Middle dividing presser foot provided with ultrashort seam allowance knife

A notch and ultra-short technology, which is applied in the field of sewing machine presser feet, can solve the problems that affect the quality grade and delivery date of knitted and woven products, cannot guarantee sewing quality and efficiency, and are difficult to control the distance between the middle part and so on. , to achieve the effect of ensuring stability and improvement, strong practicability, and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

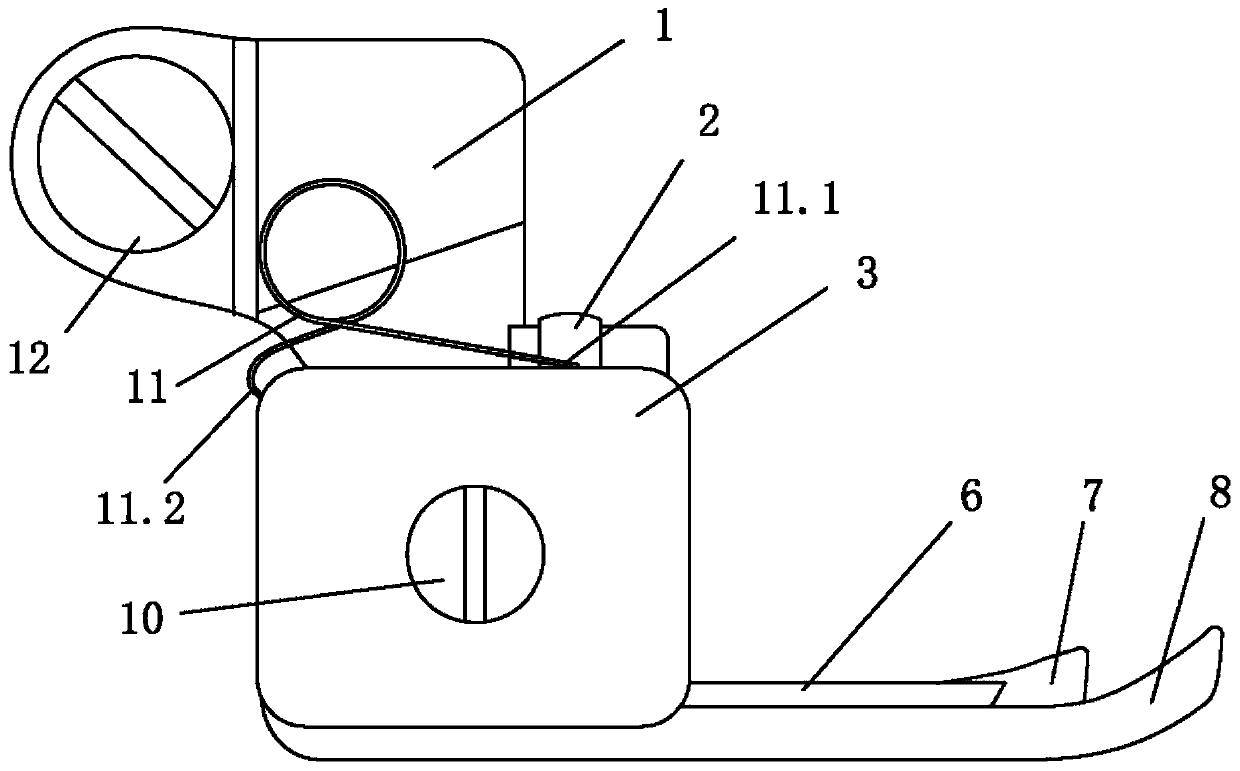

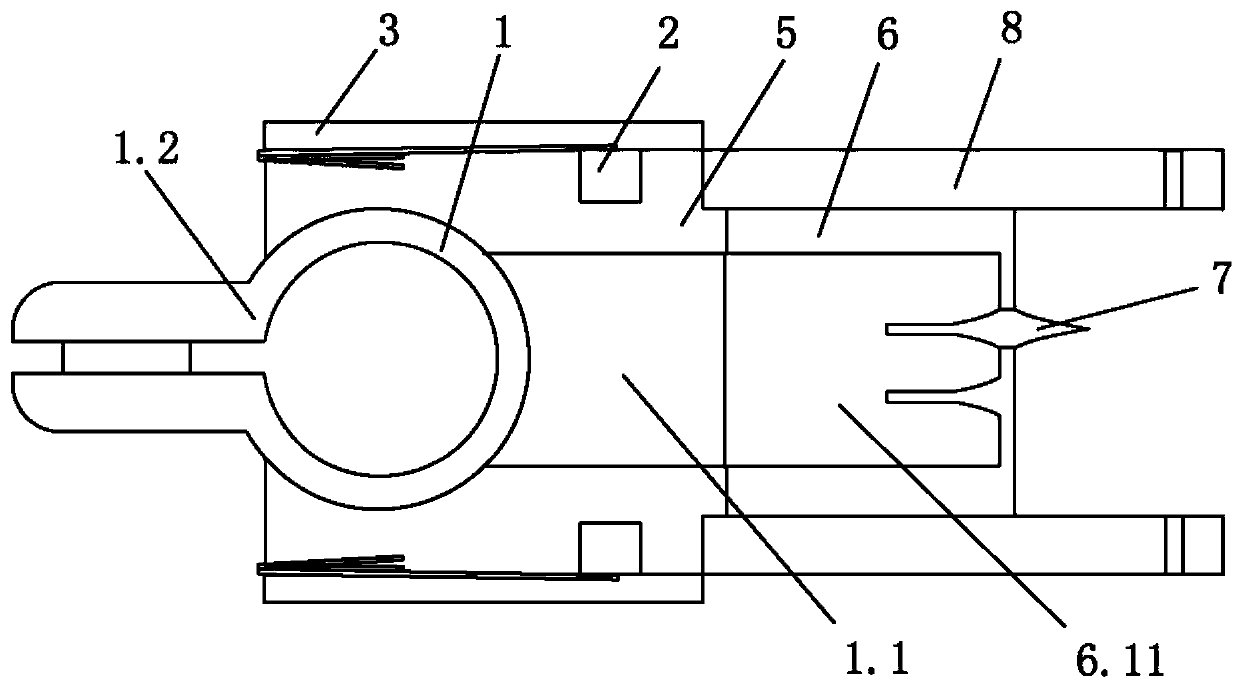

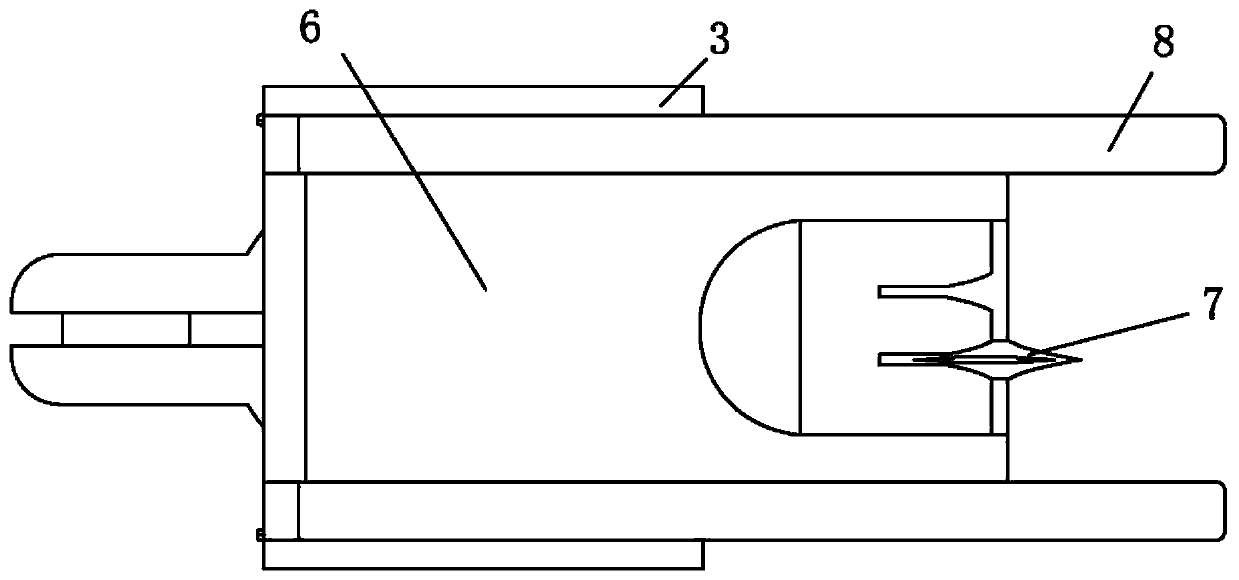

[0028] Further description will be given below in conjunction with the embodiments shown in the accompanying drawings.

[0029] The centrally divided presser foot shown in the accompanying drawings includes a connector 1 and a pressure plate 6 that is hinged to the connector and has a needle hole 6.11 (the hole that the needle passes through when sewing); Hoop 1.2; the hoop is put through the bottom of the needle bar, and then the screw 12 connecting the hoop is tightened to fasten the presser foot on the needle bar of the sewing machine. The upper part of the pressure plate is provided with two hinged ears 5 which are integrated with the pressure plate and are parallel to each other, and the hinged ears are provided with horizontally penetrating pin holes 6.5; between the two hinged ears there are front and rear ( figure 1 , Figure 8 The cavity 5.3 that penetrates through the left and right direction) and upwards; the lower part 1.1 of the connector (prefabricated with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com