A safety and reliability test device and method for a flexible air chamber jig airbag

A test device and air chamber technology, which is applied in the field of the safety and reliability test device of the flexible air chamber jig machine airbag, can solve the problems of shutdown failure, the inability to run continuously in industrial production, and airbag fatigue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In the following, the embodiments of the present invention will be described in detail with reference to the accompanying drawings.

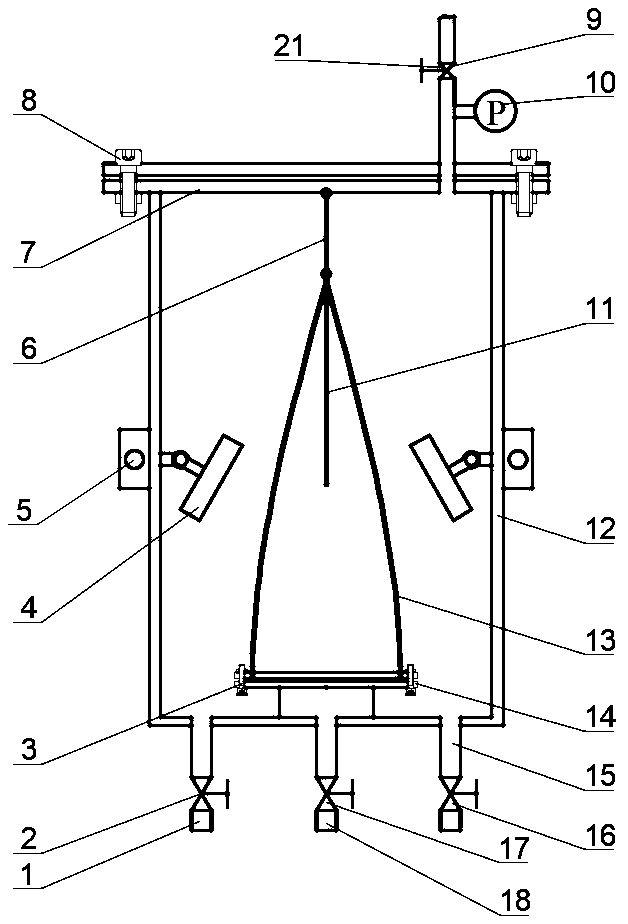

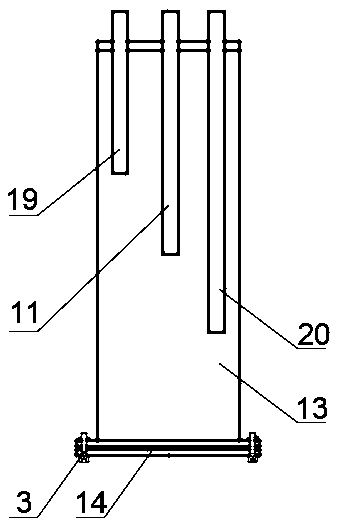

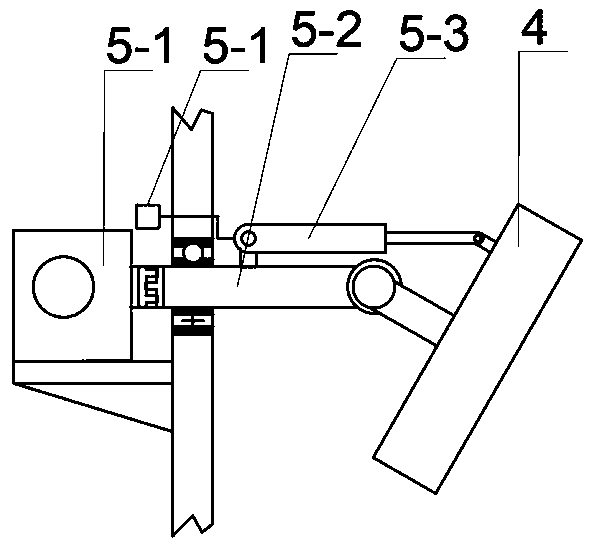

[0031] Such as figure 1 As shown, a flexible air chamber jigger airbag safety reliability test device includes a body 12, an airbag 13, a three-dimensional scanner 4, and a pressure measuring tube.

[0032] The bottom surface of the body 12 is provided with an intake pipe 1 and an exhaust pipe 15 , and an upper flange cover 7 is installed on the top, and the body 12 is connected with the upper flange cover 7 by a large screw 8 . A body pressure measuring tube 21 communicating with the body 12 is installed on the upper flange cover 7 , and a safety valve 9 and a pressure gauge 10 are installed on the body pressure measuring tube 21 . The intake pipe 1 is equipped with an intake control valve 2 , and the exhaust pipe 15 is equipped with an exhaust control valve 16 . The air intake pipe 1 fills the jig body 12 with compressed air, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com