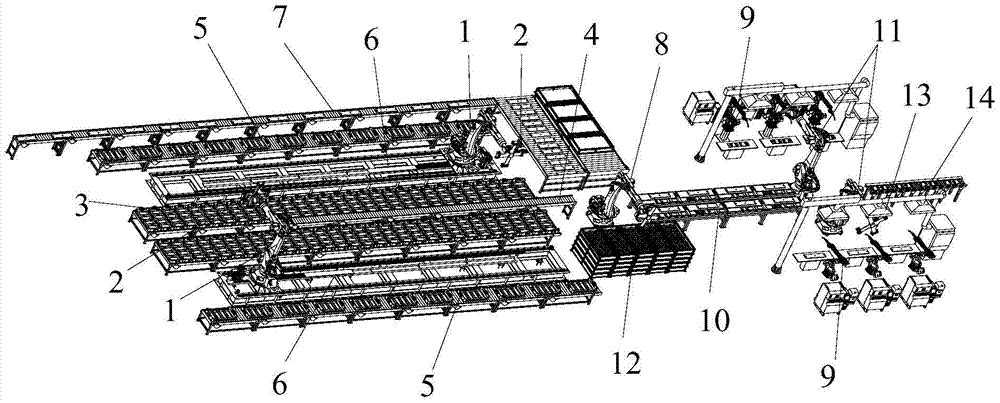

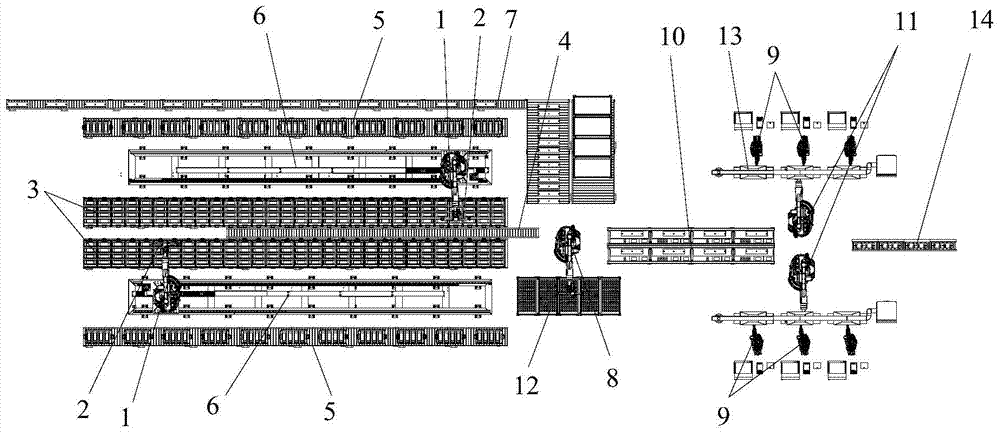

Workpiece Welding System

A welding system and workpiece technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as lack of availability and inability to use industrial robots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0038] In view of the following deficiencies in the production of intelligent sorting, positioning, assembly and welding robots in the prior art:

[0039] 1. The robot cannot select materials for randomly arranged parts;

[0040] 2. The robot must carry out tooling positioning during assembly, and a large amount of manufacturing tooling costs are required for a wide variety of workpieces;

[0041] 3. The robot can only identify the position, but cannot identify whether the parts are right or wrong. The workpiece cannot be monitored in real time during the production process. Once the parts are placed in the wrong position, waste products will be produced.

[0042] The embodiment of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com