Gasoline engine cylinder cover bolt model selection and checking method

A gasoline engine and cylinder head technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of safety risks in cylinder head bolts and imperfect design methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment provides a gasoline engine cylinder head bolt type selection and verification method, which is used to solve the technical problem that the design method of the cylinder head bolts is not perfect in the prior art, which leads to the safety risk of the cylinder head bolts during use. . Specifically, in the existing design methods of engine cylinder head bolts, the actual conditions such as the friction coefficient dispersion, yield strength dispersion, specification and size of the bolts are not considered, and most of the bolts are selected through trial and error of different specifications. If the wrong way is selected, the pretightening force of the selected bolts may not meet the requirements due to the above reasons, and the selection and verification process is complicated and error-prone, so that the selected bolts have a greater safety risk when used.

[0046] The gasoline engine cylinder head bolt type selection and checking method includes the ...

Embodiment 2

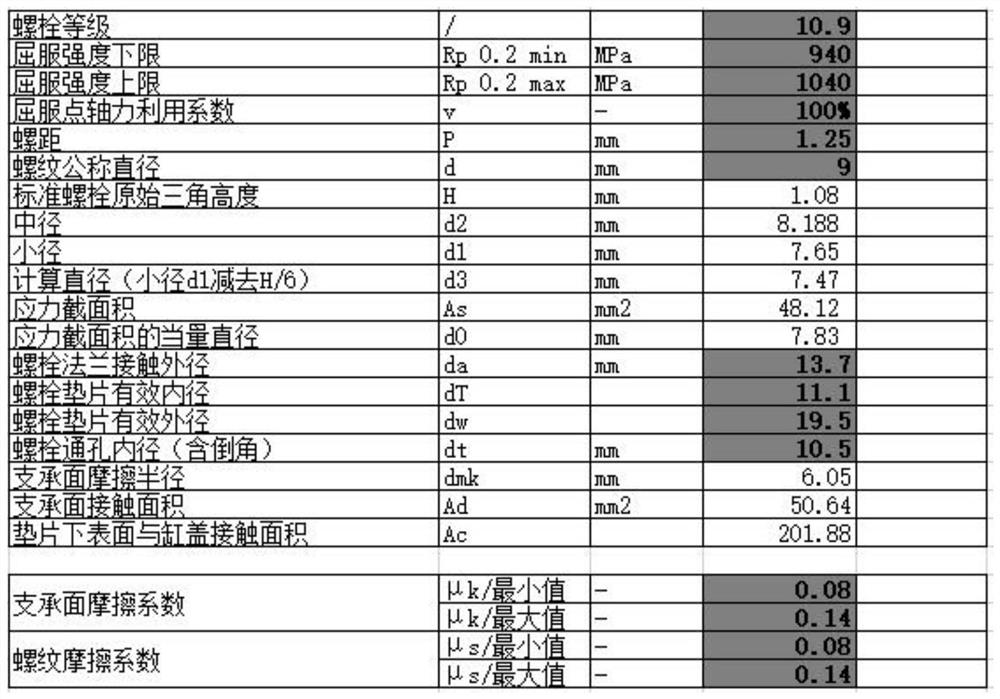

[0065] Embodiment As a kind of exemplary embodiment of embodiment 1, as follows:

[0066]Step 1.1: The maximum engine burst pressure P is known max It is 105MPa, and the diameter of the cylinder hole of cylinder block 2 is d g is 73mm, calculate the maximum working load F of the engine by formula 1 g = 43.95 kN.

[0067] Step 1.2: Calculate the maximum dynamic load F of a single bolt 3 of the cylinder head by formula 2 b = 21.97 kN.

[0068] Step 1.3: Calculate the pretightening force F required by a single bolt 3 to seal the cylinder head 1 by formula 3 v =K×F b =1.6×21.97=35.16kN. In this step, the cylinder head 1 is made of aluminum alloy, the flatness of the pressure bearing surface of the cylinder head 1 is required to be 0.1, the roughness is required to be Ra3.2, and the cylinder head gasket has a double-layer sealing structure.

[0069] Step 2.1: In order to ensure the sealing of the cylinder head gasket, the rated minimum pre-tightening force of the bolt 3 must...

Embodiment 3

[0076] The present embodiment is as a kind of practical embodiment of the present invention, and in the present embodiment, utilize the computing function of EXCEL table, carry out the method in the above-mentioned embodiment, also promptly enter formula 1 to formula 8 in the EXCEL table and carry out correlation, when When a corresponding input value is input, a corresponding output value is obtained, so that the accuracy and efficiency of the calculation of the above method can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com