Heat conduction pipe of waste gas and waste fluid waste heat recovery device

A technology of waste heat recovery device and heat pipe, which is applied in the direction of tubular elements, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of short transfer distance, low temperature, limited recovery of waste heat, etc., and achieve heat absorption efficiency and heat transfer Efficiency improvement, low manufacturing cost, remarkable energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

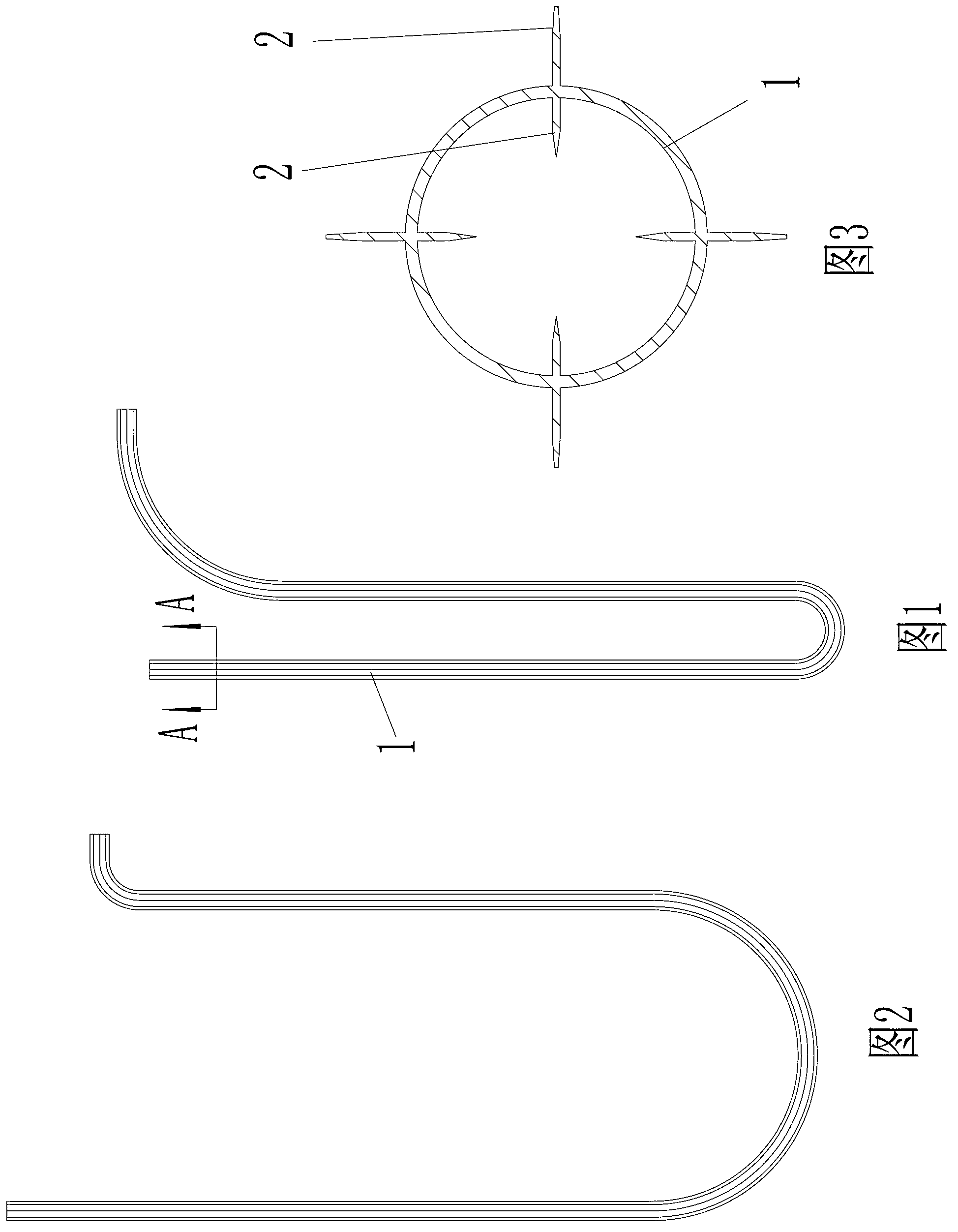

[0016] As shown in the figure, the heat conduction pipe of the exhaust gas waste liquid waste heat recovery device provided by the present invention includes a pipe body 1 made of metal material (the diameter of the pipe is usually more than 20mm, the thickness of the pipe wall is usually 0.5-3.5mm, and the length depends on the heat Recycling needs to be determined); it is characterized in that several heat conducting fins 2 are made on the inner wall surface and the outer surface of the pipeline body, and the thickness is usually 0.5-3mm; these heat conducting fins are integrated with the pipeline body, and are along the The length direction of the pipeline body is continuously extended; since the direction of the heat conduction sheet on the surface of the inner wall is consistent with the flow direction of the medium (gas or liquid medium) in the heat conduction tube, it will not hinder the movement of the medium.

[0017] like image 3 Shown: The heat conduction sheet is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com