Patents

Literature

38results about How to "Realize customized production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

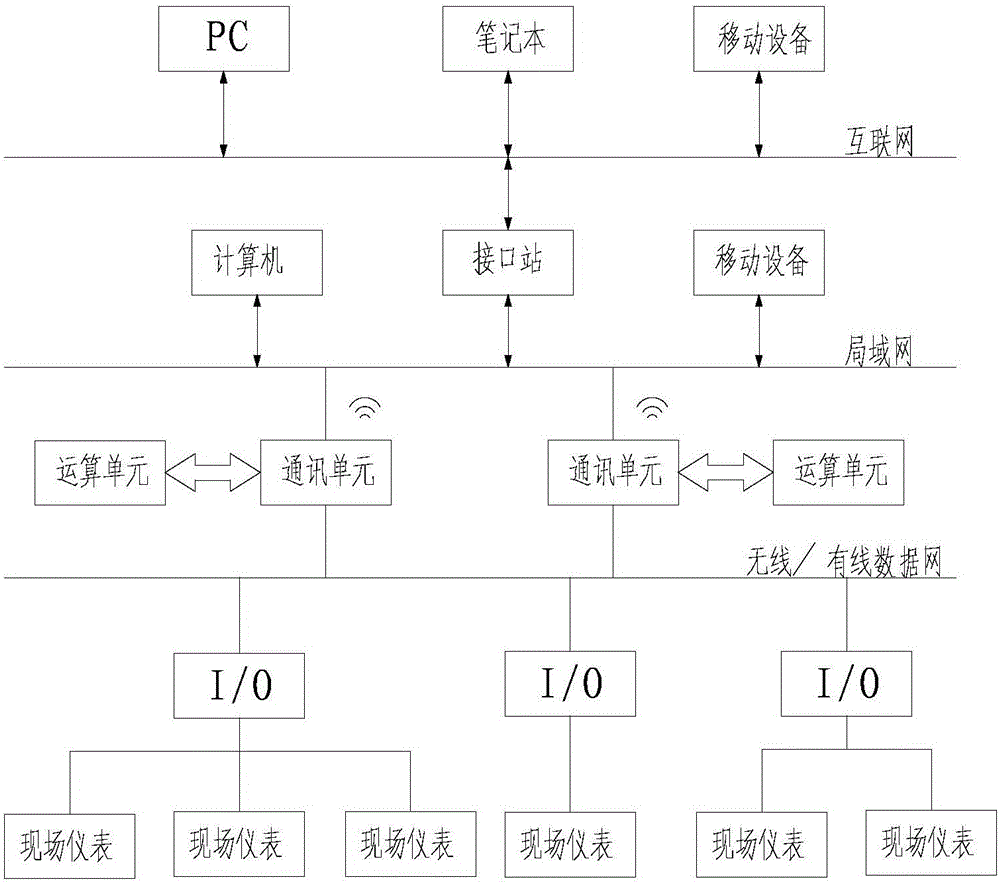

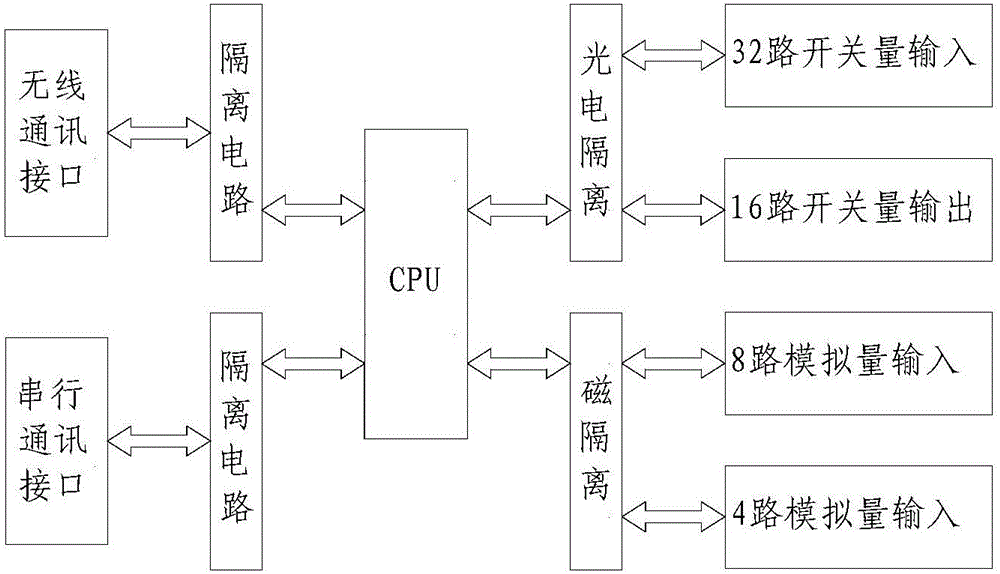

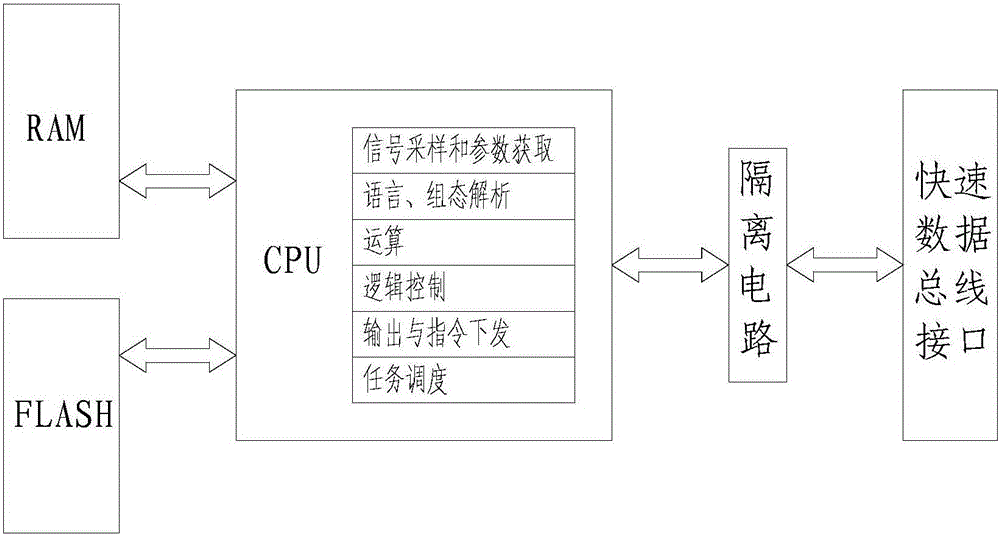

Distributed intelligent instrument control system based on Internet of things and method thereof

ActiveCN105824303ARealize production intelligenceIncrease productivityTotal factory controlProgramme total factory controlIndustrial PCLocal area network

The invention relates to a distributed intelligent instrument control system based on the Internet of Things, including an I / O (input / output) unit, a computing unit, a communication unit and a user terminal device, one end of the I / O (input / output) unit and a field instrument The other end of the I / O (input / output) unit realizes data interaction with the communication unit through the wireless network. The data bus is used between the communication unit and the calculation unit for data communication. Each calculation unit is equipped with a corresponding communication unit. Unit, to complete the transmission and forwarding tasks of signals, parameters, and instructions, the communication unit communicates with the user end equipment through the local area network, the user end equipment includes industrial computers and mobile devices, and the mobile devices include smart phones and Pads; the present invention is the same as the existing Compared with technology, it not only helps to realize intelligent production, improve production efficiency, and improve user experience, but also reduces costs, and helps to realize decentralized control and intelligent transformation of instruments.

Owner:上海颖电控制技术有限公司

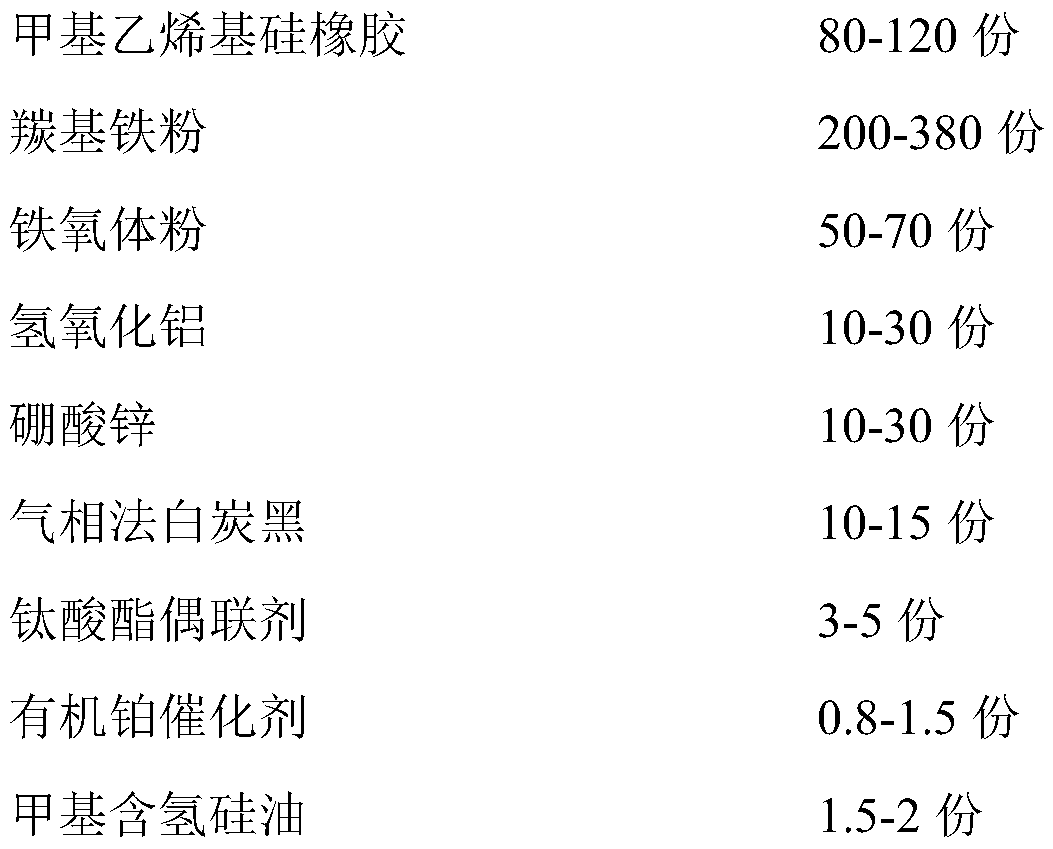

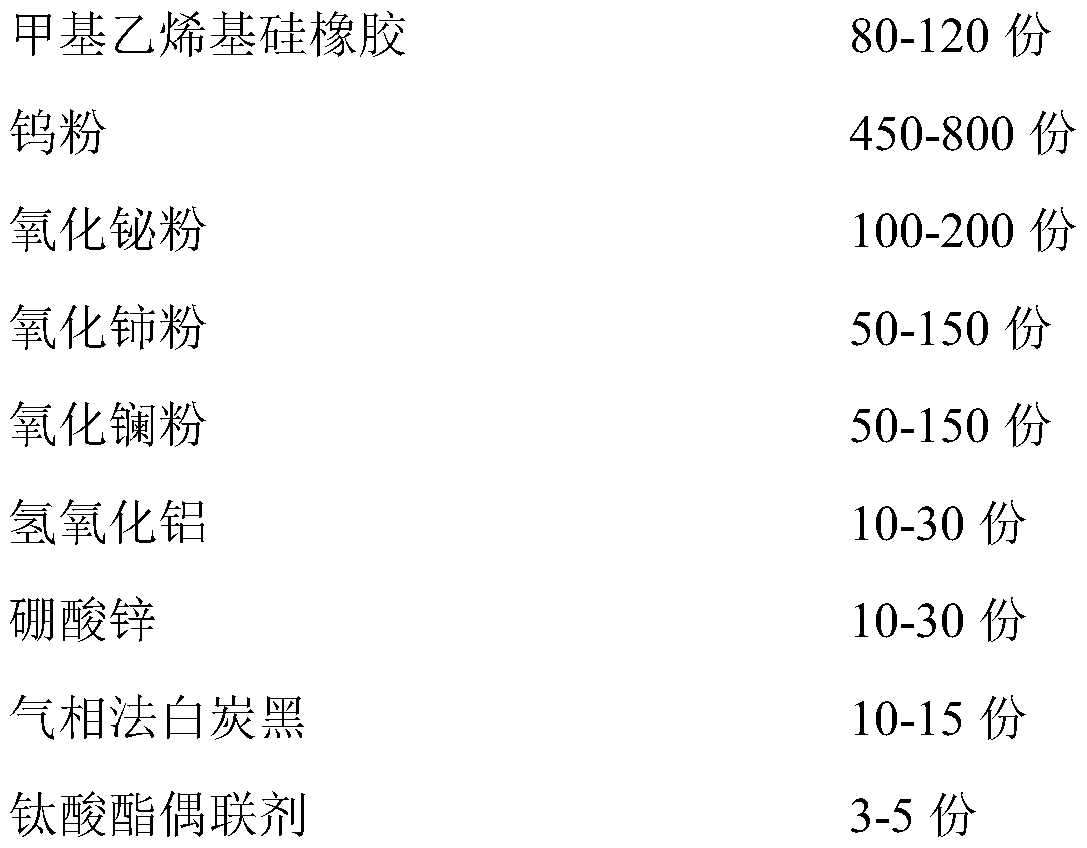

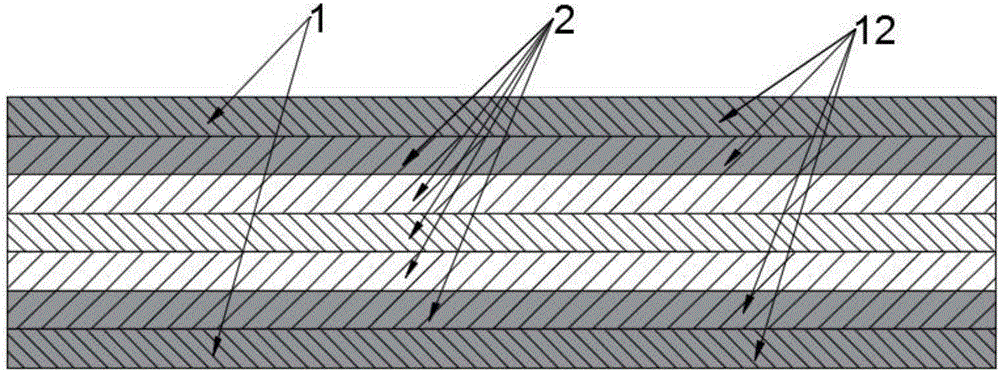

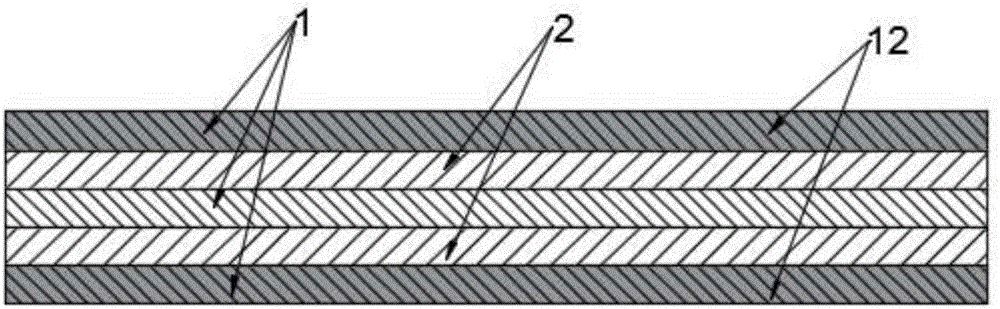

Flexible material with nuclear radiation protection and electromagnetic shielding functions, and preparation method and application thereof

InactiveCN111572133ALow densityReduce transmission intensityLaminationLamination apparatusNuclear radiationPolymer substrate

The invention discloses a flexible material with nuclear radiation protection and electromagnetic shielding functions, and a preparation method and application thereof. The flexible material comprisesfour functional layers, namely an electromagnetic radiation absorption layer, a first ray radiation shielding layer, a neutron radiation shielding layer and a second ray radiation shielding layer insequence from outside to inside, wherein each functional layer comprises a polymer base material and a functional filler. According to the flexible composite gradient material, lead powder is not added; the defects that a traditional homogeneous blending material is limited in functional filler filling amount, easy to disperse unevenly, low in material comprehensive performance and the like are overcome; and meanwhile, the weak absorption region of elemental lead in an energy interval of 40-88 keV can be effectively compensated by adopting a compounding ratio of the functional filler, so the material has excellent X-ray, gamma-ray and neutron radiation shielding performance and electromagnetic radiation absorption performance.

Owner:CHENGDU SHENGBANG SEALS

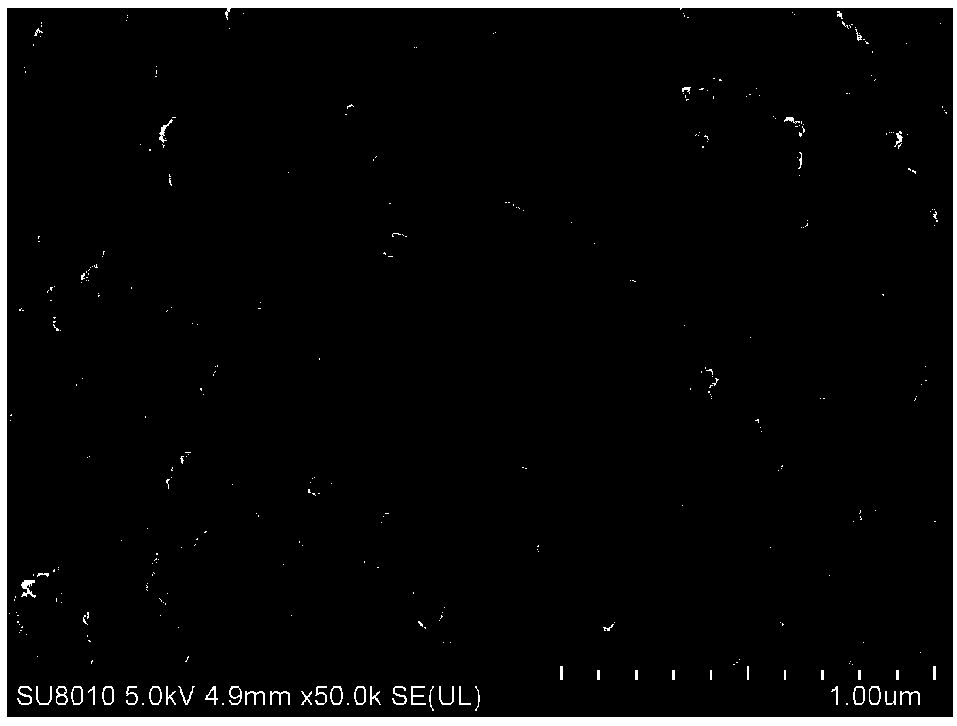

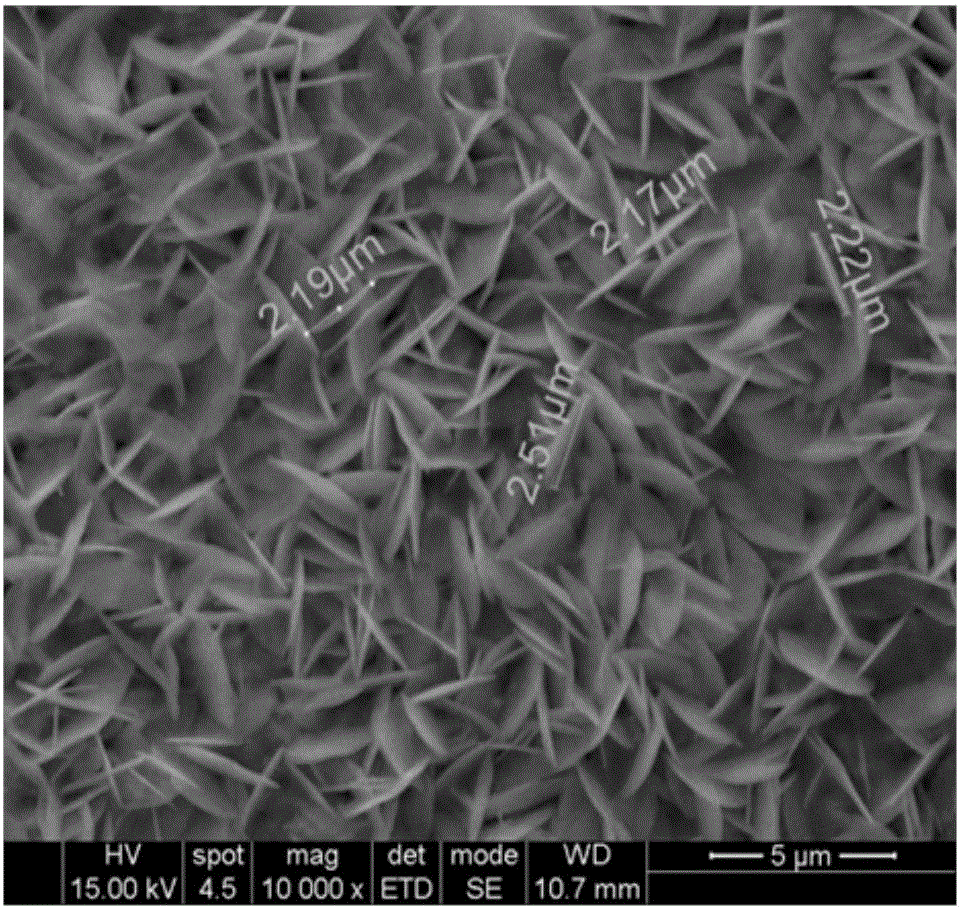

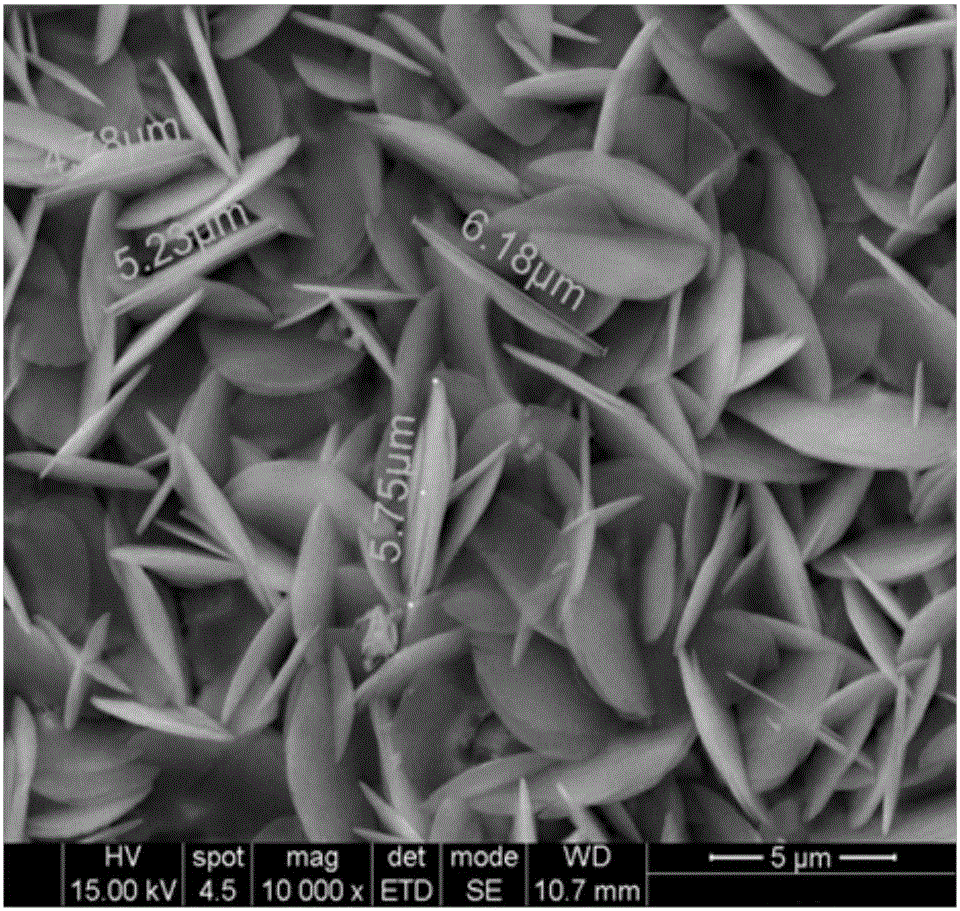

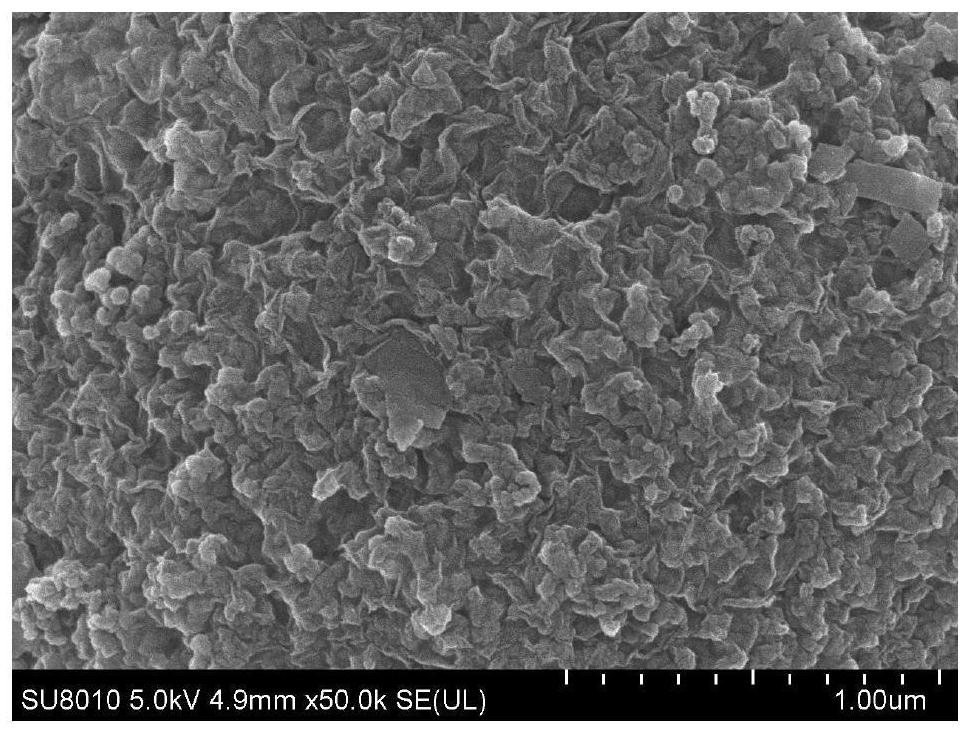

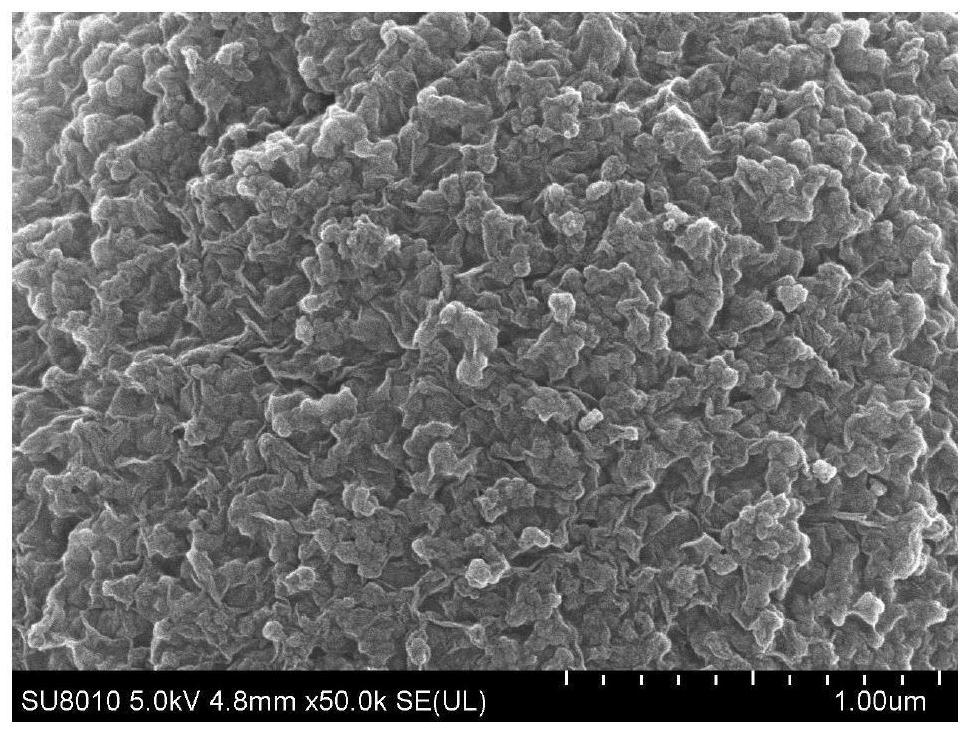

Carbon sphere/sulfur/reduced and oxidized graphene composite material for lithium sulfur battery and preparation method of carbon sphere/sulfur/reduced and oxidized graphene composite material

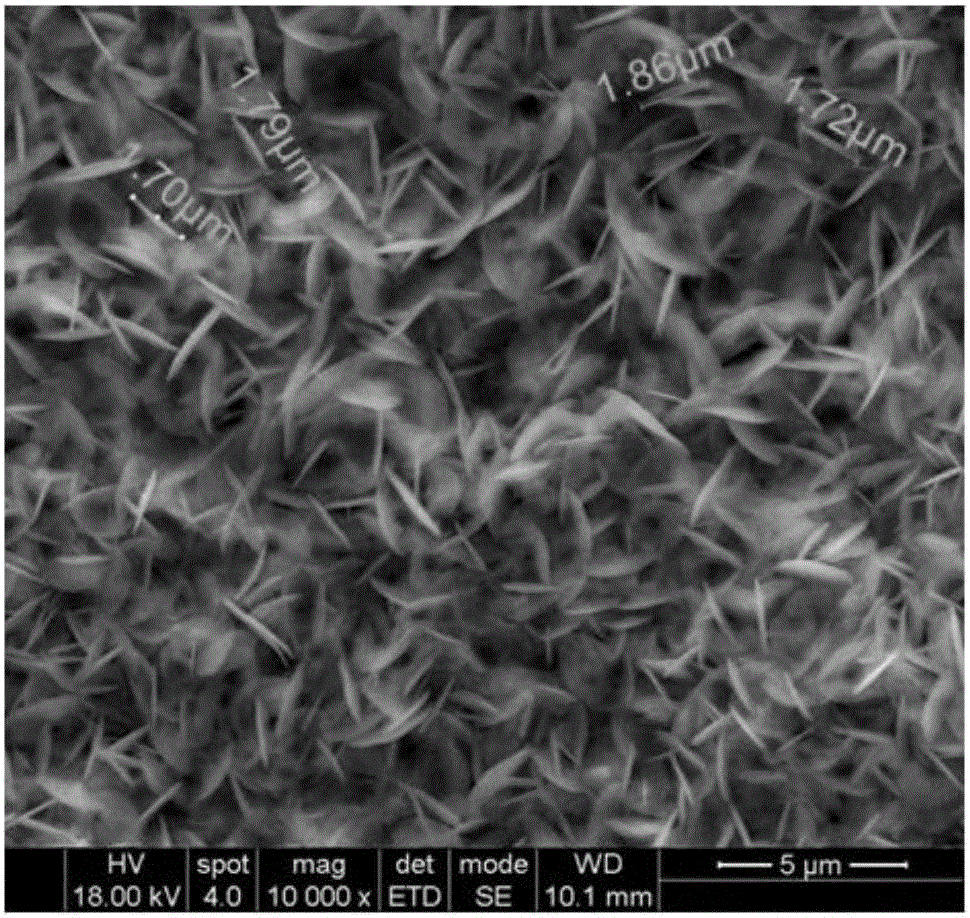

ActiveCN107768643ALarge specific surface areaCurb churnCell electrodesLi-accumulatorsLithium–sulfur batterySlurry

The invention relates to a carbon sphere / sulfur / reduced and oxidized graphene composite material for a lithium sulfur battery and a preparation method of the carbon sphere / sulfur / reduced and oxidizedgraphene composite material. The preparation method comprises the following steps: firstly, performing the heat treatment or solution soaking sulfur precipitation compounding for sulfur and carbon spheres, then mixing and stirring a sulfur / carbon sphere complex and a binder to form slurry, smearing the slurry onto an aluminum foil, drying the aluminum foil, then placing the aluminum foil in graphene oxide dispersion liquid, depositing and reducing the graphene oxide by virtue of electrochemical reduction, and thus obtaining the reduced graphene oxide-sealed sulfur / carbon sphere composite anodematerial. The carbon sphere prepared by the method of the invention has rich surface creases and inner porous structure and higher specific surface area (1000m<2> / g), and can load more sulfur, wherein the content of the solid sulfur reaches up to 80 percent. The reduced graphene oxide layer has higher conductivity and rich porous structure, facilitates the passing of lithium ions, can effectivelyinhibit the loss of sulfur and poly-sulfide, can improve the conductivity and cycling stability of the sulfur / carbon sphere composite material, and has a higher practical prospect.

Owner:SHANDONG UNIV

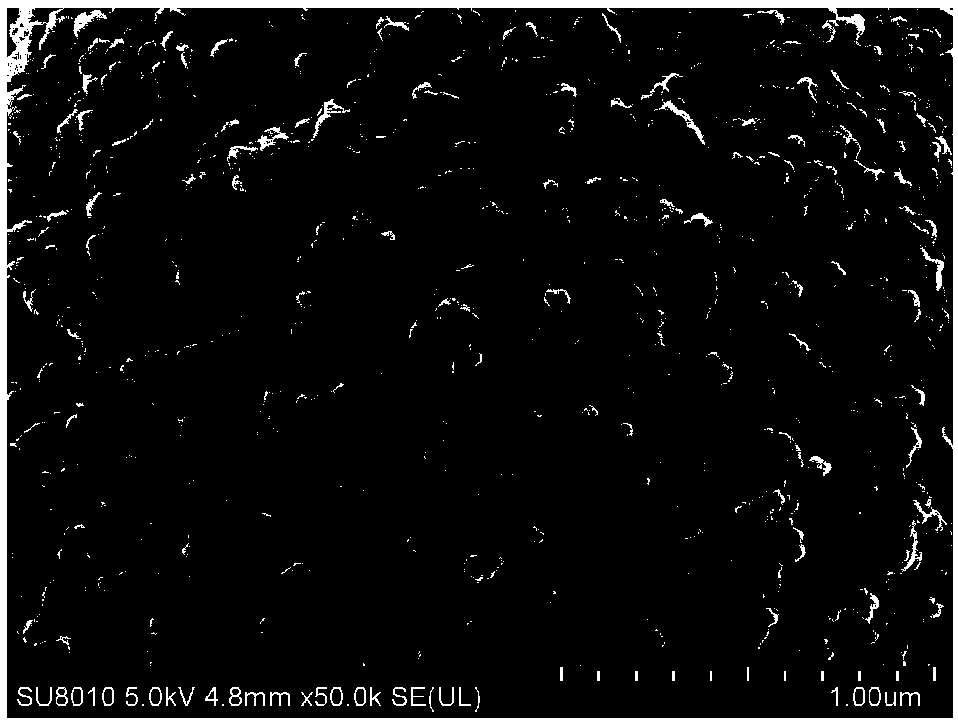

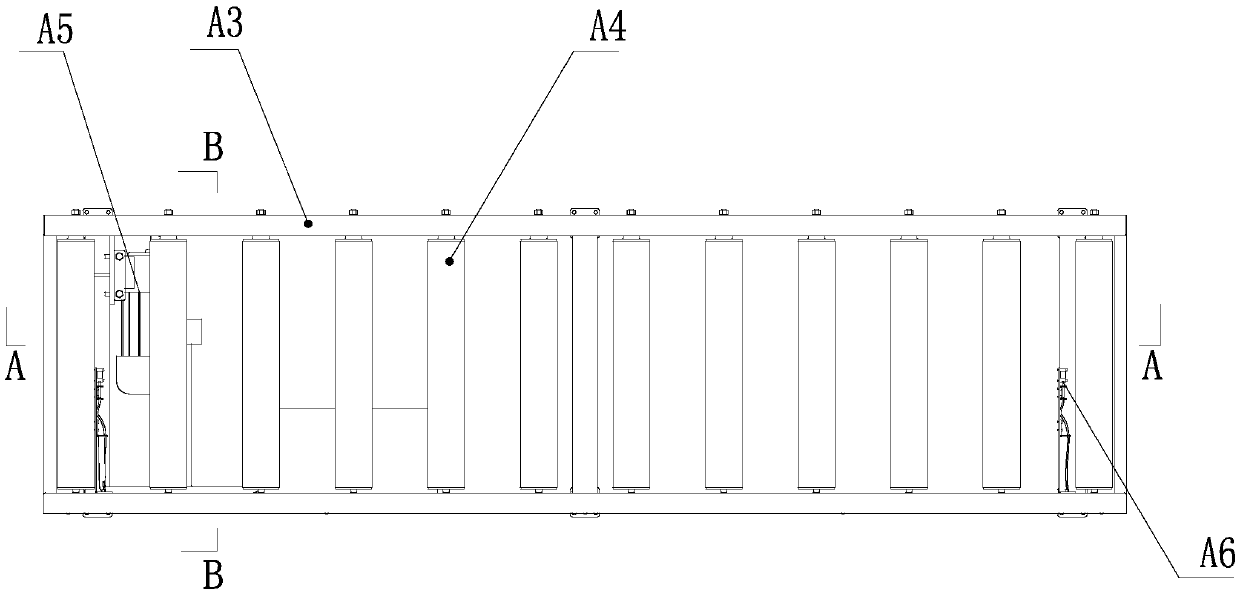

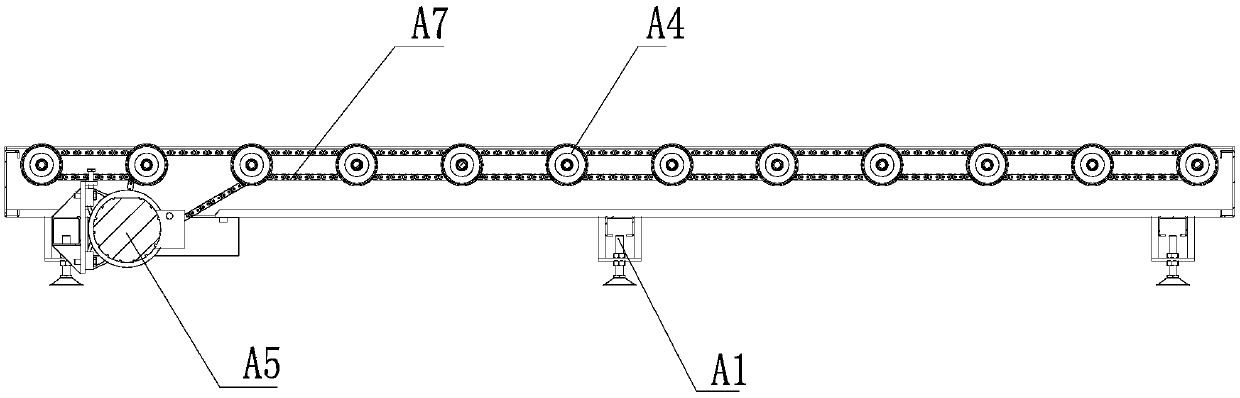

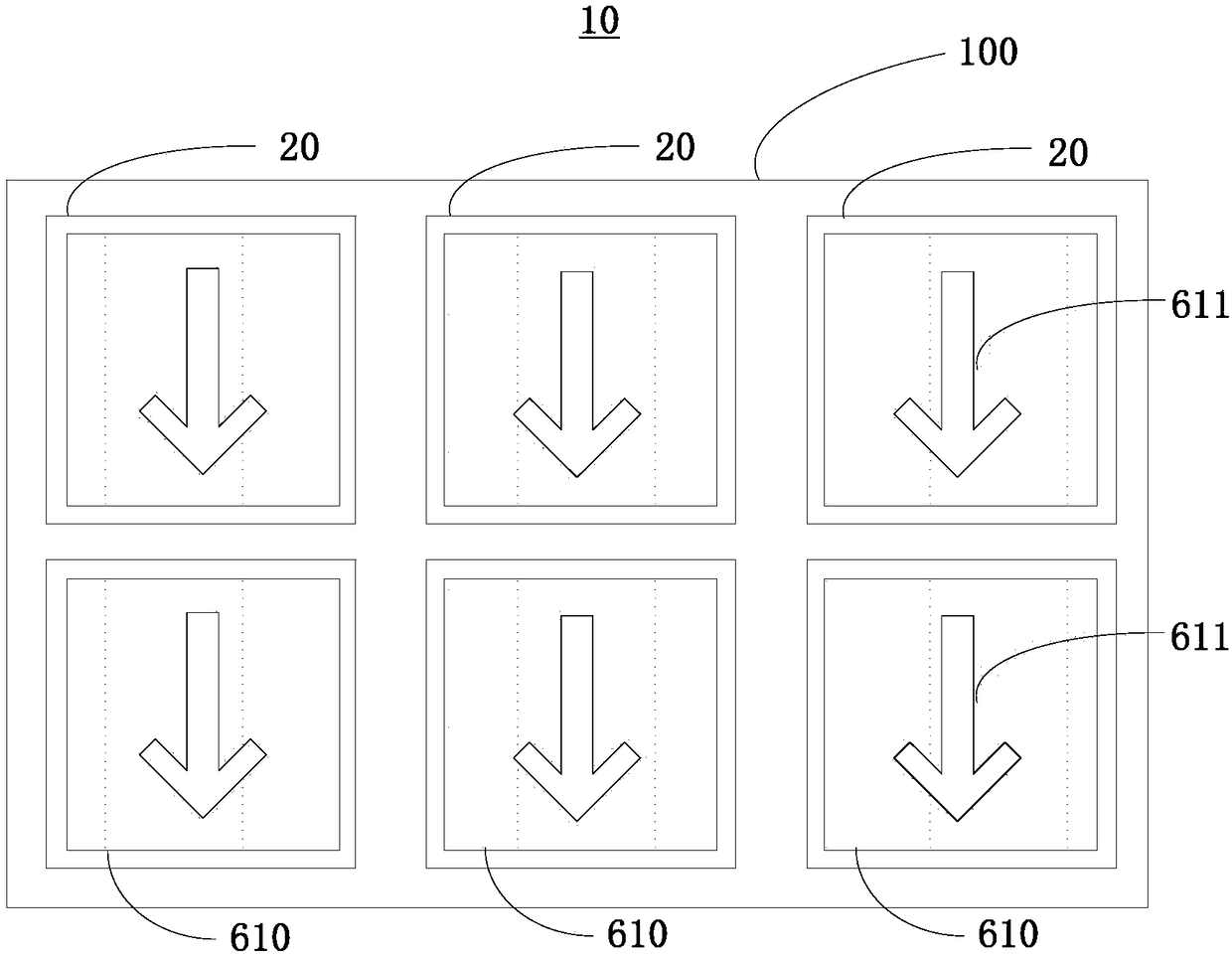

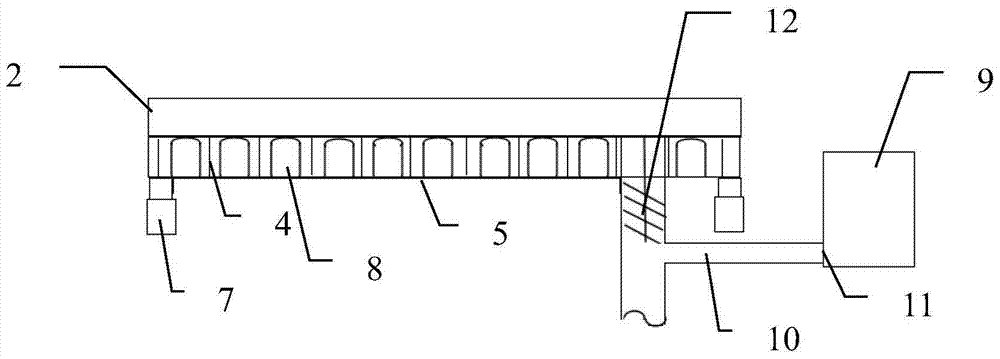

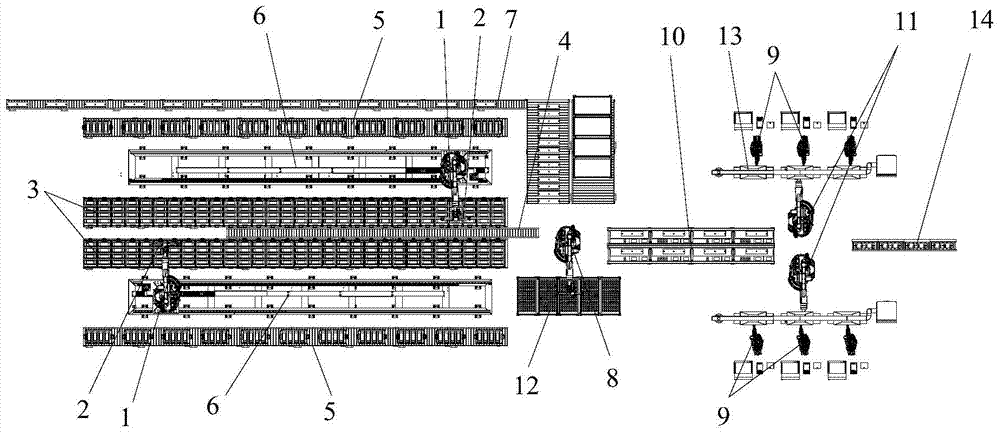

Panel furniture flexible production line

PendingCN109531757AFully automatedRealize intelligent productionOther plywood/veneer working apparatusConveyorsProduction lineStack machine

The invention discloses a panel furniture flexible production line. The panel furniture flexible production line comprises a panel storage mechanism, a rail trolley for conveying and a plate banding mechanism, and further comprises a power roller conveying line used for conveying panels, an electronic saw discharging machine used for discharging materials, a rotary lifting table used for transferring the panels, a vertical rotary sorting machine used for sorting the panels, a box sealing machine used for sealing and casing finished-products of panel furniture and a roadway stacking machine used for stereoscopic storage and automatic warehouse outlet of the finished-products of the panel furniture. By adopting the panel furniture flexible production line, customized production in the furniture industry is realized; the panel furniture flexible production line is applicable to both large-scale standard product production and small-scale customized production; labor cost is reduced; and automatic and intelligent production of the furniture is realized.

Owner:广东友力智能科技有限公司

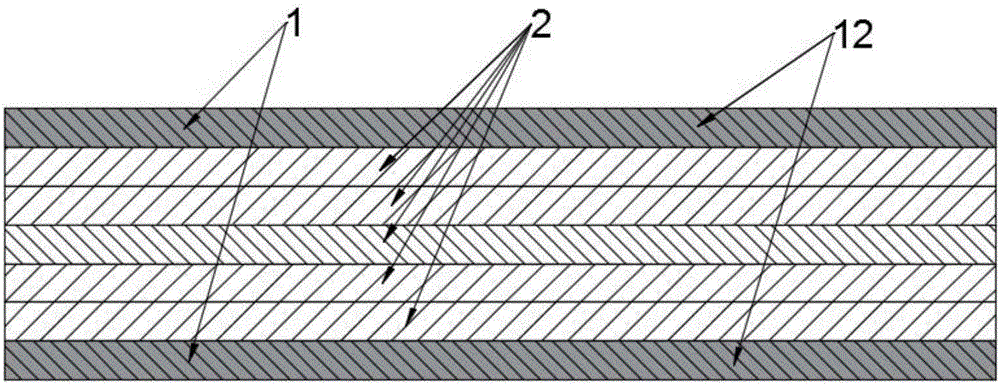

Plywood and preparation method thereof

ActiveCN106827109AImprove anti-corrosion performanceImprove water resistanceOther plywood/veneer working apparatusWood treatment detailsAdhesivePreservative

The invention discloses a plywood and a preparation method thereof. The plywood comprises multiple layers of veneers; and one or more layers of veneers on the surface of the plywood contain preservatives and / or flame retardants. The method comprises the following steps: adhesive is coated on the surfaces of the veneers; the veneers are laminated for hot pressing after cold prepressing, or the adhesive is cured by hot pressing; and finally, through impregnation, one or more layers of veneers on the surface of the plywood contain the preservatives and / or the flame retardants. The plywood is excellent in corrosion resistance, can synchronously achieve corrosion and flame resistance, and is controllable in inpregnation depth, low in needed impregnation medicine quantity, high in gluing strength, excellent in water resistance and excellent in size stability.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

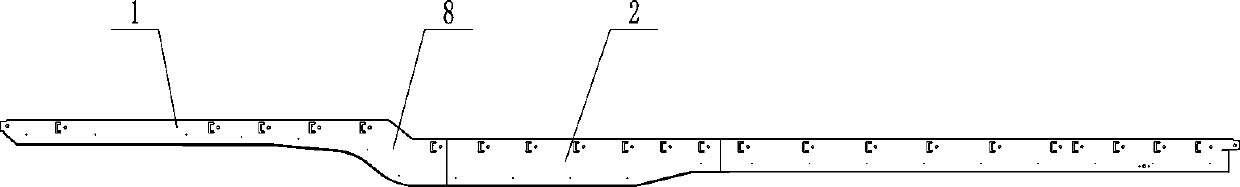

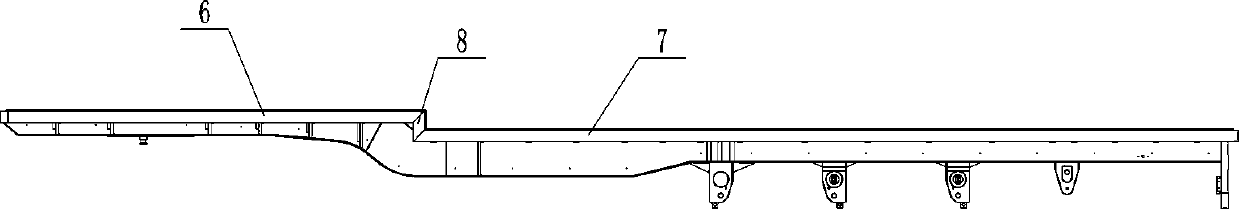

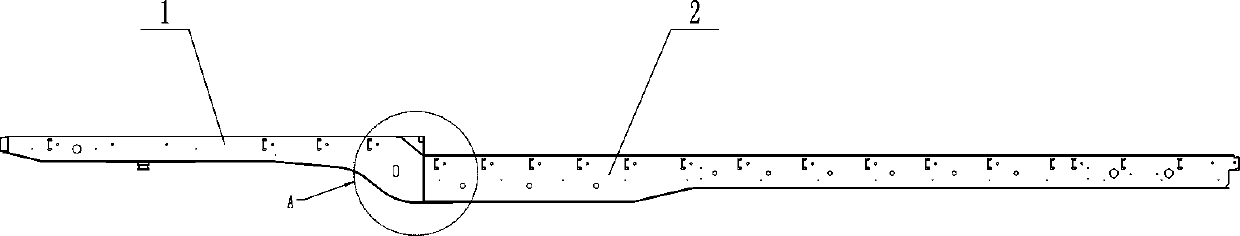

Gooseneck trailer longitudinal beam spliced in segmented manner, trailer frame and trailer

PendingCN110562325AIncrease profitHighlight substantive featuresUnderstructuresTractor-trailer combinationsVehicle frameLap joint

The invention provides a gooseneck trailer longitudinal beam spliced in a segmented manner. The gooseneck trailer longitudinal beam spliced in the segmented manner comprises a front longitudinal beambody, a rear longitudinal beam body and a splicing structure; the front longitudinal beam body and the rear longitudinal beam body are divided at the gooseneck position and connected together throughthe splicing structure; the splicing structure comprises a connection vertical plate; the two faces of the connection vertical plate are fixed to a web plate of the front longitudinal beam body and aweb plate of the rear longitudinal beam body correspondingly; the bottom end of the connection vertical plate is fixed to a lower wing plate of the front longitudinal beam body; the top end of the connection vertical plate is fixed to the front longitudinal beam body; and the tail end of the lower wing plate of the front longitudinal beam body extends backwards so that a lower wing plate of the rear longitudinal beam body can be in lap joint to the lower wing plate of the front longitudinal beam body. The gooseneck trailer longitudinal beam spliced in the segmented manner has the advantages that segmented design is performed, matching with frames in different gooseneck step height differences is achieved, and the connection structure is steady and simple.

Owner:ZHUMADIAN CIMC HUAJUN VEHICLE

Preparation device and preparation method for super high-speed sealed spiral flow field graphene nanosheets

PendingCN109502576AReduce material consumption and energy consumptionHighlight technical advantages and vitalityGrapheneEngineeringGraphene nanoplatelet

The invention relates to a preparation device and a preparation method for super high-speed sealed spiral flow field graphene nanosheets. The dust-free pretreatment of raw materials is realized by a powder suction type premixing device; a stripping device adopting a sealed spiral flow field design acts materials moving in the stripping device according to the spiral flow field by using the hydraulic (laminar flow, turbulence and hole) effect produced by super high-speed rotation, thereby damaging Vanderwals force among graphene sheets and realizing stripping of the graphene nanosheets; the graphene nanosheets with different thicknesses and sizes are obtained by using a settling device and a centrifugal separation device. The related technologies and devices break through the technical bottleneck of the current high-quality and low-cost preparation field of graphene. The preparation device and the preparation method can realize the production with low pollution, high quality, multiple specifications and customization, and have outstanding technical advantages and vitality.

Owner:SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE

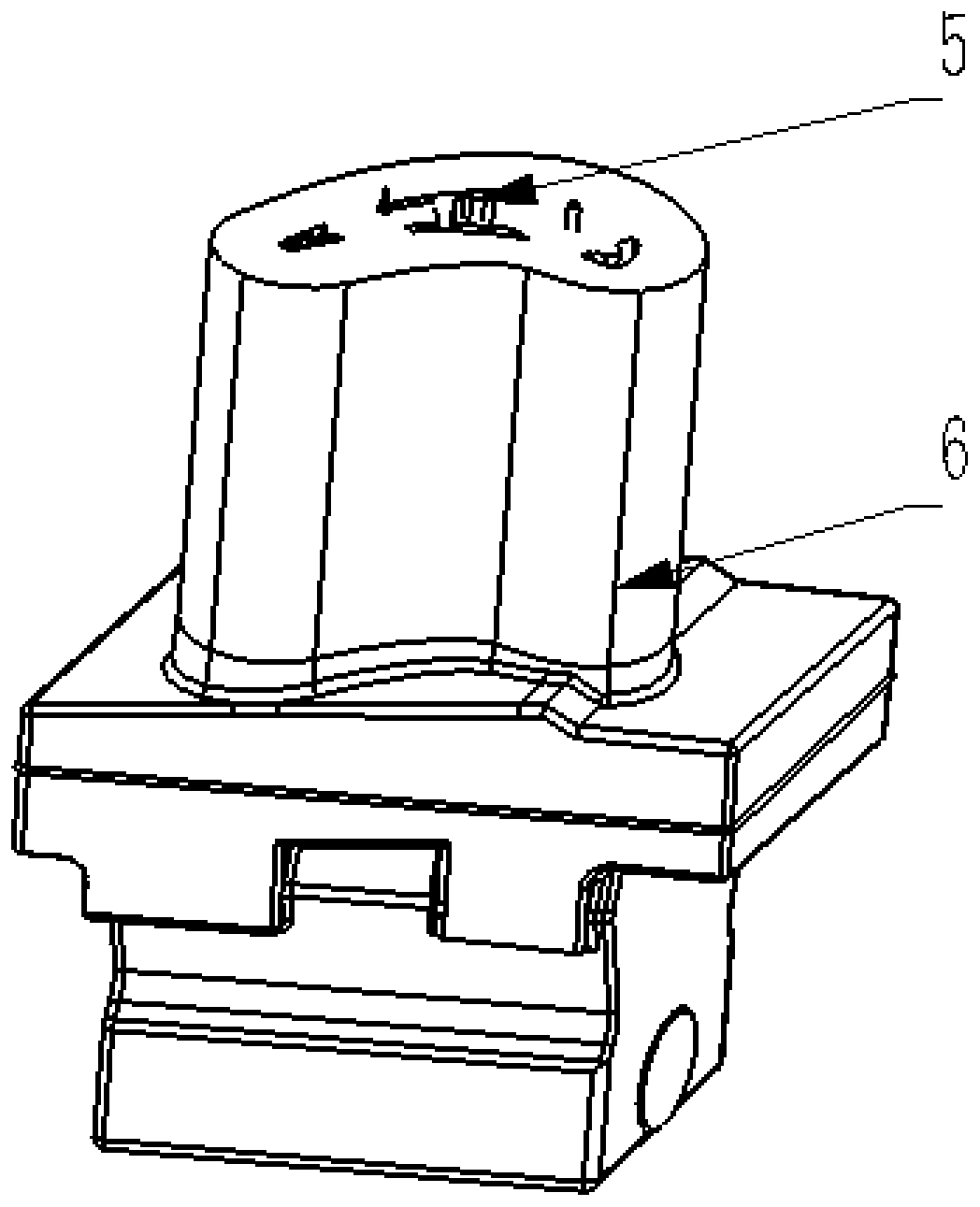

Firework powder accurate feeding device

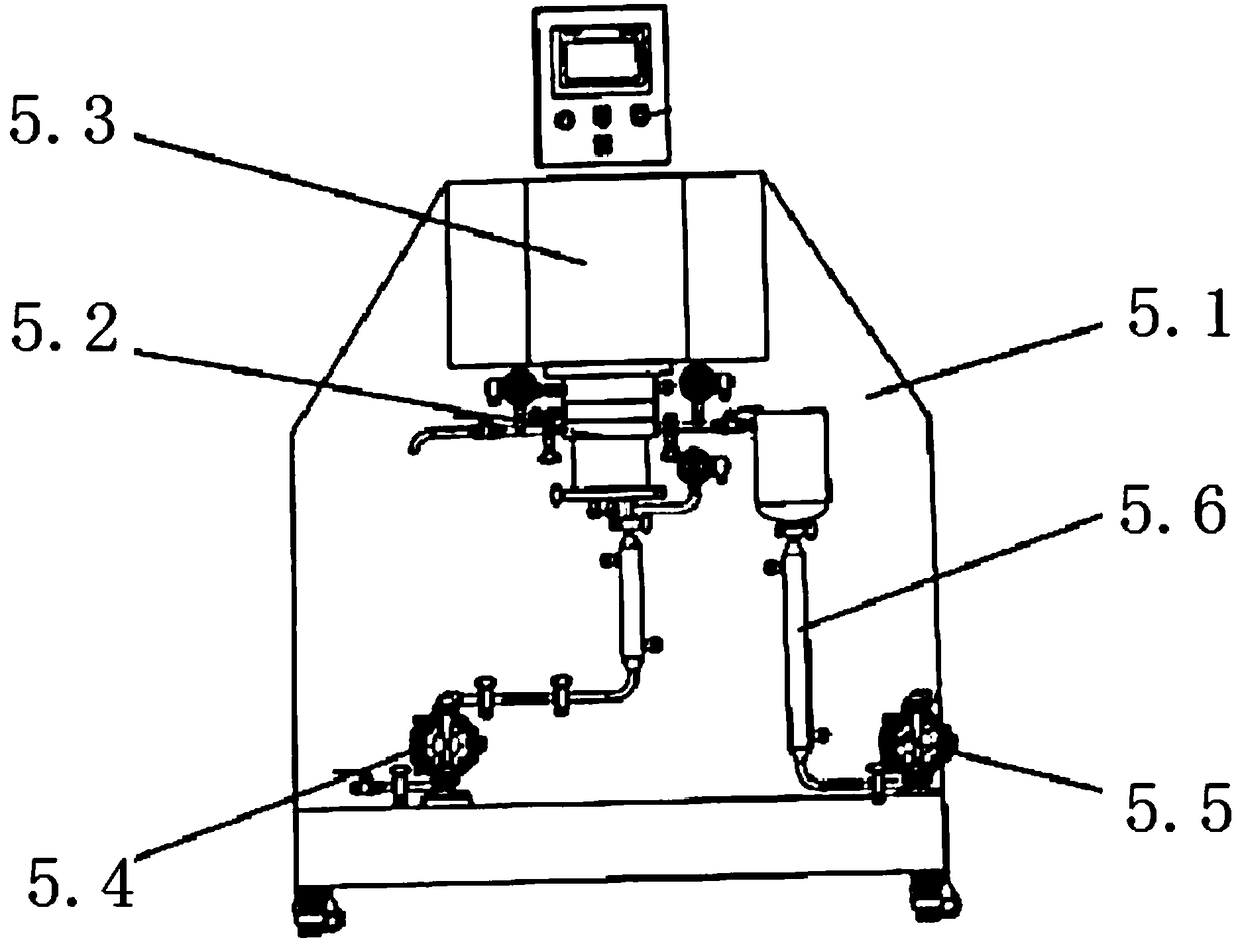

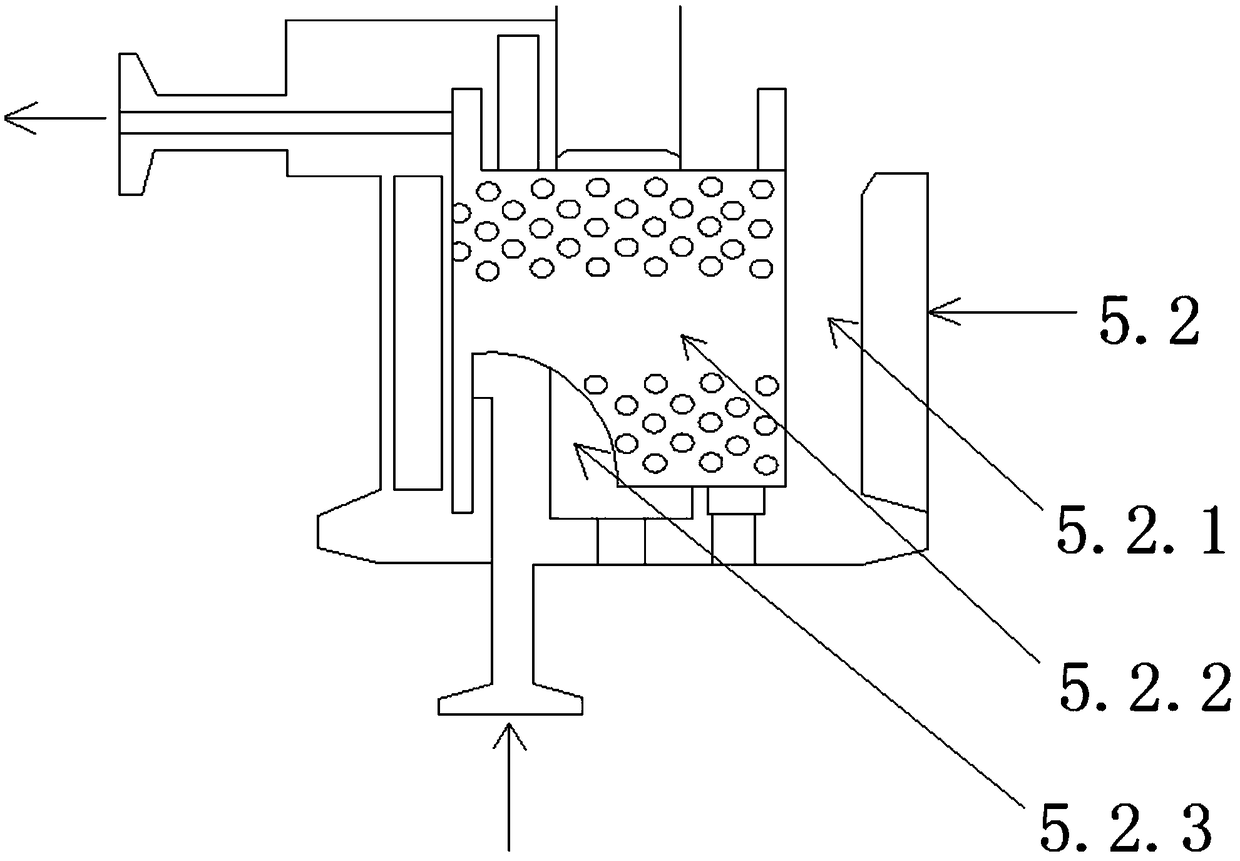

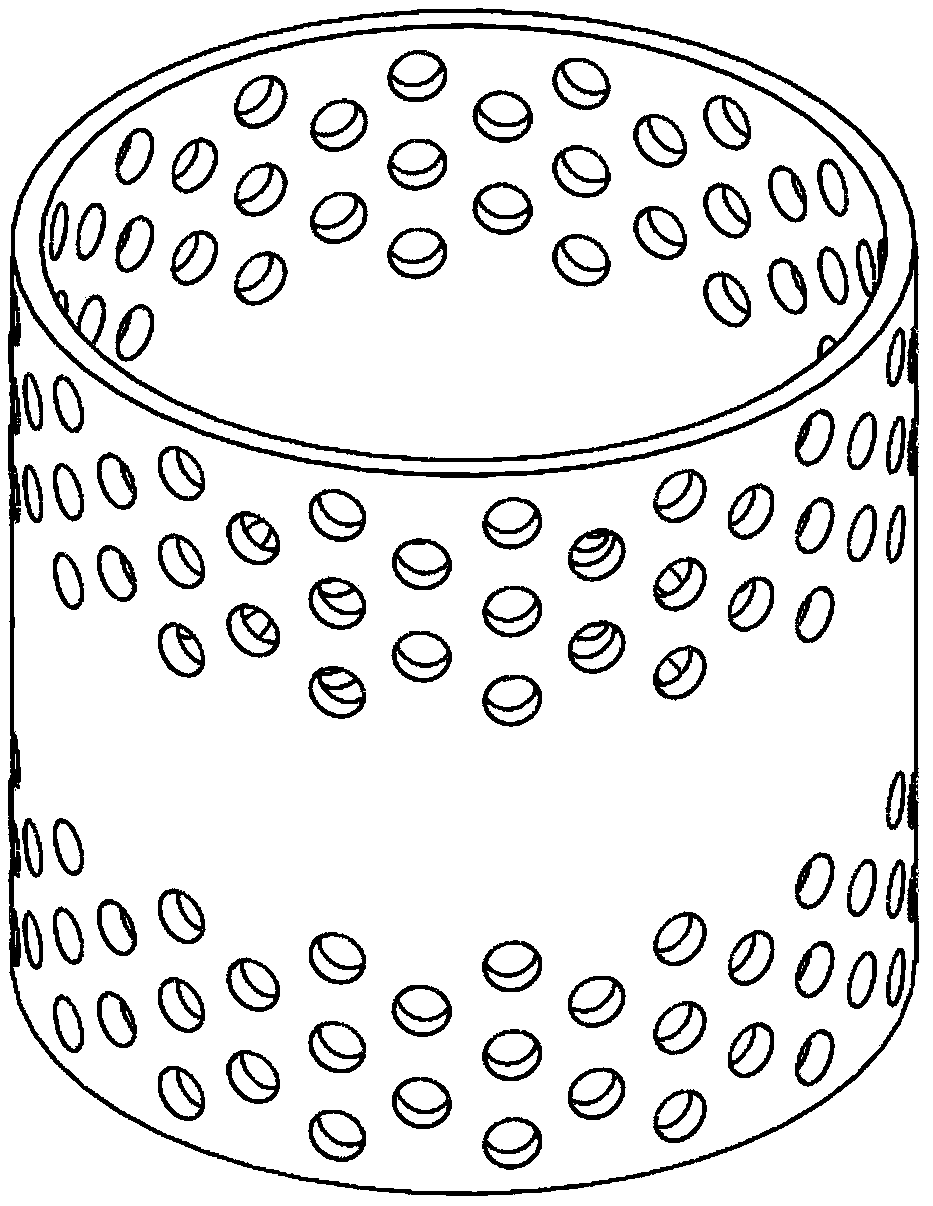

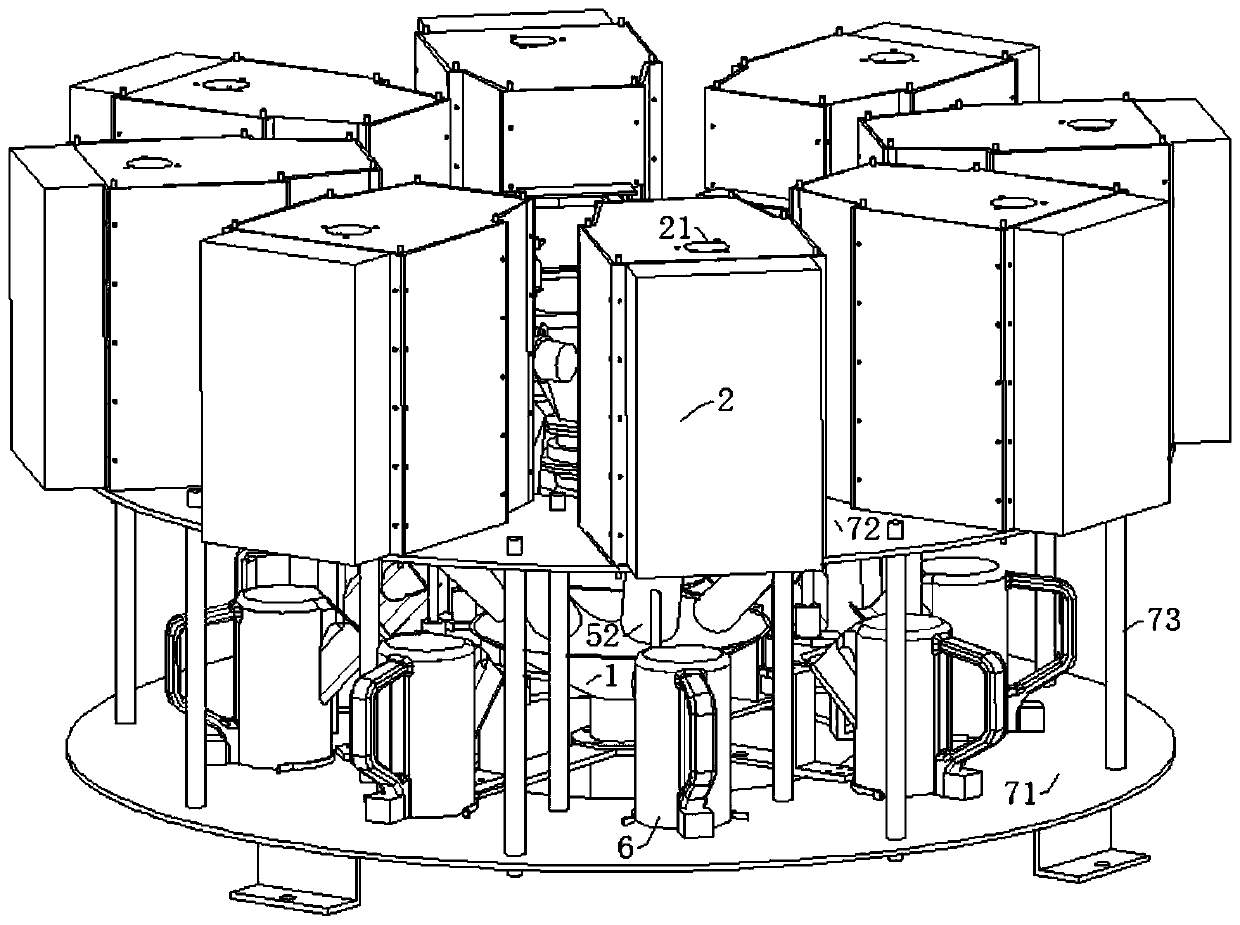

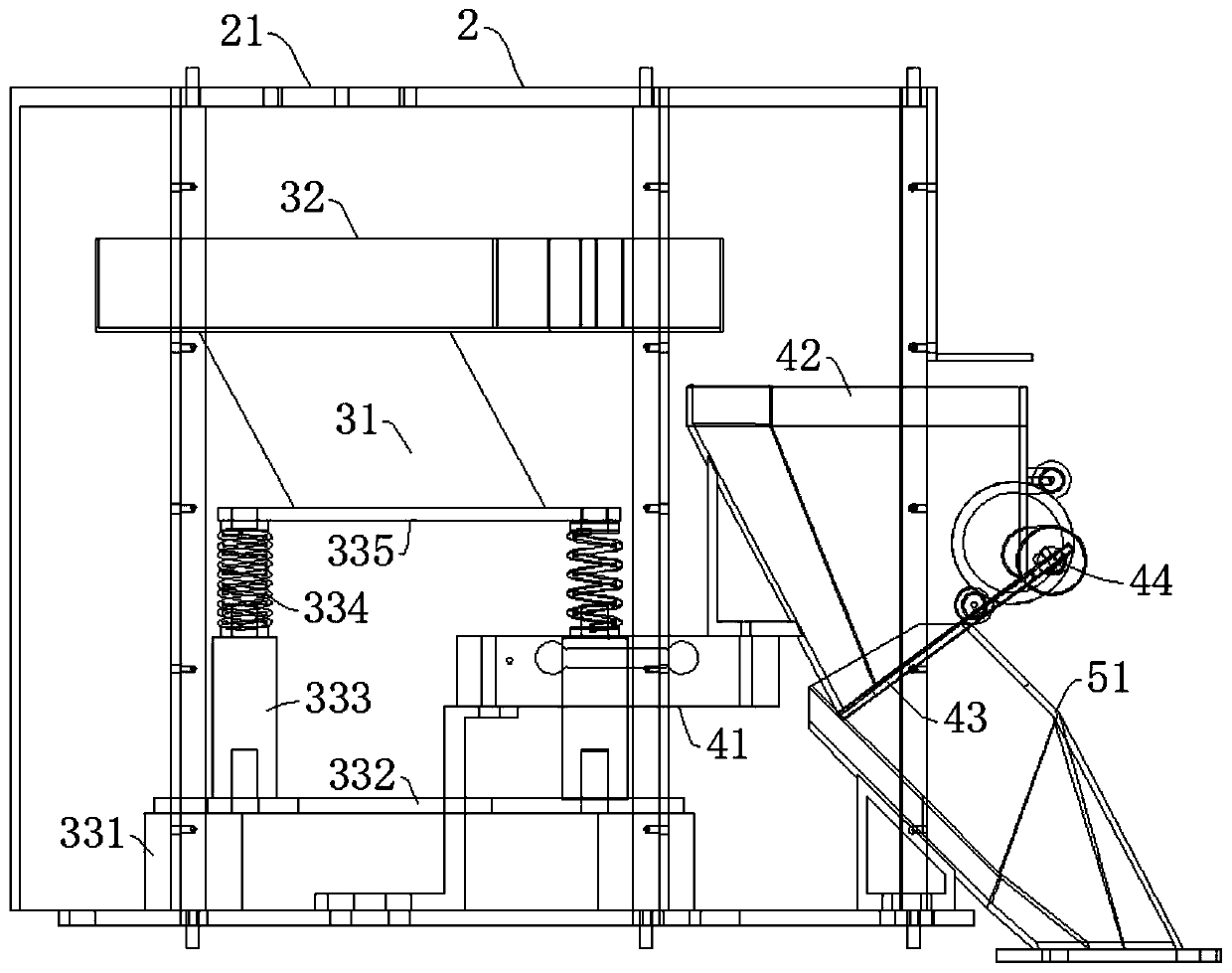

PendingCN110207550ARealize customized productionReduce labor intensityConveyorsFireworksFireworksWorking environment

The invention provides a firework powder accurate feeding device which comprises a machine frame, a collecting hopper and a plurality of distributing units, wherein the collecting hopper and the distributing units are arranged on the machine frame; the distributing units are detachably connected with the machine frame, a feeding inlet is formed in the top of each distributing unit, and a discharging outlet is formed in the bottom of each distributing unit; each distributing unit is internally provided with a weighing mechanism capable of controlling the weight of firework powder discharged outof the discharging outlet; and the discharging outlets are located above an inlet of the collecting hopper. As the plurality of detachable distributing units are arranged on the machine frame, and the discharging outlet in each distributing unit is located above the inlet of the collecting hopper, the feeding device can feed various powders at the same time, and the feeding speed can be effectively increased; and meanwhile, the weighing mechanisms are arranged in feeding boxes to control the weight of the firework powder discharged from the discharging outlets, so that the firework powder accurate feeding device has higher precision than manual weighing and is high in degree of automation, the labor intensity of operators can be greatly relieved, the production efficiency and the productquality can be improved, the working environment is improved, and safety accidents are prevented. The firework powder accurate feeding device is applied to the field of firework production equipment.

Owner:长沙华秦高新科技有限公司

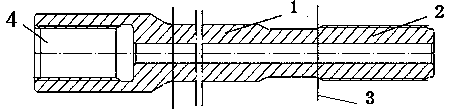

Manufacturing method for impact threaded brazing rod

InactiveCN110170801AReduce manufacturing costShorten production timeDrilling rodsDrilling casingsCustomer requirementsFriction welding

The invention discloses a manufacturing method for an impact threaded brazing rod. The manufacturing method comprises the following steps that (1): processing is conducted on threaded joints; (2): processing is conducted on a rod body, namely, A: a suitable-diameter round or multi-square hollow brazing tool steel material is selected; (3): the processed threaded joints are welded to the two ends of the rod body by using friction welding; (4): internal and external welding flying immediate-welding knob is removed, heat treatment and de-stressing heat treatment are conducted on the welding position, and welding non-destructive detection is conducted; (5) blasting is conducted, and straightening treatment is conducted; (6): correcting is conducted on the two end surfaces of a drilling rod ora drilling pipe; and (7): qualified inspection is conducted, and painting, packaging, and finished product warehousing are conducted. The various-product combination can be manufactured completely, astandard-length brazing rod can be processed, but also according to the customer requirements, brazing rods of different types and different lengths can be customized, and the flexible production andcustomized production are achieved.

Owner:刘艺纯

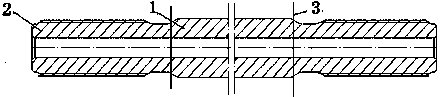

Structure design method of rotor wing paddle

InactiveCN109110125AReduce Design ComplexityShorten the design cycleFinal product manufactureGround installationsManufacturing technologyMetallic materials

The invention discloses a structure design method of a rotor wing paddle. The structure design method comprises the following steps: firstly, selecting a suitable lattice unit and a suitable engineering metal material; after selecting the lattice unit through a lattice unit mechanical analysis model, carrying out optimized design on the quantity of the lattice units in the paddle, geometric dimension of the lattice units and the distribution of the lattice units; after obtaining a lattice structure scheme meeting design requirements, directly preparing the paddle in an additive manufacturing manner. According to the structure design method disclosed by the invention, the design cost is reduced, the design period of the paddle is shortened, the complexity degree of manufacturing a paddle structure is extremely reduced, and a paddle manufacturing technology and flow are simplified; the production and manufacturing cost of the paddle is extremely reduced, the production and manufacturingefficiency of the paddle is improved, the strength can be increased, and the cost is reduced;; meanwhile, the strength and rigidity requirements of the structure can be ensured at the same time underthe condition that the weight of the material is the lightest; the recycling and utilization rate is high, the production cost is reduced, and industrial materials are saved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

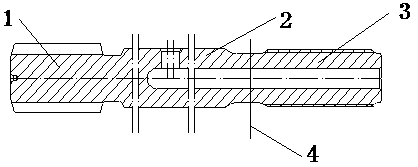

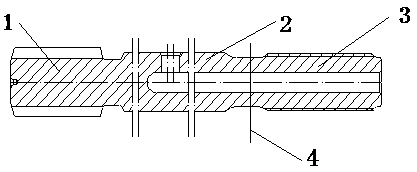

Bit shank manufacturing method

PendingCN110052794AHeat treatment process changesIncrease or decrease in lengthSolid state diffusion coatingFurnace typesFriction weldingSlag

The invention discloses a bit shank manufacturing method which comprises the following steps of regarding a bit shank as a divisible part, wherein the bit shank is divided into a left-side spline endand a right-side screw-thread male connector and is formed by combining a left part and a right part; (1) processing the screw-thread male connector; (2) processing the spline end; and (3) processingthe bit shank: A, selecting the spline end matched with a jackdrill, and the corresponding screw-thread male connector; B, using a friction welding machine for welding the spline end, the screw-threadmale connector and a middle cooperation end; C, removing internal and external welding trimmings, namely, welding slags; D, carrying out heat treatment on the welding part again; E, carrying out nondestructive inspection on the welding part; F, straightening and removing the straightening stress; G, feeding on a cylindrical grinding machine, grinding a middle part until the dimension meets the drawing requirement, polishing planes at two ends, and ensuring that the two end surfaces are parallel and perpendicular to a middle axis at the same time; and H, after passing inspection, coating anti-rust oil, packaging and storing. The spline end can be matched with multiple screwed joints, so that the material is saved; flexible and customized production can be realized; and the stock of finished goods in a warehouse is reduced.

Owner:刘艺纯

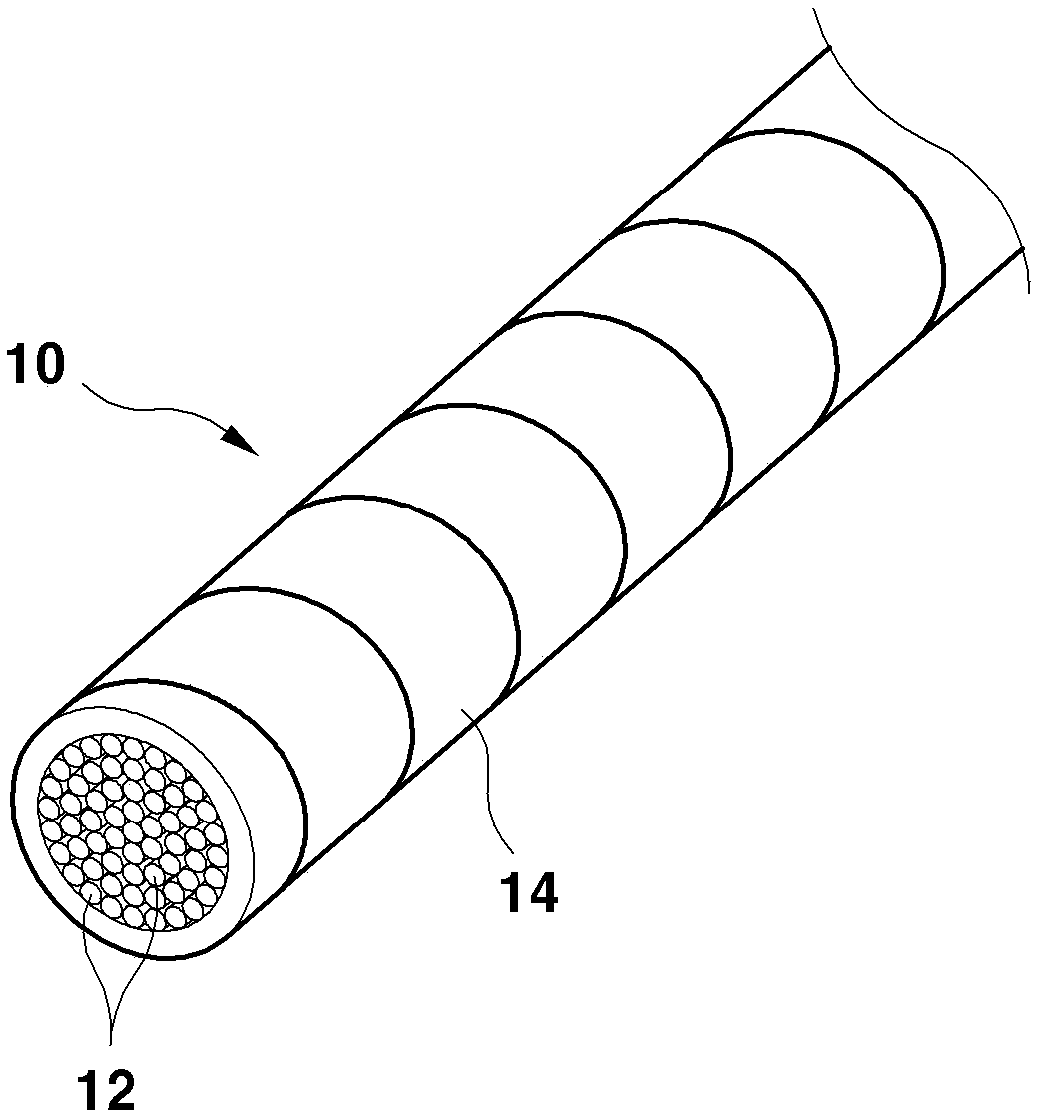

Method for manufacturing heating element, heating element manufactured thereby, and use method thereof

InactiveCN107079536AImprove heating efficiencyRealize customized productionPlastic/resin/waxes insulatorsApparatus for heat treatmentAlloyThin wire

Owner:金势玲 +1

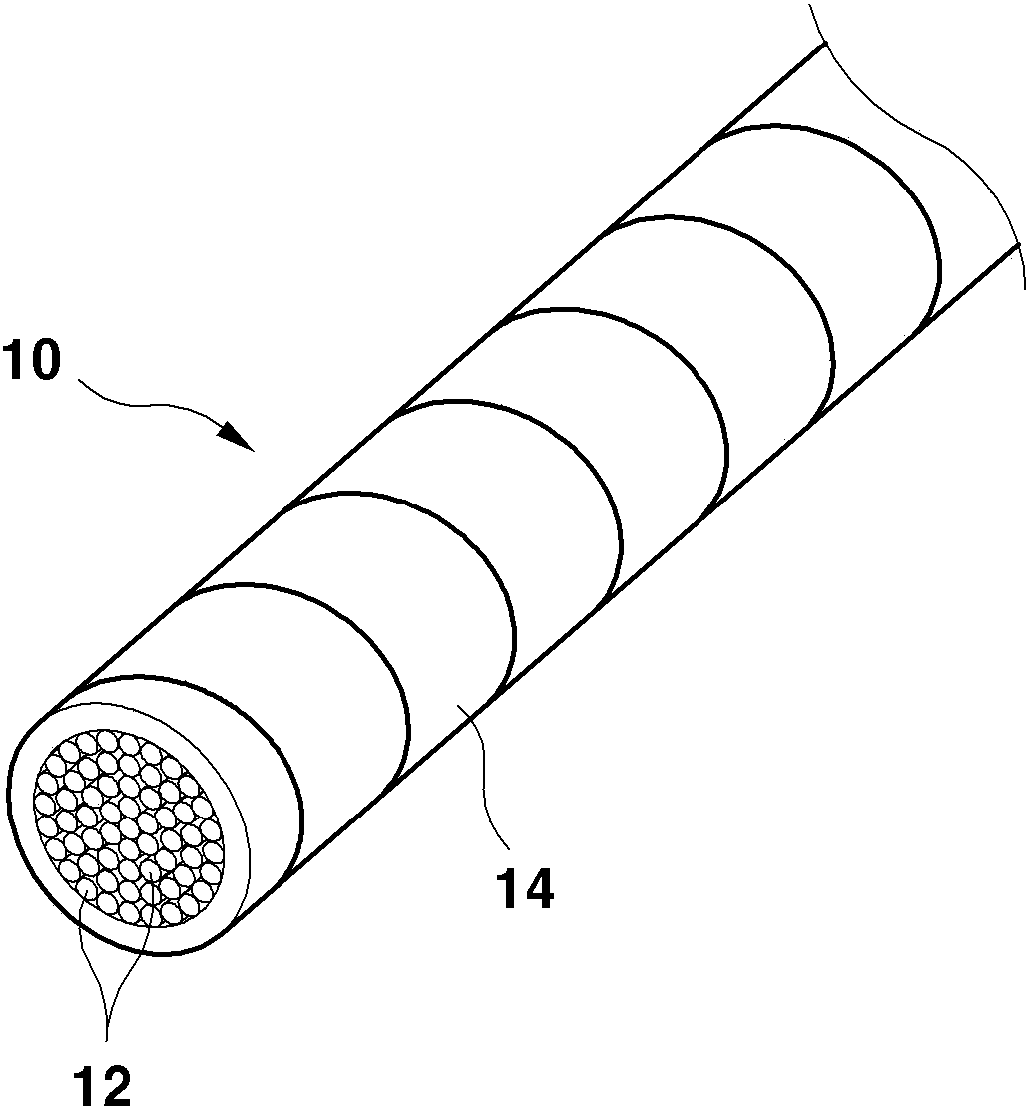

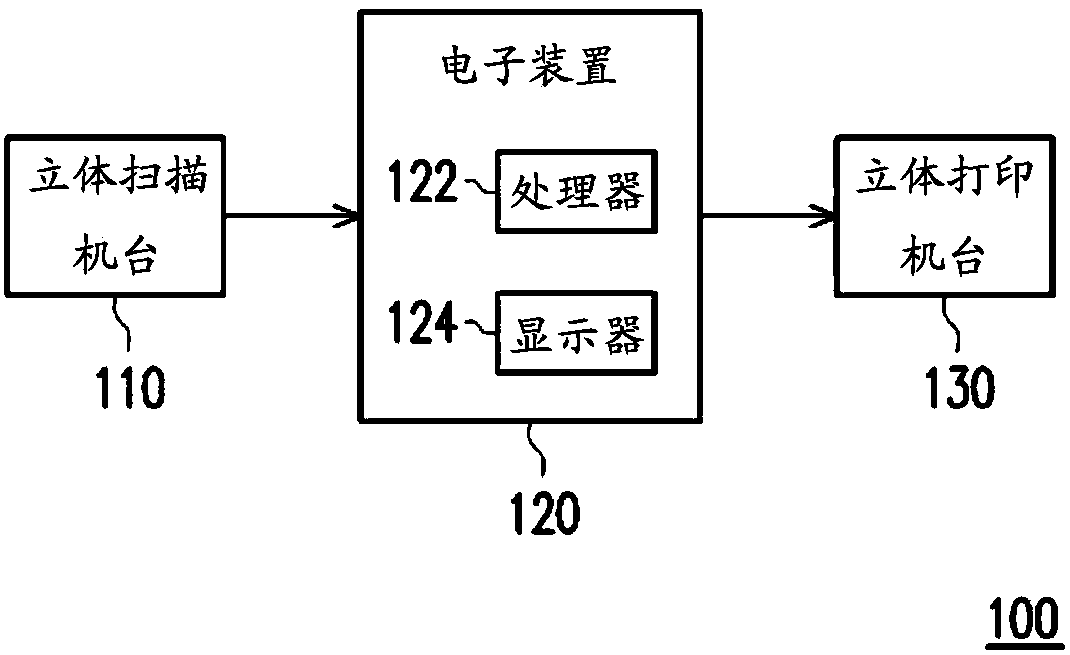

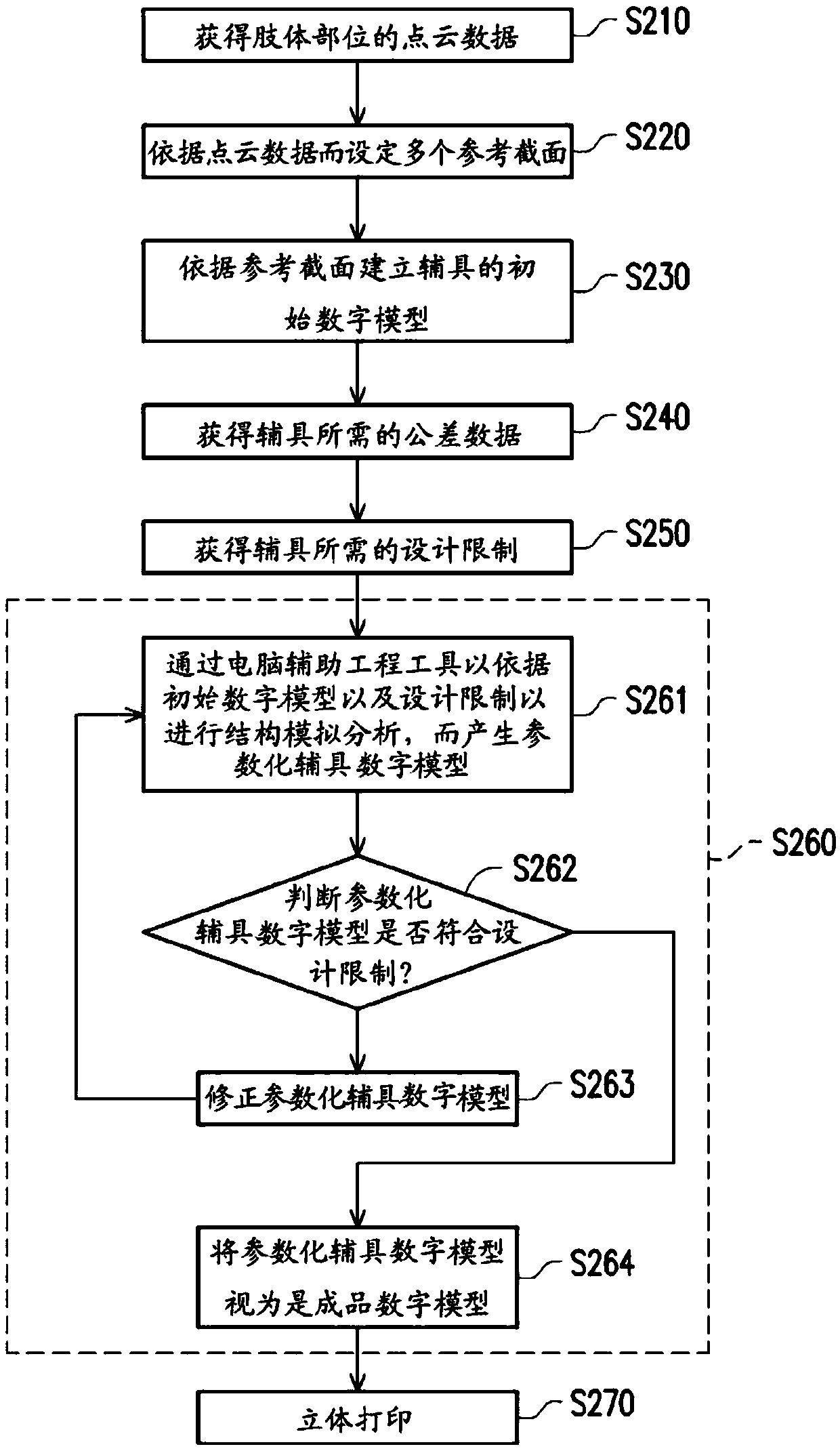

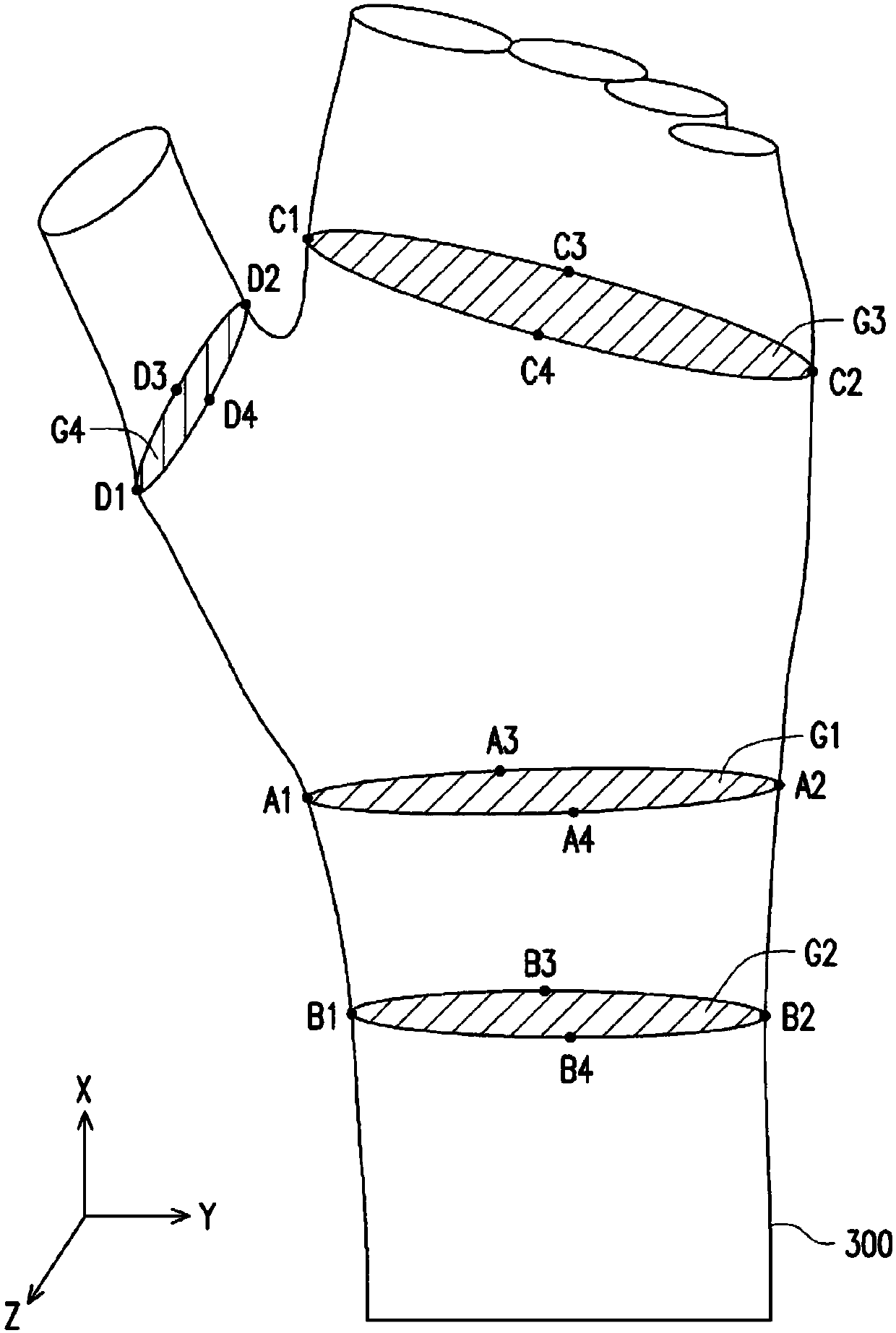

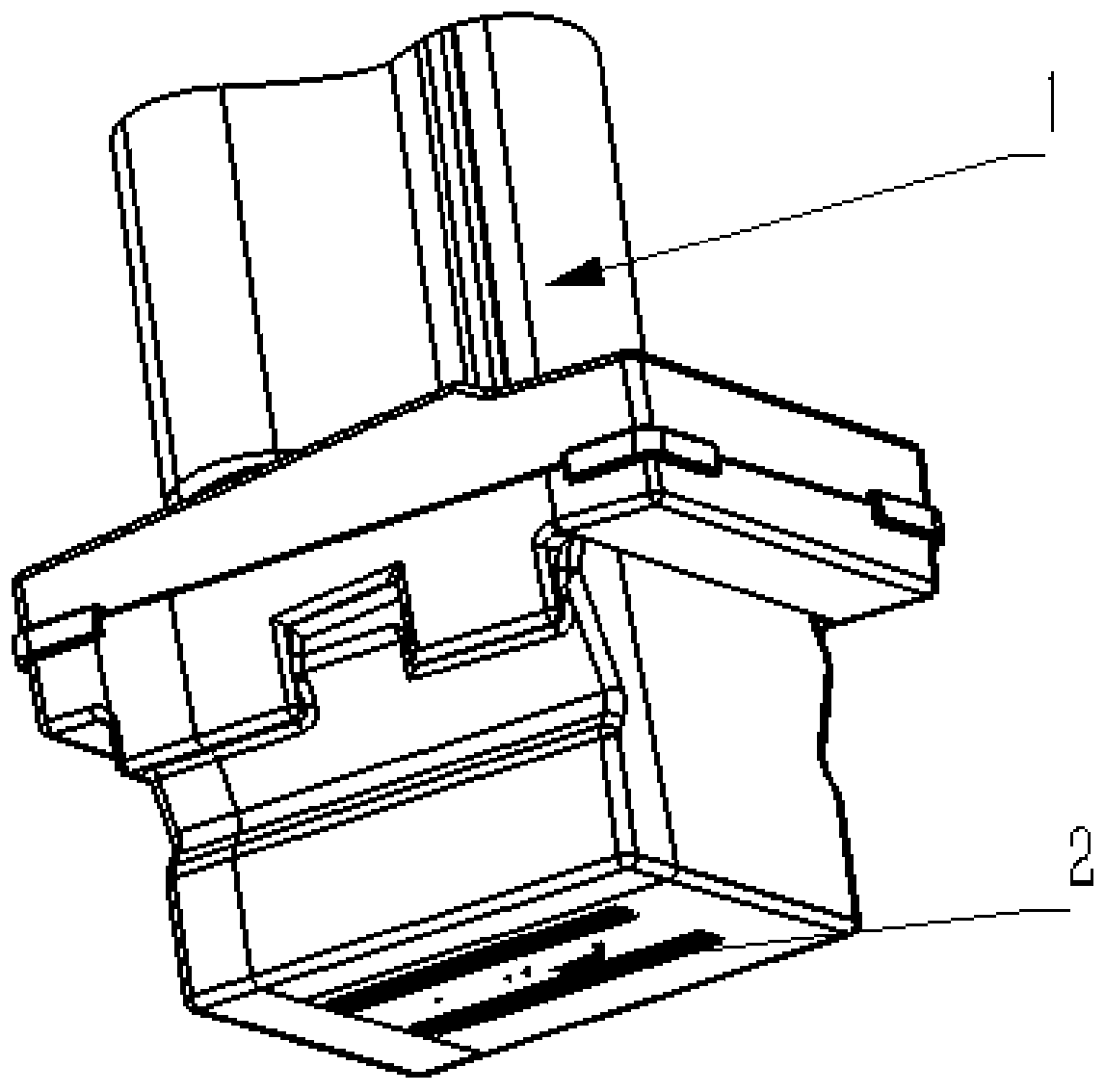

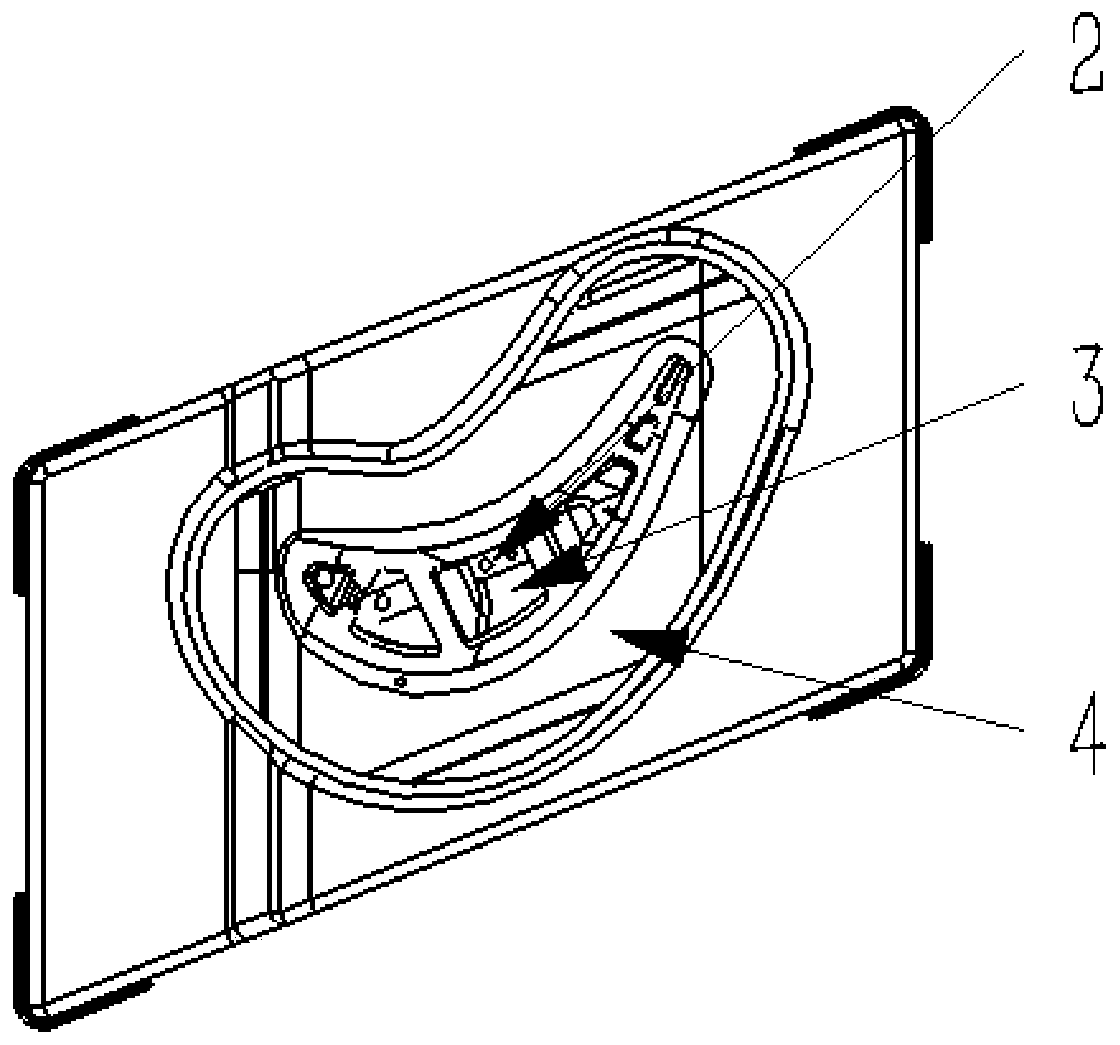

Design method for assistive device and electronic system for assistive device design

PendingCN110134977ALight structureRealize customized productionImage enhancementAdditive manufacturing apparatusElectronic systemsPoint cloud

A design method of an assistive device and an electronic system of assistive device design are provided. The design method of the assistive device is adapted for electronic devices including a processor. The design method includes: obtaining a point cloud data of a limb part; determining a plurality of reference cross sections according to the point cloud data, wherein each of the reference crosssections is determined corresponding to bone protrusion feature points of the point cloud data, wherein the bone protrusion feature points are corresponding to the bony prominences of the limb parts respectively; establishing an initial digital model of the assistive device according to the reference cross sections; and performing a structural simulation analysis according to the initial digital model and design limitations to obtain a product digital model of the assistive device.

Owner:IND TECH RES INST

Adiabatic energy-saving data acquisition and analysis system and method based on big data

PendingCN109656971AGood energy saving and emission reduction effectProcess stabilityVisual data miningStructured data browsingCollection analysisData acquisition

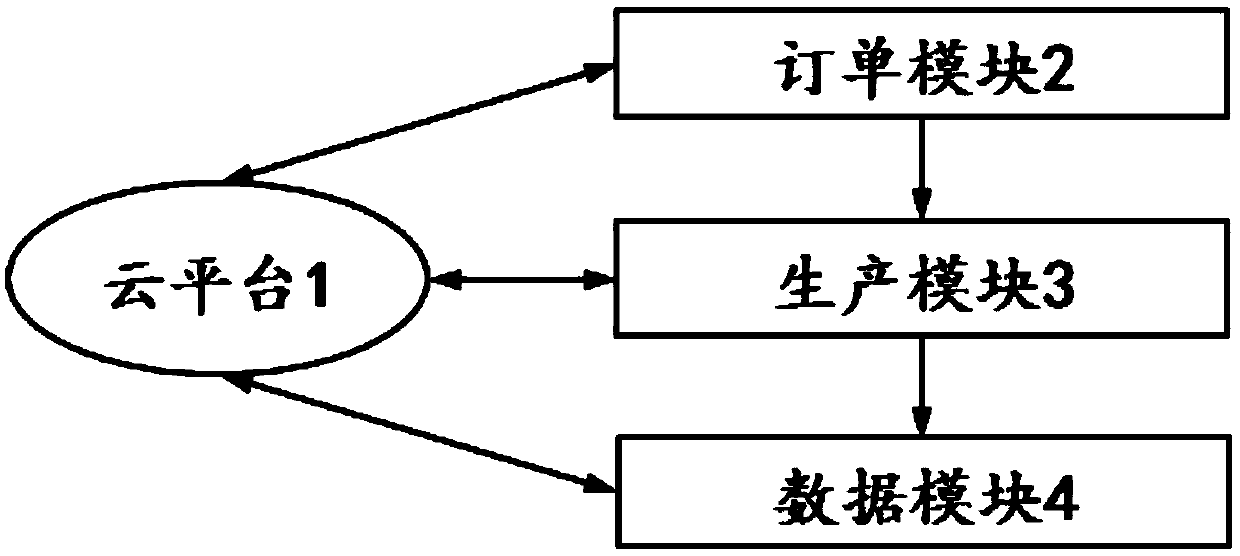

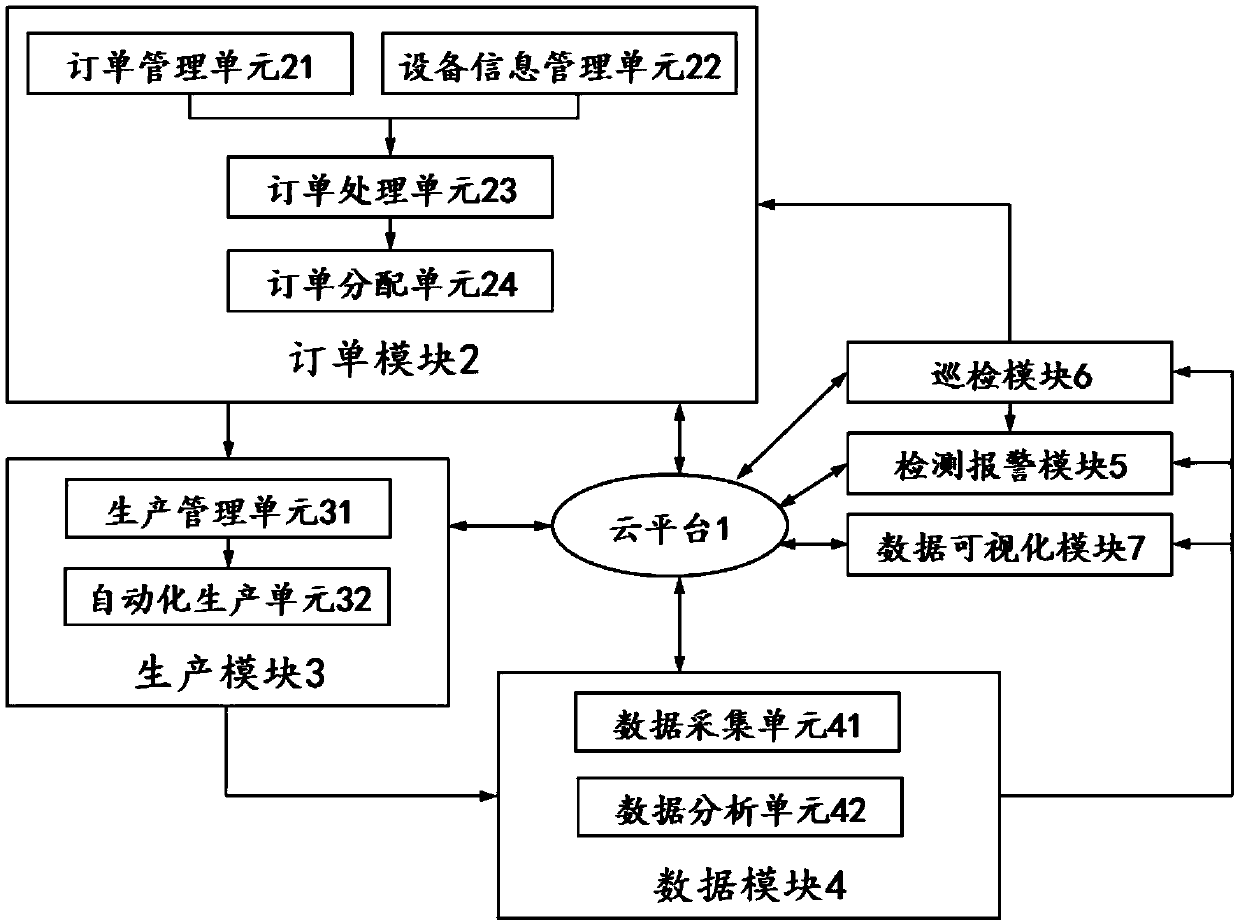

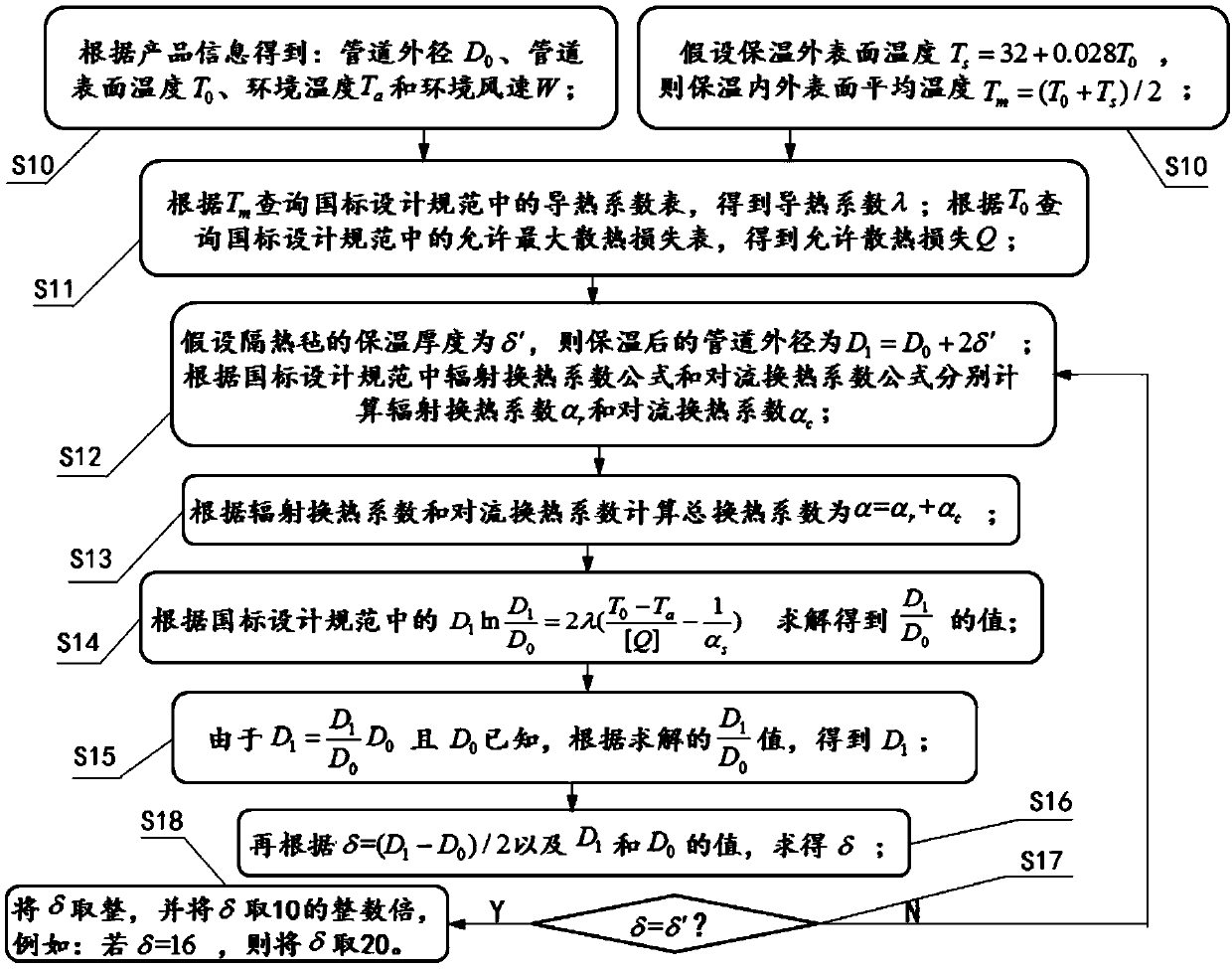

The invention relates to an adiabatic energy-saving data acquisition and analysis system and method based on big data. The system comprises a cloud platform, and an order module, a production module and a data module which are all connected with the cloud platform. The cloud platform is used for controlling and managing the work of the order module, the production module and the data module; The order module is used for receiving orders of the clients, processing the orders, matching factories according to order processing results and dispatching the orders; The production module is used for enabling the factory to automatically produce according to the dispatched orders; And the data module is used for processing the real-time data of the factory in the automatic production process and feeding back a processing result to the cloud platform. Based on the cloud platform, the modules are interconnected and intercommunicated, order, production and equipment working states are collected and analyzed in real time, customized production is achieved, and therefore client enterprises can achieve better energy conservation and emission reduction effects, the efficiency of the enterprises isimproved, and the working efficiency is improved.

Owner:SHENZHEN AEROGEL TECH CO LTD

Phosphating production method for automobile galvanized plate

ActiveCN105887064AQuality assuranceMeet production requirementsMetallic material coating processesCountermeasureSlag

The invention discloses a phosphating production method for an automobile galvanized plate and belongs to the field of automobile plate phosphating processes. The production method comprises the following steps of 1, solution compounding; 2, slag discharging; 3, titration; 4, control over phosphating process key points; 5, treatment of abnormal process in the phosphating process. Technological parameters in the activating treatment and phosphating processes are strictly controlled and adjusted in time, and quality of the phosphorized plate is guaranteed. Meanwhile, corresponding countermeasures are taken to solve abnormal problems existing in the production process, and therefore by means of the whole set of complete phosphating production method for the automobile galvanized plate, product quality is guaranteed.

Owner:武汉钢铁有限公司

Method for enhancing creep resistance of ceramic mold core through customization

InactiveCN110467466AHigh strengthStrong toughnessFoundry mouldsCeramic shaping apparatusFiberFreeze-drying

The invention discloses a method for enhancing the creep resistance of a ceramic mold core through customization, belonging to the field of rapid casting of stereolithigraphy technology. The method comprises the following steps: 1) designing a resin mold prototype by using UG software, and manufacturing a light-cured resin mold by using the stereolithigraphy technology; 2) inserting specific ceramic rods or ceramic fibers into the resin mold; 3) designing a gel-casting ceramic slurry formula, and molding a ceramic shell blank by using a gel casting molding process; and 4) after vacuum freeze drying of a ceramic mold blank, burning off the resin prototype through roasting so as to obtain a complete integrated ceramic mold. The freeze-drying and roasting processes of the method can improve the deformation resistance of the mold core; the ceramic rods and the ceramic fibers can improve the toughness and strength of the mold core; and the creep resistance of the ceramic mold core is enhanced through customized manufacturing; and the method is suitable for actual production.

Owner:XI AN JIAOTONG UNIV

Remanufacturing method after scrapping of brazing tail thread

InactiveCN110170800AThe length of the shank is the sameIncrease or decrease lengthFriction weldingHeat treated

The invention discloses a remanufacturing method after scrapping of a brazing tail thread. The remanufacturing method comprises the following steps of 1, processing, and 2, remanufacturing process. Inthe step 1, the processing comprises the following steps that threaded male joints with different thread standards are subject to heat treatment; and in the step 2, the remanufacturing process comprises the following steps that a, a scrapped drill tail is ground, and shot blasting treatment is performed to remove rust on the surface; b, integral nondestructive inspection is carried out; c, the drill tail is pre-straightened; d, a damaged threaded part is cut off; e, friction welding is used, and the machined matched new threaded joint is welded; f, inner and outer welding flash edges are removed; g, heat treatment is performed at the welding position again; h, nondestructive flaw detection is performed at the welding position; i, the straightening stress is straightened and removed; j, anexternal grinding bed is used, and two-end plane and a middle connecting part are ground, so that the two end surfaces are ensured to be parallel to the middle axis at the same time; and H, checkingis qualified, anti-rust oil is coated, and packaging and warehousing is performed. The method is used for remanufacturing a new tail thread with the scrapped tail thread, the length of the drill bit is consistent with that of the original length, and the use cost is greatly saved.

Owner:刘艺纯

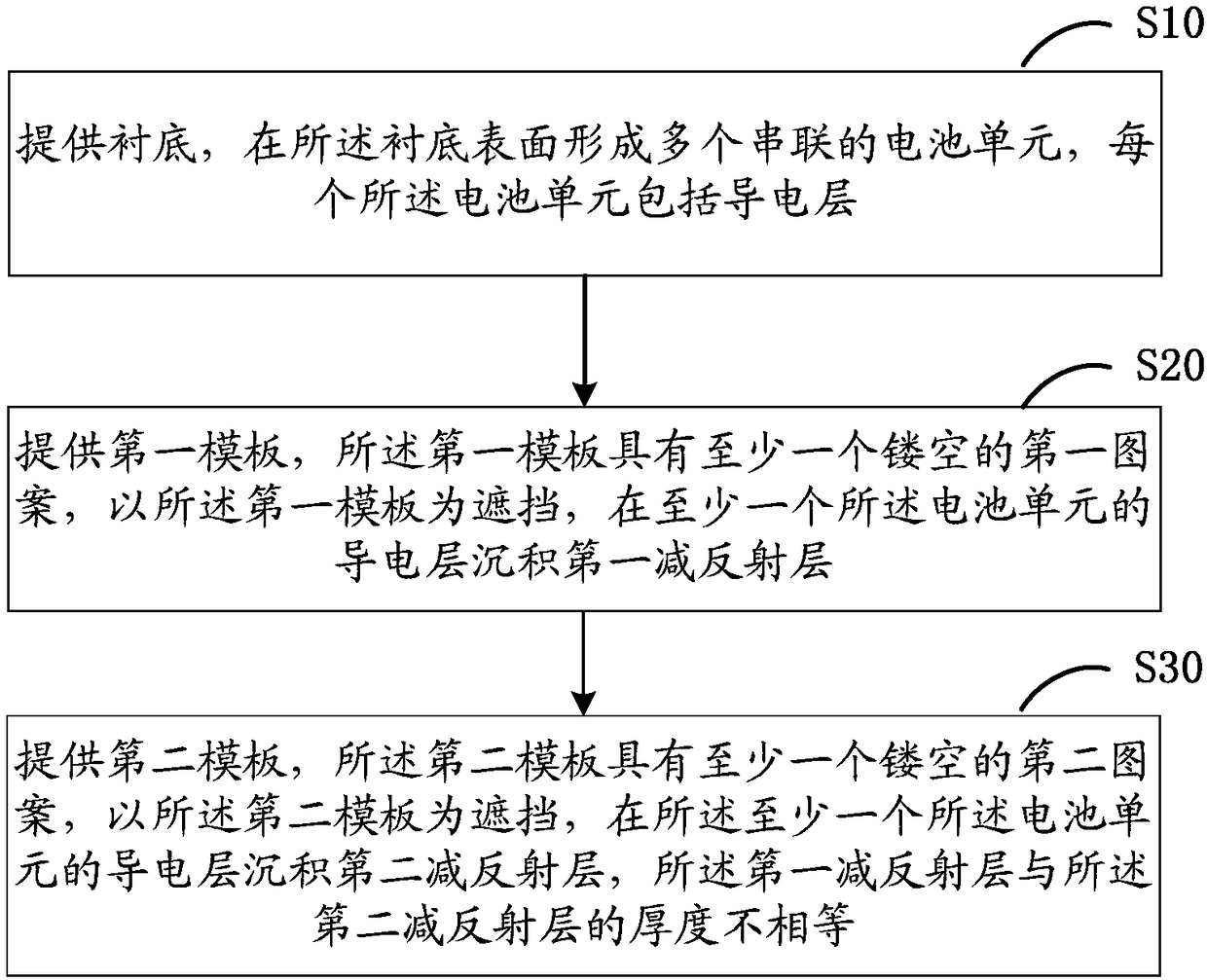

Color solar cell and preparation method thereof

InactiveCN108258068AAchieve color pattern effectRealize large-scale industrial productionPhotovoltaic energy generationSemiconductor devicesSolar cellComputer science

The invention relates to a color solar cell and a preparation method thereof. The cell is provided with several serial cell units. Each cell unit includes a conducting layer. A first template is provided. The first template includes at least one hollow first pattern. Shielding from the first template, a first anti-reflection layer is deposited on the conductive layer of at least one of the cell units. A second template is provided. The second template includes at least one hollow second pattern. Shielding from second template, a second anti-reflection layer is deposited on the conductive layerof at least one of the cell units. The thicknesses of the first anti-reflection layer and the second anti-reflection layer are not equal. The color solar cell has the advantages of simple process steps, convenient operation, good repeatability and high reliability can be industrially produced on a large scale. Customized production can be realized.

Owner:BEIJING APOLLO DING RONG SOLAR TECH

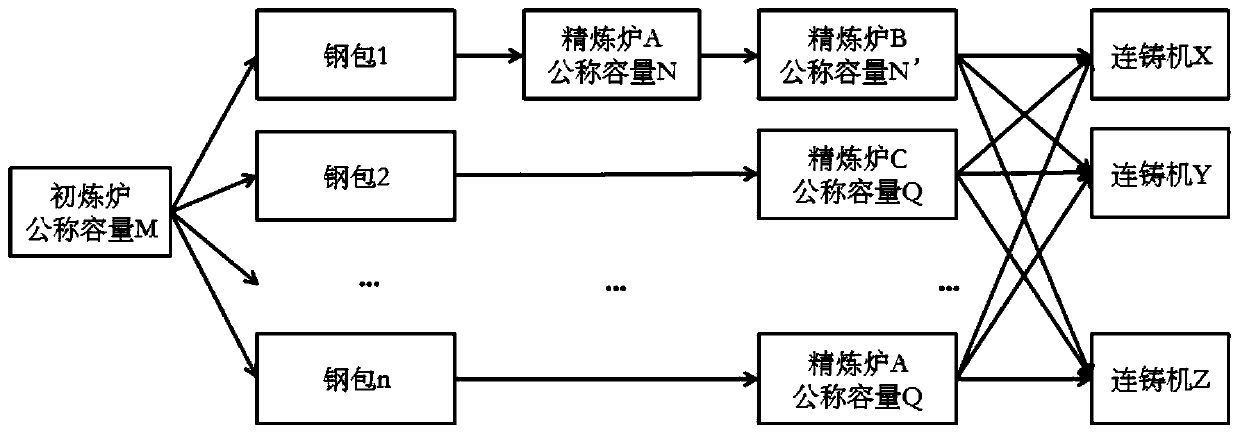

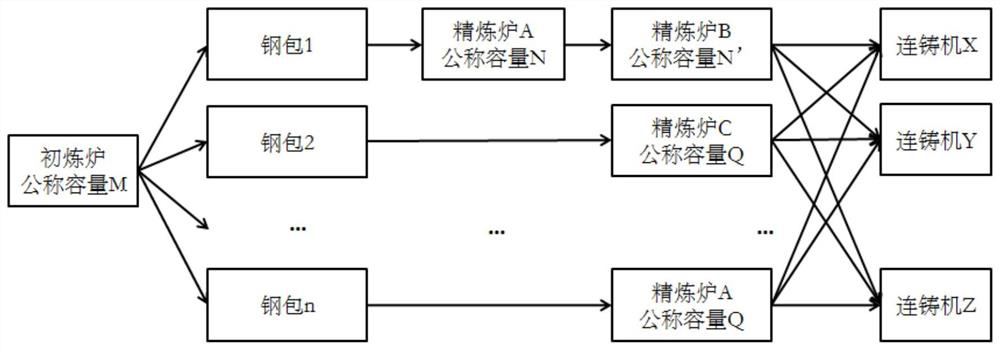

Method for achieving steelmaking flexible manufacturing

ActiveCN110229940ARealize customized productionShorten the lead timeSteel manufacturing process aspectsSteelmakingQuality control

The invention belongs to the technical field of metallurgy, and relates to a method for achieving steelmaking flexible manufacturing. The method includes the following steps that molten iron in ladlesis added into a primary smelting furnace to be subjected to primary steelmaking in a steelmaking workshop, and after steelmaking is completed, qualified molten steel in the primary smelting furnace is tapped multiple times and poured into multiple steel ladles; the molten steel in the different steel ladles enters refining furnaces corresponding to the molten steel in the following process according to a production plan, and corresponding refining operation is carried out; and qualified molten steel obtained after refining enters needed continuous casting machines to be cast. During application, the primary smelting molten steel in the primary smelting furnace can be quantitatively refined according to the requirements, customized production of products is achieved, a response is made tothe multi-variety and small-batch production requirements rapidly, the delivery cycle of the products is shortened, and wider requirements are met. Cost allowances brought by molten steel full-dose refining quality control in the steelmaking process can be reduced. Due to the application of the method, more diversified matching relationships between the primary smelting furnace, the refining furnaces and the continuous casting machines can be achieved, and flexible manufacturing in the steelmaking process is enhanced.

Owner:CISDI ENG CO LTD +1

A carbon sphere/sulfur/reduced graphene oxide composite material for lithium-sulfur batteries and its preparation method

ActiveCN107768643BLarge specific surface areaCurb churnCell electrodesLi-accumulatorsOxide compositeLithium sulfur

The invention relates to a carbon sphere / sulfur / reduced and oxidized graphene composite material for a lithium sulfur battery and a preparation method of the carbon sphere / sulfur / reduced and oxidizedgraphene composite material. The preparation method comprises the following steps: firstly, performing the heat treatment or solution soaking sulfur precipitation compounding for sulfur and carbon spheres, then mixing and stirring a sulfur / carbon sphere complex and a binder to form slurry, smearing the slurry onto an aluminum foil, drying the aluminum foil, then placing the aluminum foil in graphene oxide dispersion liquid, depositing and reducing the graphene oxide by virtue of electrochemical reduction, and thus obtaining the reduced graphene oxide-sealed sulfur / carbon sphere composite anodematerial. The carbon sphere prepared by the method of the invention has rich surface creases and inner porous structure and higher specific surface area (1000m<2> / g), and can load more sulfur, wherein the content of the solid sulfur reaches up to 80 percent. The reduced graphene oxide layer has higher conductivity and rich porous structure, facilitates the passing of lithium ions, can effectivelyinhibit the loss of sulfur and poly-sulfide, can improve the conductivity and cycling stability of the sulfur / carbon sphere composite material, and has a higher practical prospect.

Owner:SHANDONG UNIV

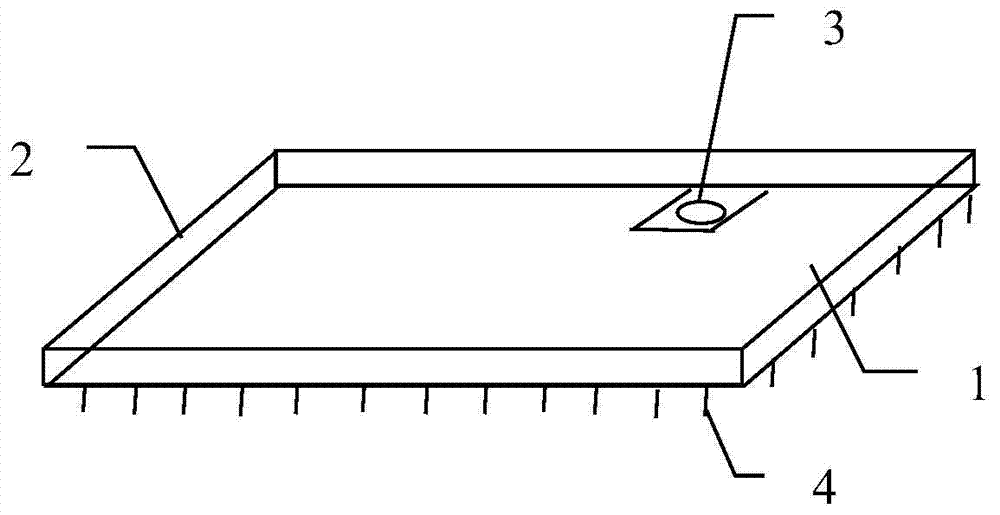

Integrated integrated bathroom chassis and preparation method of the chassis body

ActiveCN105666768BIntegrated customized productionRealize customized productionBathsDouchesHoneycombEngineering

Owner:GUANGZHOU SEAGULL KITCHEN & BATH PROD

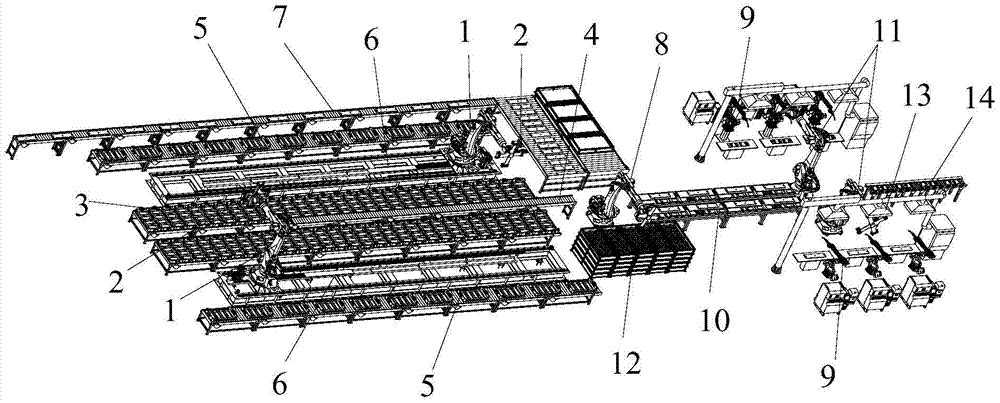

Workpiece Welding System

ActiveCN105269169BRealize intelligent identificationRealize online sortingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMaterial handling

The invention discloses a workpiece welding system. The workpiece welding system comprises a selected material storing and conveying line, a sorting robot, a distributed material conveying line, a distributed material handling robot, an assembling and conveying line, an assembly welding assistance robot and a welding robot, wherein the sorting robot is used for performing image recognition on materials to be sorted on the selected material storing and conveying line, lifting target materials from the selected material storing and conveying line and transferring the target materials to the distributed material conveying line; the distributed material conveying line is used for conveying the target materials into the working scope of the distributed material handling robot; the distributed material handling robot is used for lifting and transferring body parts and the sorted target materials to the assembly conveying line, wherein the body parts are conveyed by a body part conveying line, and the sorted target materials are conveyed by the distributed material conveying line; the assembling and conveying line is used for conveying the body parts and the matched target materials in groups, wherein the body parts and the matched target materials are used for producing one type of workpieces by assembly welding. According to the workpiece welding system, different parts can be assembled so that different workpieces can be obtained, and single-piece and custom production based on industrial robots is achieved.

Owner:CHANGSHA CTR ROBOTICS

A kind of phosphating production method of automobile galvanized sheet

ActiveCN105887064BQuality assuranceMeet production requirementsMetallic material coating processesCountermeasureSlag

The invention discloses a phosphating production method for an automobile galvanized plate and belongs to the field of automobile plate phosphating processes. The production method comprises the following steps of 1, solution compounding; 2, slag discharging; 3, titration; 4, control over phosphating process key points; 5, treatment of abnormal process in the phosphating process. Technological parameters in the activating treatment and phosphating processes are strictly controlled and adjusted in time, and quality of the phosphorized plate is guaranteed. Meanwhile, corresponding countermeasures are taken to solve abnormal problems existing in the production process, and therefore by means of the whole set of complete phosphating production method for the automobile galvanized plate, product quality is guaranteed.

Owner:武汉钢铁有限公司

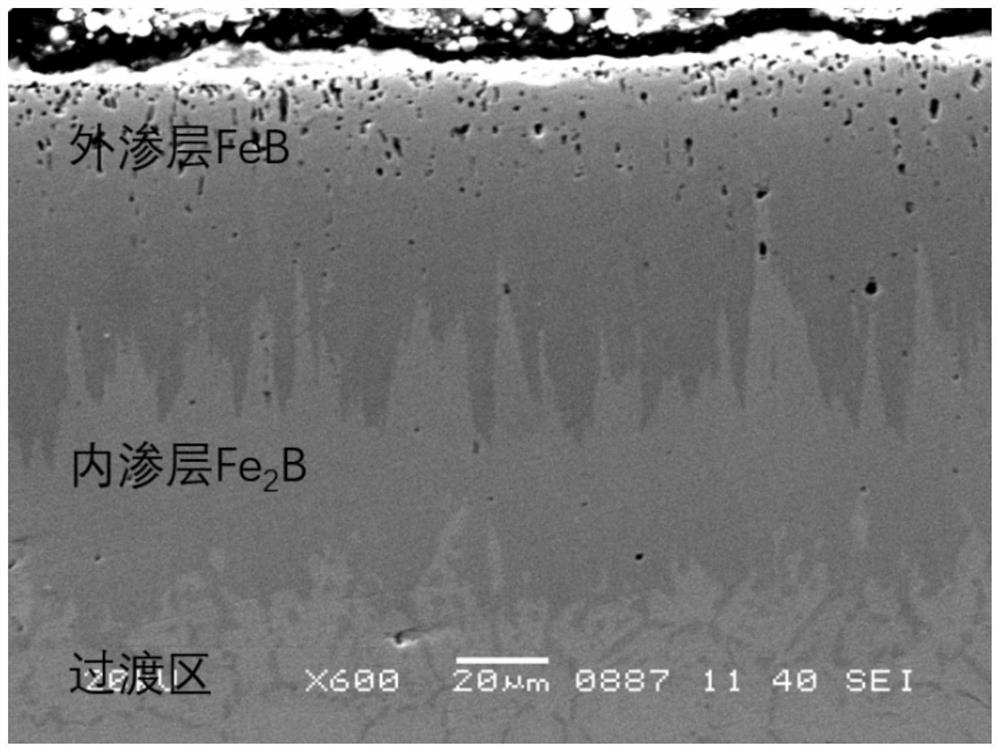

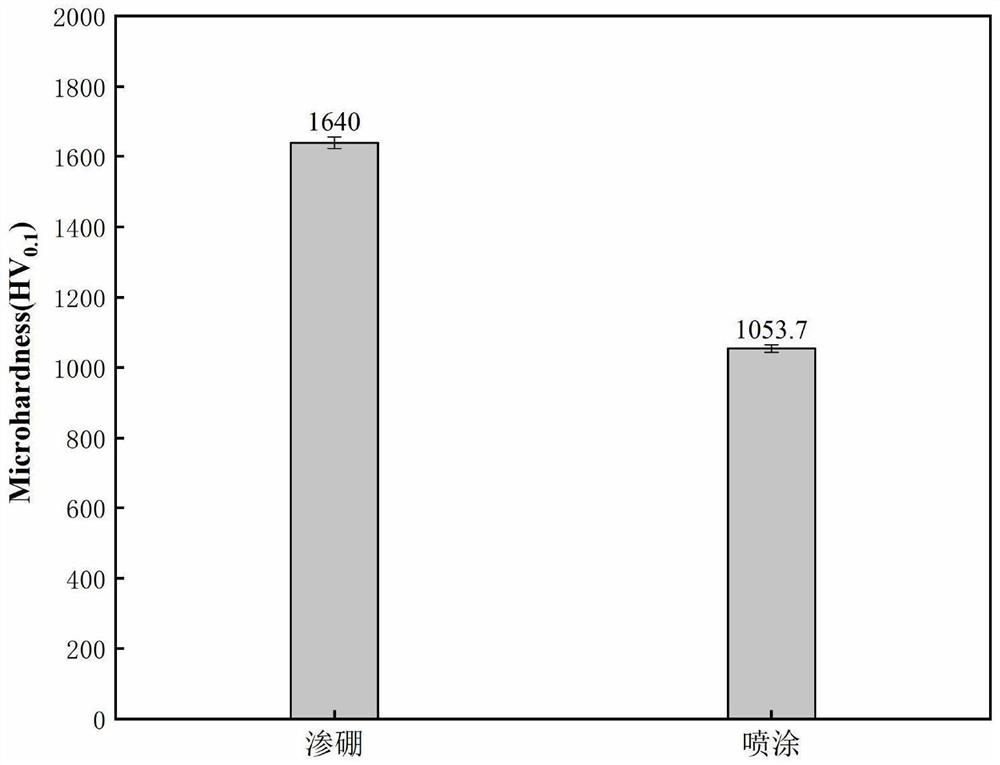

Paste boriding agent as well as preparation method and application thereof

PendingCN114703446AAccelerate reaction and decompositionPromote productionSolid state diffusion coatingCarbide siliconFluoboric acid

The invention discloses a paste boronizing agent and a preparation method and application thereof, the paste boronizing agent comprises, by mass, 30%-50% of boron carbide (B4C), 20%-40% of potassium fluoborate, 6%-10% of cerium dioxide and the balance silicon carbide, and the total mass percentage is 100%. According to the paste boronizing agent, the strength and hardness of a transition area of a boronizing layer can be remarkably improved, and compared with a thermal spraying coating, the microhardness of the boronizing layer is improved by 20%-60%. And the preparation method is low in cost, simple in process and convenient for large-scale engineering application, and particularly, directional precise boriding can be carried out on the specific part of the part, a local area is strengthened, and customized production of a product is realized.

Owner:JIANGSU UNIV OF SCI & TECH

A method for flexible manufacturing of steelmaking

ActiveCN110229940BRealize customized productionShorten the lead timeSteel manufacturing process aspectsSteelmakingRefining (metallurgy)

The invention belongs to the technical field of metallurgy, and relates to a method for achieving steelmaking flexible manufacturing. The method includes the following steps that molten iron in ladlesis added into a primary smelting furnace to be subjected to primary steelmaking in a steelmaking workshop, and after steelmaking is completed, qualified molten steel in the primary smelting furnace is tapped multiple times and poured into multiple steel ladles; the molten steel in the different steel ladles enters refining furnaces corresponding to the molten steel in the following process according to a production plan, and corresponding refining operation is carried out; and qualified molten steel obtained after refining enters needed continuous casting machines to be cast. During application, the primary smelting molten steel in the primary smelting furnace can be quantitatively refined according to the requirements, customized production of products is achieved, a response is made tothe multi-variety and small-batch production requirements rapidly, the delivery cycle of the products is shortened, and wider requirements are met. Cost allowances brought by molten steel full-dose refining quality control in the steelmaking process can be reduced. Due to the application of the method, more diversified matching relationships between the primary smelting furnace, the refining furnaces and the continuous casting machines can be achieved, and flexible manufacturing in the steelmaking process is enhanced.

Owner:CISDI ENG CO LTD +1

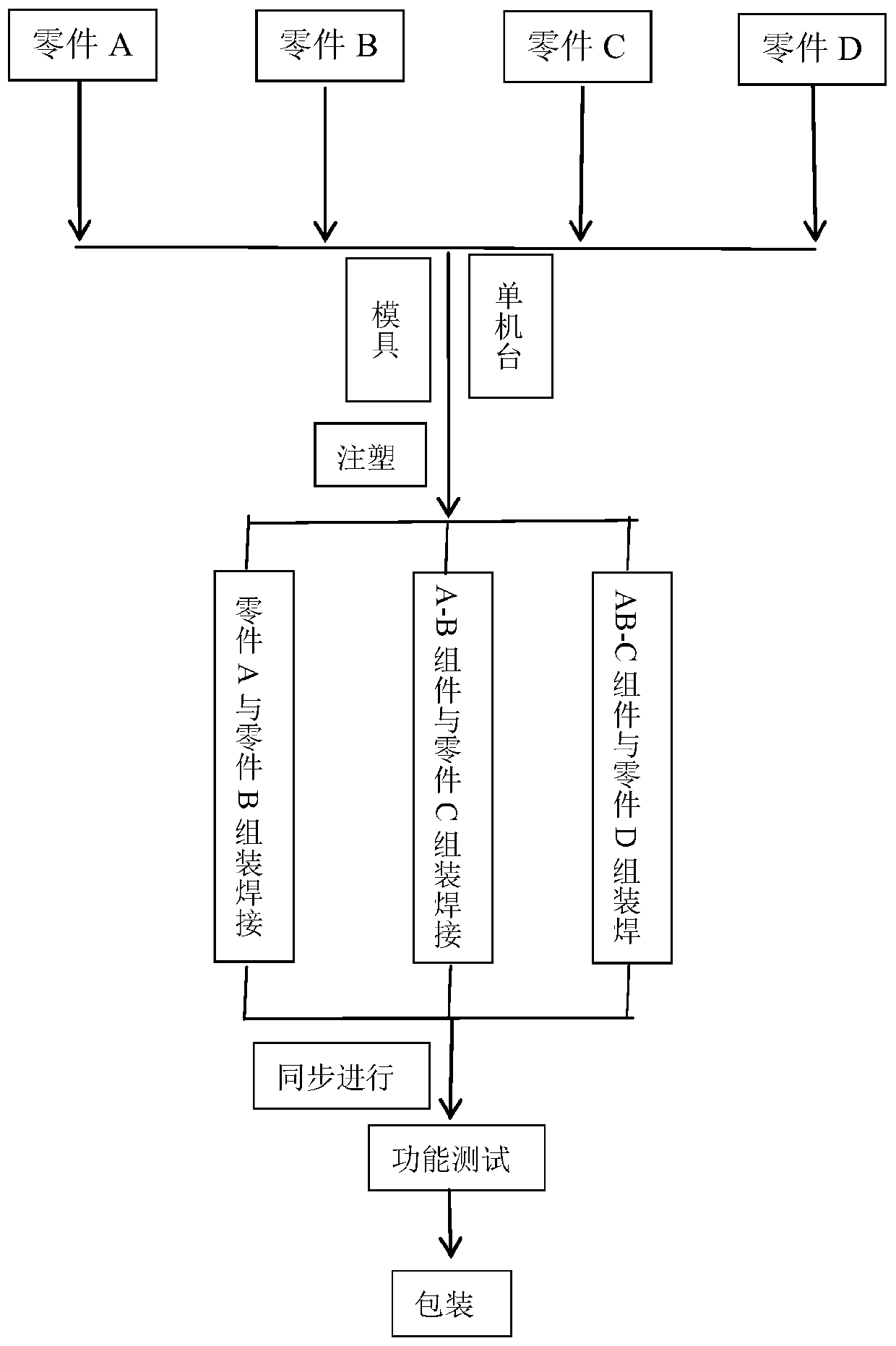

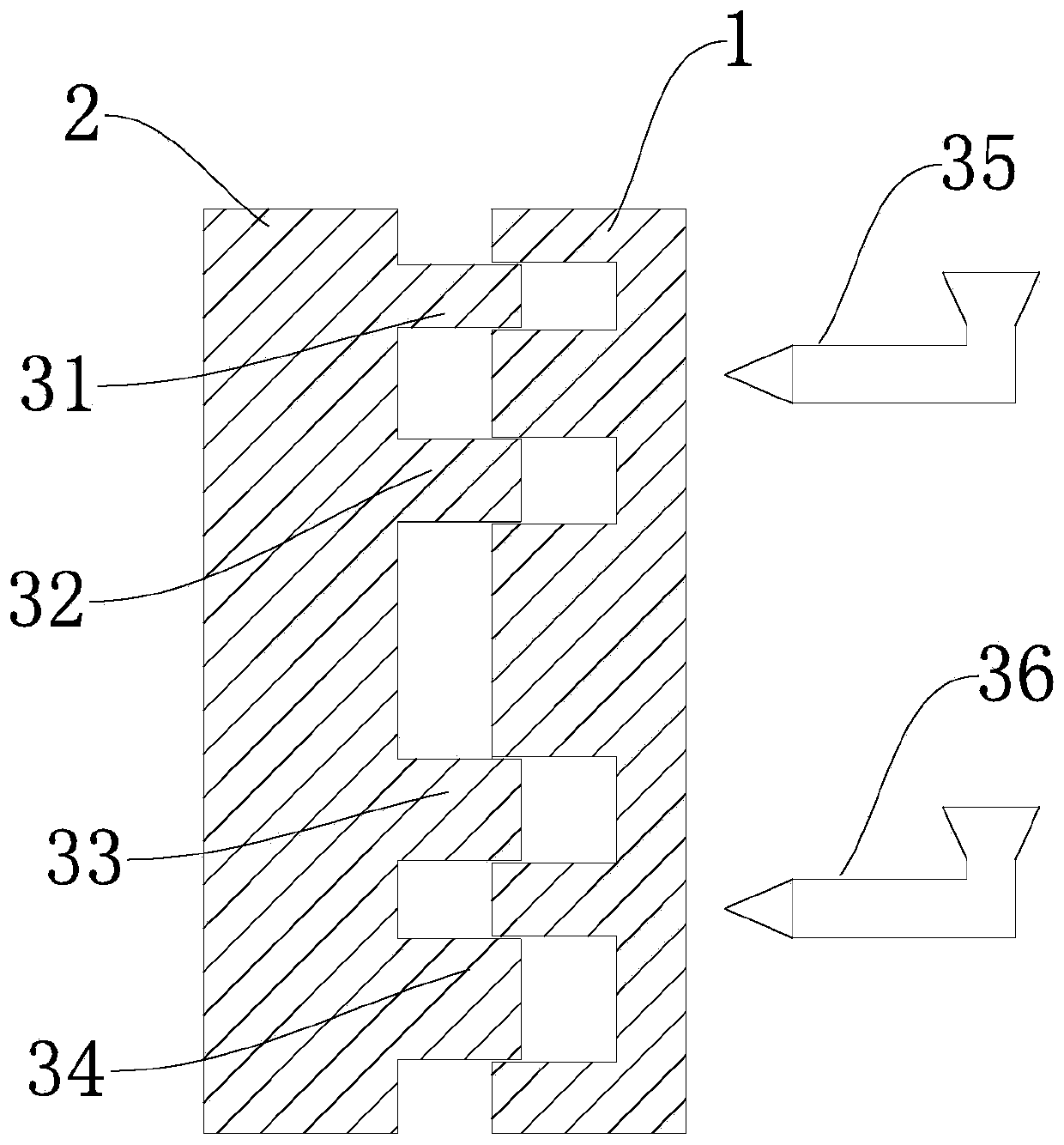

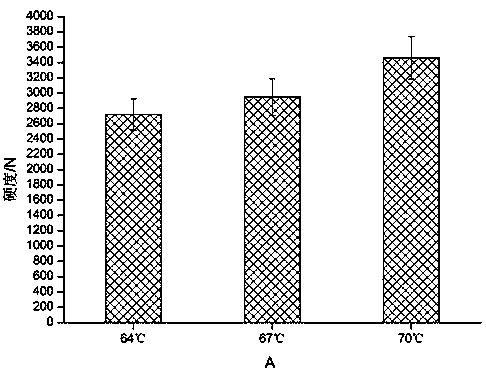

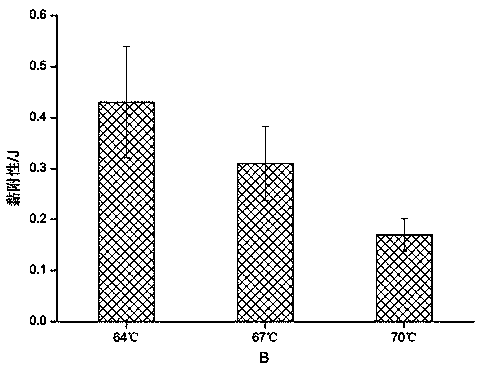

Efficient injection molding method

PendingCN111391213AReduce investmentReduce labor costsCoatingsInjected materialInjection molding process

The invention discloses an efficient injection molding method. An injection molding assembly comprises a plurality of parts, the injection molding method comprises the following molding steps that aninjection system is used for injecting materials into cavities of the same mold for injection molding, wherein the mold comprises a fixed mold plate and a movable mold plate, a plurality of mold coresare detachably arranged in the fixed mold plate and the movable mold plate, the mold cores form the mold cavity, all the parts are clamped in an automatic clamping mode to be subjected to a welding procedure, and are packed for later use after a function test is finished. According to the efficient injection molding method, an injection molding process and a mold structure are combined, a moldingmethod with higher efficiency is adopted so that the mold cost and the equipment investment can be greatly reduced, the delivery cycle is shortened, meanwhile, a product flow can be shortened, the labor cost is reduced, the production efficiency is improved, repeated material carrying work is not needed, and customized production is achieved.

Owner:XIAMEN RUNNER IND CORP

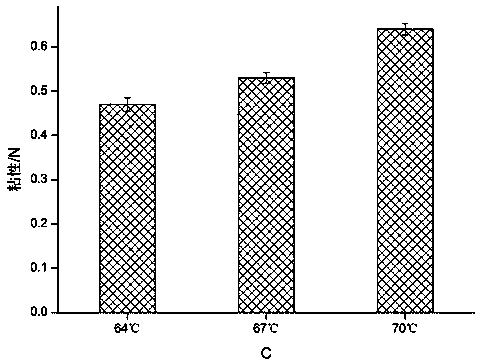

Method for preparing 3D printing material from composite starch added with persimmon juice

InactiveCN108851021AImprove the rigidity of the structureEnhanced network structureFood shapingCooking & bakingFood material

The invention belongs to the technical field of 3D printing food processing and provides a method for preparing a 3D printing material from composite starch added with persimmon juice. The preparationmethod provided by the invention comprises the following specific steps: adding composite starch to water to be uniformly mixed, then adding a proper amount of persimmon juice to obtain gel with proper viscosity, ductility and tensile property, taking out the gel, kneading the gel into a ball, and performing 3D printing for forming a 3D printed object, wherein the content of the composite starchis 30%-45%, the content of the persimmon juice is 1%-5%, and the content of the water is 45%-65%. As a 3D printed and formed material, the material prepared by the preparation method provided by the invention is simple and easy to obtain, low in cost and bright in color, can promote appetite of people, and can be applied to a screw pushing type 3D printer to make any shape of food materials, models, props, sand tables and the like; and the printed object is high in resolution, good in formability and unobvious in laminating limit, and subsequent processes of cooking, baking, frying and the like can also be performed.

Owner:SHANDONG UNIV OF TECH +1

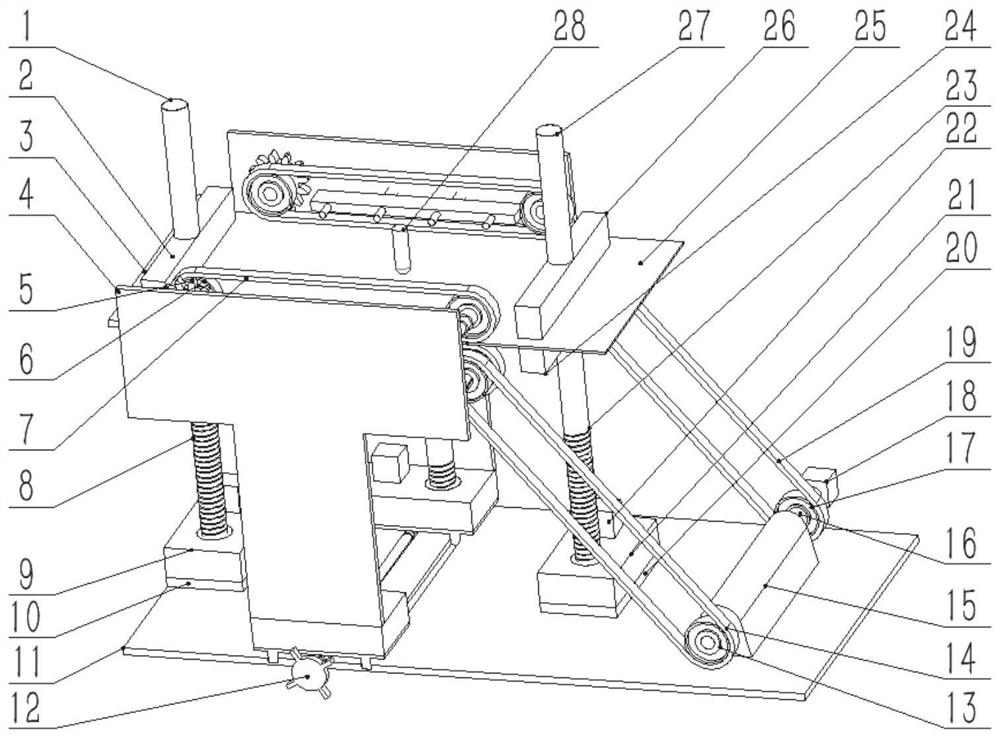

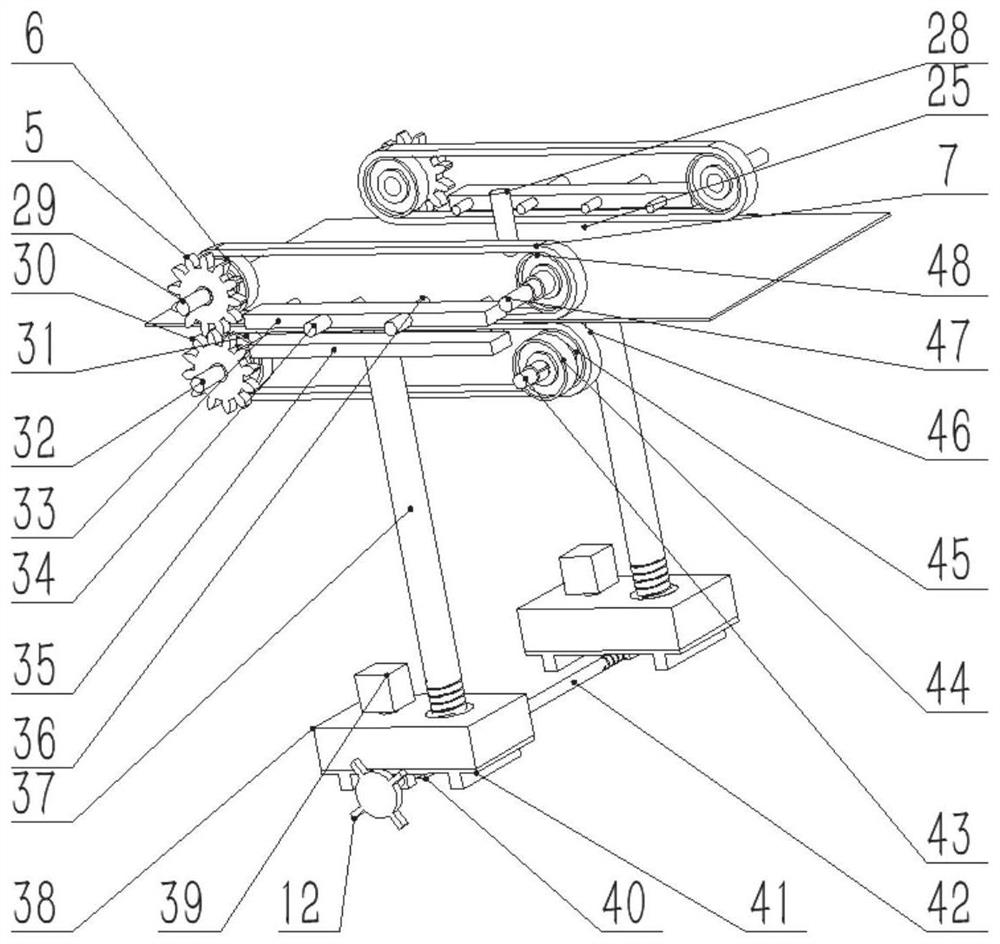

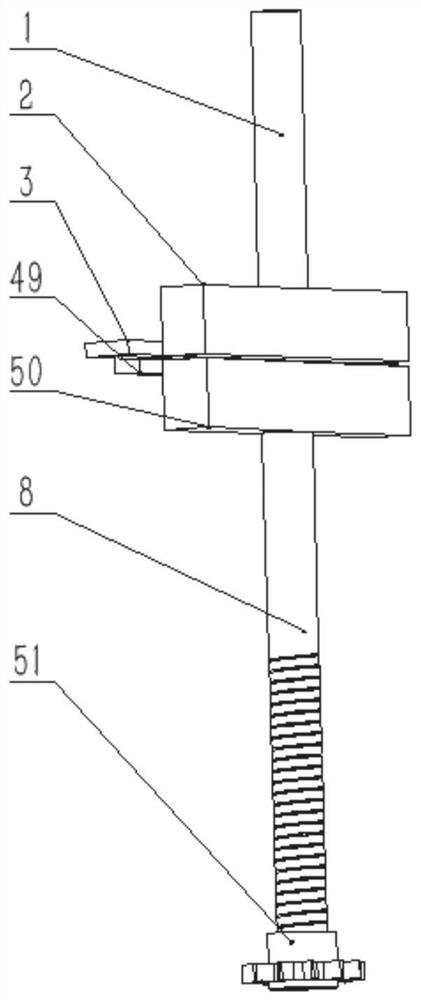

A continuous flexible incremental forming processing device and method for sheet metal

ActiveCN112719455BImprove efficiencyReduce workloadFeeding apparatusPositioning apparatusStructural engineeringMechanical engineering

The invention discloses a continuous flexible progressive forming processing device and method of a plate, which solves the problem in the prior art that the continuous flexible progressive forming process of the plate cannot be realized because the processing fixture needs to be continuously disassembled and assembled to clamp the plate. Its technical solution is: comprising a conveying device, a clamping device, a vertical adjustment device, a longitudinal adjustment device and a cutting device. The transmission device is fixed on the front and rear vertical plates through the short axis, and the front and rear vertical plates are installed on the longitudinal adjustment device; there are four clamping devices, which are respectively installed in four directions, front, rear, left, and right. Each clamping device consists of upper and lower parts. Composition, the front and rear clamping devices are connected with the longitudinal adjustment device through the vertical adjustment device, and the cutting device is installed on the left clamping device; the transmission device and the front and rear clamping devices can move forward and backward through the longitudinal adjustment device.

Owner:SHANDONG UNIV

Production method and production system of cadmium telluride solar cell

InactiveCN108878593AReduce logistics costsAvoid impact on battery performanceFinal product manufacturePhotovoltaic energy generationSolar cellKiln

The invention discloses a production method and production system of a cadmium telluride solar cell. The production method comprises the steps of FTO glass production, cadmium telluride solar cell production and package production. The production system comprises an FTO glass production section, a cadmium telluride solar cell production section and a package production section to form a one-kiln and multi-line production mode, a cutting process is put on the cadmium telluride solar cell production section and cutting is carried out according to the requirements, so that customized production is achieved and the production cost is reduced.

Owner:CNBM CHENGDU OPTOELECTRONICS MATERIAL

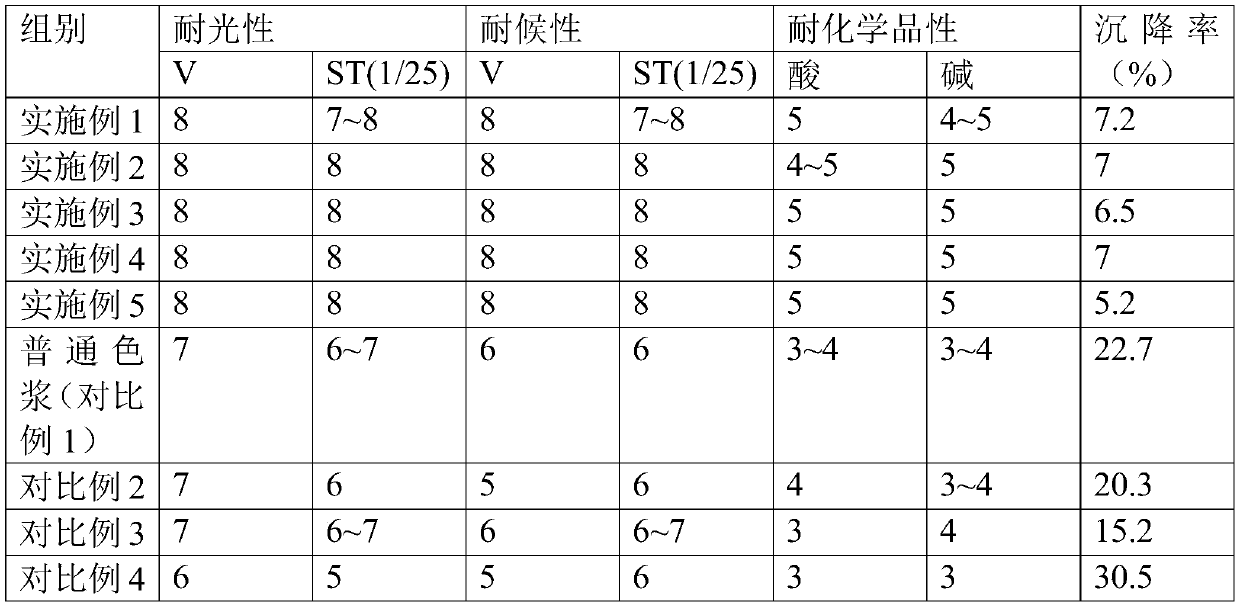

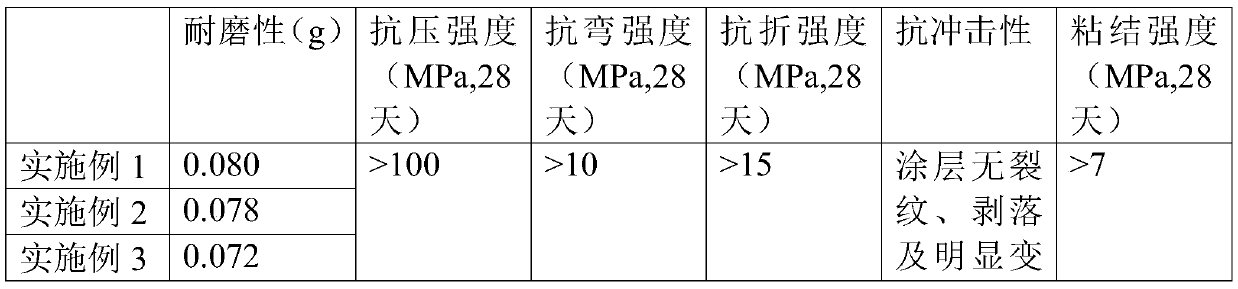

Environment-friendly wall cement mortar without chromatic aberration and preparation method thereof

ActiveCN111377669ARadiation-freeSimple preparation processSolid waste managementBreaking strengthCement mortar

The invention provides environment-friendly wall cement mortar without chromatic aberration, which is prepared from the following components in percentage by weight: 20 to 30 percent of cement, 2 to 4percent of rubber powder, 0.1 to 0.2 percent of water reducing agent, 0.01 to 0.2 percent of sodium sulfate, 7 to 12 percent of volcanic ash, 2 to 7 percent of calcium powder, 2 to 5 percent of silicon dioxide aerogel, 10 to 15 percent of color paste, 1 to 7 percent of aluminum oxide and the balance of aggregate, totaling 100 percent. Compared with similar cement mortars, the environment-friendlywall cement mortar without chromatic aberration is shorter in drying time, free of shrinkage, small in deformation coefficient, higher in bending strength, tensile strength and breaking strength andhigher in adaptability.

Owner:深圳市纳路特建材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com