Bit shank manufacturing method

A manufacturing method and technology of shank tails, which are applied in the direction of manufacturing tools, coatings, furnace types, etc., can solve the problems of strong rigidity in the production process, damage to shank tails, and lack of flexibility, so as to save processing time, save money, The effect of reducing finished goods inventory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

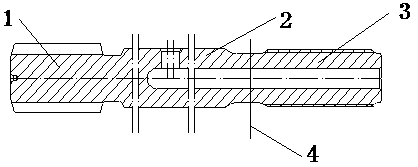

[0073] T45-600 Sandvik HL700 Rock Drill Tail

[0074] The length of the male joint is 250mm, the diameter of the shank is 52mm, and 23CrNi3Mo (EN40B) is selected,

[0075] Heat treatment method 1: Carburizing at 930°C, then air cooling, the thickness of the carburized layer is 0.8-1.0mm.

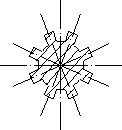

[0076] Spline end material: choose 23CrNi3Mo (EN40B),

[0077] Heat treatment method 1: Carburizing at 930°C, then air cooling, the thickness of the carburized layer is 0.8-1.0mm.

[0078] a: Use friction welding to weld the processed spline end and male joint on the middle mating end;

[0079] b: 840°C annealing treatment at the welding place to remove internal and external welding flashes, that is, welding nodules;

[0080] c: 930 ° C quenching treatment at the welding place again, and then air cooling;

[0081] d: Non-destructive testing of welds;

[0082] e: Straightening and tempering at 240°C to remove straightening stress;

[0083] f: On the cylindrical grinder, grind the planes...

Embodiment 2

[0087] T45-575 Atlas COP1238 Rock Drill Tail

[0088] The length of the male joint is 300mm, the diameter of the shank is 45mm, and 23CrNi3Mo (EN40B) is selected,

[0089] Heat treatment method 1: Carburizing at 930°C, then air cooling, the thickness of the carburized layer is 0.8-1.0mm.

[0090] Spline end material: 25Cr3MnMo (SANBAR 23),

[0091] Heat treatment method 1: Carburizing at 930°C, then air cooling, the thickness of the carburized layer is 0.6-0.8mm.

[0092] a: Use friction welding to weld the processed spline end and male joint on the middle mating end;

[0093] b: 840°C annealing treatment at the welding place to remove internal and external welding flashes, that is, welding nodules;

[0094] c: 930 ° C quenching treatment at the welding place again, and then air cooling;

[0095] d: Non-destructive testing of welds;

[0096] e: Straightening and tempering at 240°C to remove straightening stress;

[0097] f: On the cylindrical grinder, grind the planes at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com