Fatigue strength detecting machine of trundle brake sheet

A technology of fatigue strength and brake pads, which is applied in the field of testing machines for detecting the fatigue strength of caster brake pads, can solve problems such as potential safety hazards, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

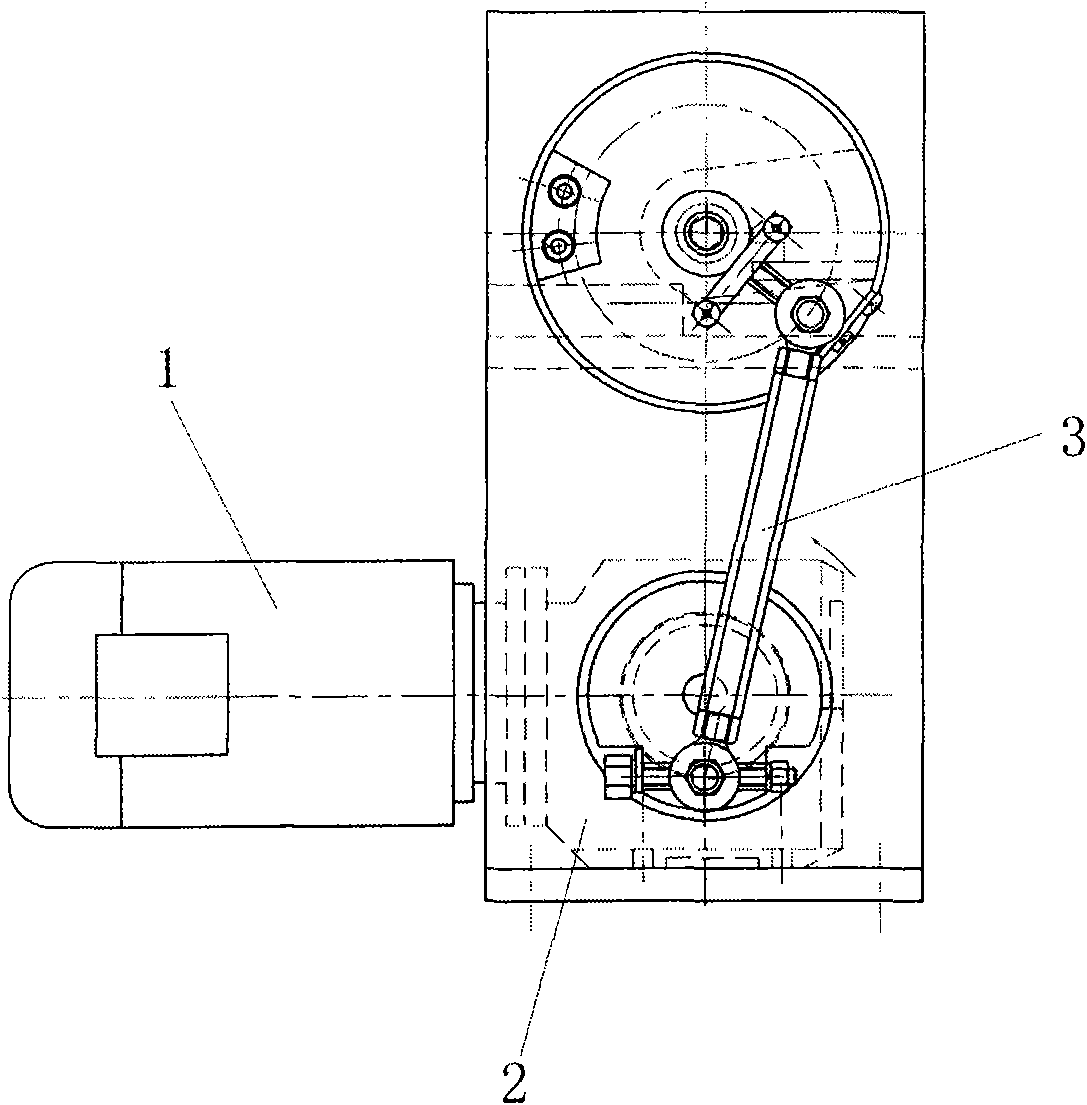

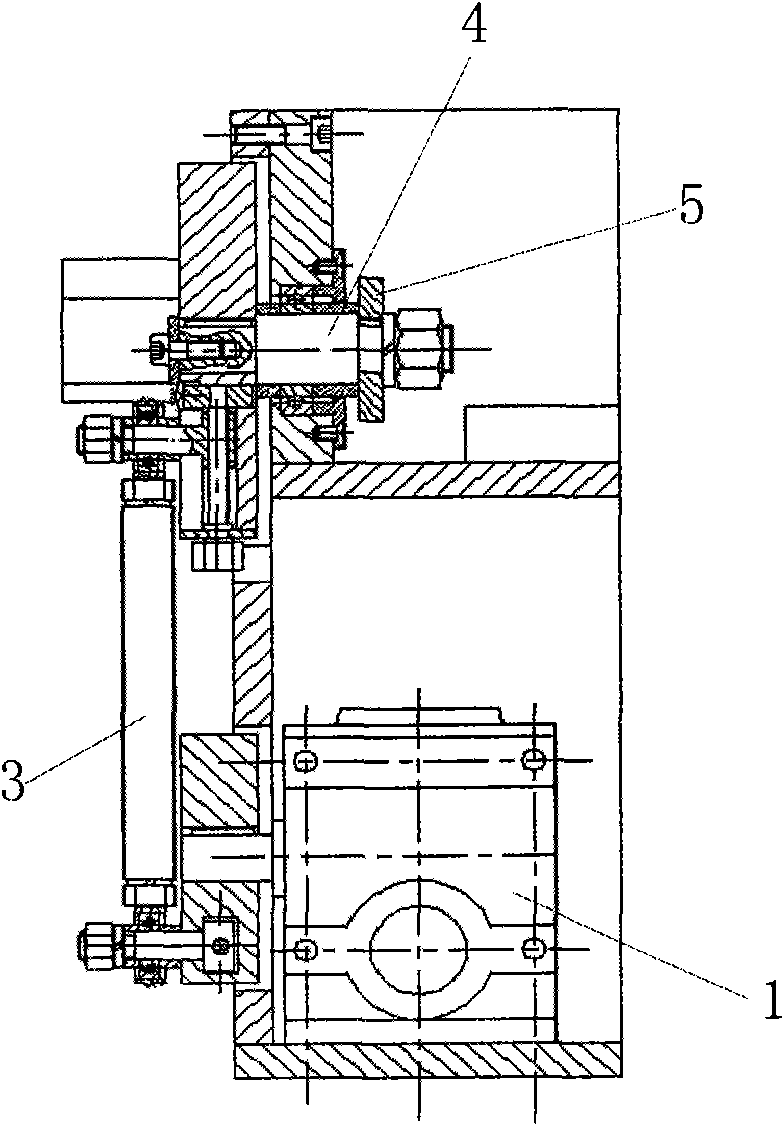

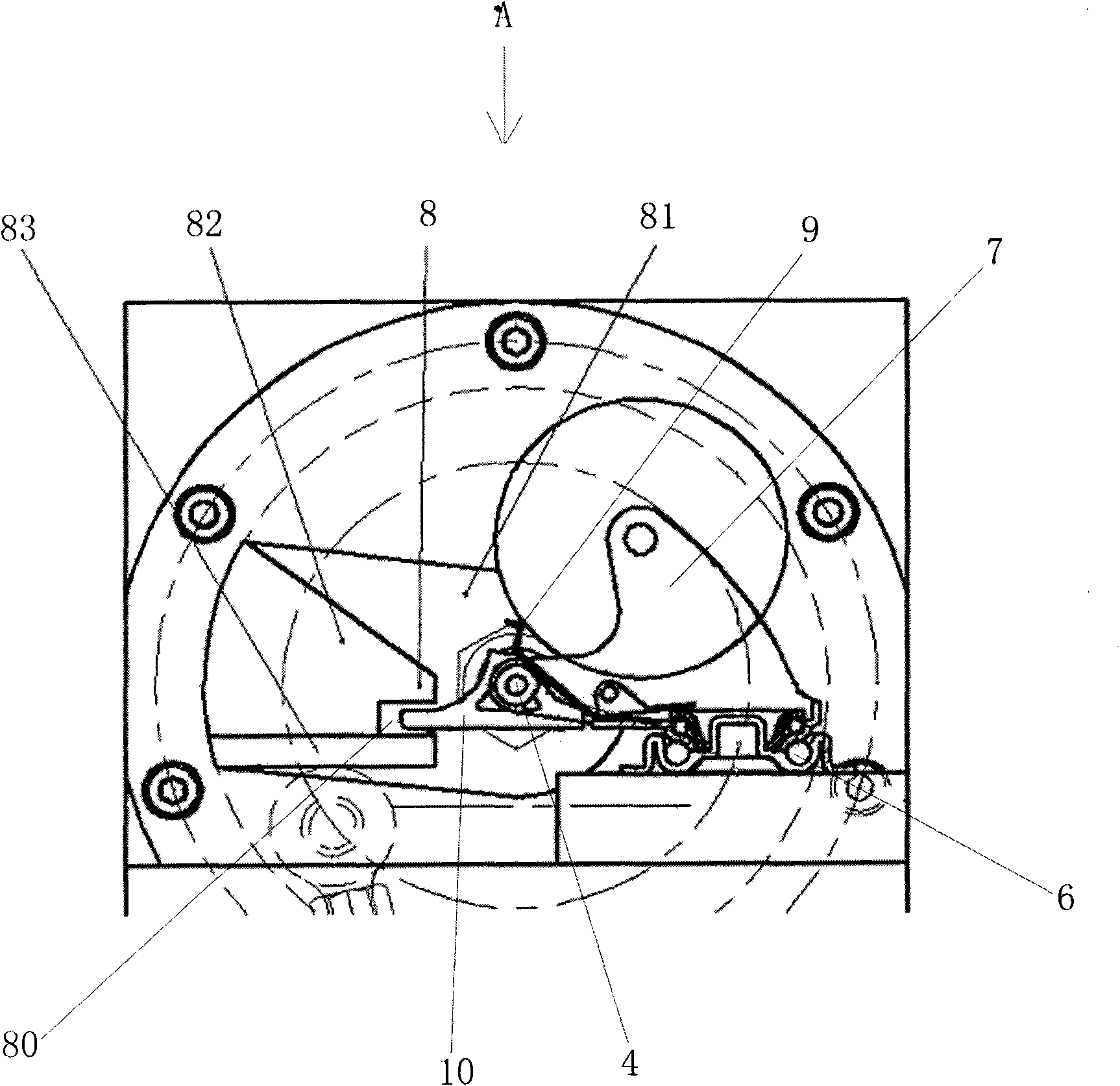

[0013] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the caster brake pad fatigue strength testing machine has a frame, and a motor 1 is arranged horizontally at the lower end of the frame. connect. The output shaft of the motor 1 is connected with the reduction mechanism 2 . One end of the rocking bar in the crank-rocker mechanism 3 is connected with the reduction mechanism 2, and the other end is connected with the rotating shaft 4 above it, and the other end of the rotating shaft 4 is then connected with the brake pad driving mechanism 5. Described brake pad driving mechanism 5: has driving arm 8 and caster fixing mechanism 6, and driving arm 8 is fixed on the rotating shaft 4 by flat key, and driving arm 8 comprises straight arm 81, upper driving piece 82 and lower driving piece 83, and this straight One end of the arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com