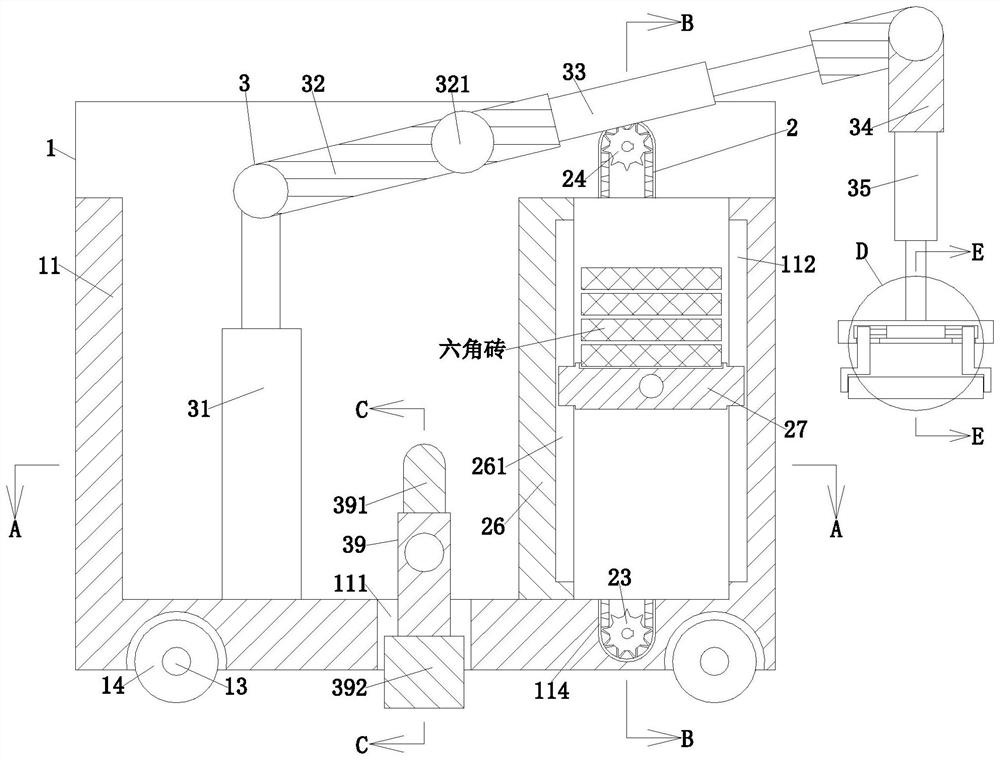

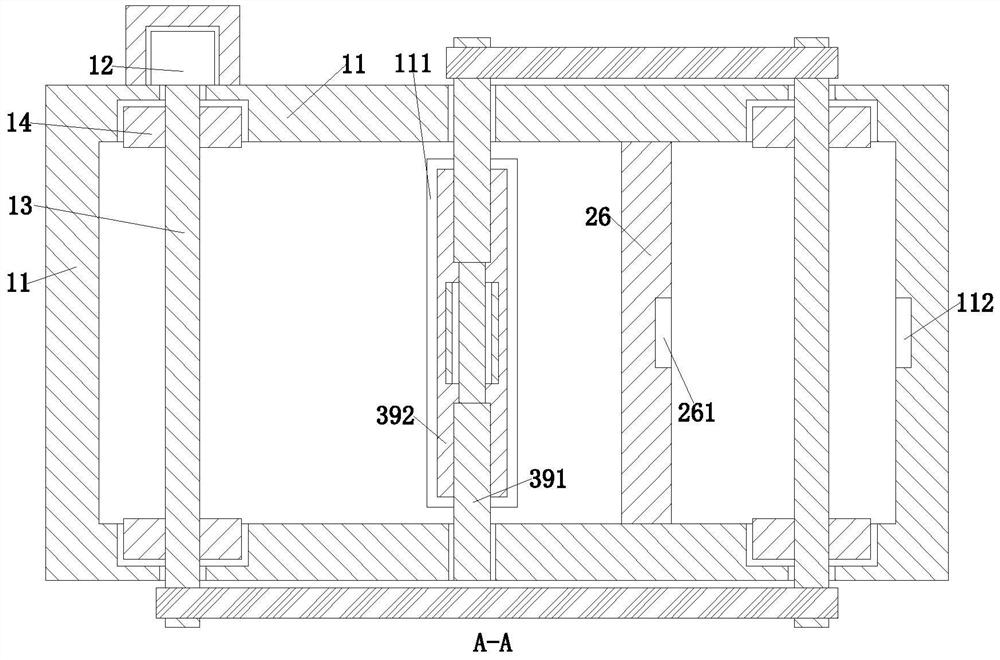

A landscape garden pavement laying machine

ActiveCN112501995BEasy to laySave man hoursRoads maintainenceArchitectural engineeringStructural engineering

The present invention provides a machine for laying landscape garden pavement, which includes a frame, a feeding unit and an execution unit. On the inner wall on the left side of the middle part of the lower end of the frame, the execution unit is arranged on the inner wall of the linkage hole on the inner wall of the lower end of the frame; Laying is easy to make workers tired; workers have to perform multiple actions of picking, laying and knocking when laying, and manual laying needs to be laid one by one, so labor costs are consumed, laying efficiency is low, and laying hours are wasted".

Owner:广州市华实生态园林有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com