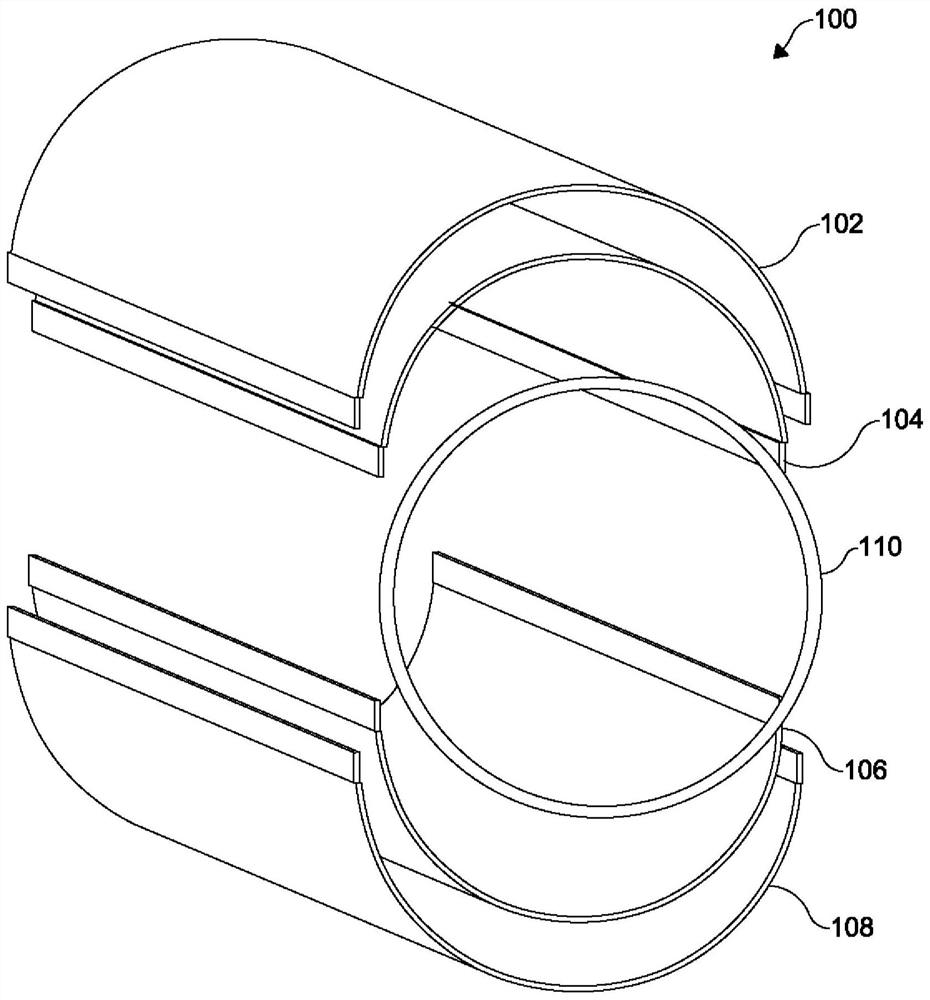

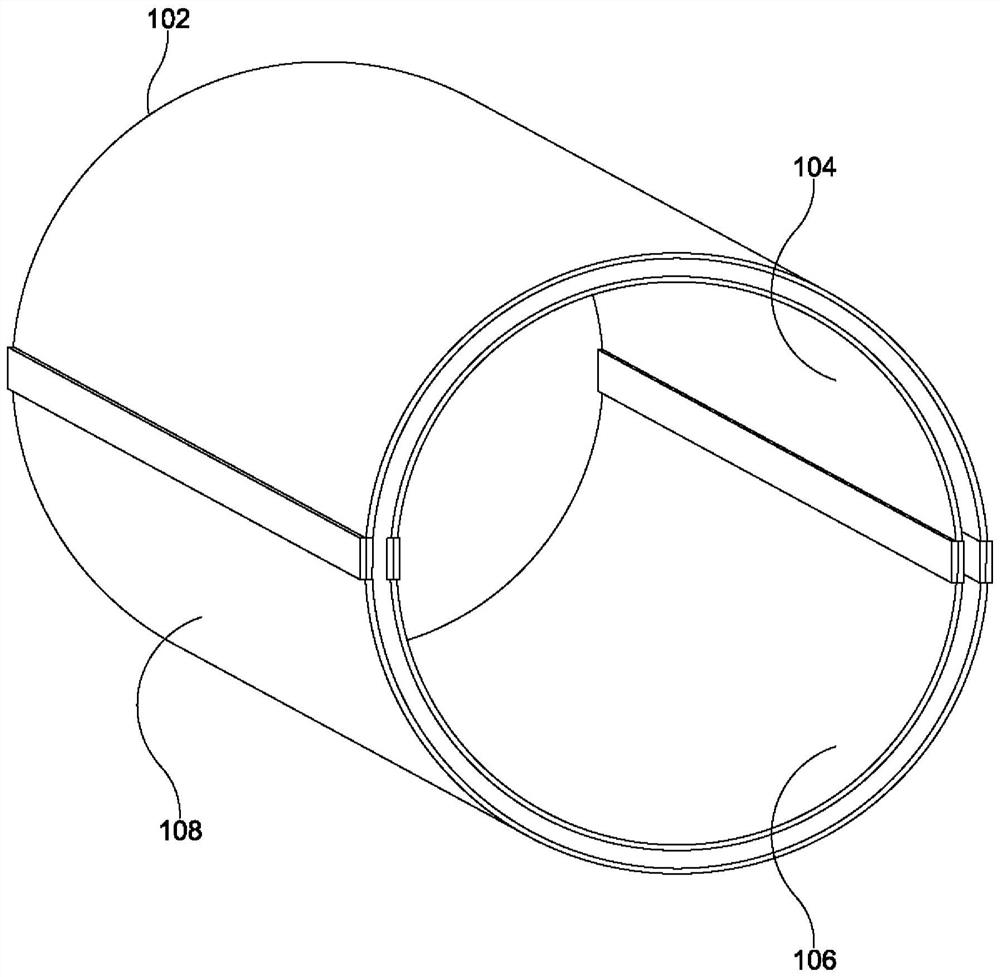

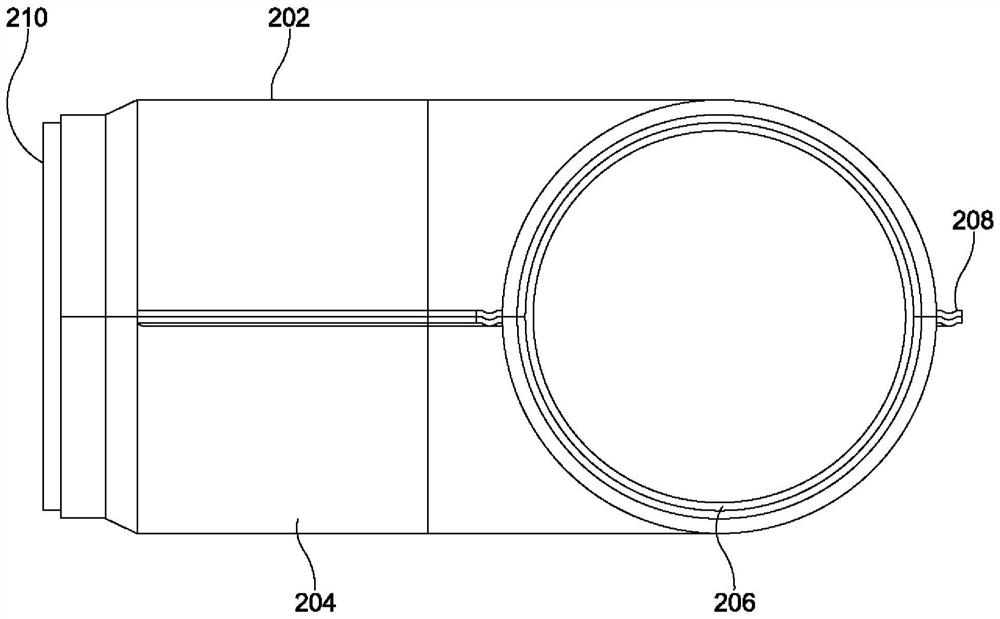

Multi-geometry and multi-material insulation components

A heat-insulating space and arch-shaped technology, which is applied in heat-insulating containers, lighting and heating equipment, and protecting pipelines through heat insulation, and can solve the problems of not providing heat-insulating sheaths and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0170] Example 1. An insulated pipe comprising: (a) an outer tube having a distal end and a proximal end, the outer tube also comprising a first corrugated region having a length and including a length extending from the distal end of the outer tube to the outer tube a plurality of corrugations extending along the proximal end of the outer tube; an inner tube disposed within the outer tube, the inner tube having a distal end and a proximal end, the inner tube defining a lumen; the inner tube and the outer tube at a joint, optionally the inner tube are sealed to each other at distal ends thereof, the seal defining a pressure-reduced sealed insulating region between the outer tube and the inner tube, the inner tube and the outer tube are sealed to each other such that the length of the first corrugated region of the outer tube increases in response to temperature or or (b) an outer tube, the outer tube has a distal end and a proximal end, an inner tube is disposed within the out...

Embodiment 2

[0174] Example 2. The insulated duct of claim 1, wherein the sealed insulation area is defined within a range from about 10 -2 Torr to about 10 -9 pressures in the Torr range, for example, about 10 -3 Torr, 10 -4 Torr, 10 -5 Torr, 10 -6 Torr, 10 -7 Torr, 10 -8 Torr or even about 10 -9 Torr and all intermediate values.

Embodiment 3

[0175] Example 3. An insulated duct according to any one of claims 1-2, wherein the joint comprises (a) a first vent in communication with the sealed insulating area to provide a path for gas molecules to escape from the sealed insulating area, section a vent is sealable for maintaining a reduced pressure within the first insulated space after gas molecules are evacuated through the first vent, and (b) sealing the first insulated space at the first vent The first seal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com