Camshaft module

A technology of camshafts and modular bodies, applied in the direction of valve devices, housings, machines/engines, etc., capable of solving impossible problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

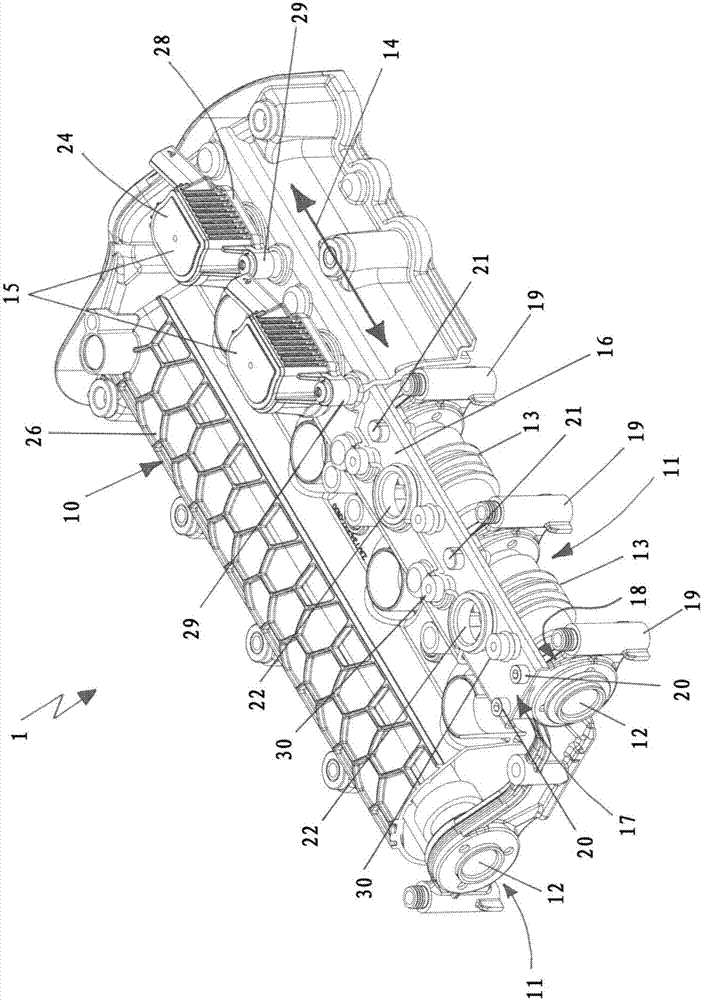

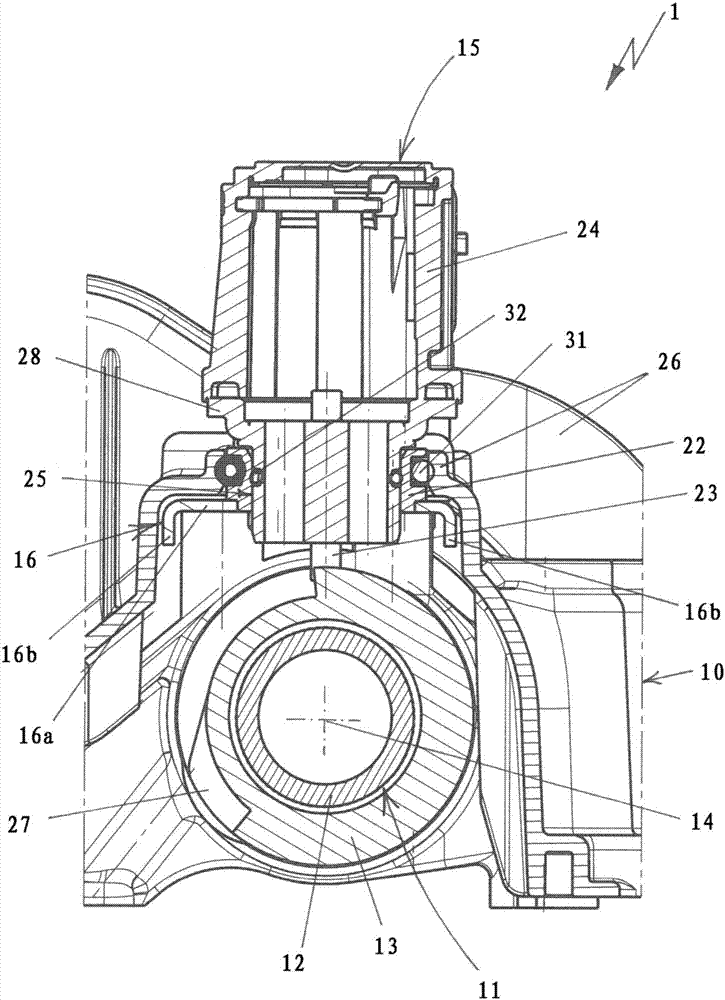

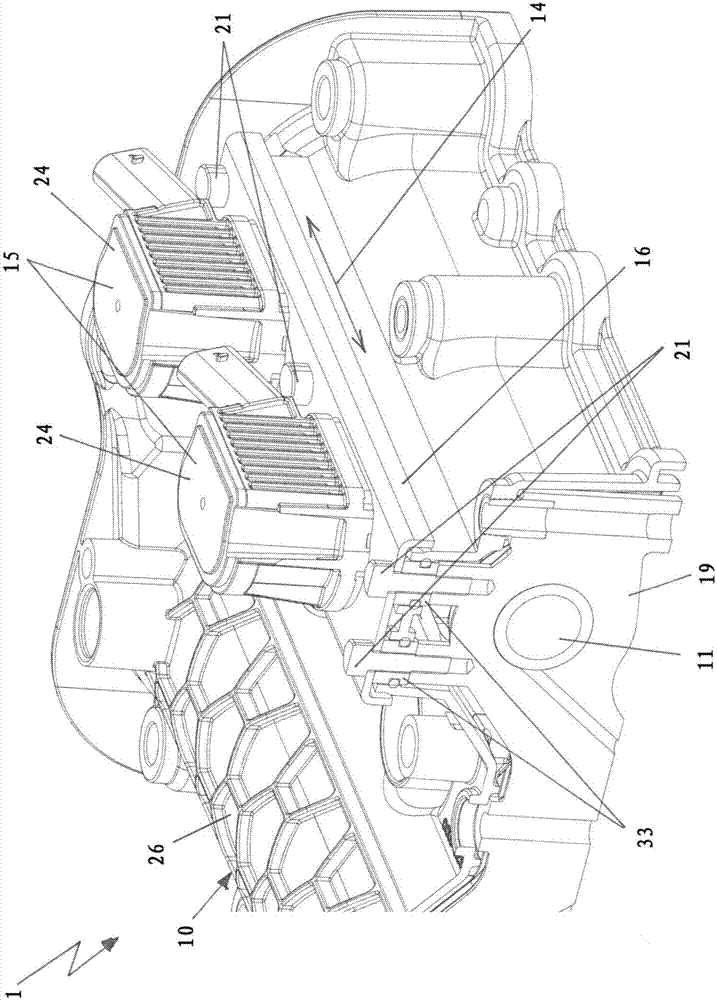

[0028] figure 1 A perspective view is shown of a camshaft module 1 with a module body 10 in which two camshafts 11 for controlling valves for a charging cycle of an internal combustion engine are accommodated. The camshaft module 1 is intended in particular for mounting on a cylinder head of an internal combustion engine.

[0029] The module body 10 has a cover 26 and on the underside of the cover 26 a plurality of bearing bridges 19 connected to the cover 26 are arranged. The camshaft 11 is rotatably accommodated on the module body 10 by means of a bearing bridge 19 . The camshafts 11 each have a support shaft 12 , and a plurality of slide cam pieces 13 are accommodated to be movable in an axial direction 14 on each of the support shafts 12 . In order to change the axial position of the sliding cam elements 13, actuators 15 are assigned to the corresponding sliding cam elements 13, wherein, for the shown camshaft module 1, four actuators 15 are provided, but only shown Two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com