Crystal bar workpiece plate, and crystal bar cutting device and cutting method

A cutting method and cutting device technology, applied to fine working devices, working accessories, manufacturing tools, etc., can solve problems such as time-consuming and labor-intensive damage to crystal rods, and achieve the effects of convenient use, improved quality, and reduced labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

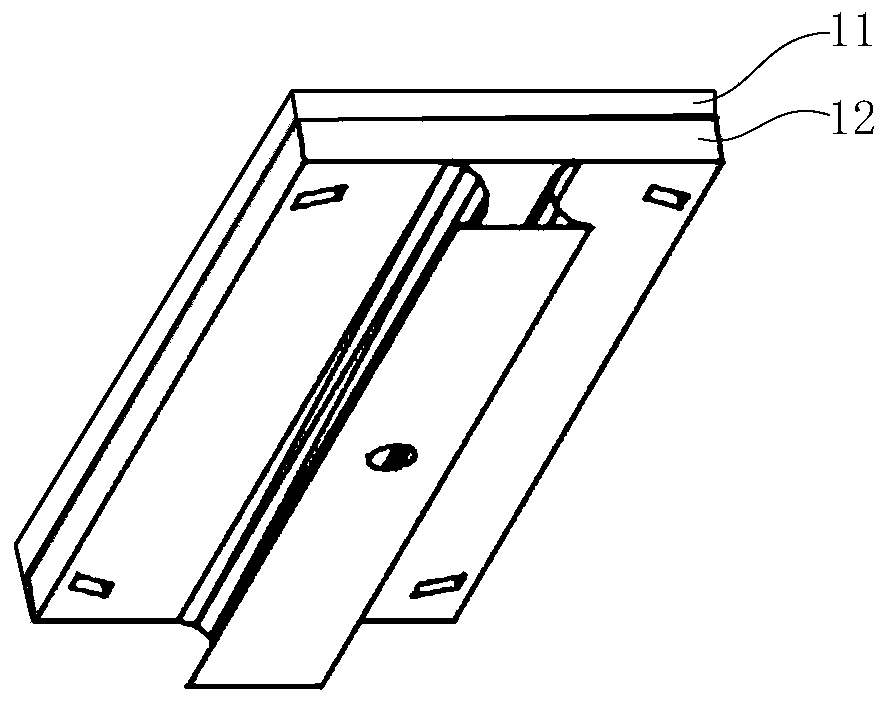

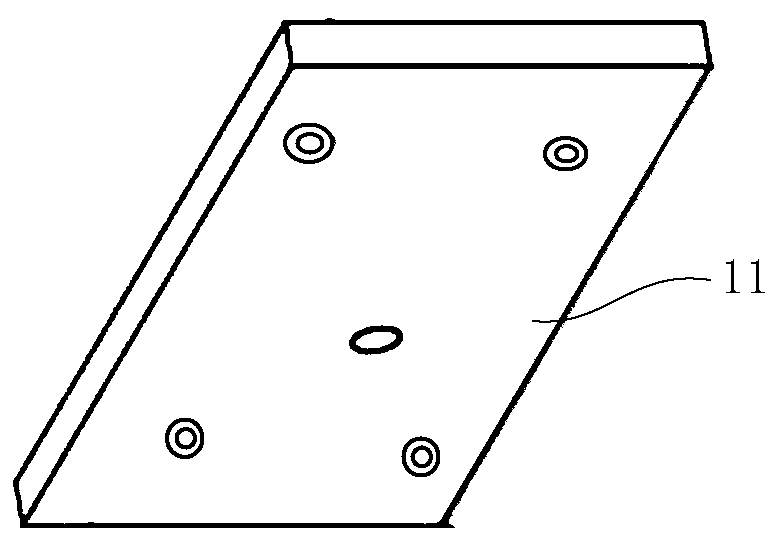

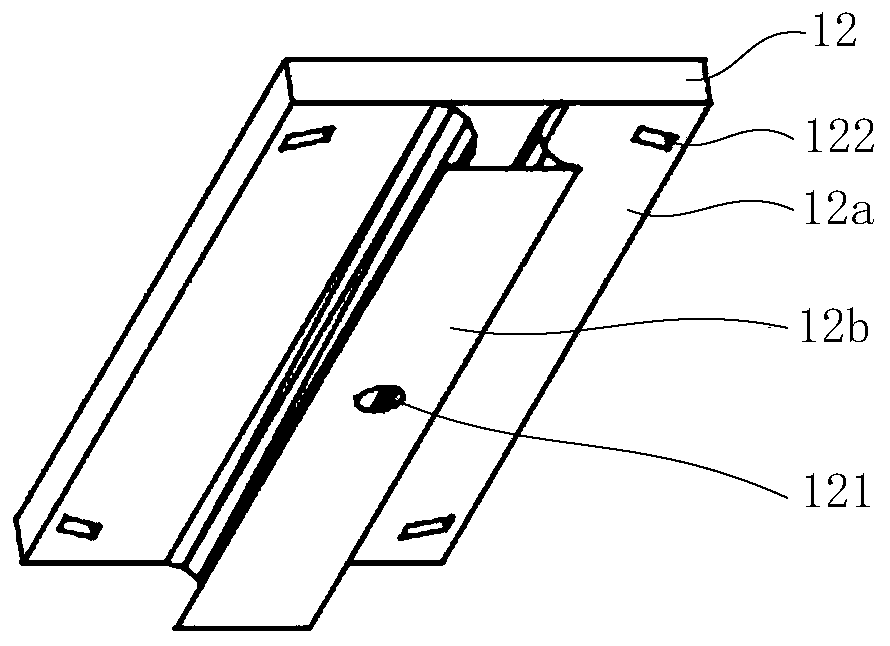

[0039] Such as Figure 1 to Figure 4 As shown, the present invention provides a crystal ingot workpiece plate, comprising: a fixed plate 11 and an adjustment plate 12, the fixed plate 11 is used to place crystal ingots; the adjustment plate 12 is located on the fixed plate 11 away from the ingot The surface of the adjustment plate 12 is provided with a center hole 121 and several waist-shaped through holes 122, the center hole 121 is located in the middle of the adjustment plate 12, and the several waist-shaped through holes 122 are located at the center of the circle The periphery of the hole 121; the fixed plate 11 and the adjustment plate 12 are connected by bolts located in the center hole 121 and the several waist-shaped through holes 122, and the bolts located in the waist-shaped through holes 122 It can be moved in the waist-shaped through hole 122 to adjust the relative positions of the fixing plate 11 and the adjusting plate 12, so as to realize the adjustment of the ...

Embodiment 2

[0049] Such as Figure 5 As shown, the present invention also provides a crystal rod cutting device, comprising:

[0050] Ingot workpiece plate as described in embodiment one;

[0051] The carrying platform 3, the ingot 2 to be cut is placed on the carrying platform 3 through the ingot workpiece plate;

[0052] A cutting unit 4, the cutting unit 4 is located above the crystal ingot 2 during non-cutting operation;

[0053] The detection unit 5 is located above the crystal ingot 2 and is used for detecting the off-angle of the crystal ingot 2 .

[0054] For the introduction of the crystal ingot workpiece plate, please refer to Embodiment 1, and details are not repeated for the purpose of brevity.

[0055] The specific structure of the carrying platform 3 can be adjusted according to the specific structure of the adjusting plate 12. For example, in this embodiment, the carrying platform 3 can be provided with a recess corresponding to the boss portion 12b of the adjusting plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com