RF terminal assembly device

A technology for assembling equipment and terminals, which is applied to the assembly/disassembly of contact parts, etc. It can solve the problems of assembly misalignment, front and rear, left and right skew, low efficiency, etc., and achieve the effect of improving production efficiency and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

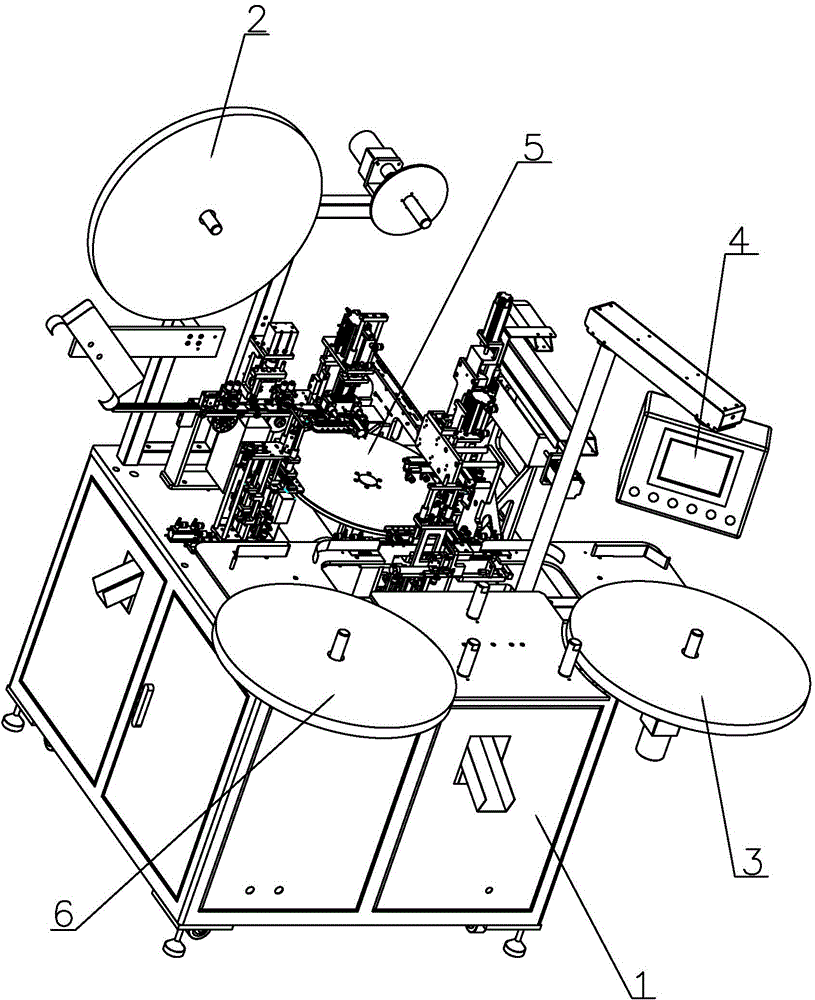

[0018] Such as figure 1 As shown, an RF terminal assembly equipment is characterized in that it includes a workbench 1, and the center of the workbench 1 is provided with an indexing plate 5 driven by a motor, a grabbing mechanism for grabbing a plastic carrier, and a A material breaking mechanism for cutting off material tape 1, a component assembly mechanism for assembling RF assembly parts, a separation mechanism for separating material tape 1 and RF assembly parts, and a finished product assembly mechanism for assembling RF finished products, the grasping mechanism , the component assembly mechanism, the material cutting mechanism, the separation mechanism and the finished product assembly mechanism are distributed around the index plate 5 in clockwise order, wherein the component assembly mechanism and the material cutting mechanism are arranged at On one side of the workbench 1, the grabbing mechanism, the separation mechanism and the finished product assembly mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com