Oxidizing catalytic converter, tail gas after-treatment system and tail gas after-treatment method

A catalytic converter and exhaust gas post-treatment technology, which is applied to exhaust gas treatment, electronic control of exhaust gas treatment devices, diagnostic devices of exhaust gas treatment devices, etc. Matching a variety of models, increasing fuel consumption and other issues, to achieve good adaptability, reduce fuel injection, and improve the effect of oxidation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

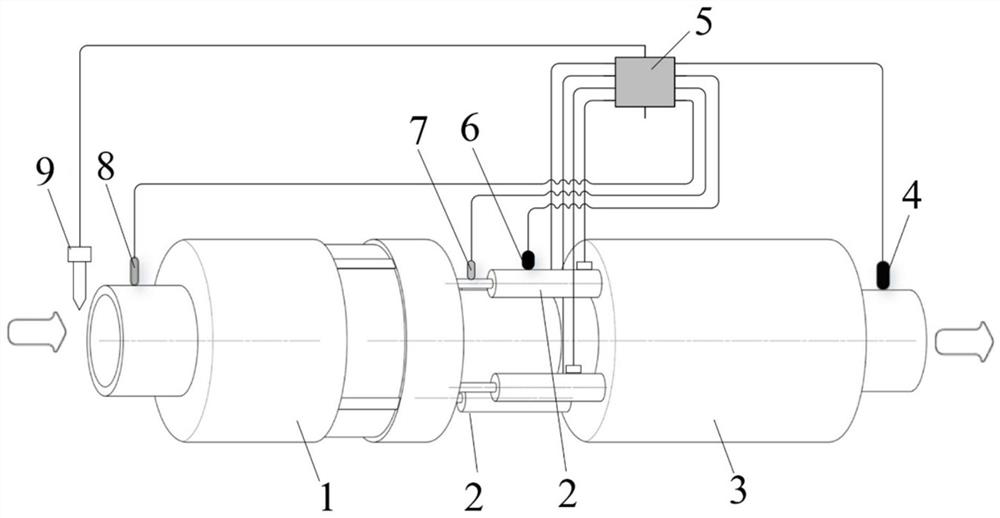

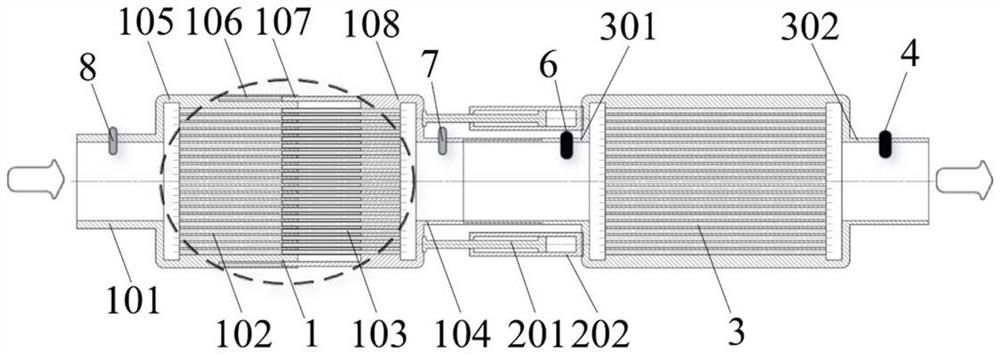

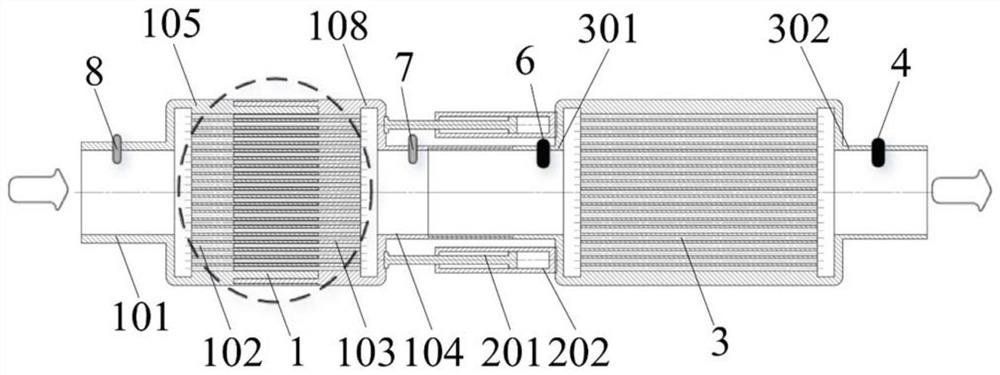

[0047] An exhaust gas aftertreatment system, such as figure 1 As shown, including oxidation catalytic converter 1 (DOC), particle filter 3 (DPF), ECU controller 5, sensor unit and fuel injector 9;

[0048] Both ends of the oxidation catalytic converter 1 are respectively provided with a first pipeline 101 and a second pipeline 104, and both ends of the particle trap 3 are respectively provided with a third pipeline 301 and a fourth pipeline 302, the first pipeline 101 is used to connect exhaust gas, the second pipeline 104 communicates with the third pipeline 301, and the fourth pipeline 302 is used to discharge the exhaust gas;

[0049] The fuel injector 9 is arranged in the first pipeline 101, and the sensor unit includes a first air pressure sensor 6, a second air pressure sensor 4, a first temperature sensor 8 and a second temperature sensor 7, and the first air pressure sensor 6 and the second air pressure sensor 4 They are respectively arranged on the third pipeline 301...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com