Wind generator gear lubricating oil on-site regeneration treatment system and method

A technology for gear lubricating oil and wind turbine, which is applied in the field of on-site regeneration treatment system of wind turbine gear lubricating oil, can solve the problems of increased operation and maintenance costs, unstable load, deterioration and deterioration of gear lubricating oil, etc., and achieves efficient and rapid regeneration treatment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

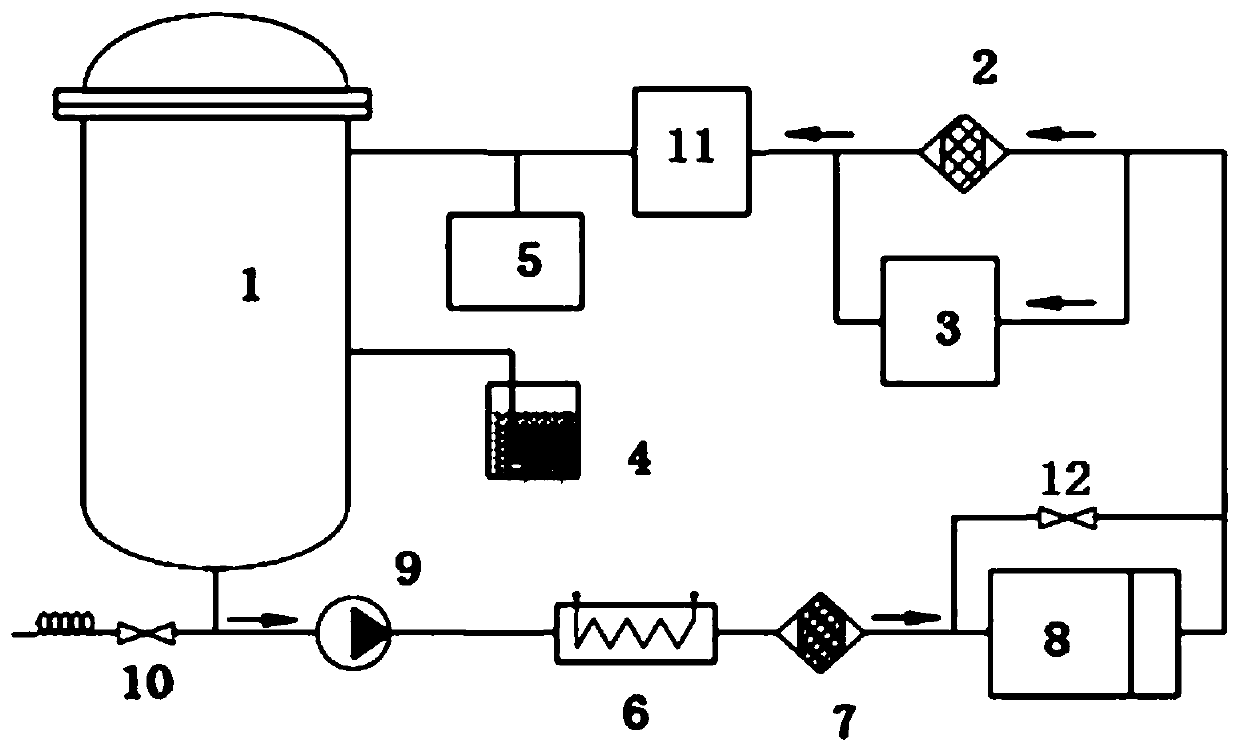

[0043] To solve the problem of gear oil recycling and regeneration in wind power generation sites, it is necessary to solve the problem of recovering the base oil quality of waste gear oil after deterioration, removing dissolved water from waste gear oil, filtering particulate matter generated by wear, automatic additive addition, and online real-time oil quality The integration of monitoring and gear oil regeneration treatment.

[0044] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0045] Such as figure 1 As shown, the present invention presents a wind power generator gear lubricating oil on-site regeneration treatment system, including a vacuum dehydration system 1 for providing a vacuum environment and quickly discharging the moisture in the gear oil under the vacuum environment, the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com