Patents

Literature

45 results about "Energy interval" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Interval energy data is a fine-grained record of energy consumption, with readings made at regular intervals throughout the day, every day. Interval energy data is collected by an interval meter, which, at the end of every interval period, records how much energy was used in the previous interval period.

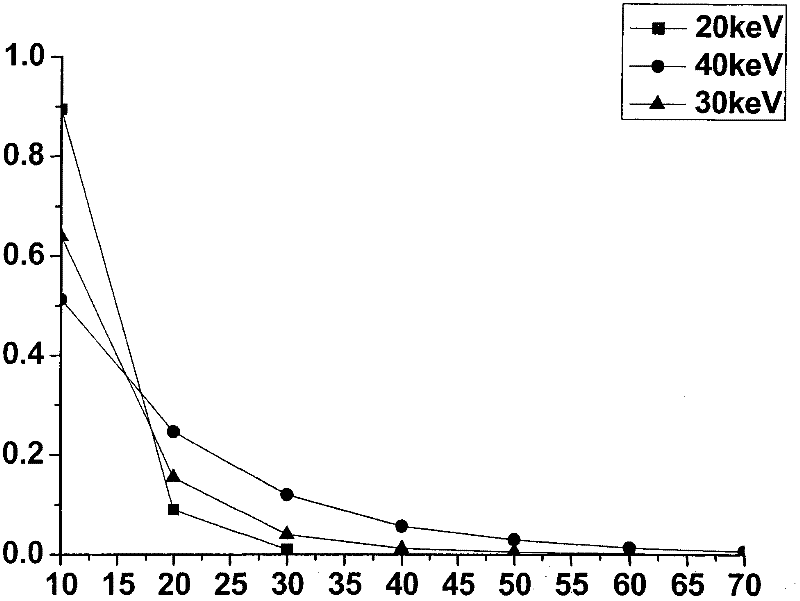

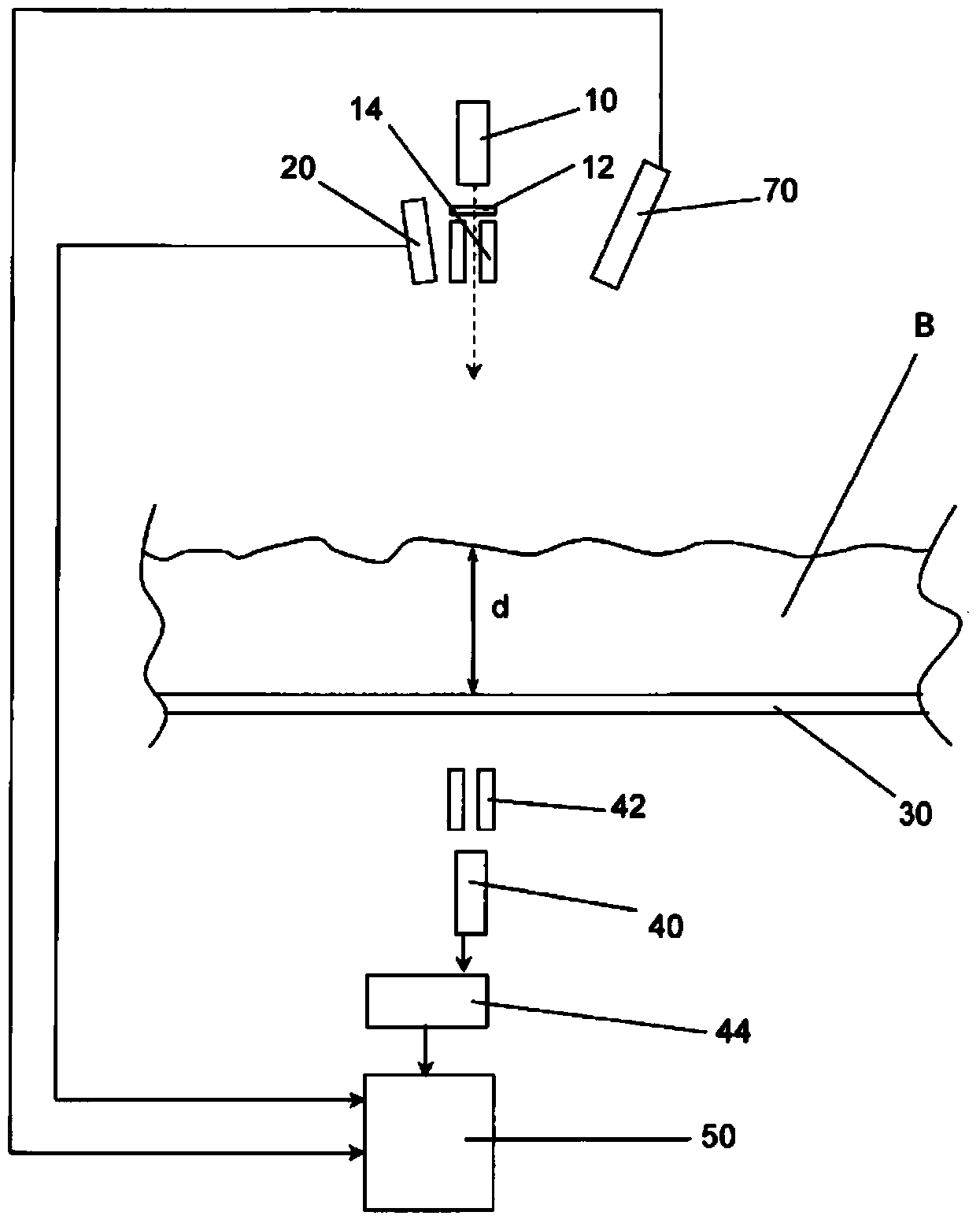

Downhole gamma-ray detection

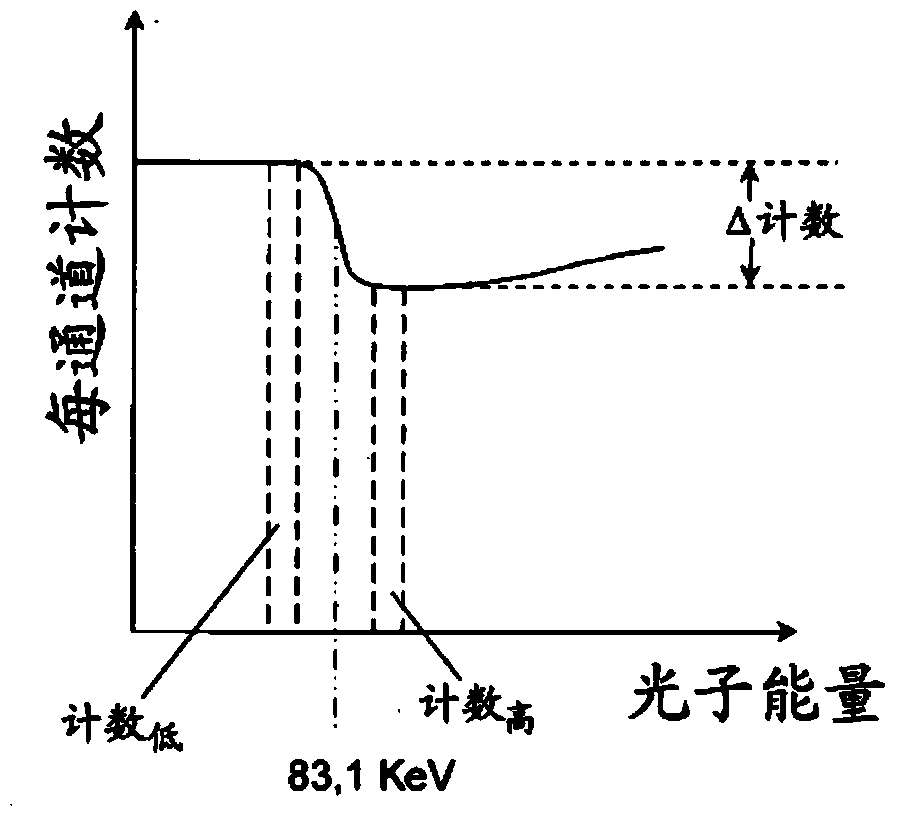

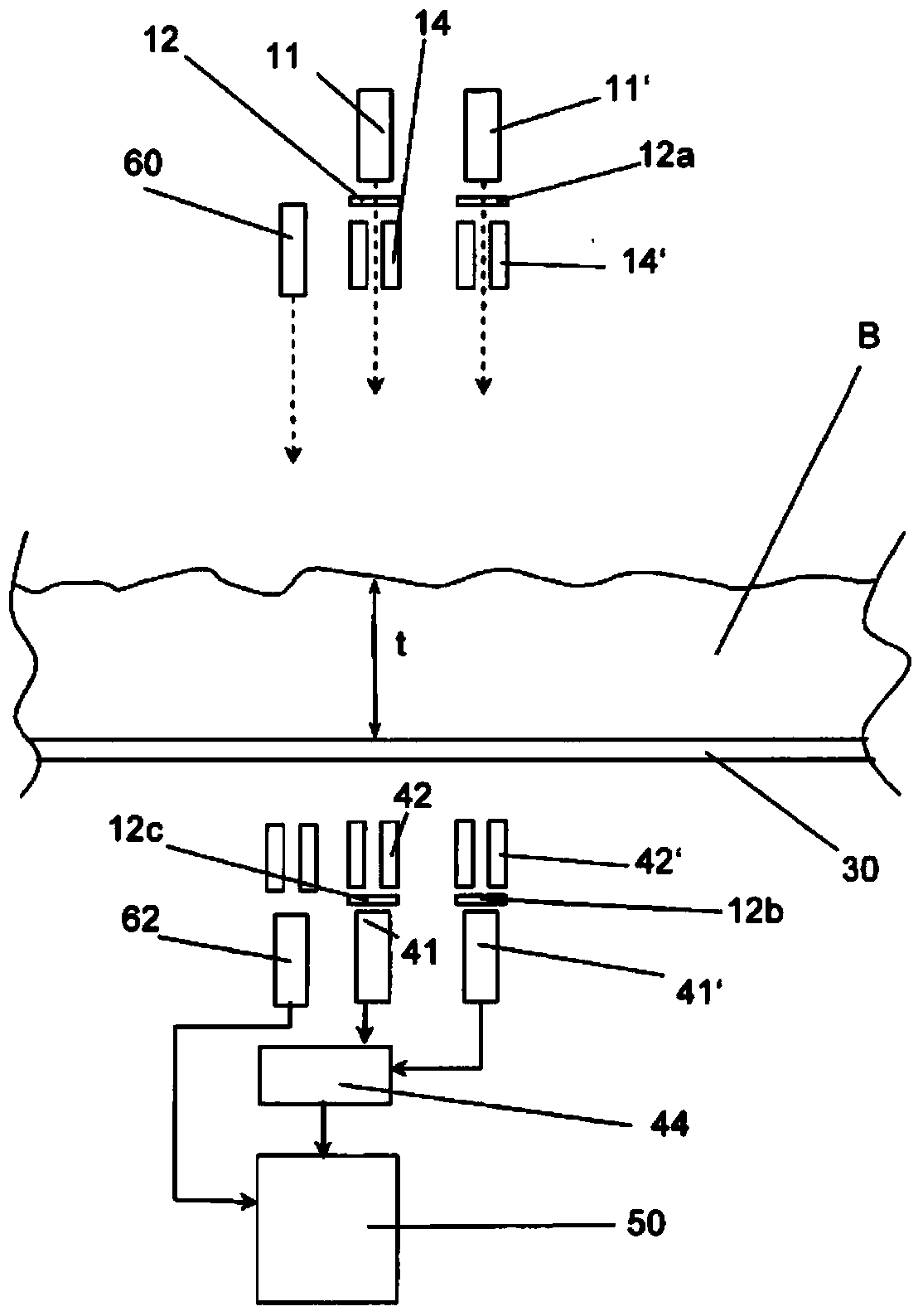

ActiveUS7081616B2Reduce detectionSpread the wordX-ray spectral distribution measurementSolid-state devicesCounting rateGamma ray detection

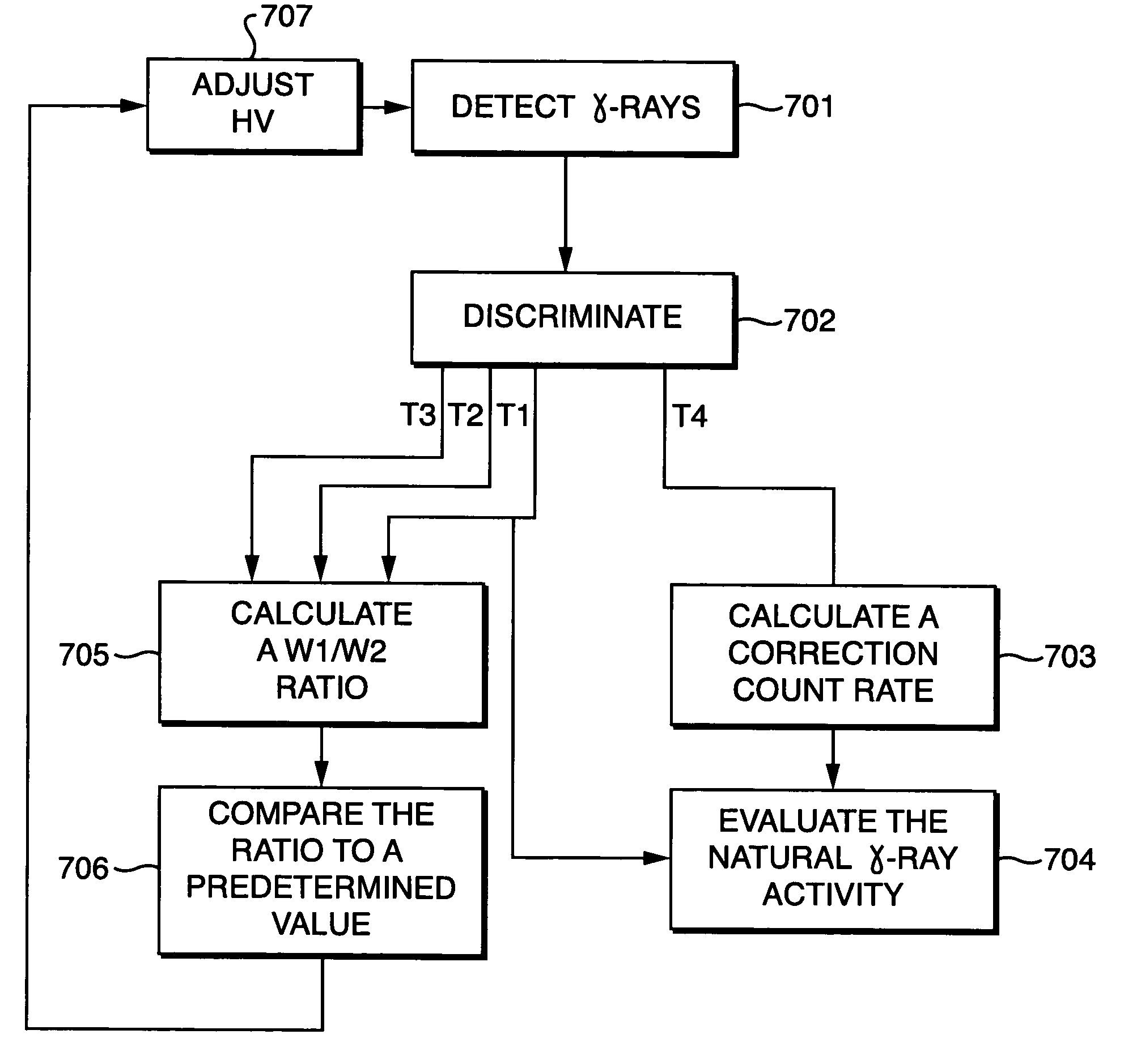

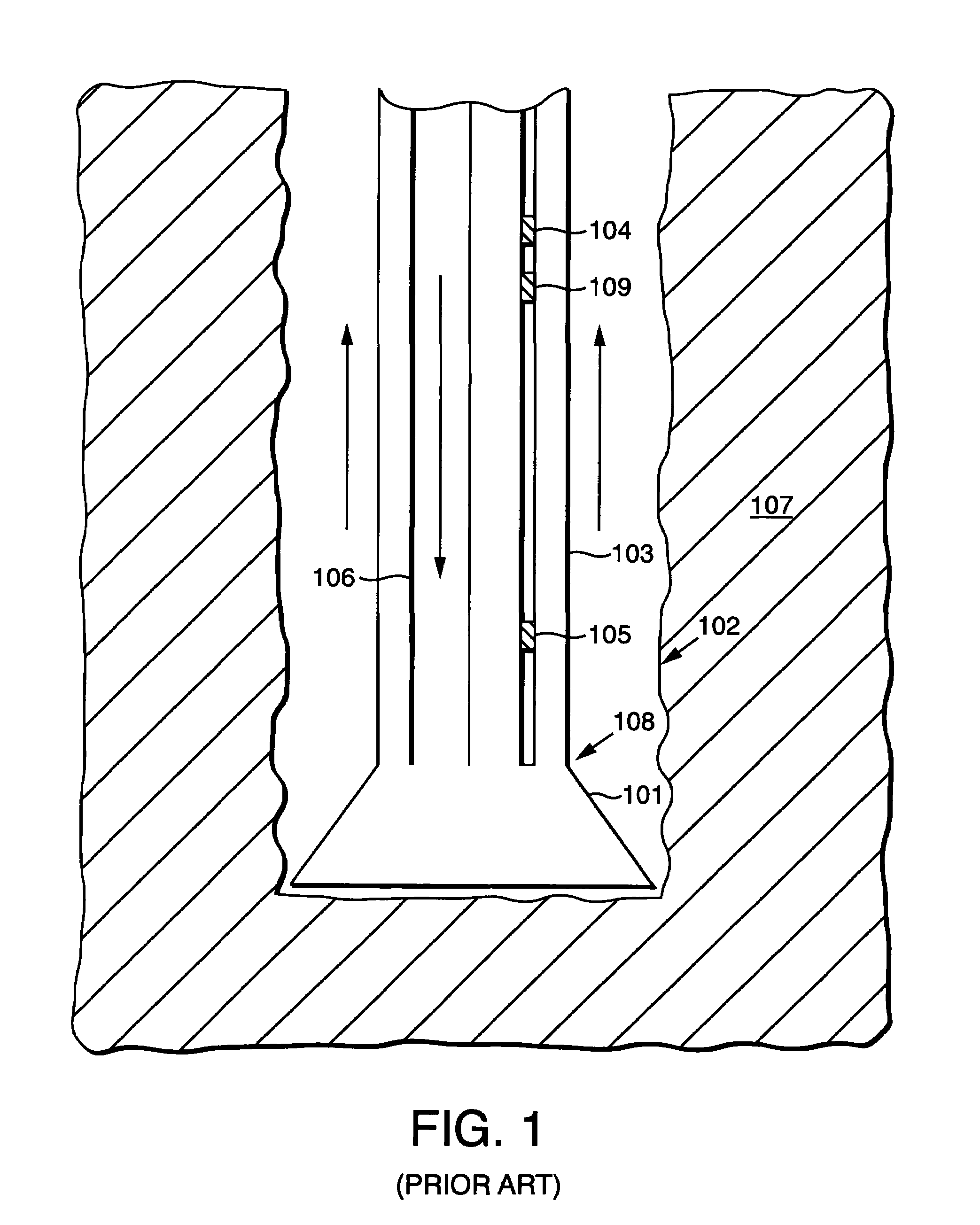

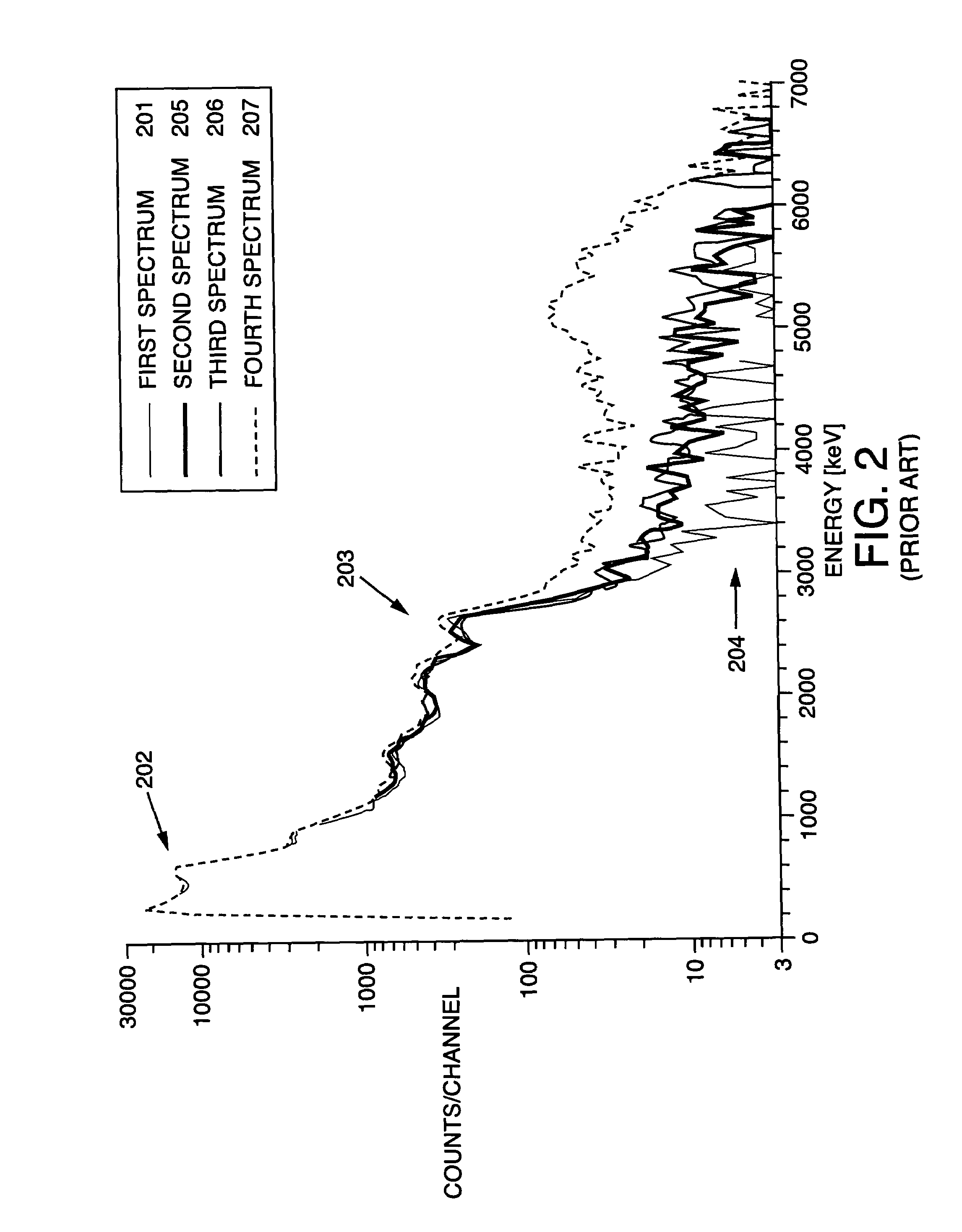

A method for evaluating a natural gamma-ray activity within a borehole, comprises the steps of:stabilizing the gain according to a method for stabilizing a gain of a gamma-ray detector for use in a downhole logging tool;determining an interval count rate, the interval count rate corresponding to gamma-rays having an energy within a predetermined correction interval;calculating a correction count rate from the determined interval count rate; andusing the correction count rate to evaluate the natural gamma-ray activity.The method for stabilizing the gain of the gamma-ray detector for use in the downhole logging tool, comprises the steps of:processing a backscatter peak of a full gamma spectrum such that the backscatter peak constitutes a reference peak;determining a first rate, the first rate corresponding to gamma-rays having an energy within a first predetermined energy interval;determining a second rate, the second rate corresponding to gamma-rays having an energy within a second predetermined energy interval; andthe first predetermined energy interval and the second predetermined energy interval straddle the backscatter peak.

Owner:SCHLUMBERGER TECH CORP

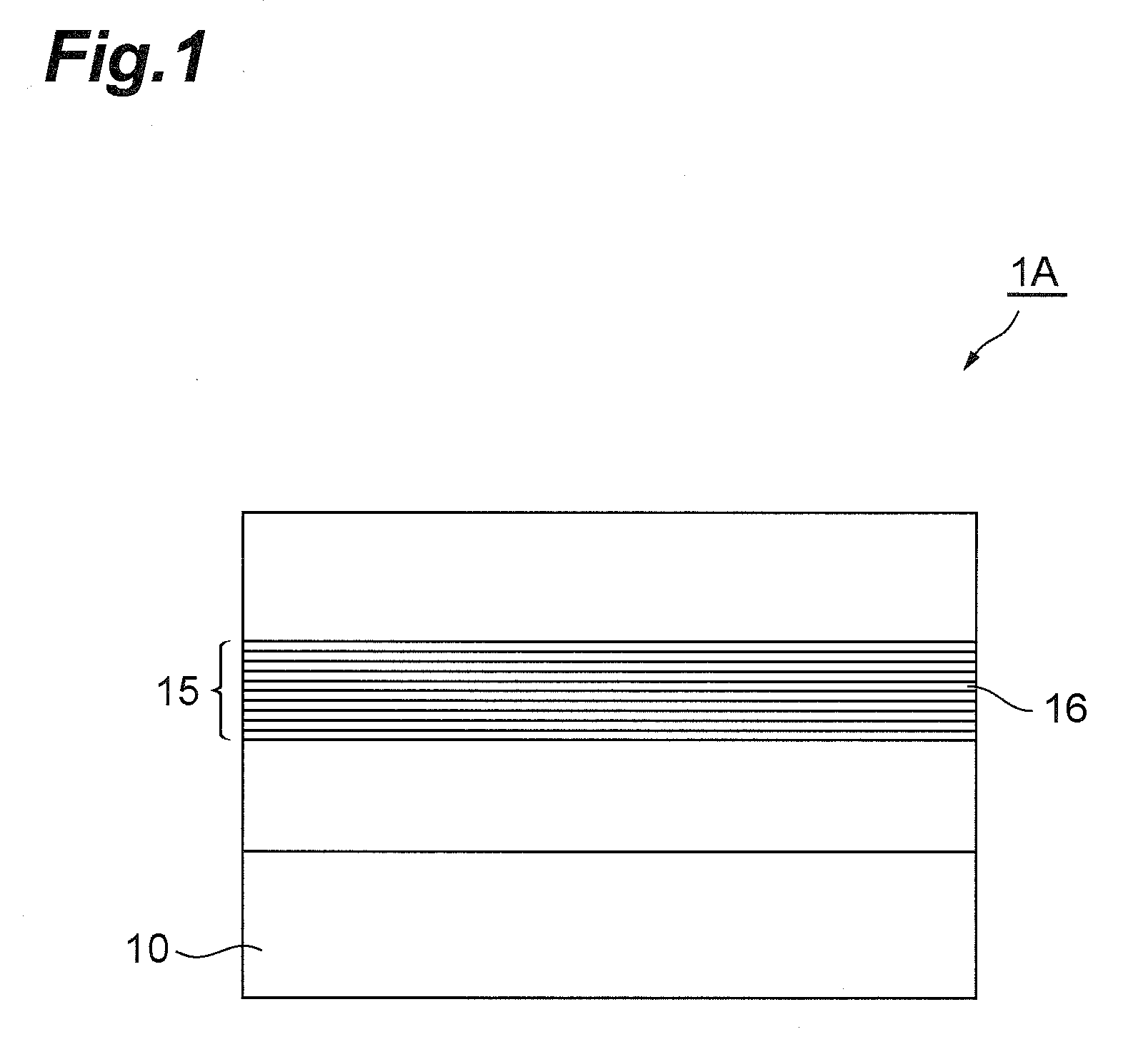

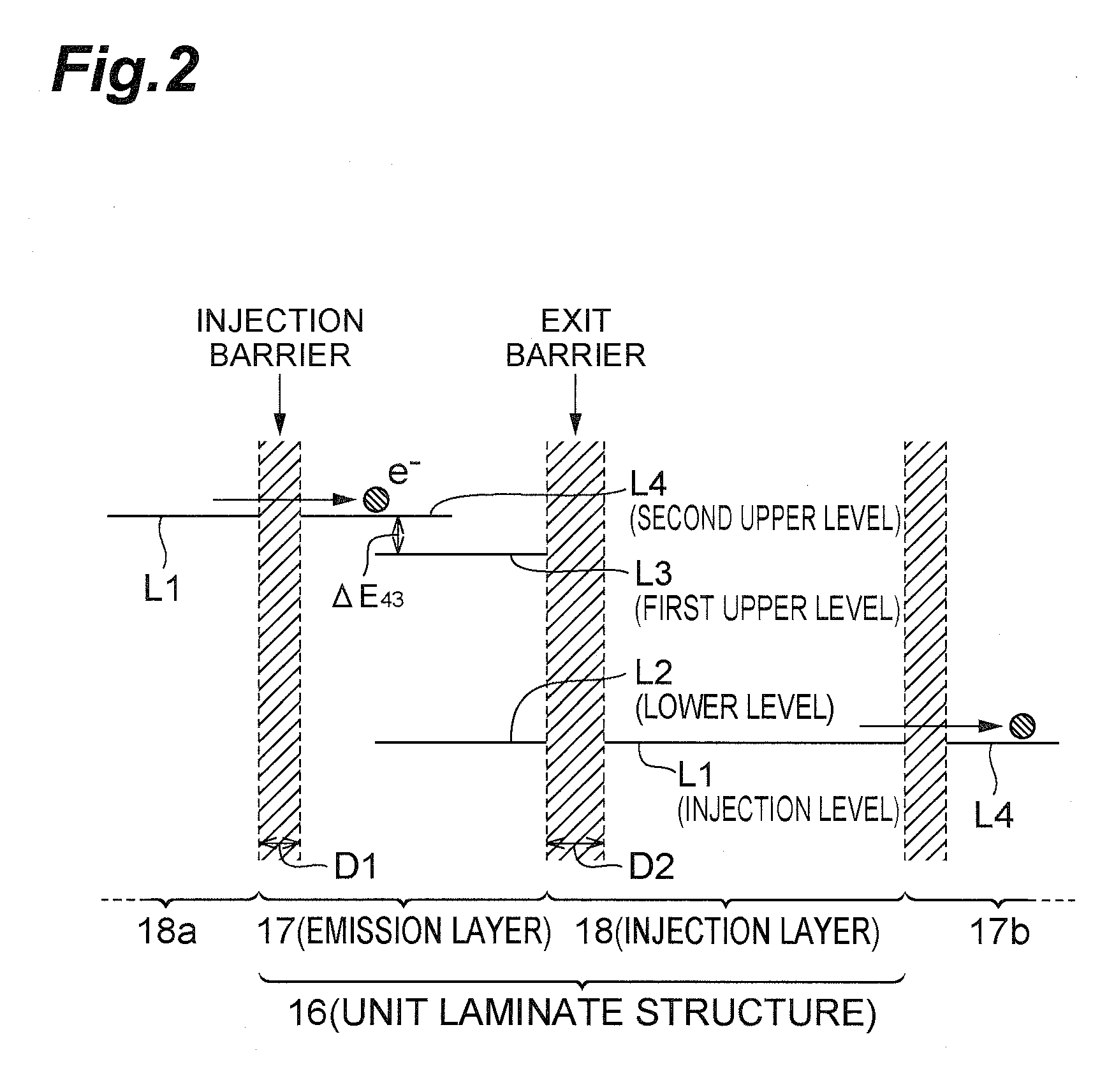

Semiconductor light emitting device

InactiveUS20110024721A1High-efficiency and high-output operationNanoopticsSemiconductor lasersPower flowLayer thickness

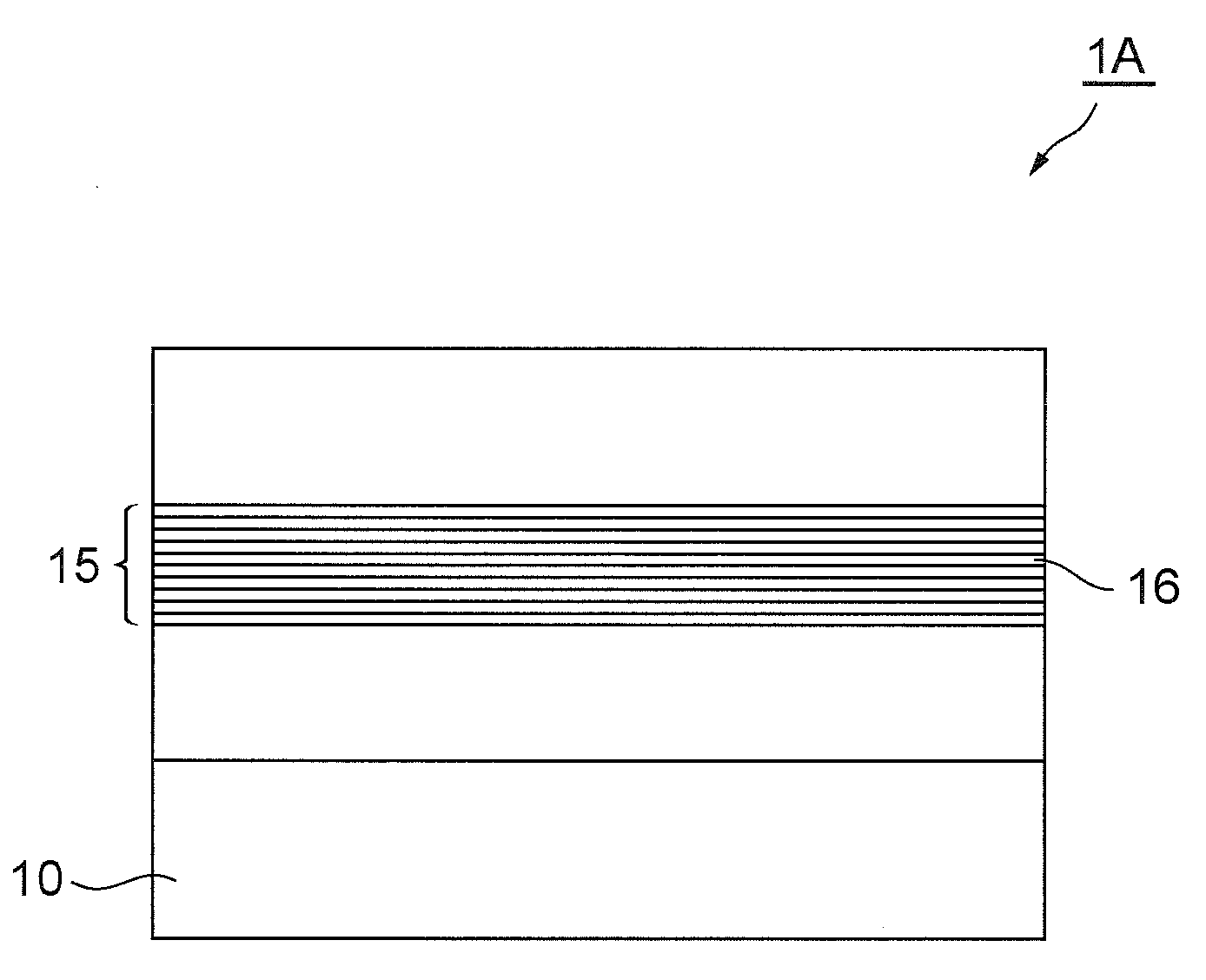

A semiconductor light emitting device including a semiconductor substrate and an active layer which is formed on the substrate and has a cascade structure formed by multistage-laminating unit laminate structures 16 each including an emission layer 17 and an injection layer 18 is configured. The unit laminate structure 16 has a first upper level L3, a second upper level L4, and a lower level L2 in the emission layer 17, and an injection level L1 in the injection layer 18, an energy interval between the levels L3 and L4 is set to be smaller than the energy of an LO phonon, the layer thickness of the exit barrier layer is set in a range not less than 70% and not more than 150% of the layer thickness of the injection barrier layer, light is generated by emission transition in the emission layer 17, and electrons after the emission transition are injected from the level L2 into the level L4 of the emission layer of a subsequent stage via the level L1. Accordingly, a semiconductor light emitting device using polaritons, capable of performing a light emitting operation by current injection, is realized.

Owner:HAMAMATSU PHOTONICS KK

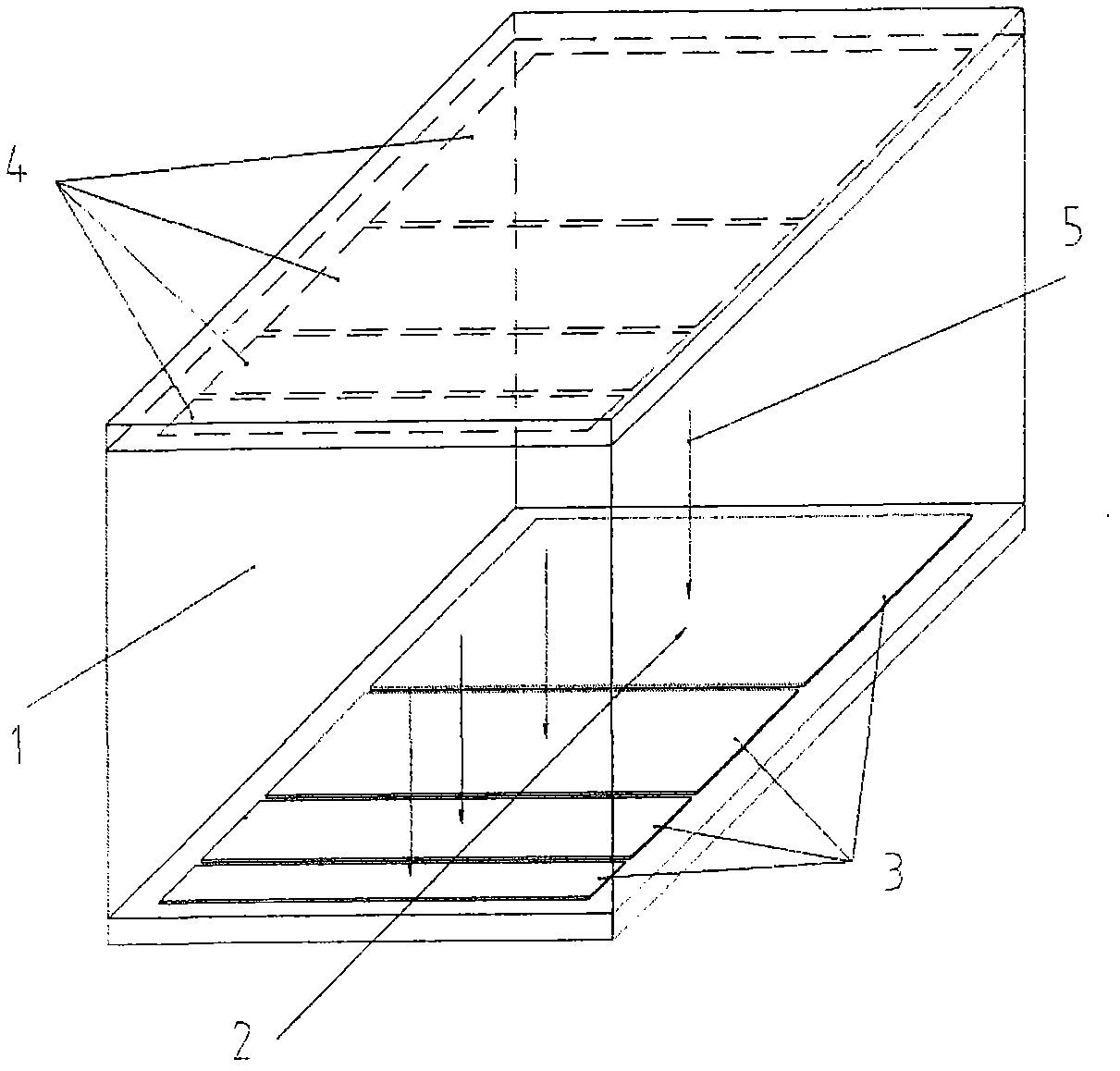

Gas radiation detector and radiation imaging system

ActiveCN102183776ARaise demand limit for source strengthLow costX/gamma/cosmic radiation measurmentRadiation imagingDual energy

The invention discloses a gas radiation detector which comprises an electrode pair, wherein the electrode pair comprises a plurality of sub-electrode pairs which are arranged along the incident direction of a ray and used for respectively detecting rays in different energy regions. The invention can realize the function of simultaneously measuring rays in different energy regions in the same gas chamber with low material cost, simple geometric structure, convenient operation, and long service life; the gas sort and pressure can be flexibly adjusted according to the applied ray energy interval to achieve high detection efficiency, thereby solving the problem that the low-energy detector of a dual-energy solid detector is too thin to manufacture; and meanwhile, the same gas chamber can guarantee the high consistency of the signals, and the follow-up data processing is simple. The gas radiation detector can be widely applied to the radiation imaging field.

Owner:NUCTECH CO LTD +1

Optimizing the distribution of electrical energy

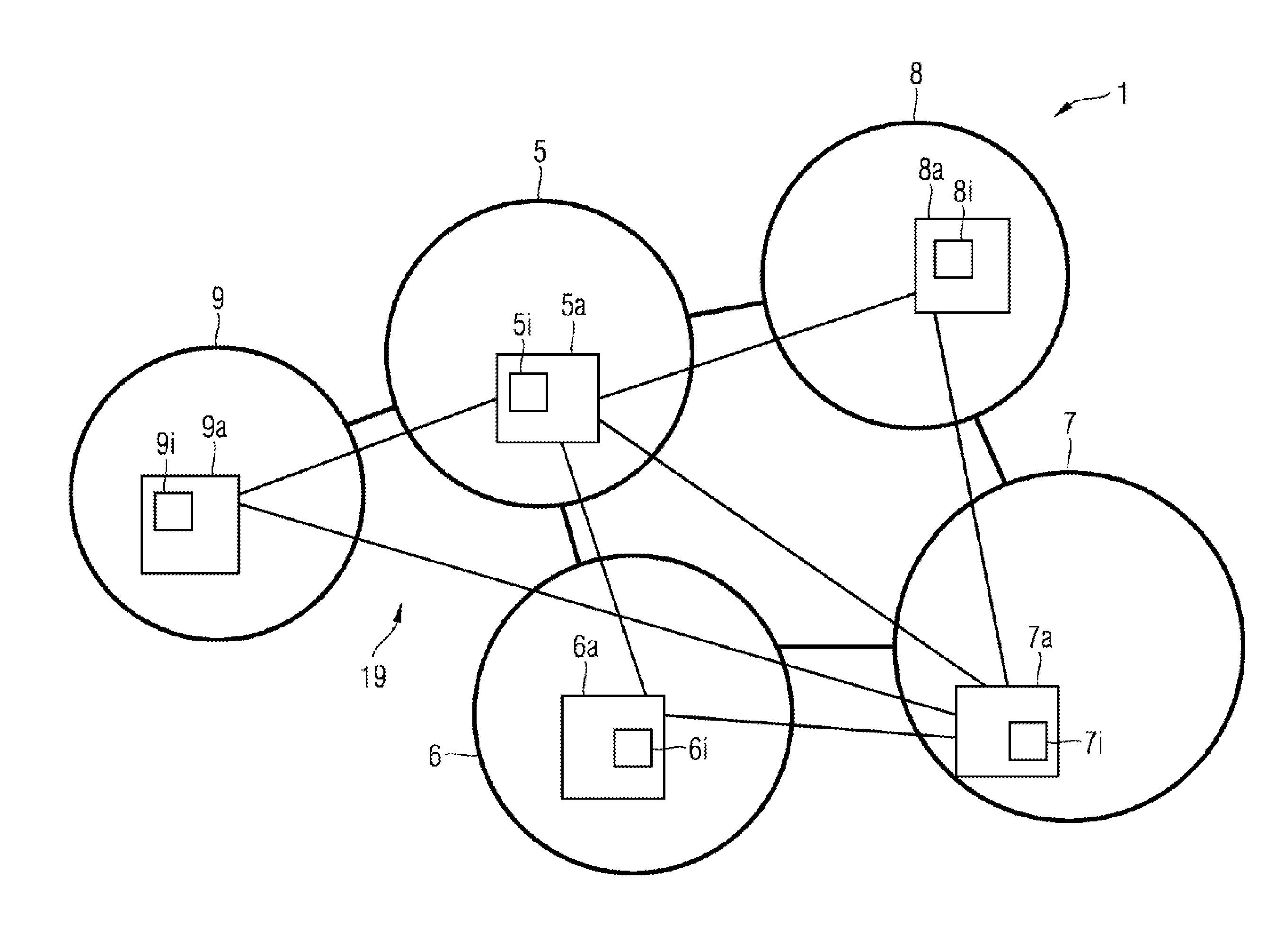

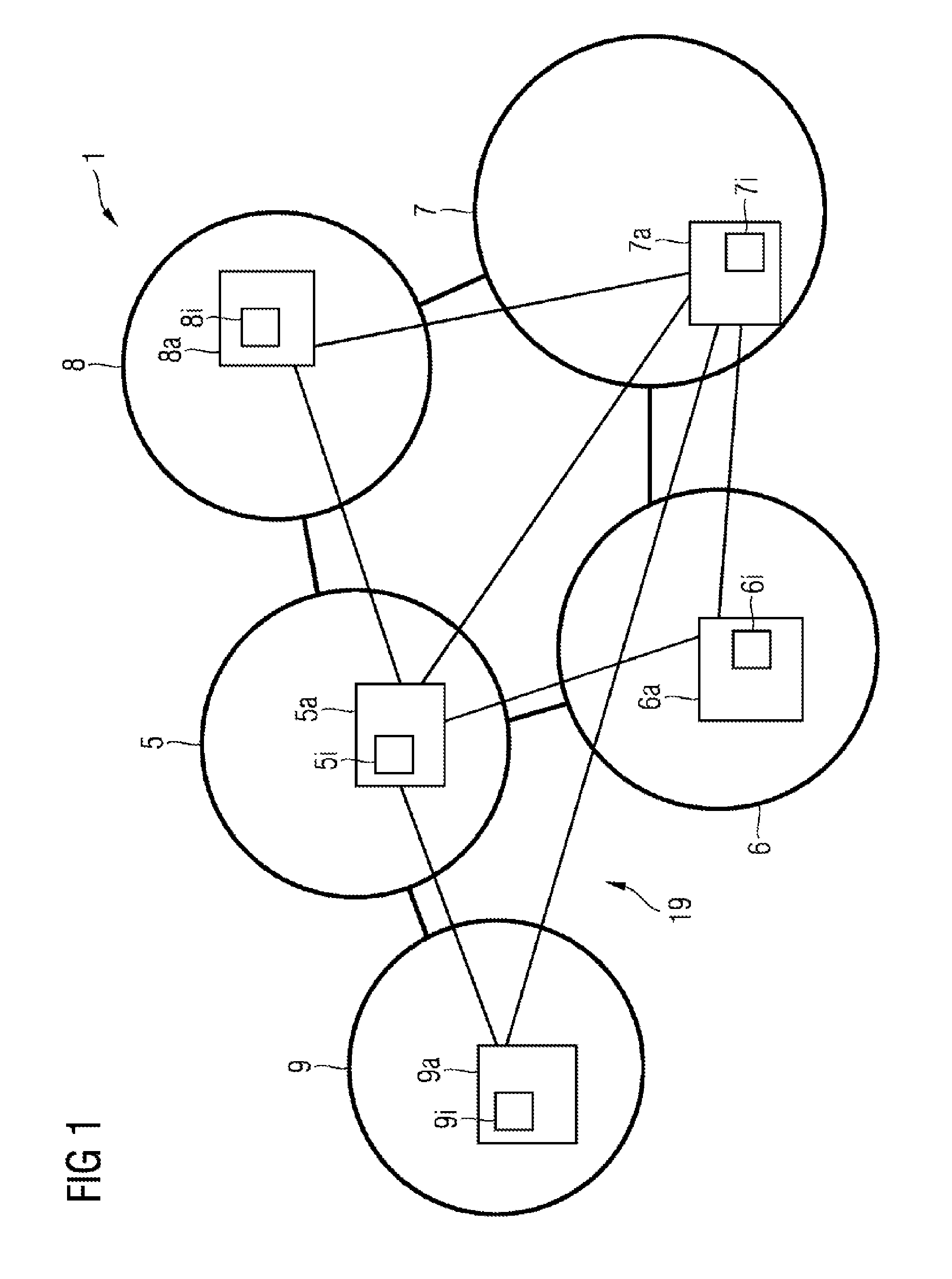

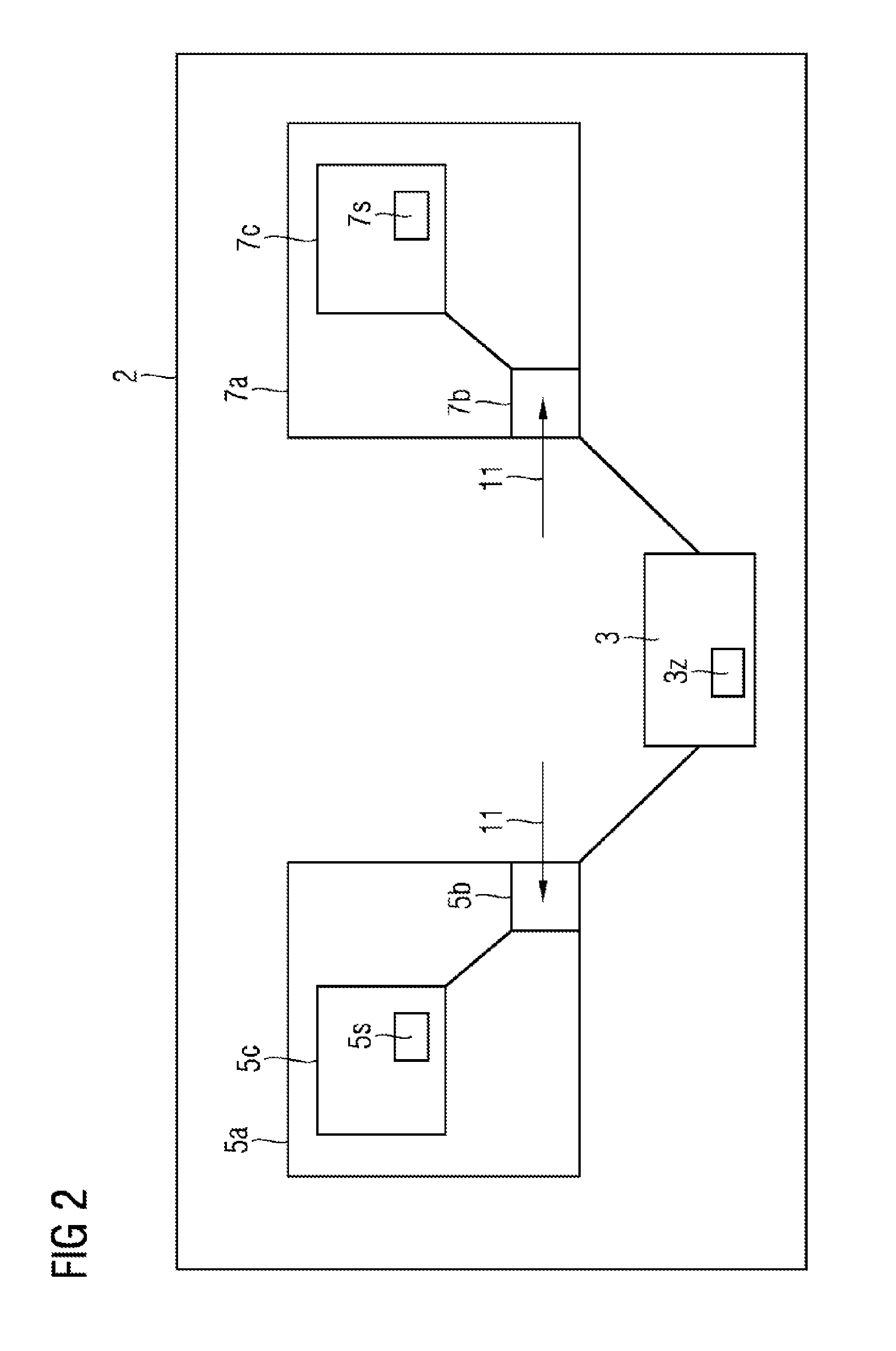

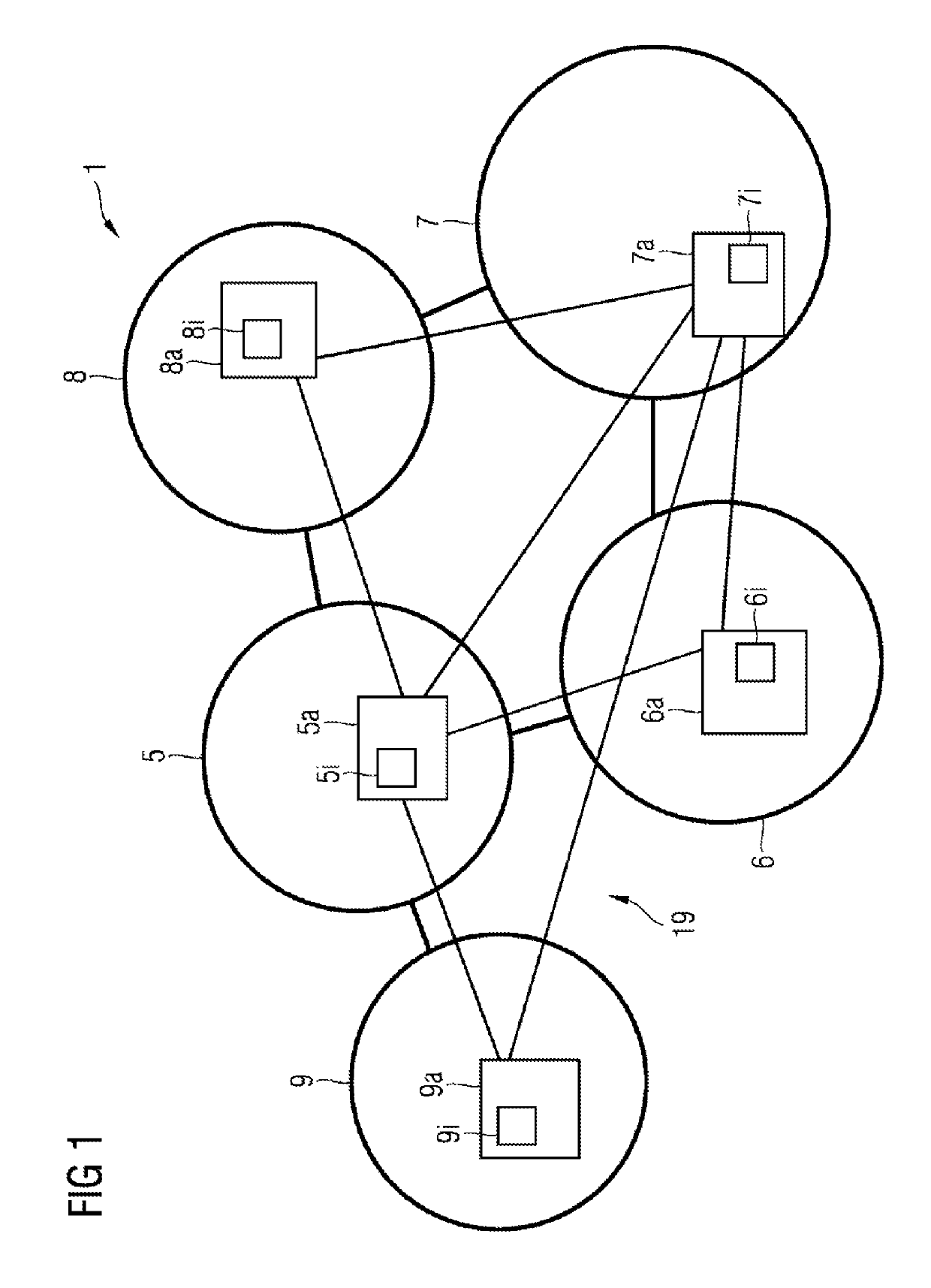

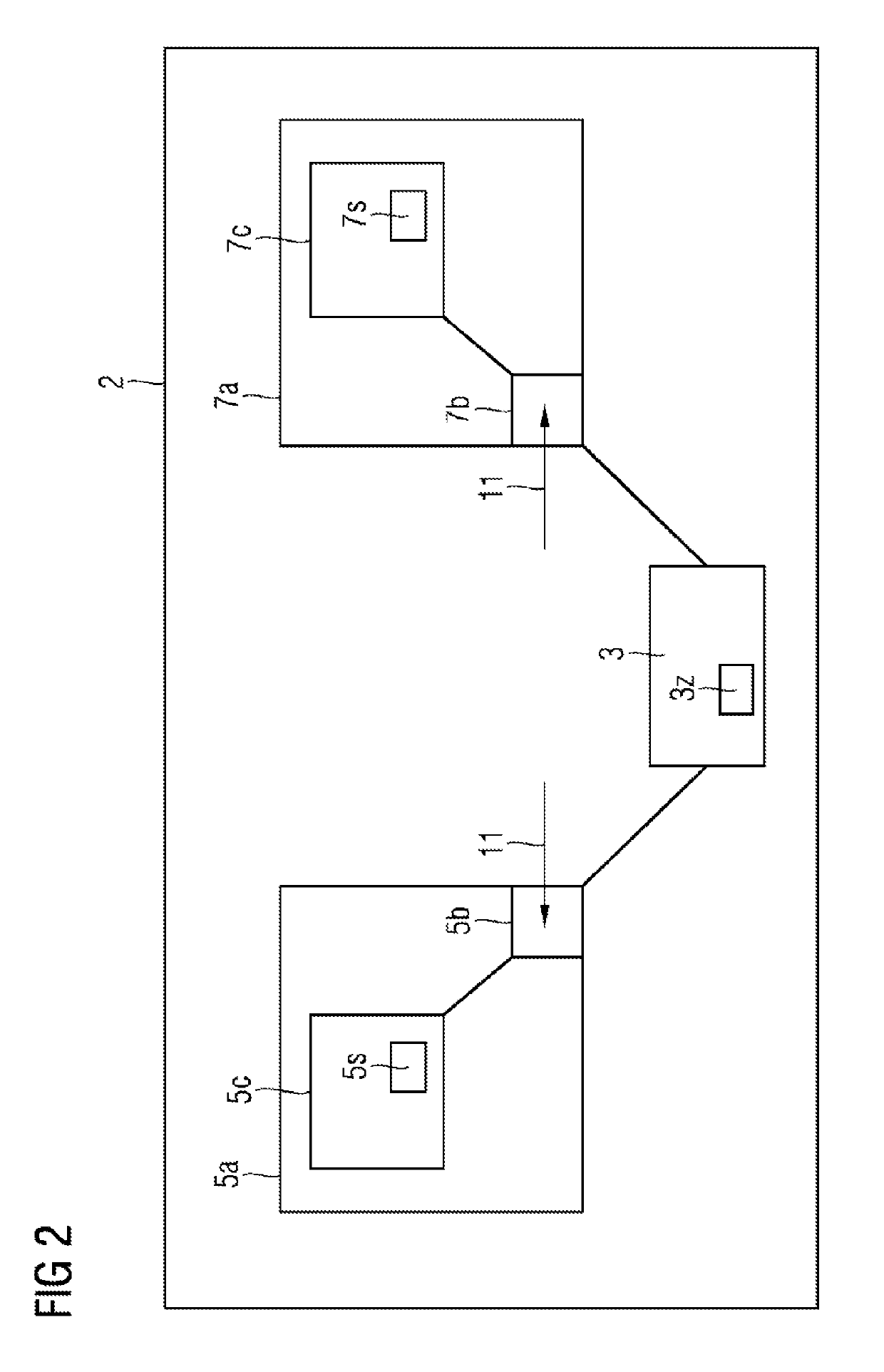

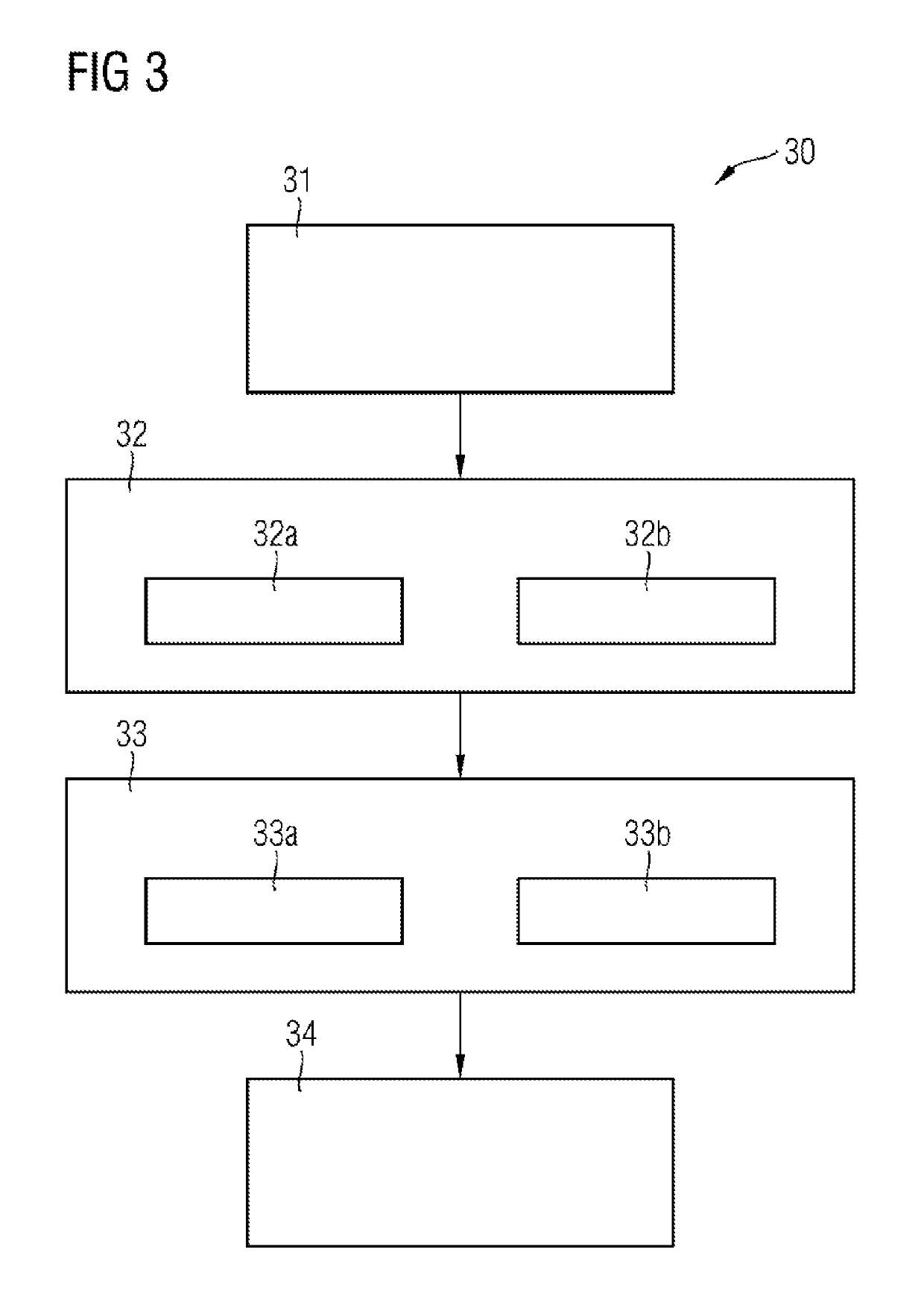

The invention relates to methods and systems for optimizing the distribution of electrical energy in an electrical power supply system (I) which comprises autonomous supply system regions (5, 6, 7, 8, 9), comprising the method steps of:—receiving input data (II) by at least two dispatcher instances (5a, 7a), wherein the input data (II) represents energy intervals (5i, 6i, 7i, 8i, 9i) which are requested by the autonomous supply system regions (5, 6, 7, 8, 9);—calculating at least one solution (5s, 7s) of the distribution of electrical energy to the supply system regions (5, 6, 7, 8, 9) by each of the at least two dispatcher instances (5a, 7a);—selecting one of the calculated solutions (5s, 7s) for the distribution of electrical energy in the power supply system (I) by means of a leader election. The invention relates to the technical field of distributing electrical energy and can be used, for example, for smart grids.

Owner:SIEMENS AG

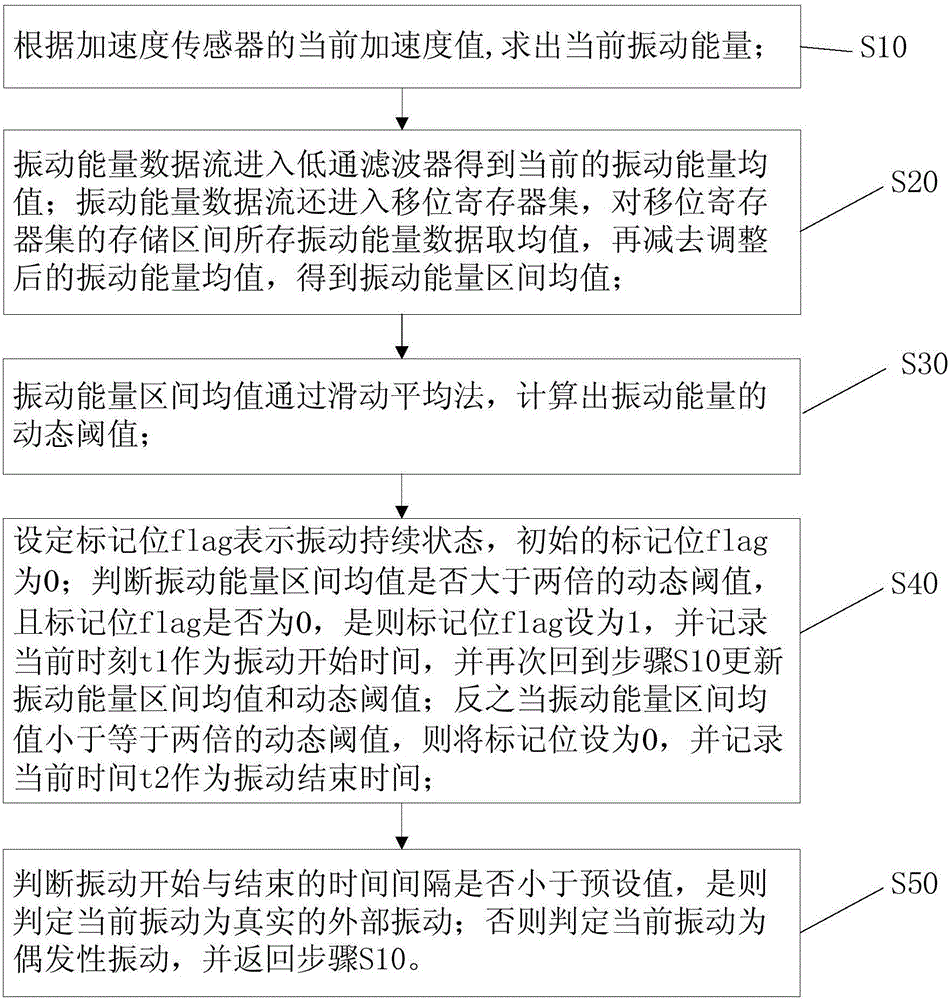

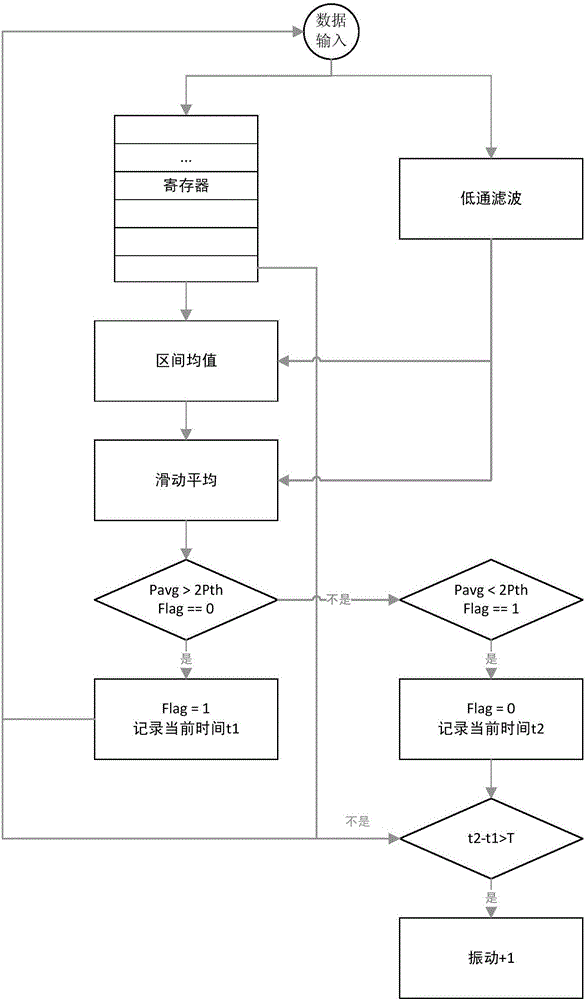

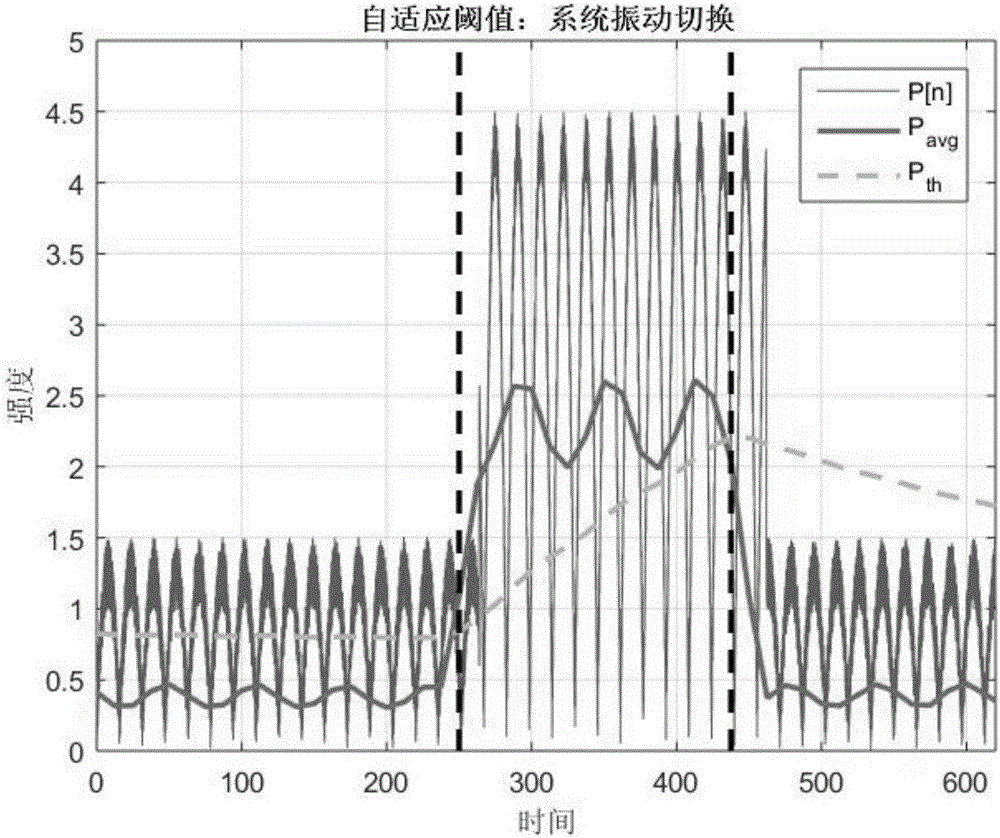

Self-adaptive threshold value adjusting method

ActiveCN106485070AImprove accuracyAccurate removalSubsonic/sonic/ultrasonic wave measurementInformaticsVibration detectionSelf adaptive

The invention discloses a self-adaptive threshold value adjusting method. The self-adaptive threshold adjusting method comprises the following steps: determining a threshold value dynamically by calculating inherent vibration energy and bottom noise of equipment in order to adapt to the change of the equipment; judging whether a mean value of vibration energy intervals is larger than twice of the dynamic threshold value or not, wherein a different value between a moment at which the mean value of the vibration energy intervals is larger than twice of the dynamic threshold value and a moment at which the mean value of the vibration energy intervals is smaller than or equal to twice of the dynamic threshold value is taken as abnormal vibration duration; detecting whether the abnormal vibration duration is less than a set value T or not; and eliminating wrong reporting about the vibration caused by state change of the equipment. Through adoption of the self-adaptive threshold value adjusting method, self-adaptive vibration detection is performed in a learning way, so that the accuracy of vibration detection is increased effectively, and misjudgment caused by state change of a system is eliminated effectively.

Owner:GUANGZHOU JIESHENG INFORMATION TECH

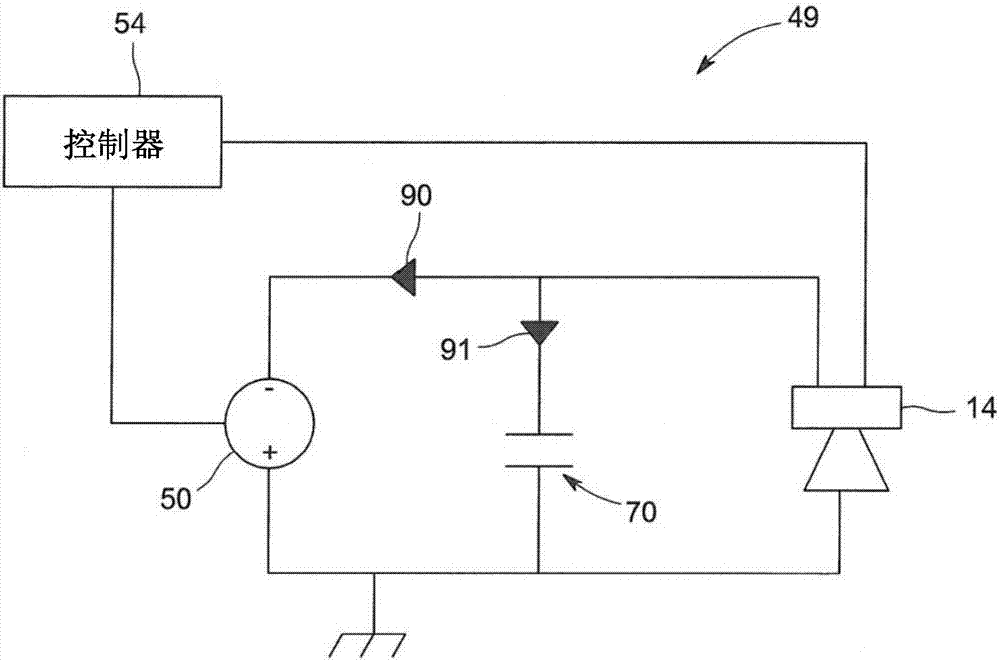

Energy imaging with generally constant energy separation

The present inventors have recognized that fall times between high-kV to low-kV levels (during a dual energy or fast-kV energy scan) are linked to the discharge of HV (high voltage) capacitance. In an embodiment of the invention, a high voltage generator may be activated during fall transitions from first to second energy levels in order to substantially maintain a predetermined fall transition time. Accordingly, substantially equal energy distributions between high-kV and low-kV levels may be achieved.

Owner:GENERAL ELECTRIC CO

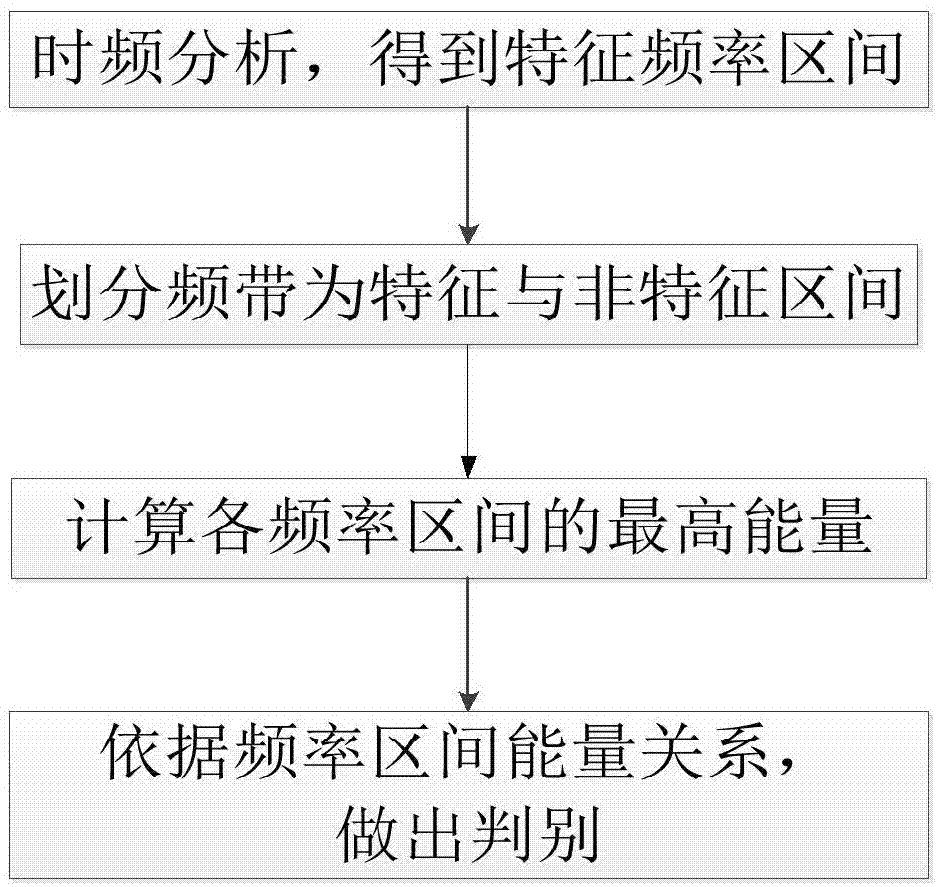

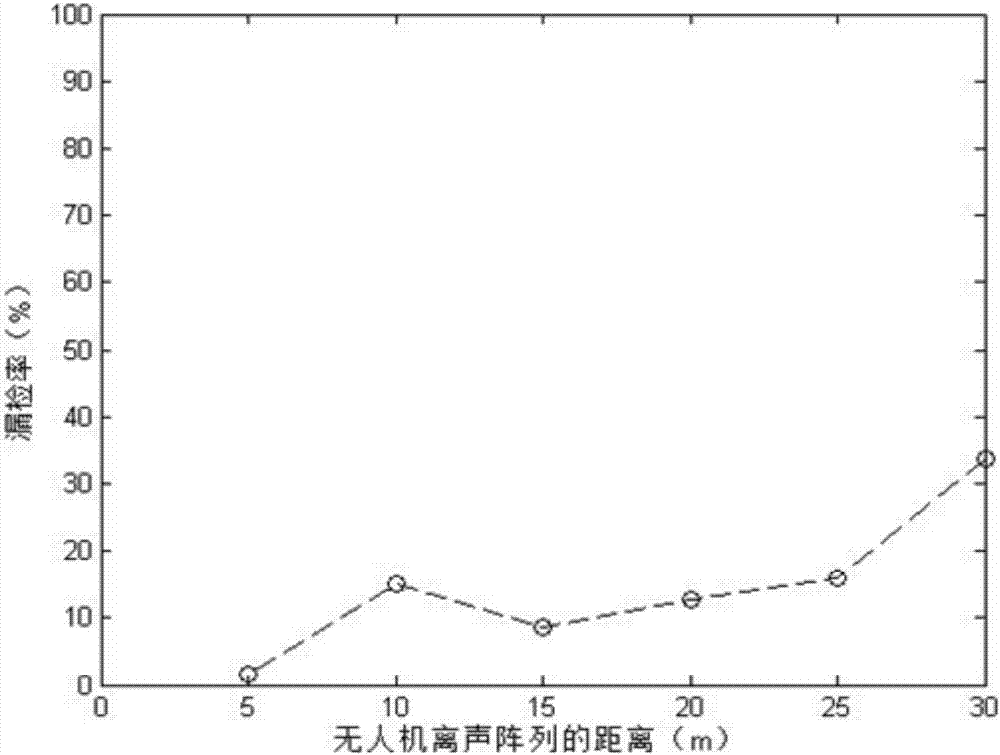

Unmanned plane detection method based on voiceprint multi-harmonic wave identification

ActiveCN107576387AEasy to detectReduce missed detection rateSubsonic/sonic/ultrasonic wave measurementComplex mathematical operationsFrequency spectrumTarget signal

The invention discloses an unmanned plane detection method based on voiceprint multi-harmonic wave identification. A traditional harmonic wave detection method based on Fourier transform is established on a stationary signal hypothesis base for analysis, frequency domain characteristics are acquired by the time domain information of use signals, frequency, amplitude and phase of harmonic waves ofthe stationary signals can be accurately determined, disadvantages of the traditional harmonic wave detection method are that non-stationary signals can not be processed and the traditional harmonic wave detection method is not suitable for analyzing dynamic harmonic waves and abrupt change signals, and harmonic waves dynamically change in actual harmonic wave detection applications. The unmannedplane detection method is advantaged in that characteristic frequency is acquired through carrying out time frequency analysis on sound signals of target signal sources; according to the position of characteristic frequency in frequency spectrum, frequency band width is equally divided into characteristic frequency intervals and non-characteristic frequency intervals which are sequentially alternate, and the maximum energy value of each frequency interval is solved; based on the energy fluctuating relationship of the energy intervals, the relationship of the maximum energy values of the frequency intervals is taken as discrimination standards, and excellent detection performance can be realized.

Owner:ZHEJIANG UNIV

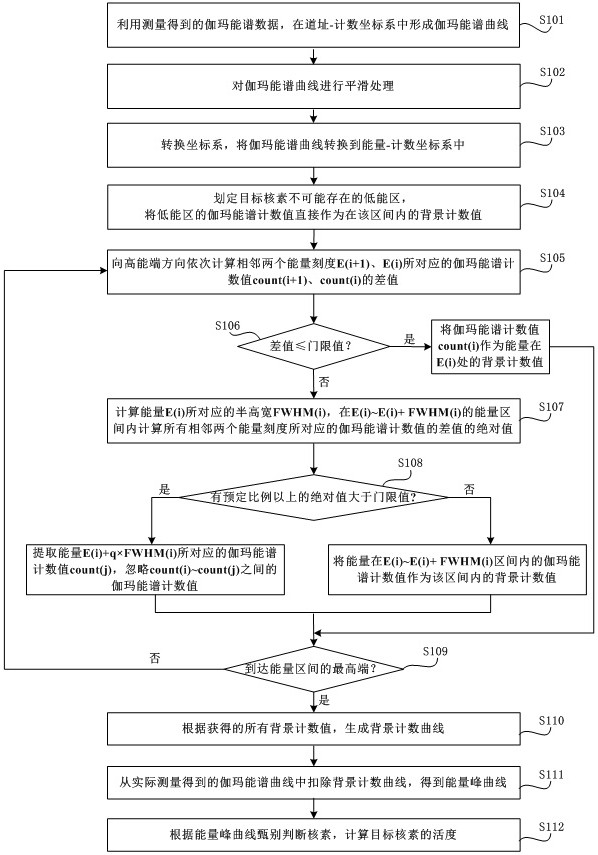

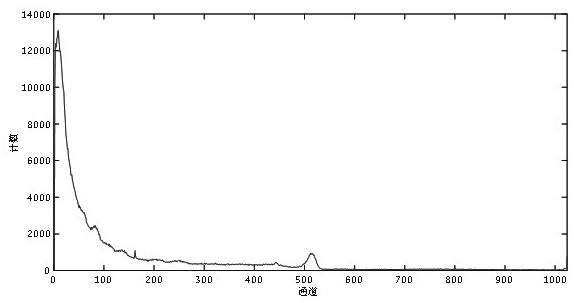

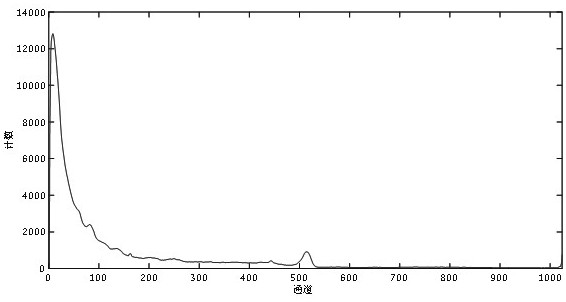

Gamma energy spectrum background counting method

ActiveCN111812703AThe background count method worksComply with activity testing requirementsX-ray spectral distribution measurementNuclear energy generationNuclear engineeringMeasuring instrument

The invention discloses a gamma energy spectrum background counting method. The method comprises steps of a gamma energy spectrum curve being generated in an energy-counting coordinate system according to gamma energy spectrum data obtained through measurement; calculating a difference value of gamma energy spectrum count values corresponding to two adjacent energy scales from a low-energy end ofthe gamma energy spectrum curve; if the difference value is smaller than the threshold value, taking the difference value as a background count value; if the difference value is greater than the threshold value, further judging in an energy interval of the full width at half maximum FWHM(i) corresponding to the E(i), if the absolute value of most counting difference values in the interval is greater than a threshold value, extracting a gamma energy spectrum count value count (j) corresponding to the energy E(i) + q*FWHM(i), and neglecting the gamma energy spectrum count value between count (i)and count (j); otherwise, taking the gamma energy spectrum count value in the interval as a background count value. The background counting method is simple and effective, and the monitoring result can be directly generated when the method is applied to a measuring instrument.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

Method for determining the concentration of an element in a material

A method for determining the concentration of an element in a material includes irradiating the material with an X-ray beam having a continuum in the area of an absorption edge of the element to be measured. The intensity of the transmitted X-ray beam is measured with an energy dispersive sensor. The intensity of the transmitted X-ray beam in an energy interval above the absorption edge and in an energy interval below the absorption edge is determined. The concentration of the element is computed on the basis of said intensities.

Owner:E·克茨

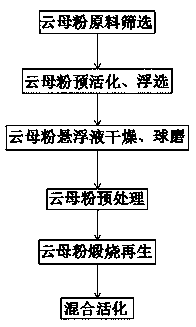

Mica powder activation method

InactiveCN109096795AProcess easy to controlImprove regeneration efficiencyPigment physical treatmentActivation methodOctahedron

The invention discloses a mica powder activation method. The mica powder activation method comprises the following steps that a mica powder raw material is screened, wherein mica powder is silicate ofa laminated structure, the structure is a compound silica layer formed by clamping a layer of aluminum-oxygen octahedrons between two layers of silica tetrahedrons, so that nonuniform grains in the mica powder are screened through a screening machine before activation is performed, the purity of the mica powder raw material is ensured, and follow-up activation is facilitated; the mica powder is subjected to pre-activation and flotation, wherein activating reaction is conducted on an oxidation layer on the surface of the screened mica powder through a first activating agent. The activating agent used in the method is a common inorganic material, no impurity is not introduced, the mica powder is calcined through two times of variable-temperature adjustment, jump from ground state level to higher energy level of electrons is activated, the temperature interval and an energy interval required for jump of the mica powder are similar, the raw material is subjected to screening, flotation and redrying, the impurities in the mica powder can be effectively removed, activation is performed after ball milling, an activation surface area is larger, and the activation efficiency is improved.

Owner:ANHUI HENGHAO SCI & TECH

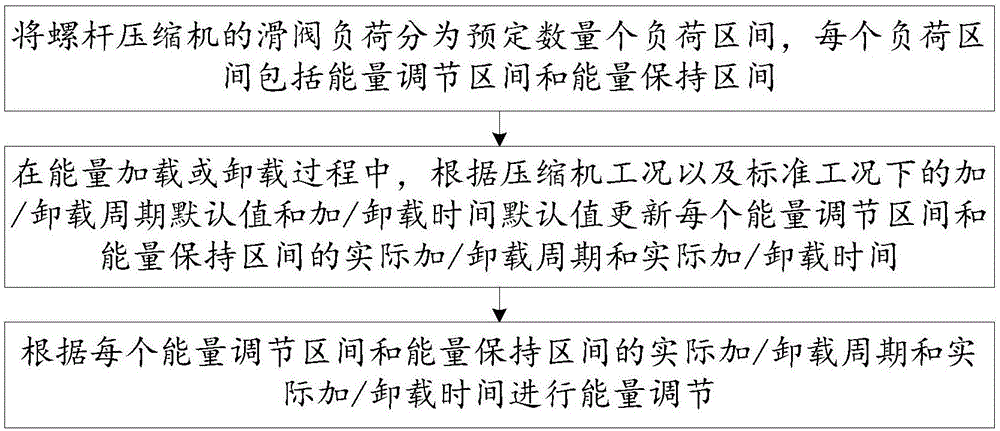

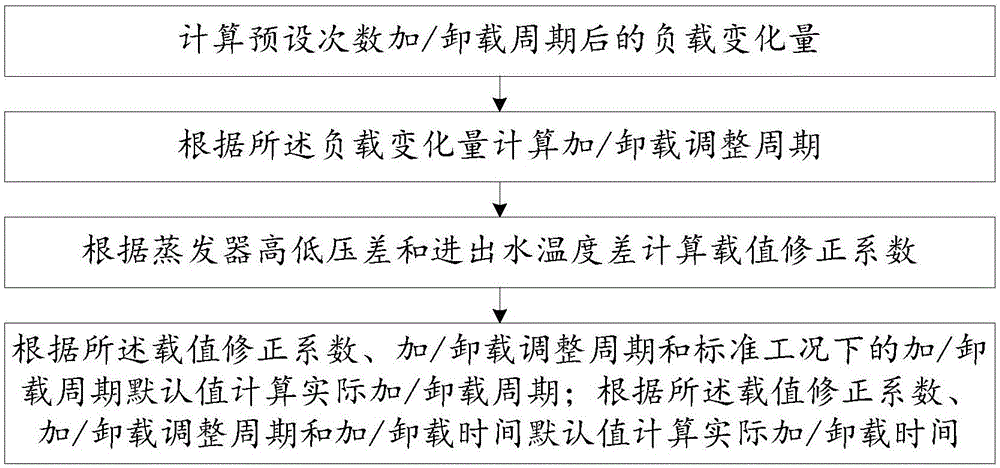

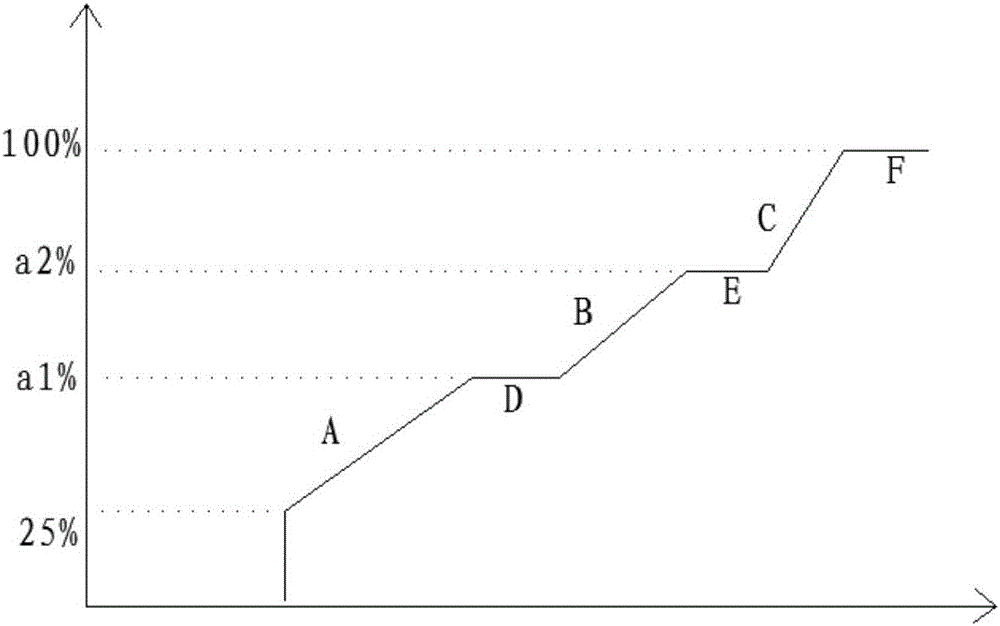

Stepless energy regulation method and device of screw compressor and screw compressor

ActiveCN106640656AImprove energy efficiencyAvoid the phenomenon of low voltage failureMachines/enginesEnergy regulationEnergy interval

The invention relates to a stepless energy regulation method and device of a screw compressor and the screw compressor. The stepless energy regulation method comprises the steps that a slide valve load of the screw compressor is divided into load intervals of a preset number, and each load interval comprises an energy regulating interval and an energy maintaining interval, wherein energy of the energy maintaining interval is a preset value; in the process of energy loading or energy unloading, according to loading / unloading cycle default values and loading / unloading time default values under the actual working condition and the standard working condition of the compressor, actual loading / unloading cycles and actual loading / unloading time of each energy regulating interval and each energy maintaining interval are updated; and according to the actual loading / unloading cycles and the actual loading / unloading time of each energy regulating interval and each energy maintaining interval, the energy is regulated. Energy fine regulation is achieved, the energy efficiency of a machine set can be optimal rapidly, and the phenomenon of a low-pressure failure because of the failure, caused by a large load span and a sharp jump of the energy intervals, of timely refrigerant flow regulation is avoided.

Owner:CHONGQING MIDEA GENERAL REFRIGERATING EQUIP

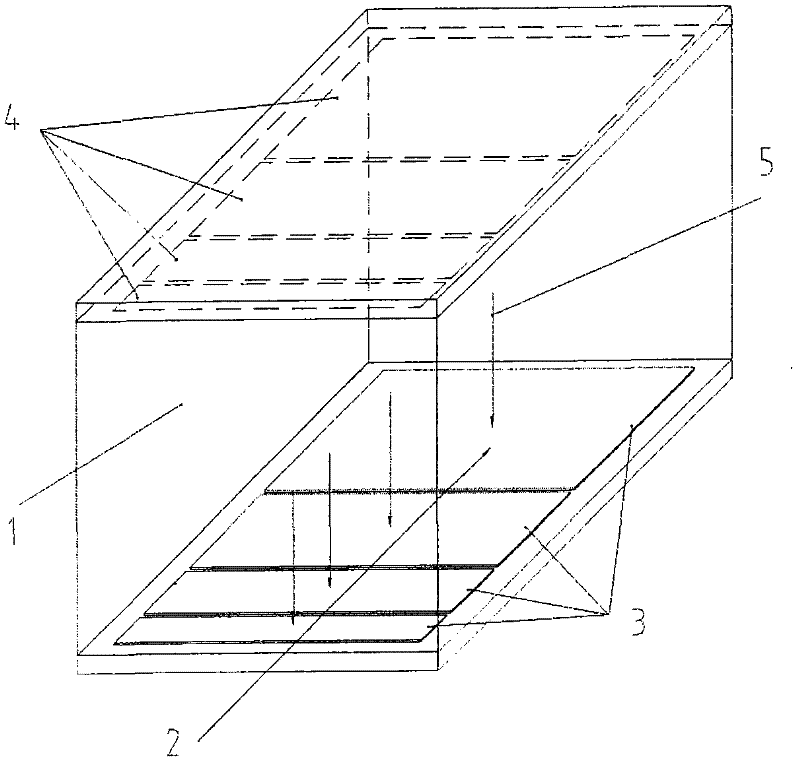

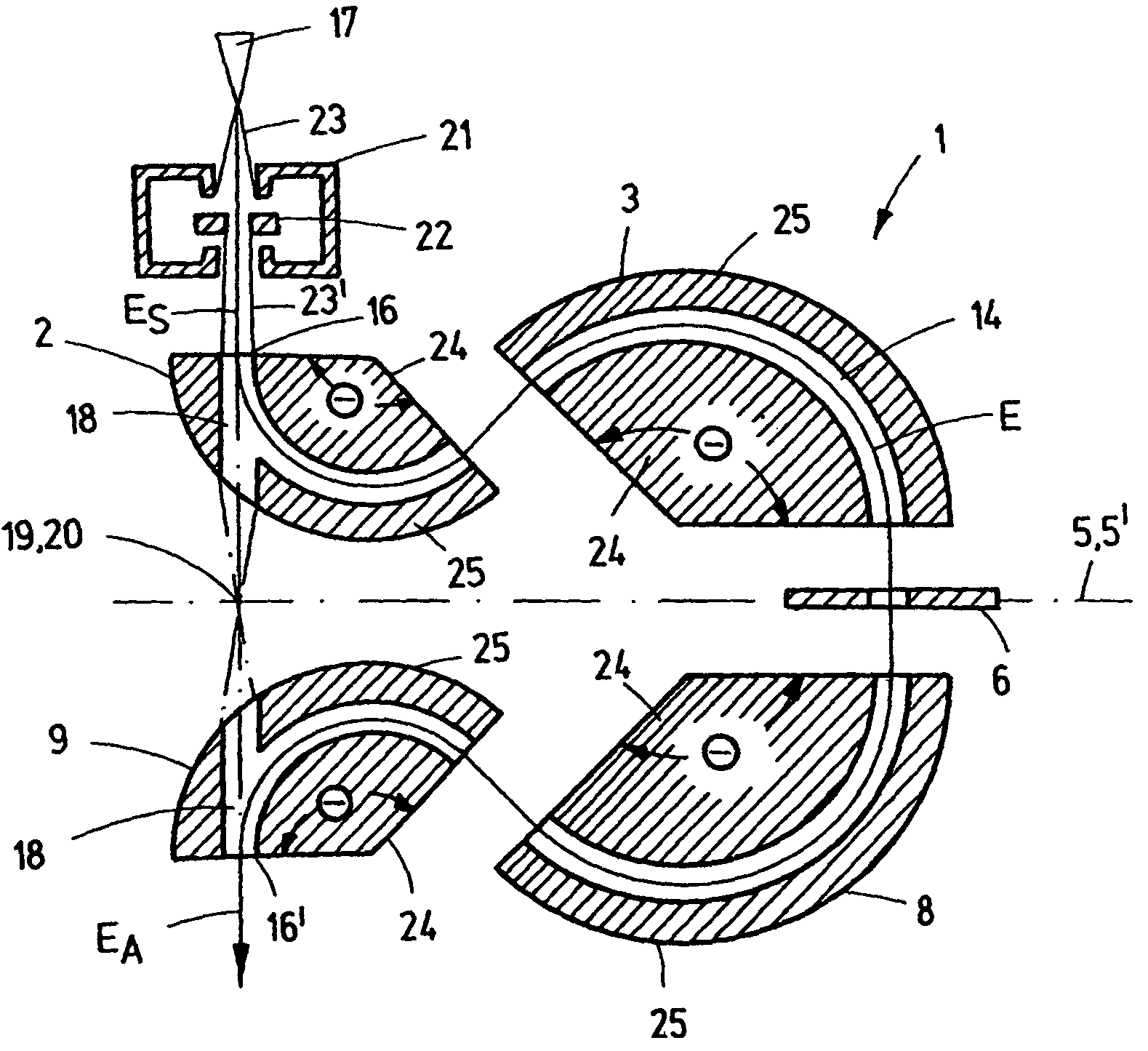

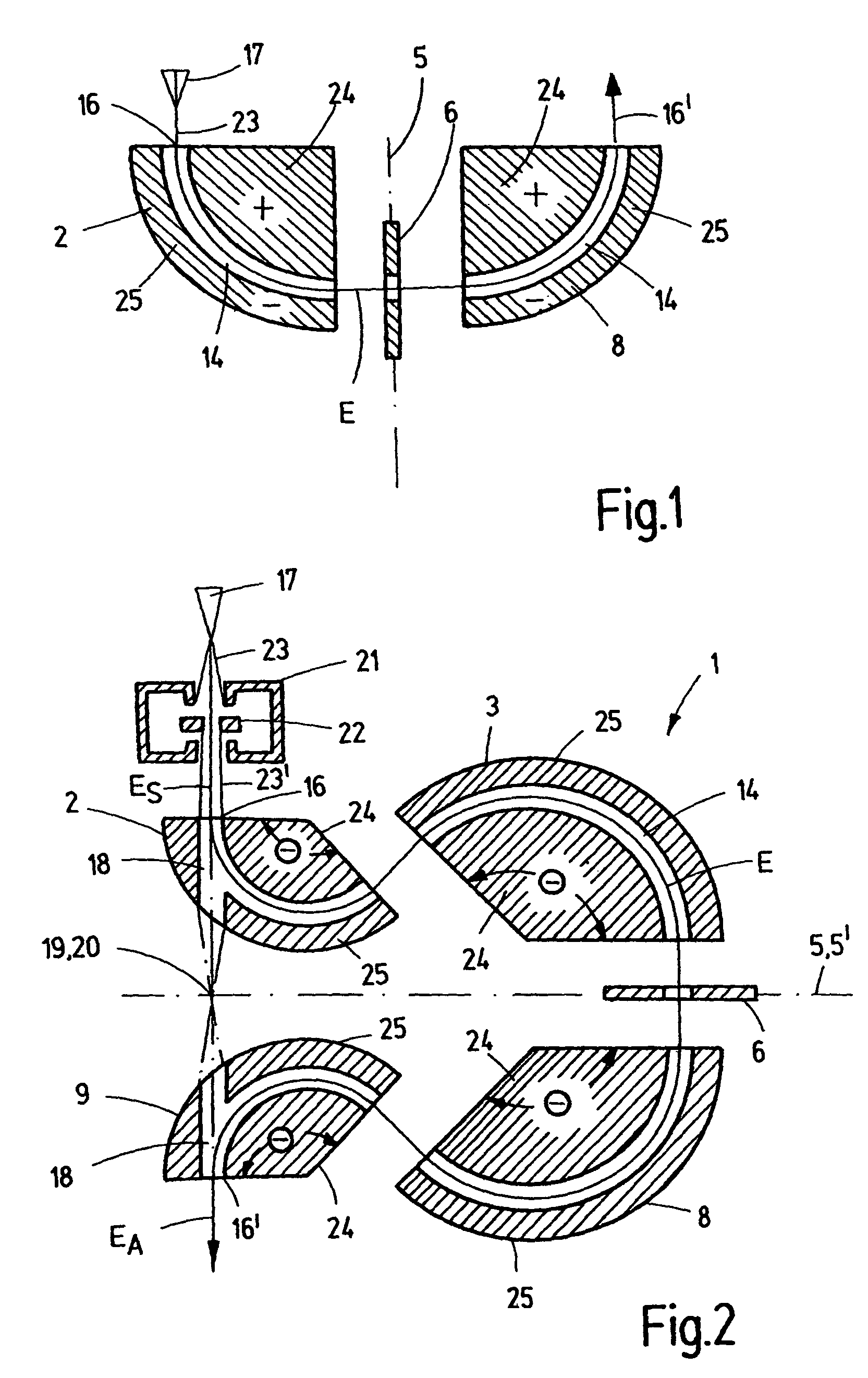

Monochromator and radiation source with monochromator

ActiveUS7745783B2Small energy widthHigh resolutionStability-of-path spectrometersBeam/ray focussing/reflecting arrangementsMonochromatorElectron microscope

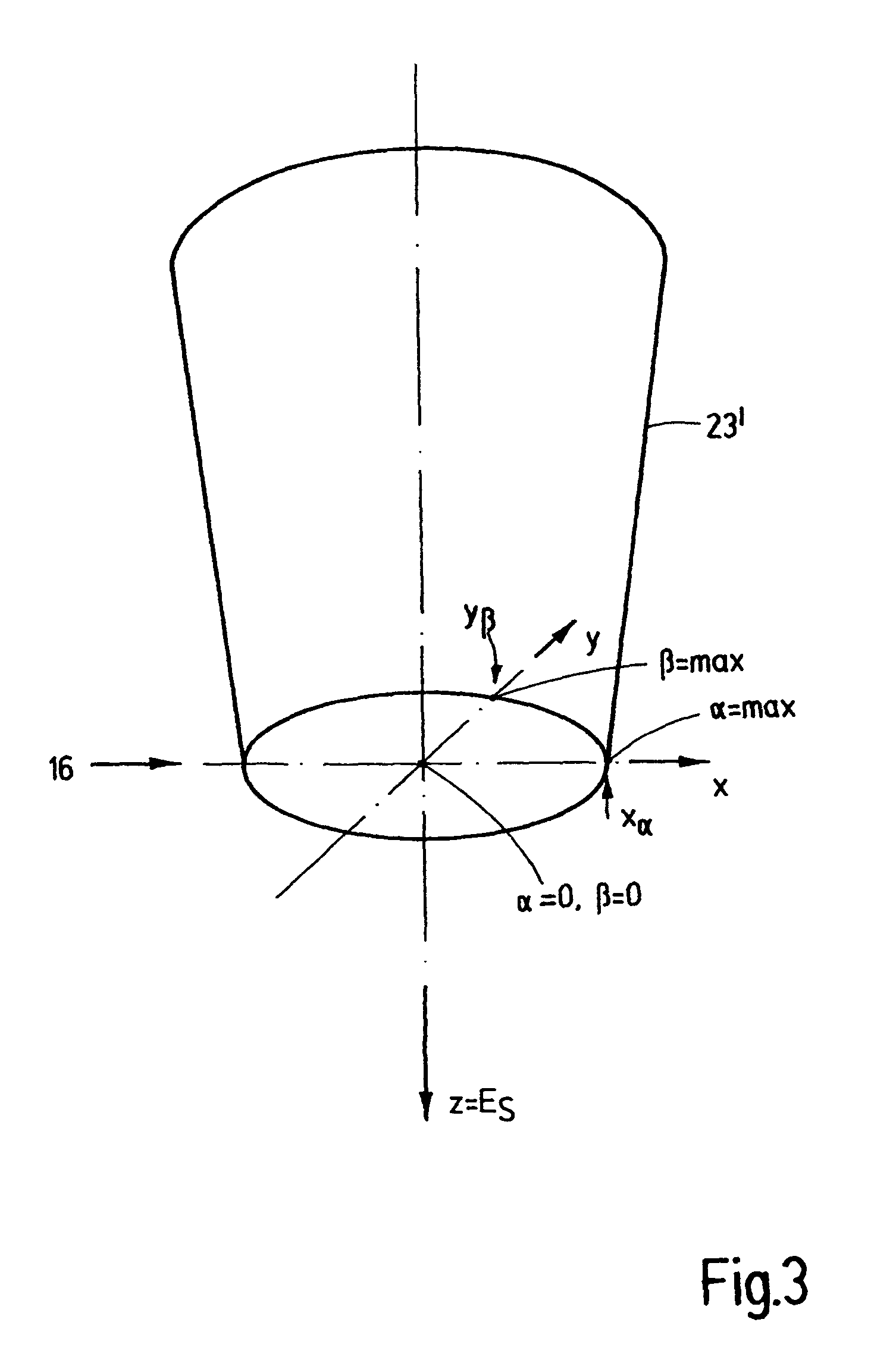

A monochromator (1) for a charged particle optics, in particular, for electron microscopy, comprises at least one first deflection element (2, 3) with an electrostatic deflecting field (2′, 3′) for generating a dispersion (4) in the plane (5) of a selection aperture (6) to select charged particles of a desired energy interval (7) and at least one second deflection element (8, 9) with an electrostatic deflecting field (8′, 9′) which eliminates the dispersion (4) of the at least one first deflecting field (2′, 3′). A radiation source (17) comprises such a monochromator (1). High monchromatism without intensity contrasts caused by defects of the slit aperture is thereby achieved in that the deflection elements (2, 3, 8, 9) have a design other than spherically shaped and their electrodes (24, 25) are given a potential (φ+, φ−) such that the charged particles (xα, yβ) which virtually enter the image of the radiation source (17) at different respective angles (α, β) in different sections (x, y), are differently focused such that charged particles (xα, yβ) of one energy are point focused (10, 10′, 10″) exclusively in the plane (5) of the selection aperture (6), since zero-crossings (11, 12) of the deflections (A) of the charged particles (xα, yβ) of the different sections (x, y) only coincide there at the same axial position (z, E).

Owner:CEOS CORRECTED ELECTRON OPTICAL SYST

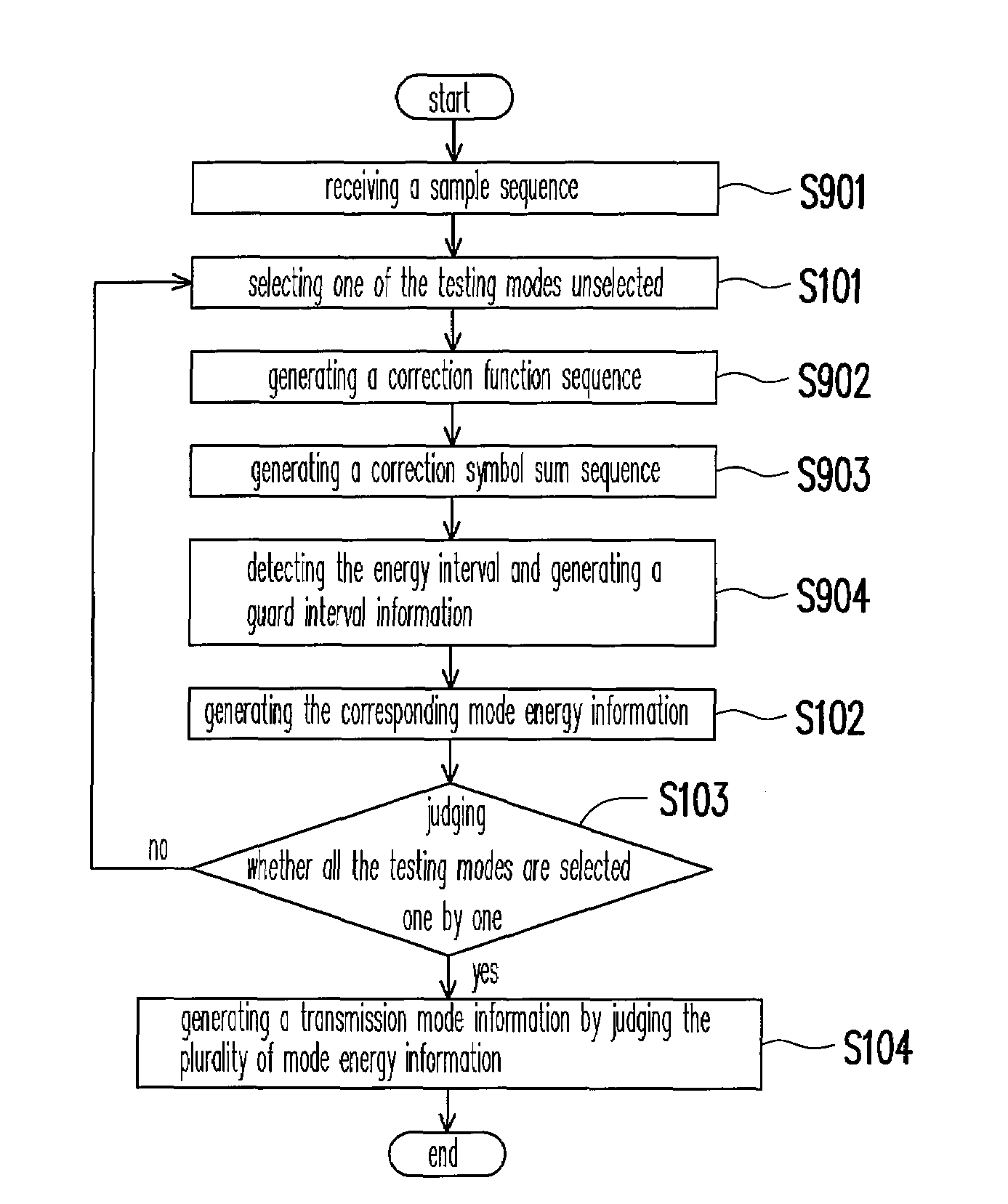

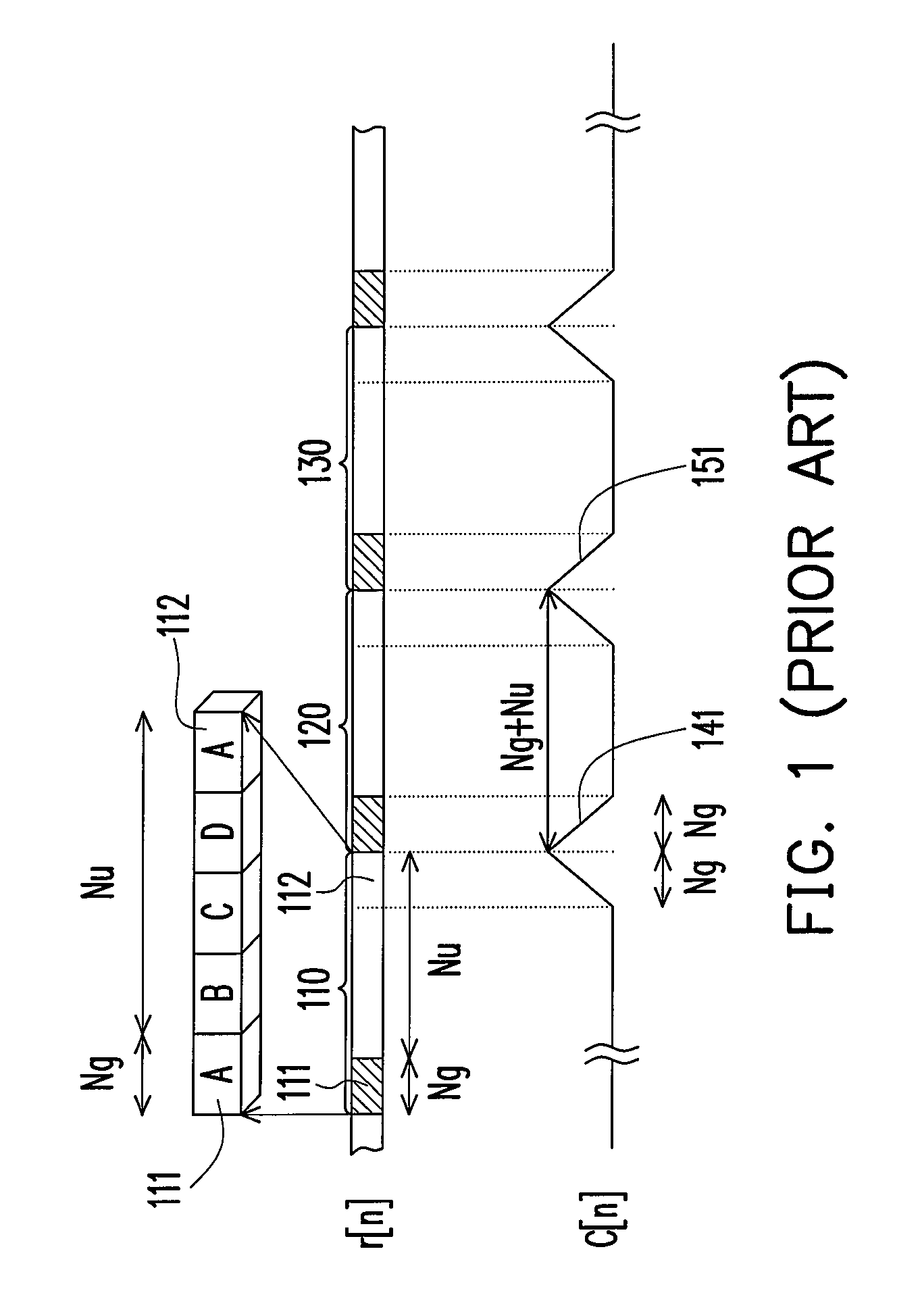

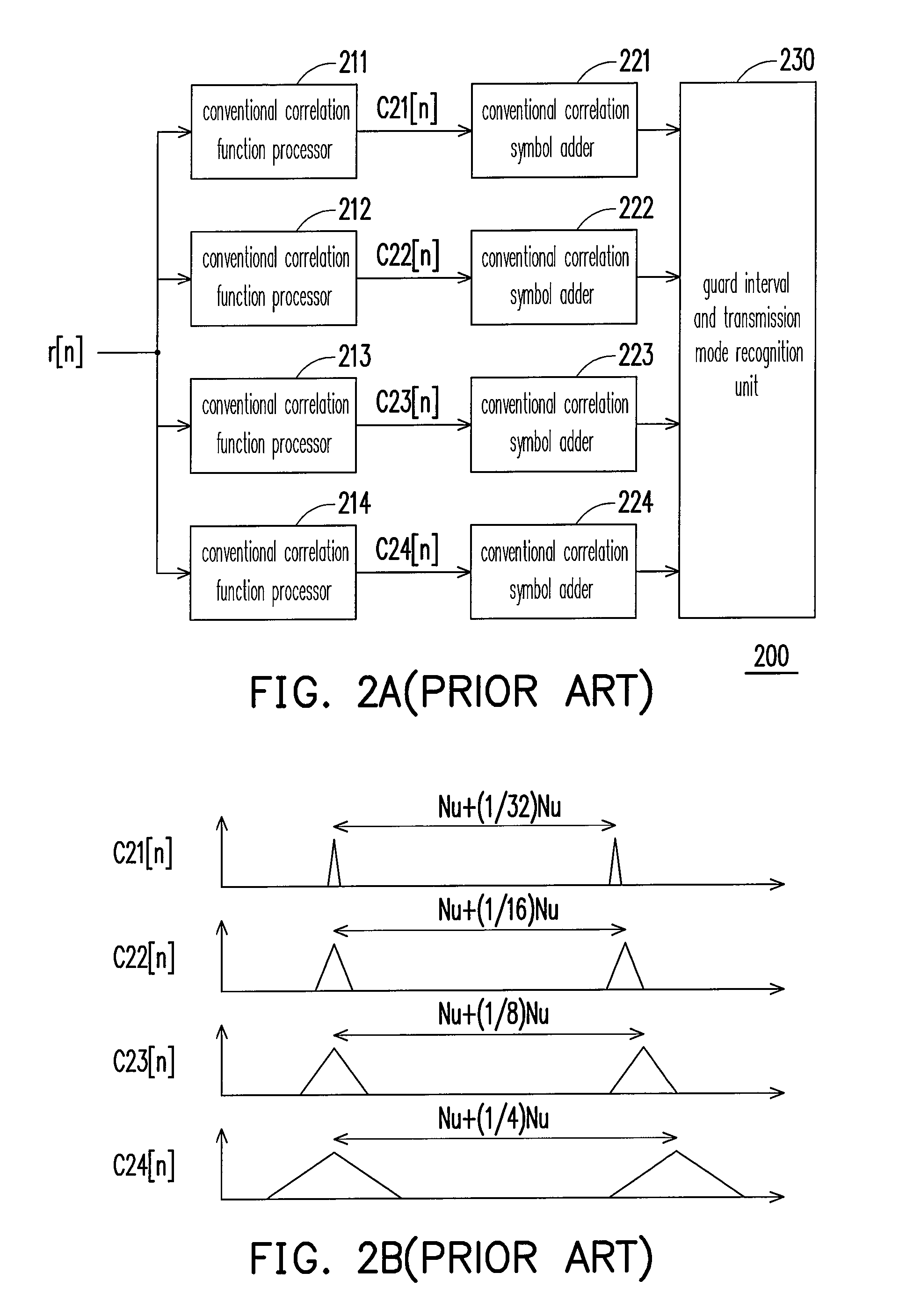

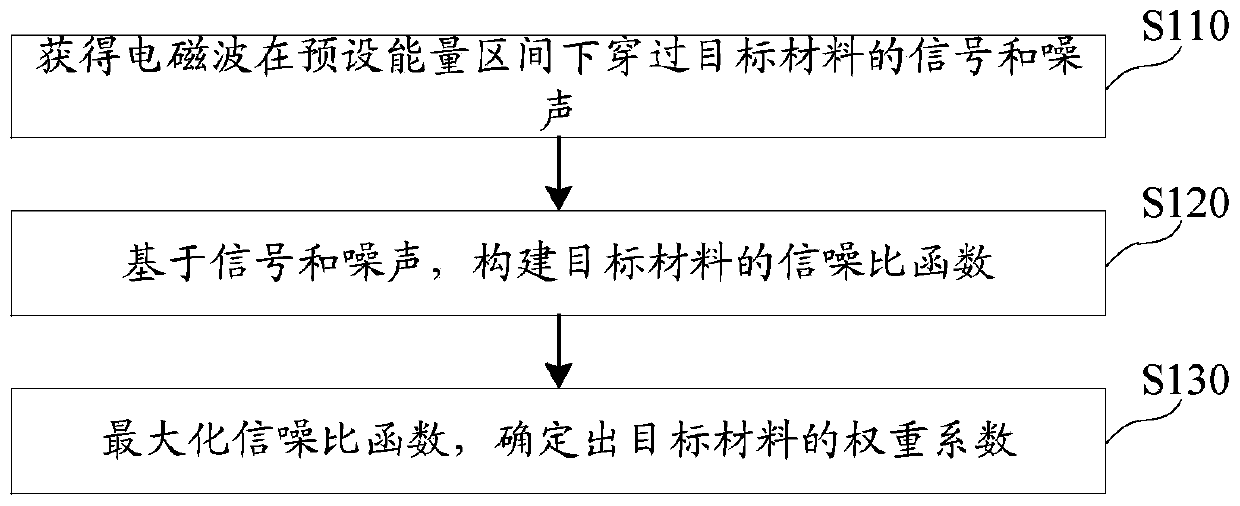

Transmission parameter recognition apparatus and method thereof

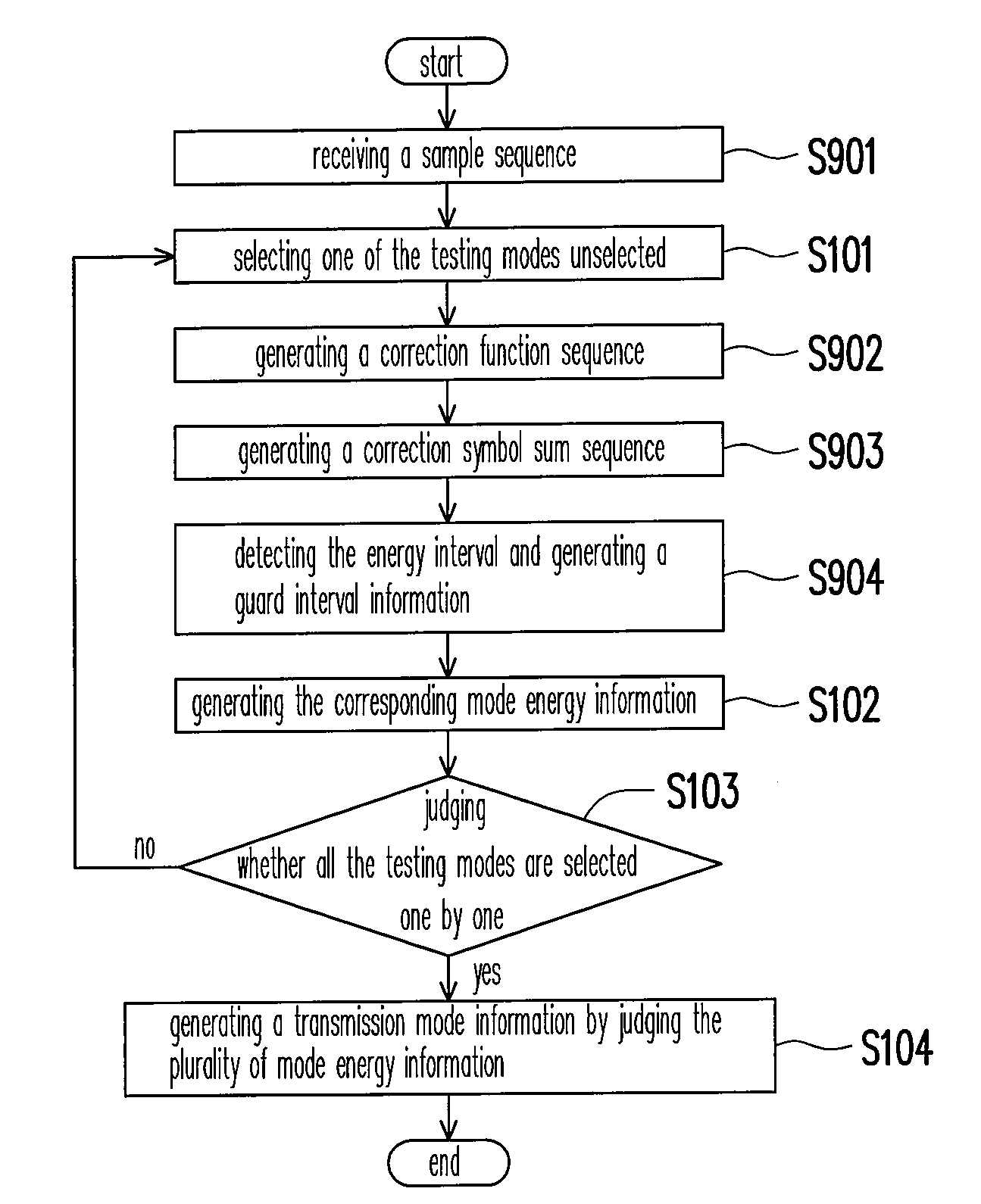

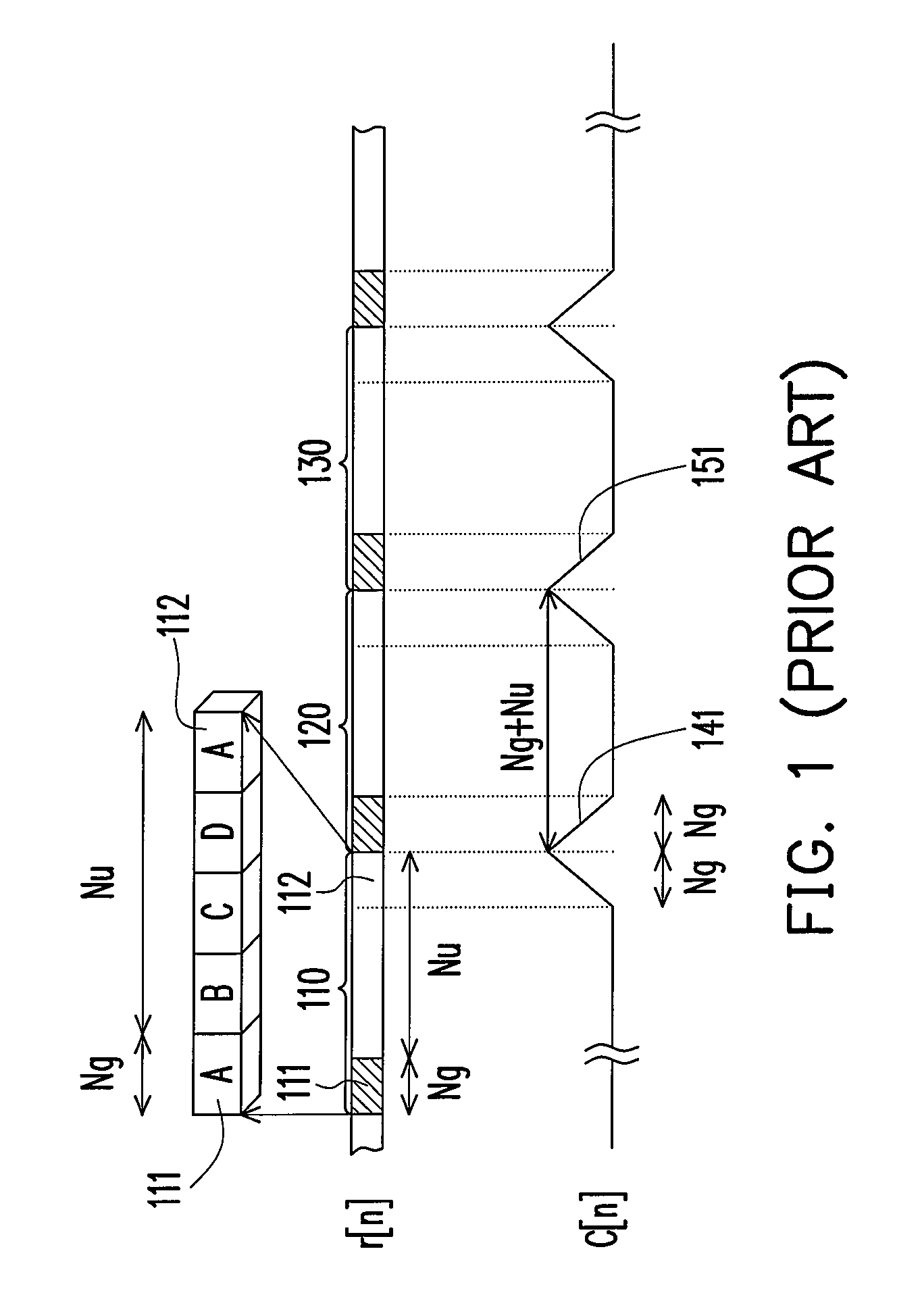

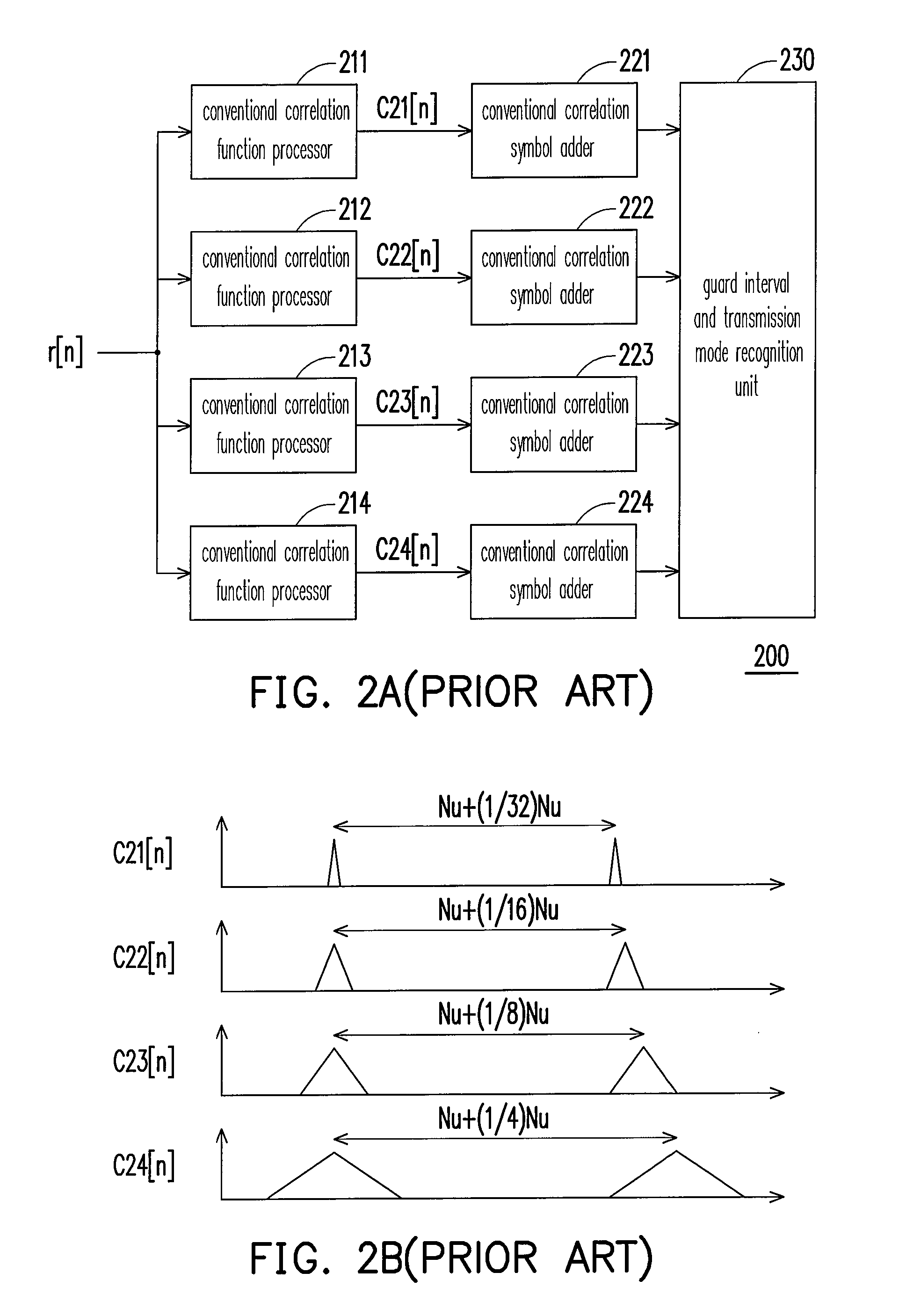

InactiveUS20080069154A1Simplifying hardware architecture complexityReduce power consumptionTime-division multiplexAmplitude-modulated carrier systemsProcess moduleSample sequence

A transmission parameter recognition apparatus and the method thereof are disclosed. The transmission parameter recognition apparatus includes a correlation function processing module, a correlation symbol summing module and an energy interval detection module. The correlation function processing module computes a correction between two adjoining symbols in a sample sequence to generate a correlation function sequence. The correlation symbol summing module accumulates M symbols in the correlation function sequence to generate an energy interval. Since the distribution of the energy interval is related to the guard interval type, therefore, the energy interval detection module detects the distribution of the energy interval to generate a piece of guard interval information.

Owner:SUNPLUS TECH CO LTD

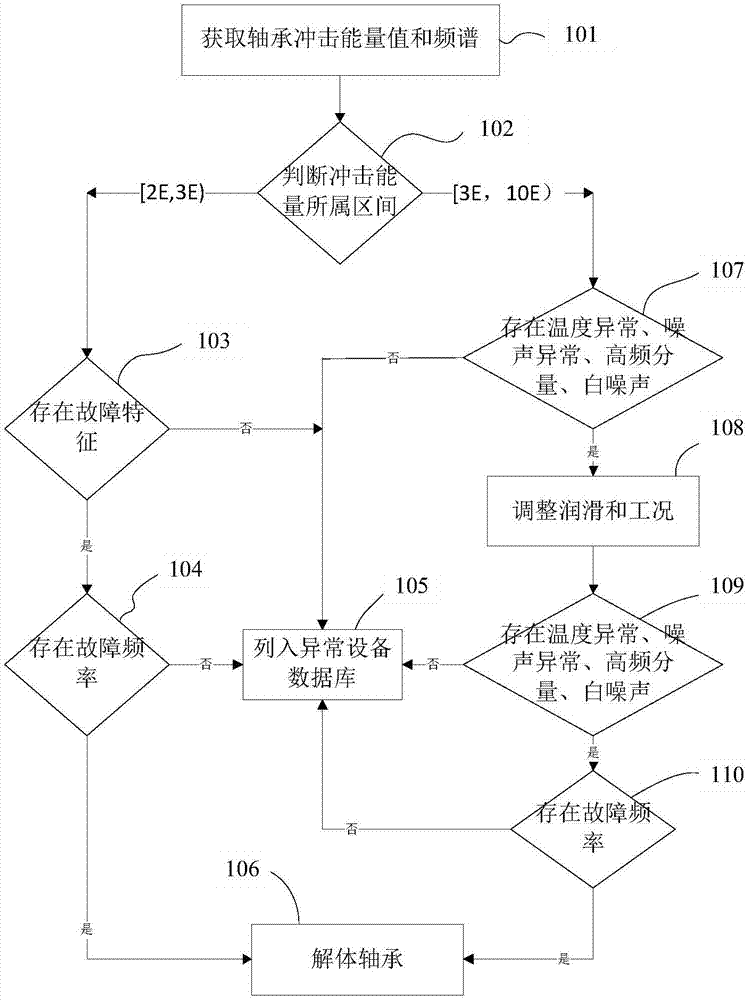

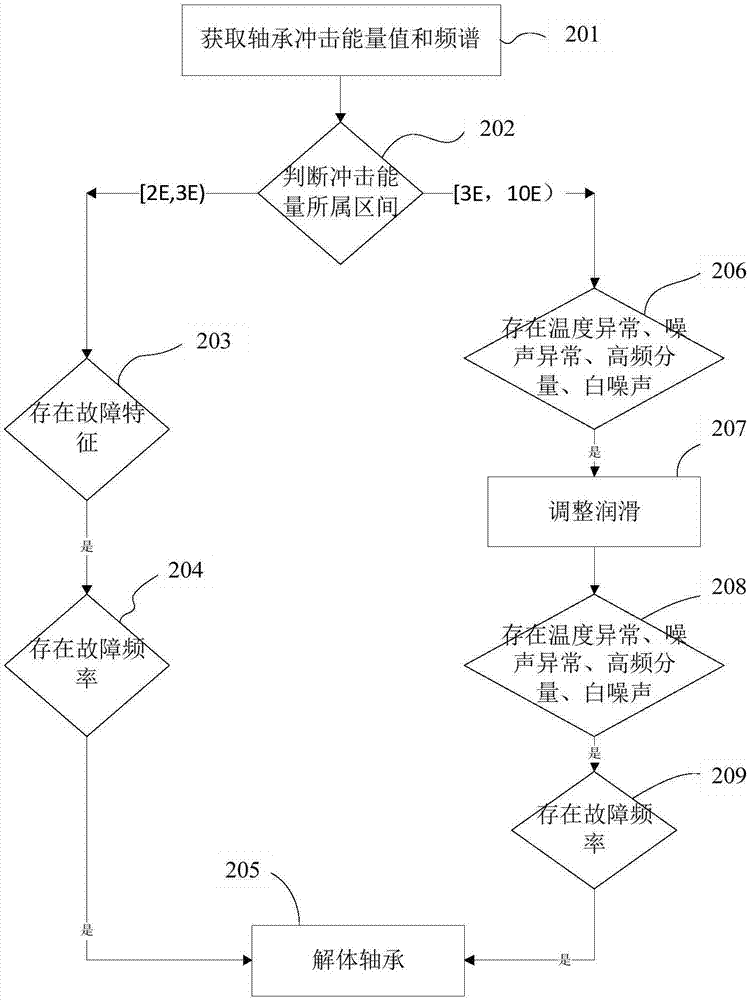

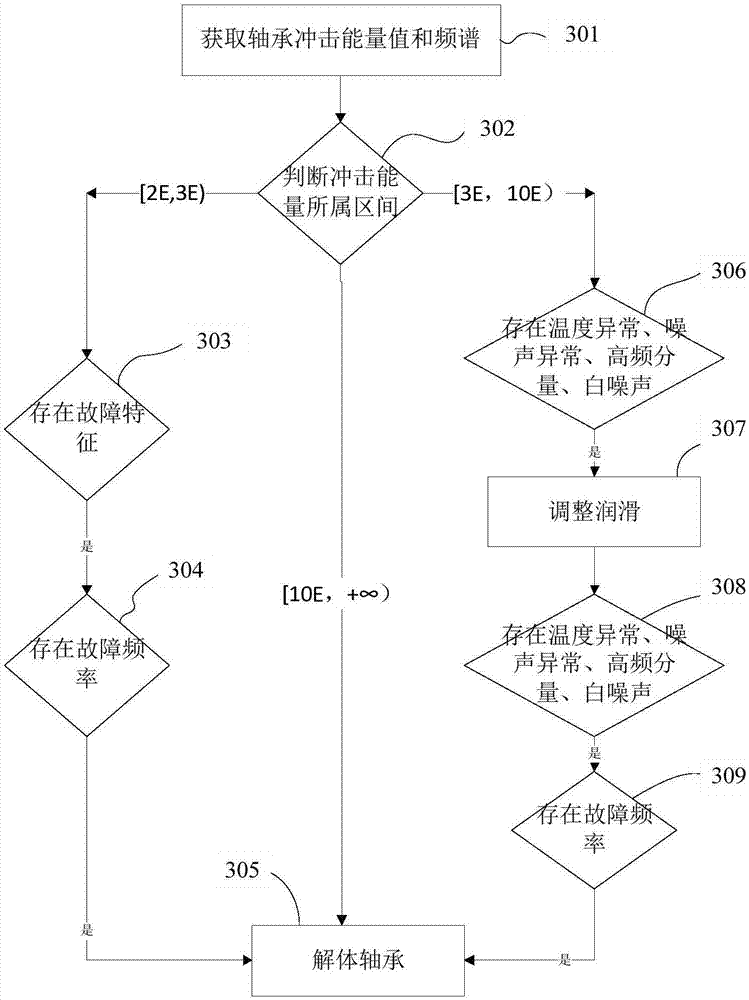

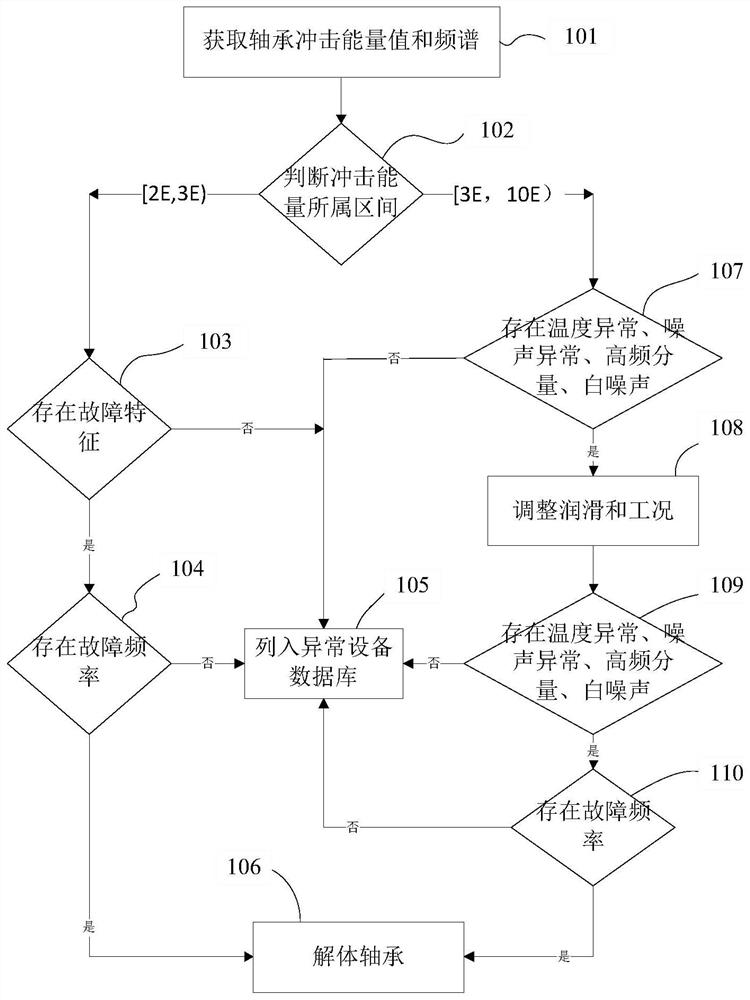

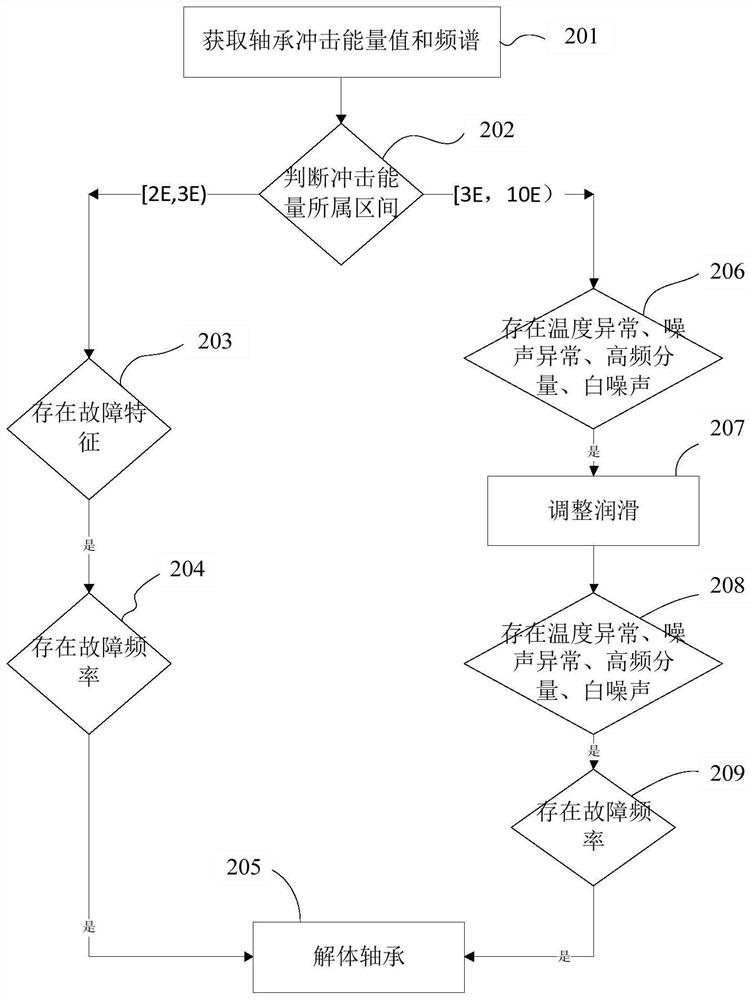

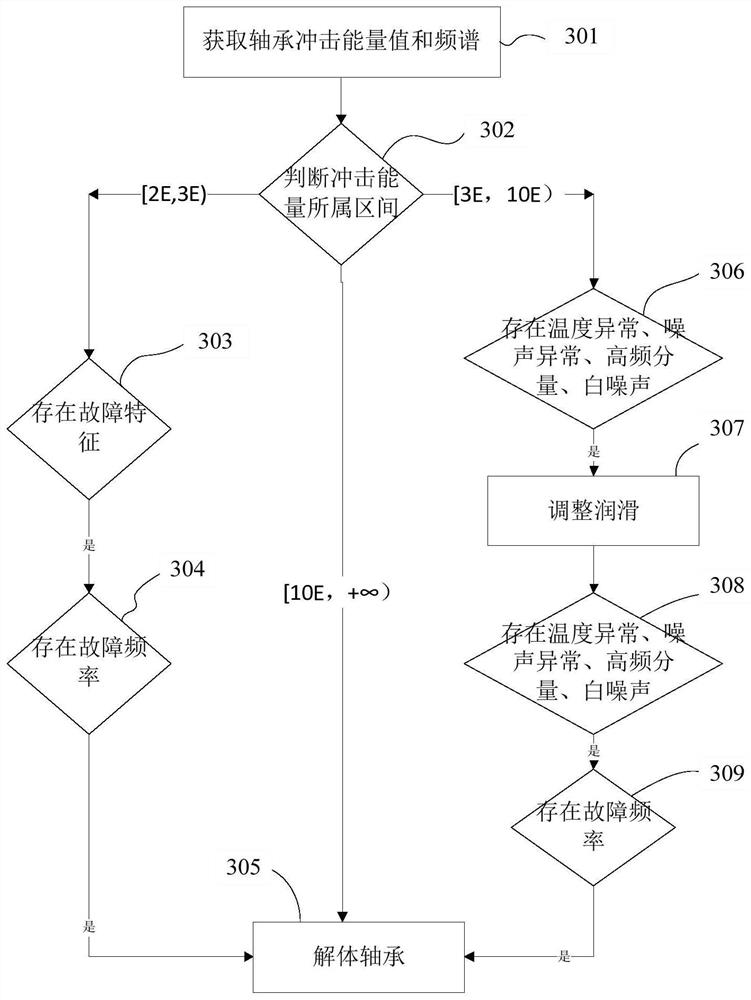

Fault diagnosis method

ActiveCN107884189AShort measuring cycleClear judgmentMachine bearings testingFrequency spectrumDiagnosis methods

The invention discloses a fault diagnosis method. A bearing impact energy value and a spectrum are acquired from a detection end; the belonging interval is judged according to the impact energy value,if the impact energy value is located in a supervision enhancement interval, whether fault features happen to the spectrum is judged, if the fault features appear, whether a fault frequency exists iscalculated according to the spectrum, and if the fault frequency exists, the bearing is disintegrated; if the impact energy value is located in a device fault interval, whether temperature abnormality, noise abnormality, white noise and a high-frequency component appear is judged, if any of the above features appears, lubrication is carried out, if the temperature abnormality, the noise abnormality, the white noise and the high-frequency component do not disappear completely after the lubrication, whether a fault frequency exists is judged, and if the fault frequency exists, the bearing is disintegrated. As interval processing is carried out on the impact energy, various fault features appearing in the spectrum and the fault frequency are combined in different energy intervals to judge the bearing, the state of the bearing can be accurately judged, and the bearing can be disintegrated in a corresponding state.

Owner:LINGDONG NUCLEAR POWER +4

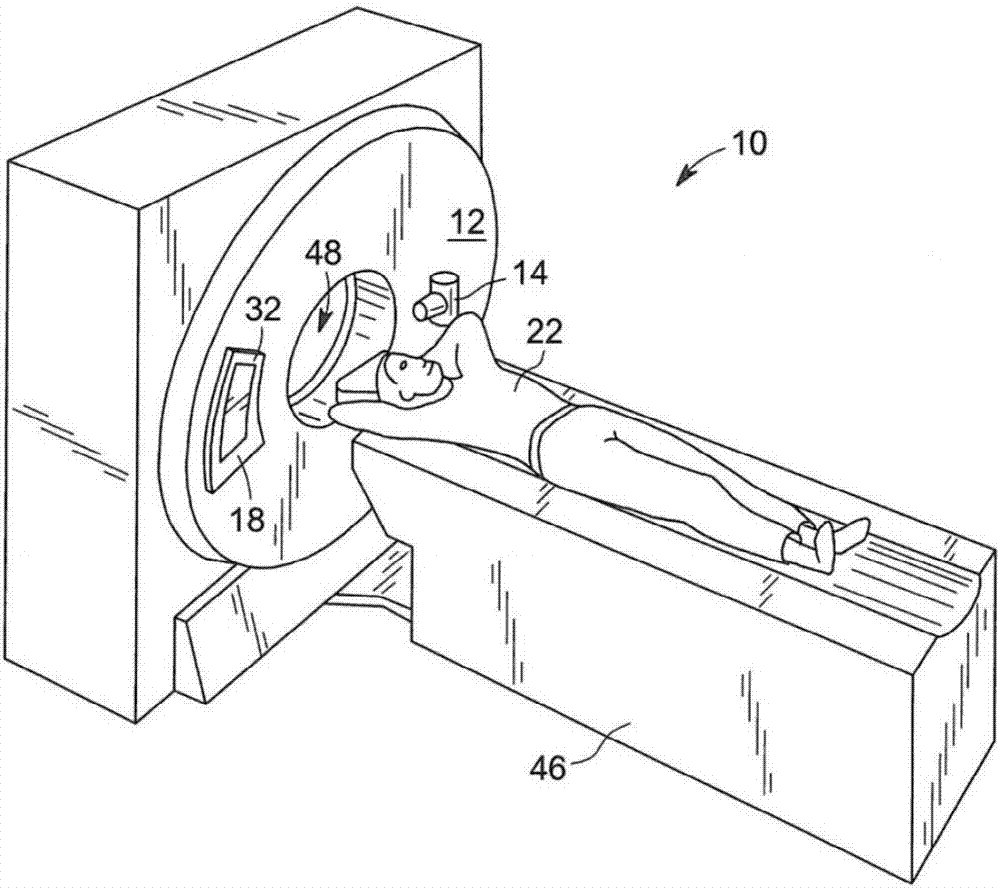

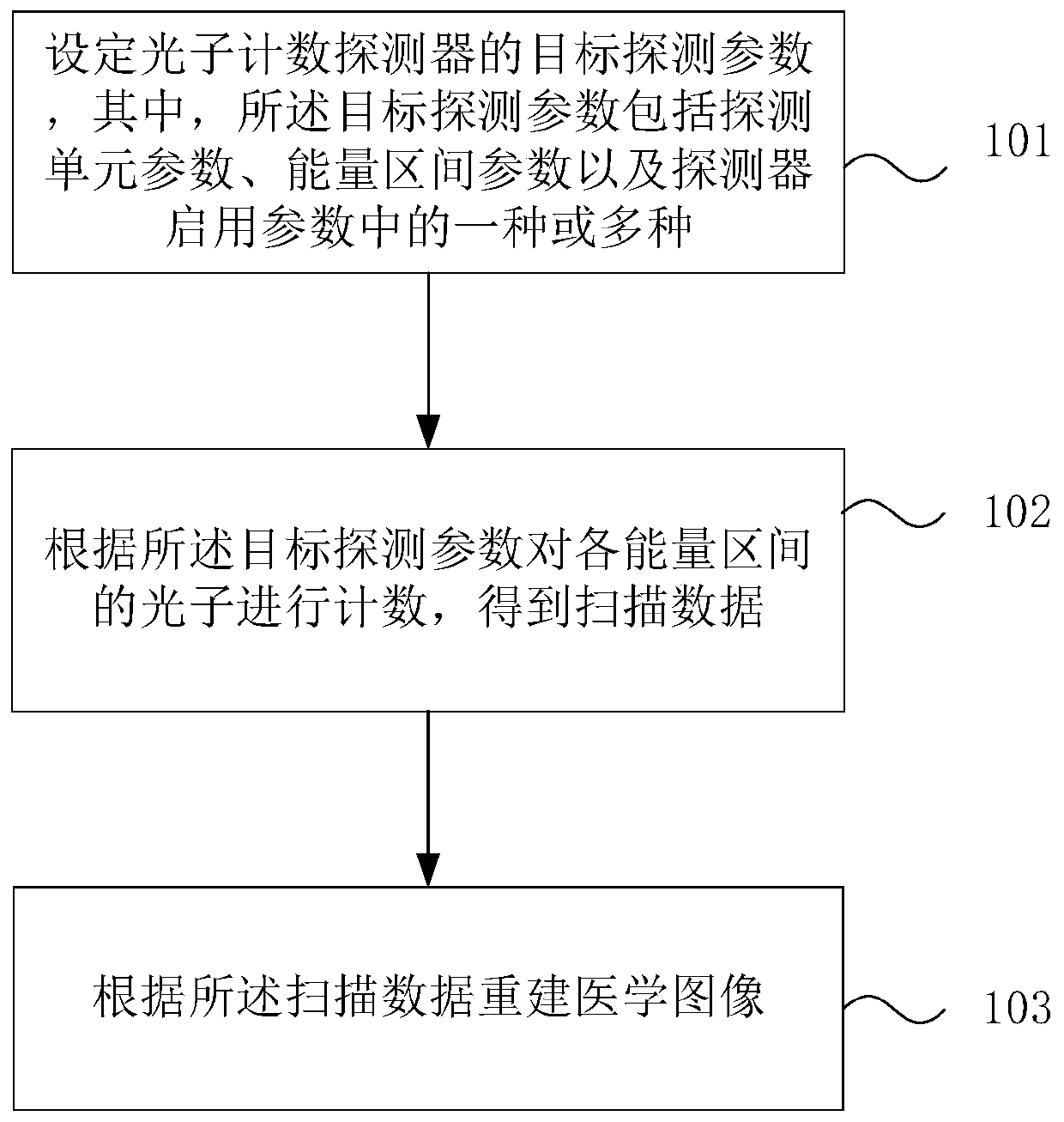

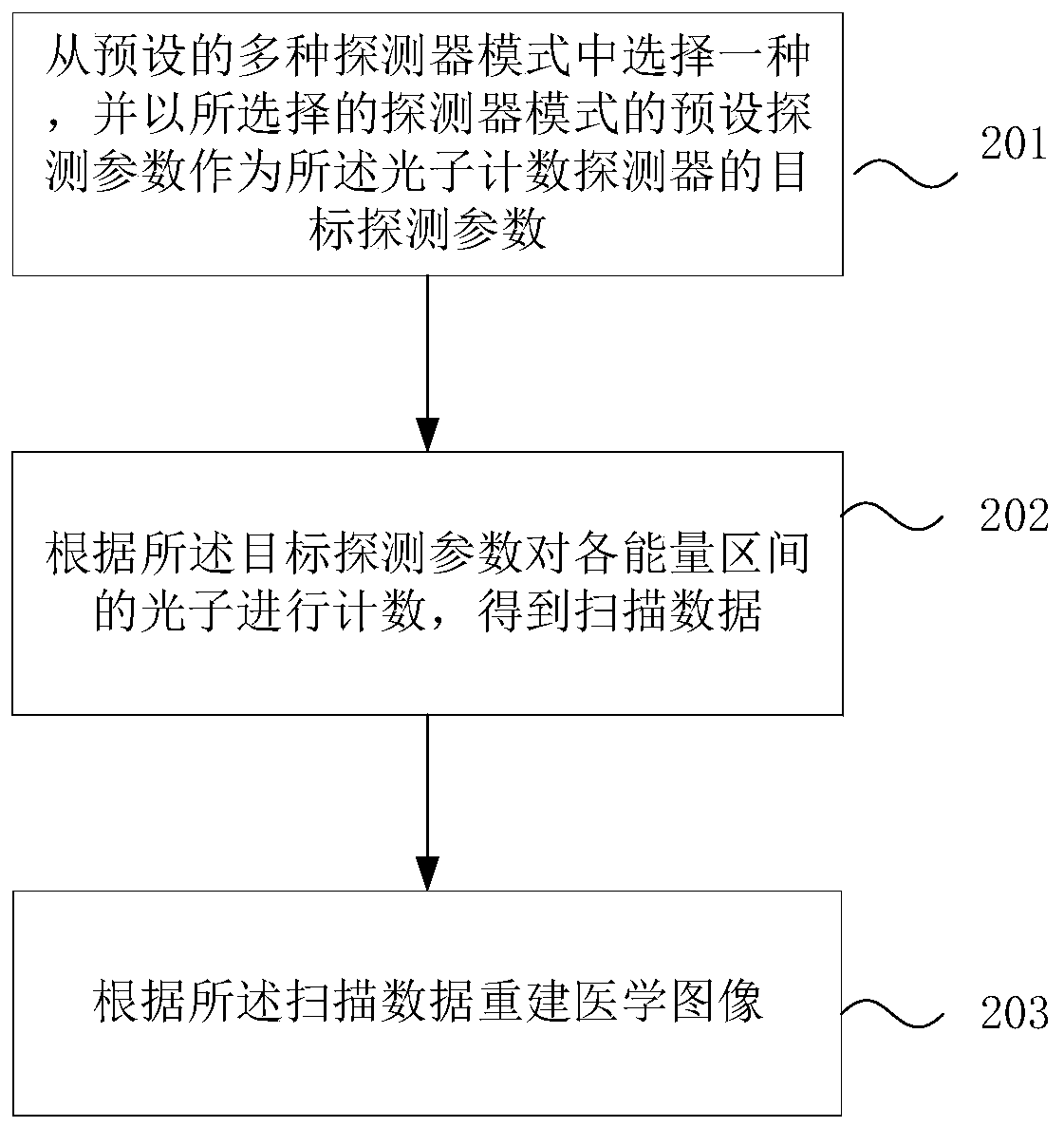

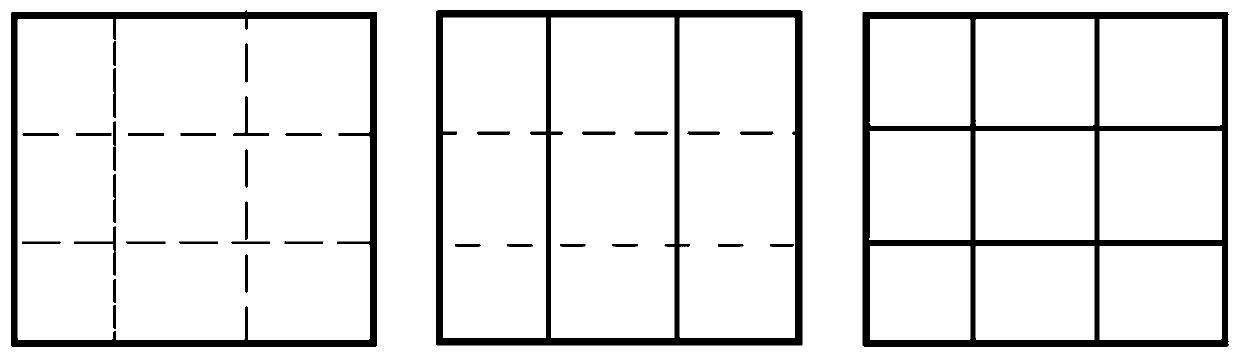

Medical imaging method and photon counting energy spectrum CT imaging device

PendingCN109924998AReduce the amount of scanned dataReduce data volumeComputerised tomographsTomographyBiological activationCell parameter

Embodiments of the invention disclose a medical imaging method and a photon counting energy spectrum CT imaging device. The method includes: setting a target detection parameter of a photon counting detector, wherein the target detection parameter includes one or more of a detection unit parameter, an energy interval parameter, and a detector activation parameter; counting photons in each energy interval according to the target detection parameter to obtain scan data; reconstructing a medical image according to the scan data. According to the technical scheme, the problems that the data size of photon counting energy spectrum CT is large and a data link design is difficult in a conventional solution, and the image data is reduced while the spatial resolution of the image cannot be ensuredare solved, detection parameters of the photon counting detector are set according to clinical needs, the actual clinical needs are met better, and the image data size is reduced while the spatial resolution of the image is ensured.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

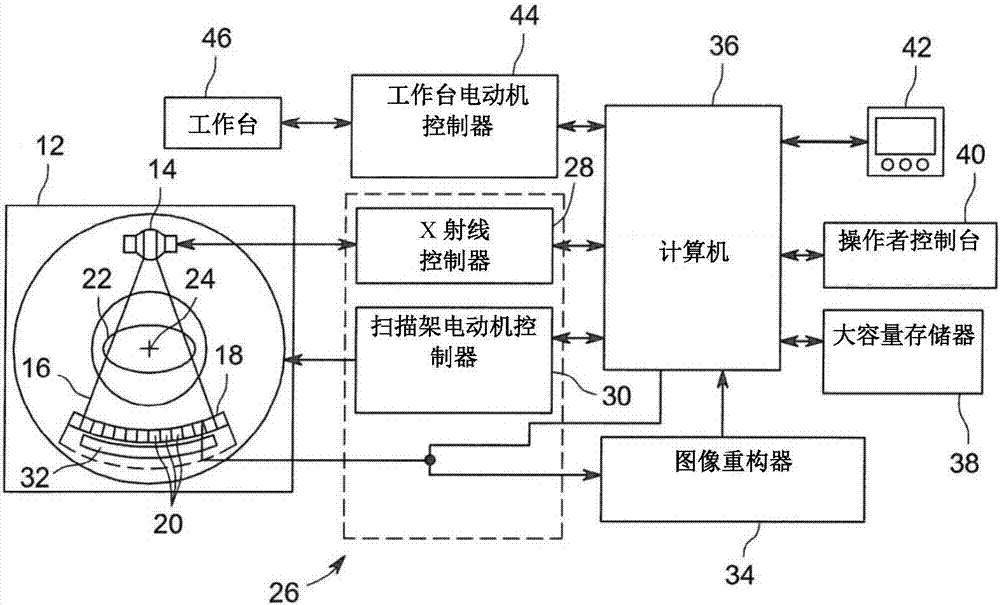

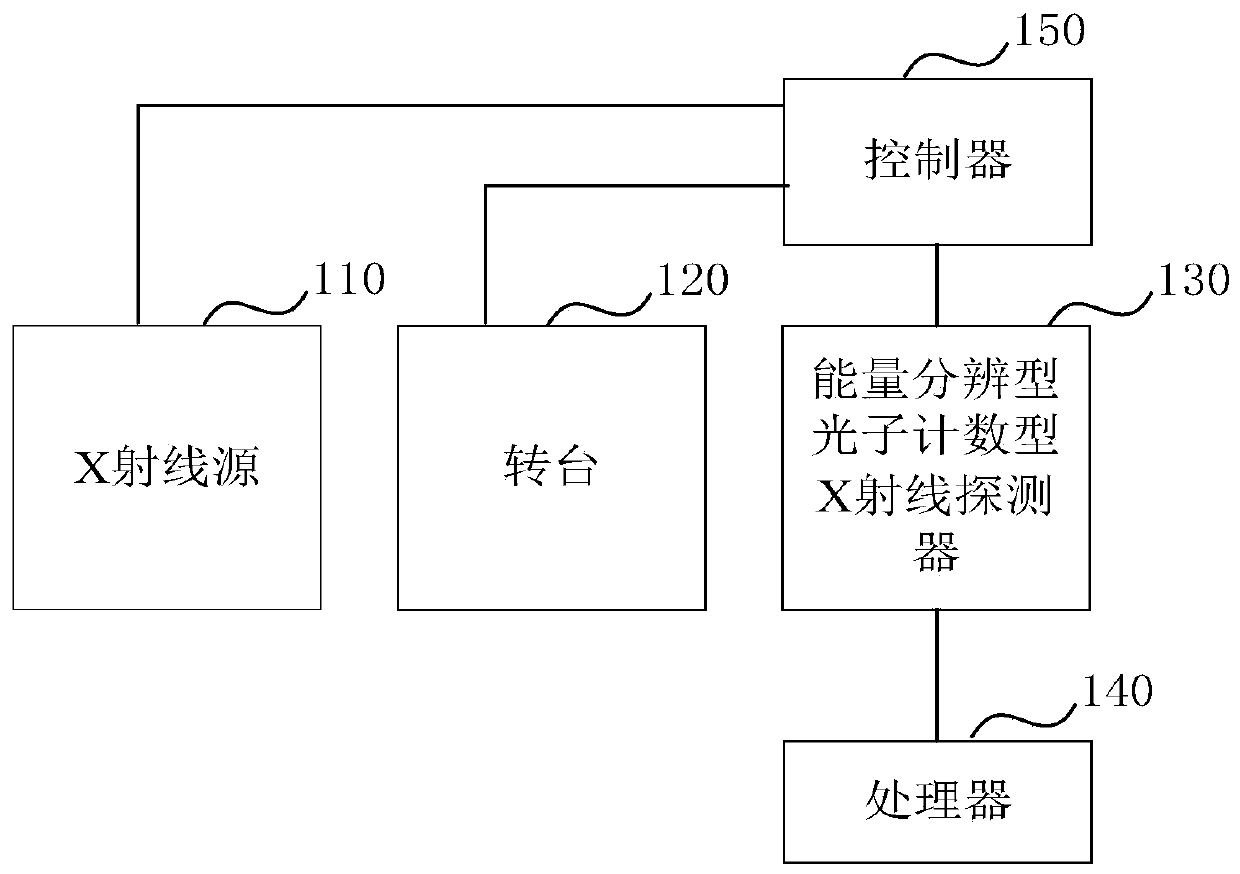

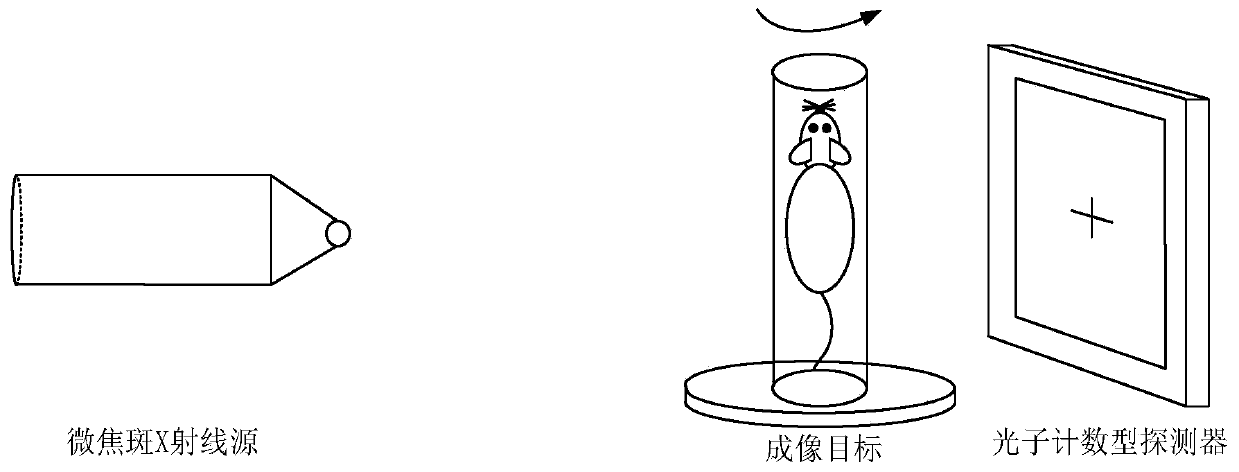

CT imaging system and CT imaging method

ActiveCN110090039AAvoid lostAvoid the problem of increasing the risk of radiation and increasing the difficulty of image registrationRadiation diagnostic image/data processingComputerised tomographsElectricityContrast level

The invention discloses a CT imaging system and a CT imaging method. The system includes: an X-ray source, a rotary table, an energy-resolving photon counting-type X-ray detector, and a processor, wherein the rotary table is configured to carry an imaging target, and carries the imaging target to rotate with a rotary table rotating shaft as a rotation center. The X-ray source is used for emittingX-rays to the imaging target; the energy-resolving photon counting-type X-ray detector is electrically connected to the processor for collecting the imaging targets passing through the X-rays, and theprojection data is sent to the processor in the projection data of the at least two energy intervals; the processor is configured to process the received projection data of the at least two energy intervals to generate the CT image of the imaging target. The technical scheme of the system achieves improving the contrast of the CT image and reducing the radiation risk.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

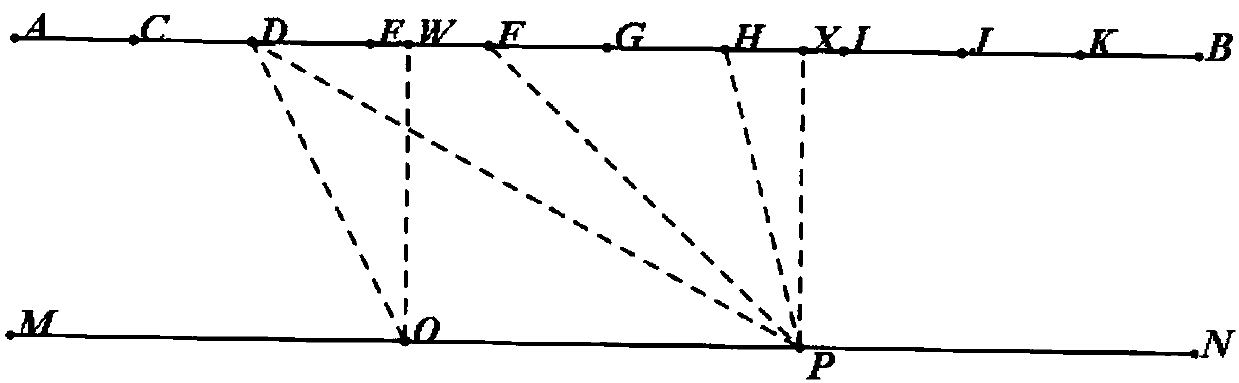

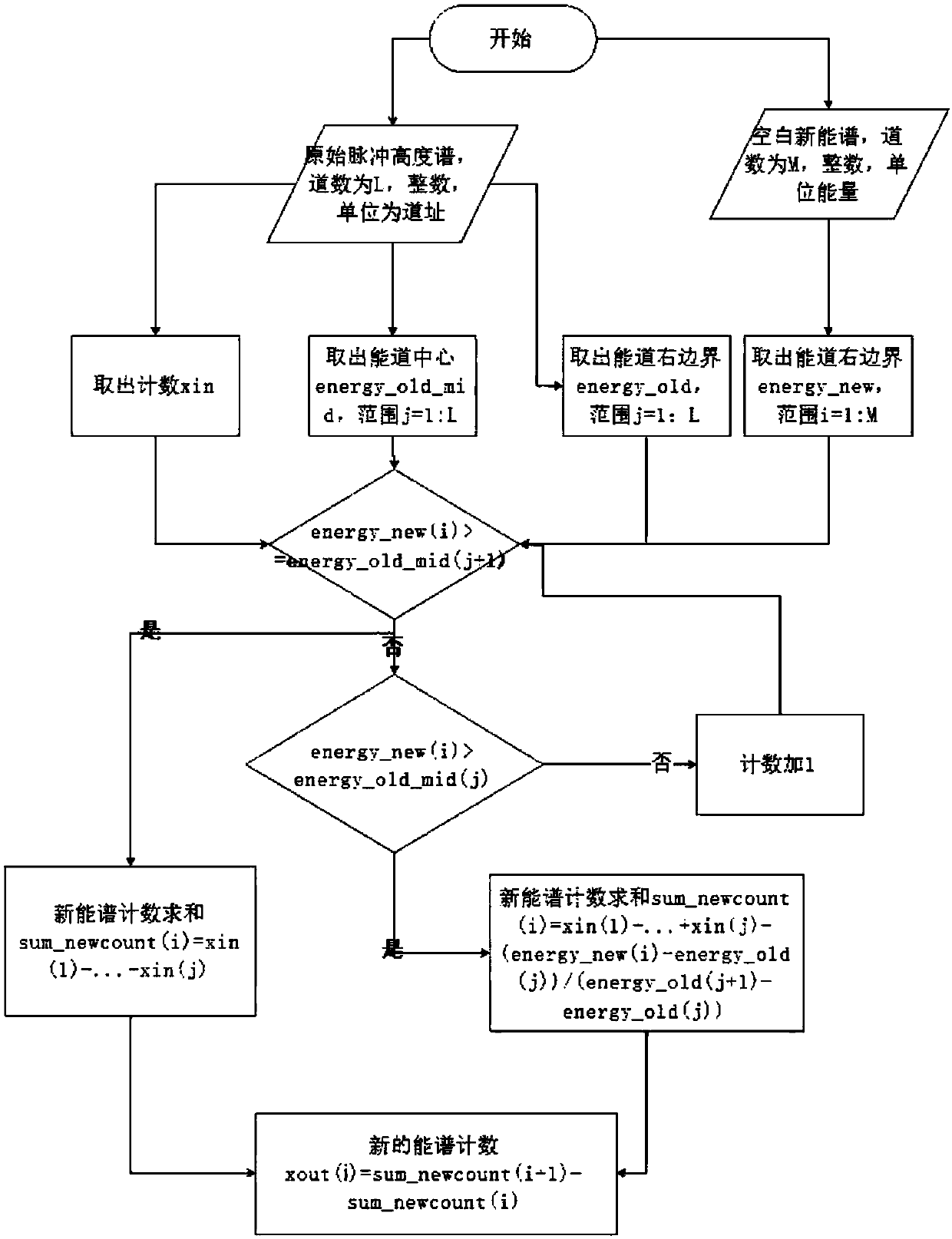

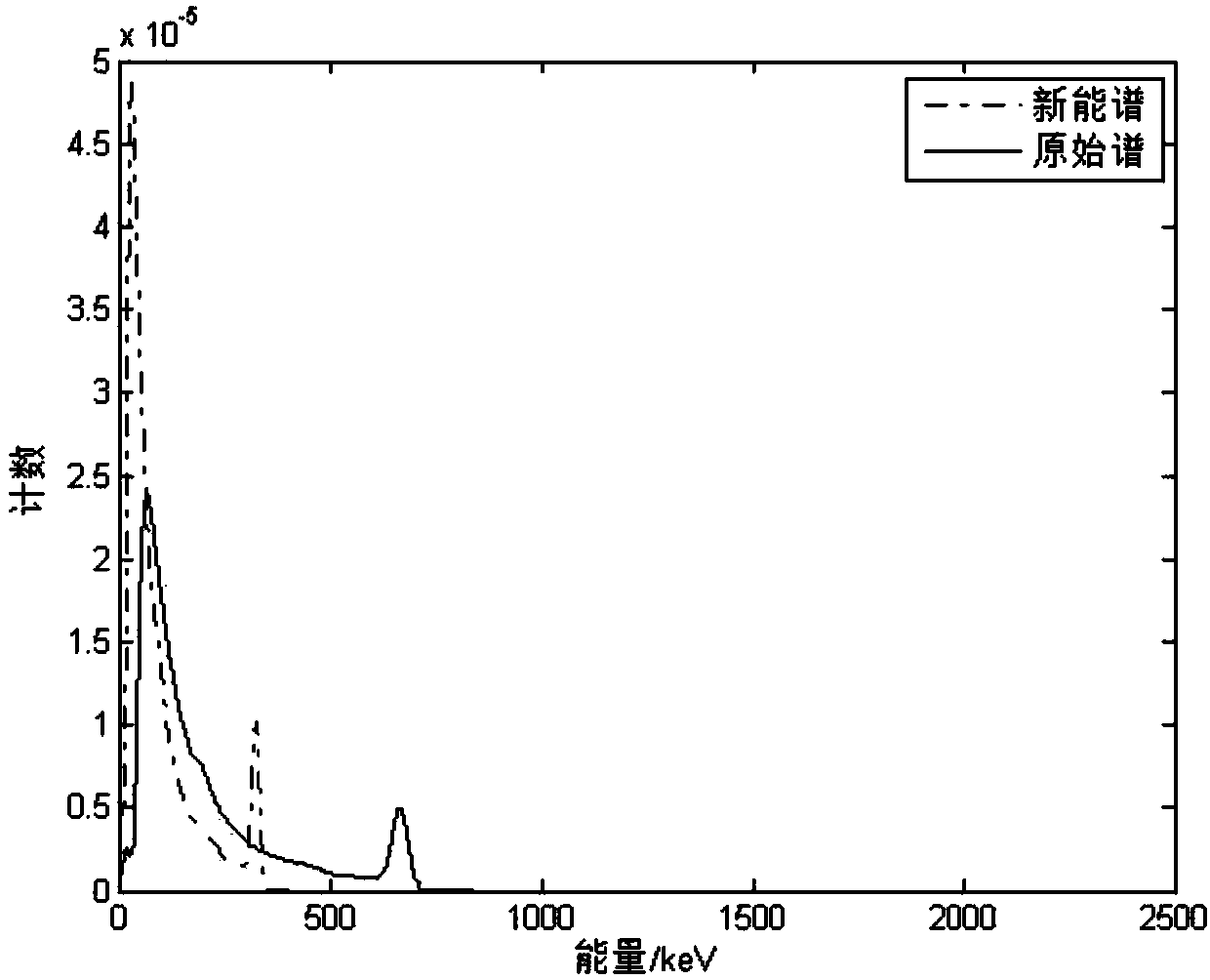

Energy channel counting redistribution process and method for gamma spectrum analysis

ActiveCN110082811AImprove analysis efficiencyEasy to analyzeX-ray spectral distribution measurementOriginal dataDeconvolution

The invention relates to an energy channel counting redistribution process and method for gamma spectrum analysis. The energy channel counting redistribution process and method for gamma spectrum analysis comprise the following steps of: determining two line segments, which are mutually parallel and equal in length, wherein the two line segments are respectively named AB and MN; MN represents an integer energy channel; AB represents a non-integer energy channel, and is original data; separating the AB line segment into multiple energy intervals, and selecting midpoints in the middle parts of the energy intervals, wherein both endpoints and midpoints of the various intervals are nodes; and the nodes are identified by letters; separating the MN line segment into multiple target intervals, and identifying the endpoints of the target intervals by letters; and, selecting the endpoint of the corresponding target interval, making a vertical line towards the line segment AB, identifying the pedal on the line segment AB by adopting a letter, obtaining the length ratio thereof in the energy channel according to the position, where the pedal is, and calculating energy channel integer countingof the target interval. Integer operation on a non-integer energy channel address is carried out; gamma spectrum analysis is conveniently carried out based on a deconvolution iterative algorithm of aresponse matrix; and the gamma spectrum analysis efficiency is increased.

Owner:CHINA INST FOR RADIATION PROTECTION

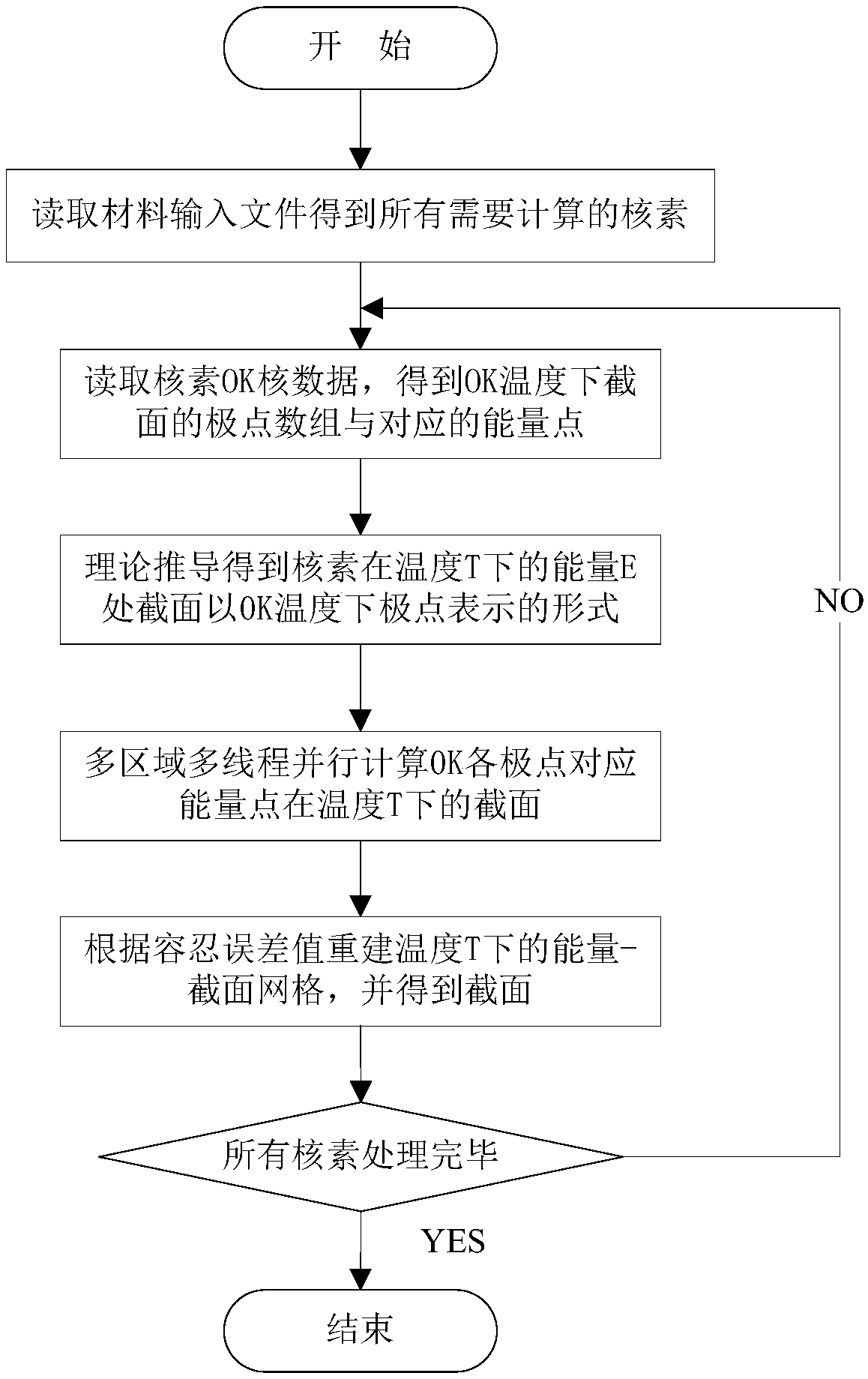

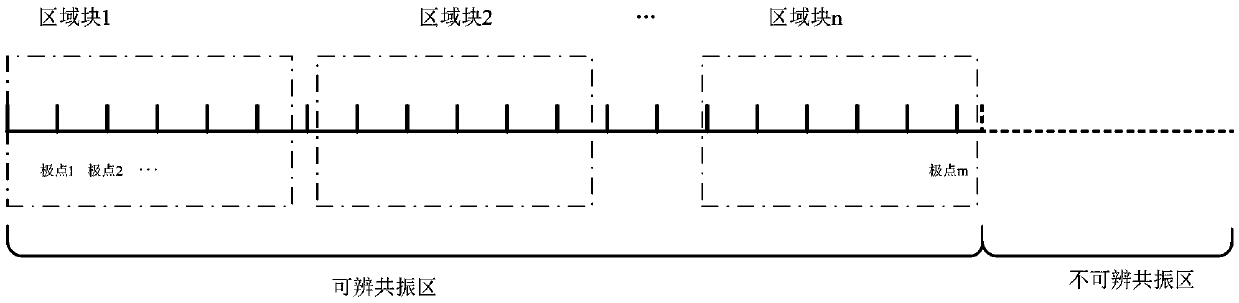

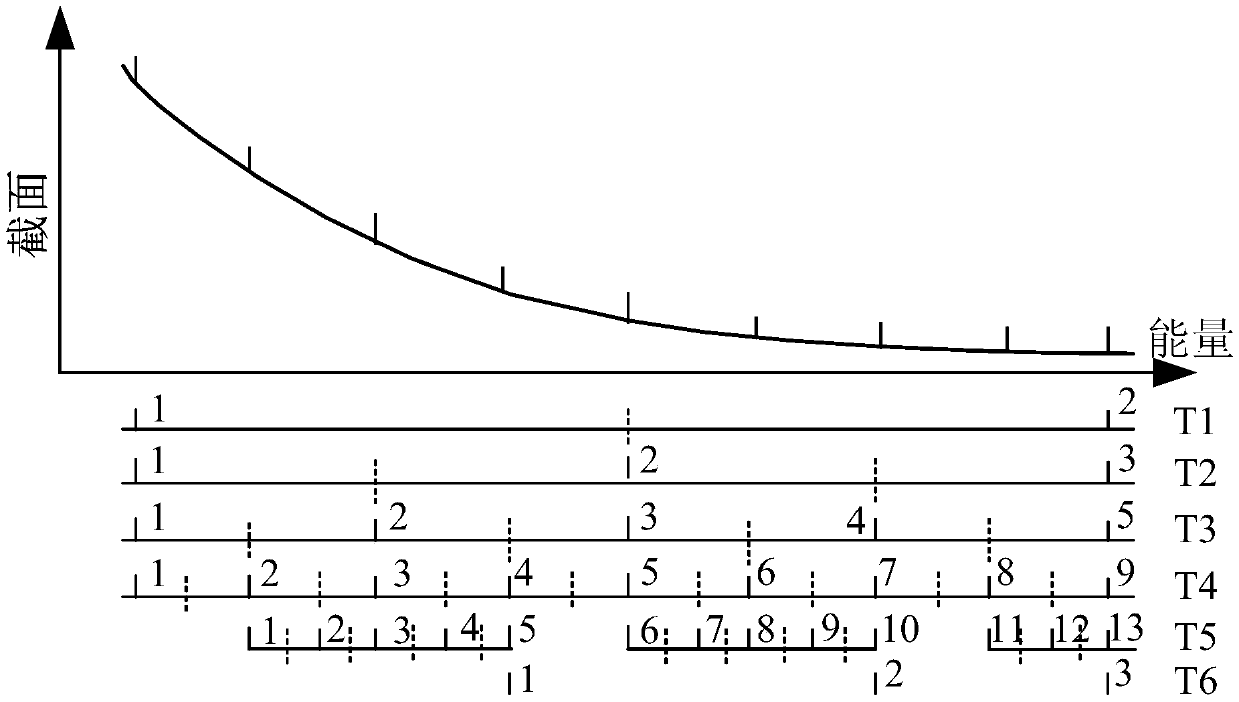

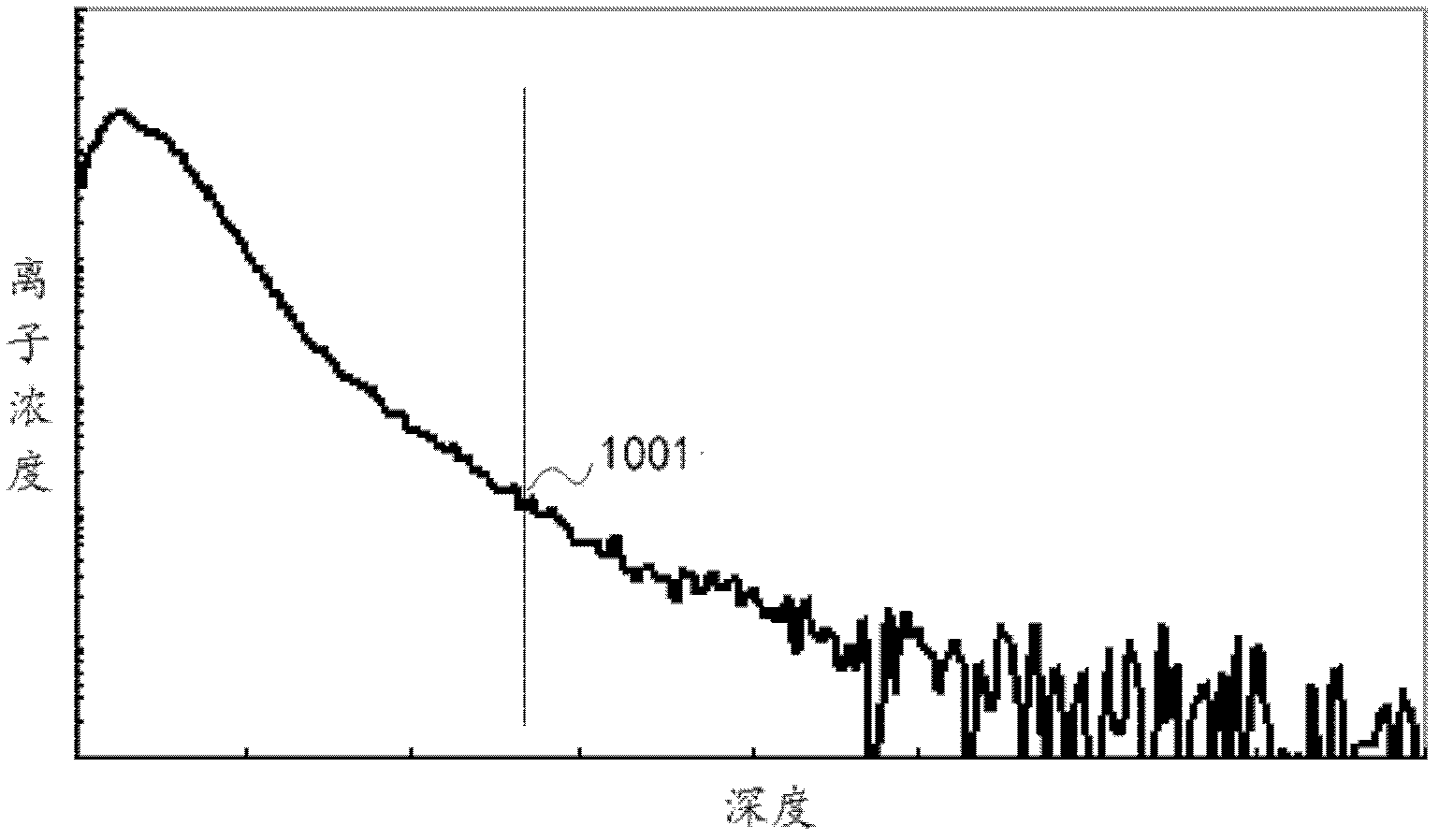

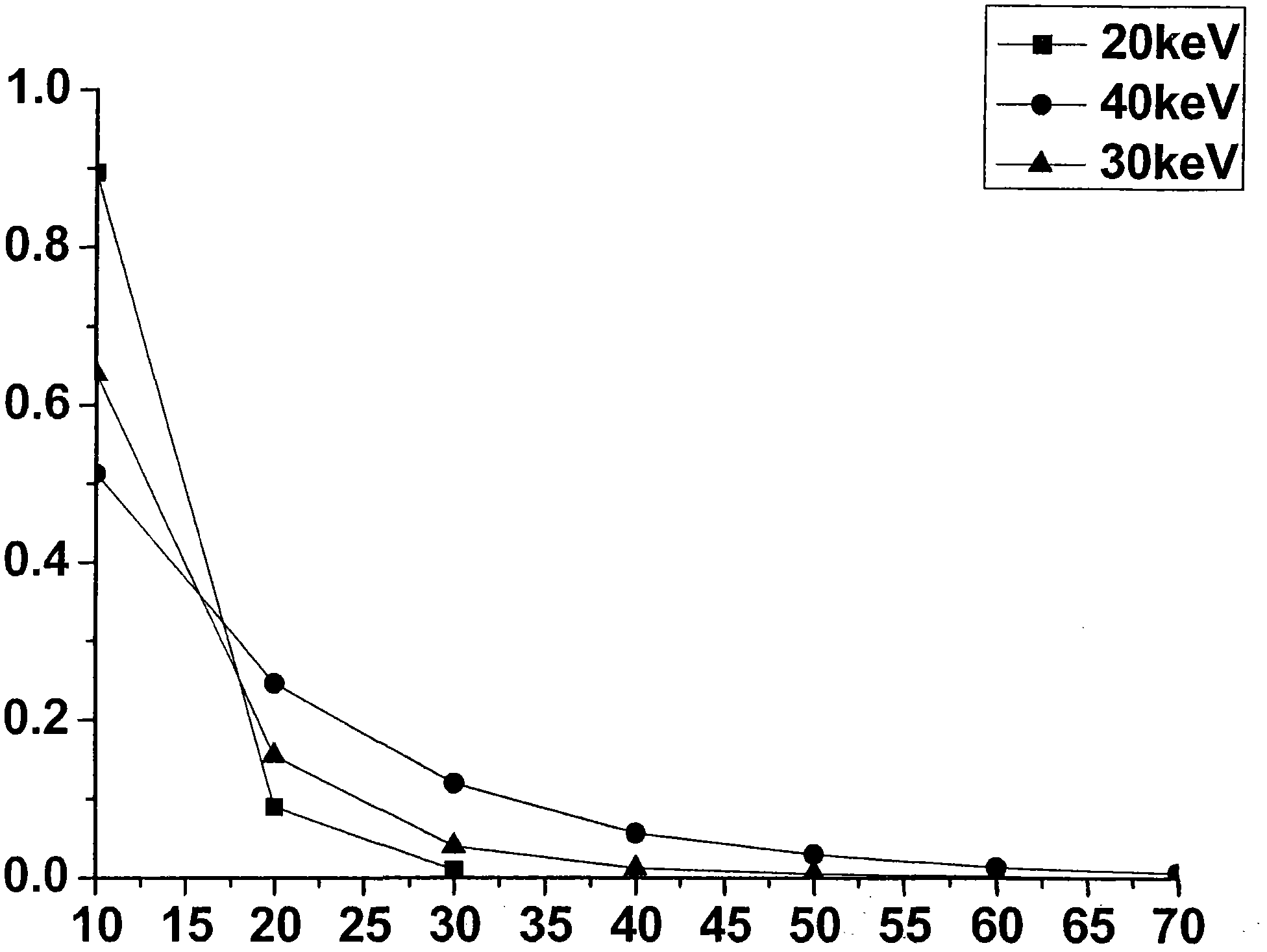

A Fast Nuclear Section Doppler Broadening Method

ActiveCN106405622BFast Multi-Temperature Section CalculationAccurate multi-temperature section calculationX/gamma/cosmic radiation measurmentNeutron radiation measurementArray data structureResonance

The invention discloses a rapid nuclear cross section Doppler broadening method. Firstly the pole array of nuclides under the 0K temperature is calculated, and the cross section of the nuclides under the temperature T is derived in the form of pole expression under energy, temperature, atomic weight and 0K temperature; and then pole corresponding energy points of a distinguishable resonance area are equally divided through the number of parallel computing units, threads are allocated to each equally divided area according to the energy level span of energy E, and each thread independently performs Doppler broadening computation so as to generate the nuclear cross selection under the temperature T. Ordering is performed according to different energy corresponding to the pole array so that the cross section value of the whole energy interval after broadening under the temperature T is obtained; and finally a broadened energy framework under the temperature T is reestablished according to the energy corresponding to the pole array and the cross section value and a specified tolerance error value and the corresponding nuclear cross section is obtained. The simplified pole nuclear cross section expression form and multi-area and multi-thread parallel computing are put forward so that the effect of rapid and accurate computation of multiple temperature cross sections can be achieved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Method of controlling distribution gradient of filled elements in soaking and filling of plasm

The invention discloses a method of controlling distribution gradient of filled elements in soaking and filling of plasm and belongs to the technical field of semi-conductor manufacture. According to the method of controlling the distribution gradient of the filled elements in soaking and filling of the plasm, filling and mixing of ions are performed in a manner of multiple kinds of energy filling. The multiple kinds of energy relate to multiple kinds of energy in an energy interval where the lowest energy the highest energy exists. The lowest energy is the minimum energy for achieving that mixed elements are filled but do not deposit on the surface of a silicon substrate. The highest energy is the maximum filling energy which can meet filling junction depth. With the method of controlling the distribution gradient of the filled elements in soaking and filling of the plasm, condensation of the mixed ions is distributed along the depth and in compliance with Gaussian distribution and condensation of the filled elements is abruptly distributed on a PN place.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

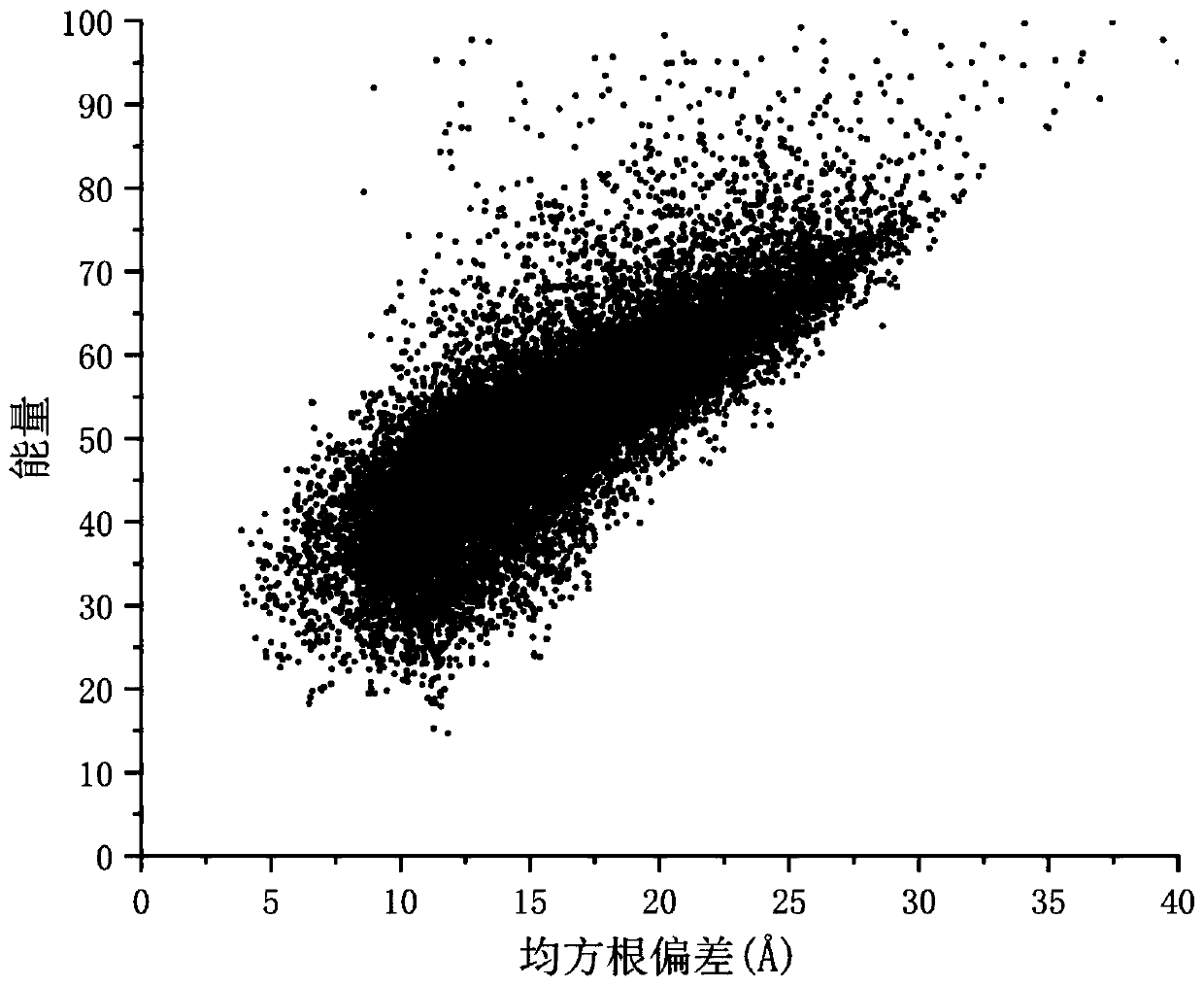

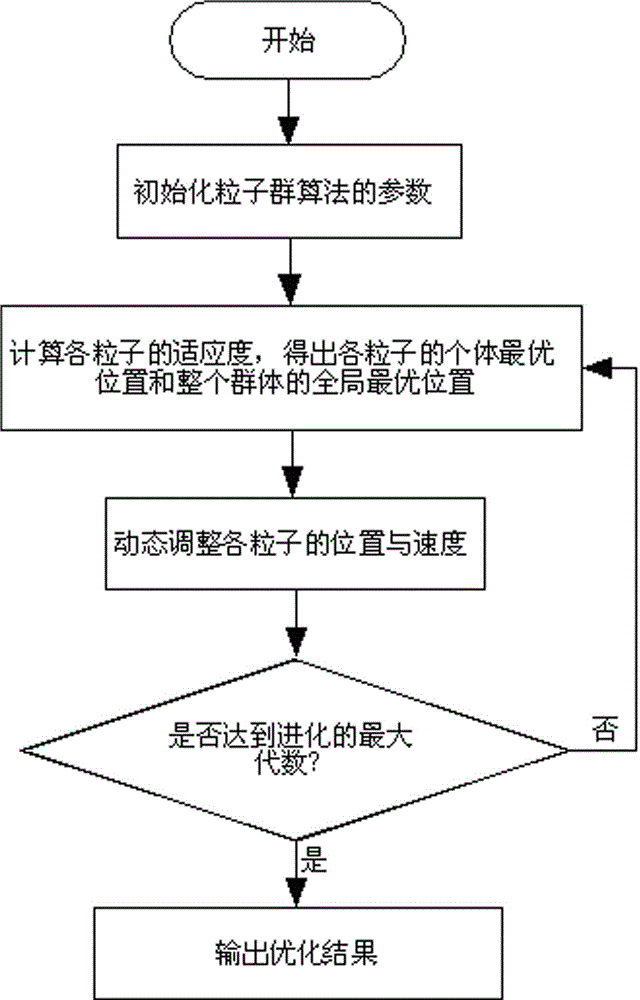

Protein structure prediction method based on double-layer biased search

ActiveCN110634531AIncrease diversityImprove sampling efficiencyInstrumentsMolecular structuresSpatial structureAlgorithm

The invention relates to a protein structure prediction method based on double-layer biased search. The method is characterized by under a genetic algorithm framework, firstly, initializing a population, and distributing the population to different energy intervals according to conformation energy; and then, selecting a parent generation and eliminating the conformation in a biased manner according to an energy and space structure difference double-layer selection index. A problem of an inaccurate energy function can be relieved, the conformation with a more reasonable structure can be searched according to biased sampling, and prediction precision is improved while sampling efficiency is increased. The invention provides the protein structure prediction method based on the double-layer biased search and the method is high in prediction precision.

Owner:ZHEJIANG UNIV OF TECH

Optimizing the distribution of electrical energy

Owner:SIEMENS AG

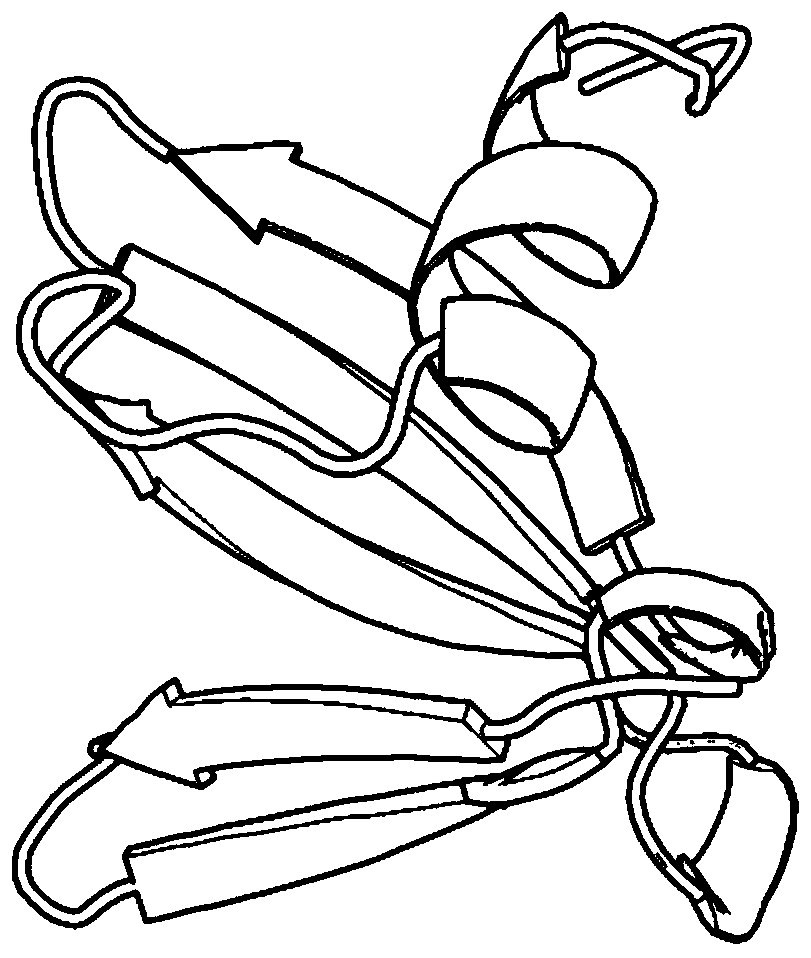

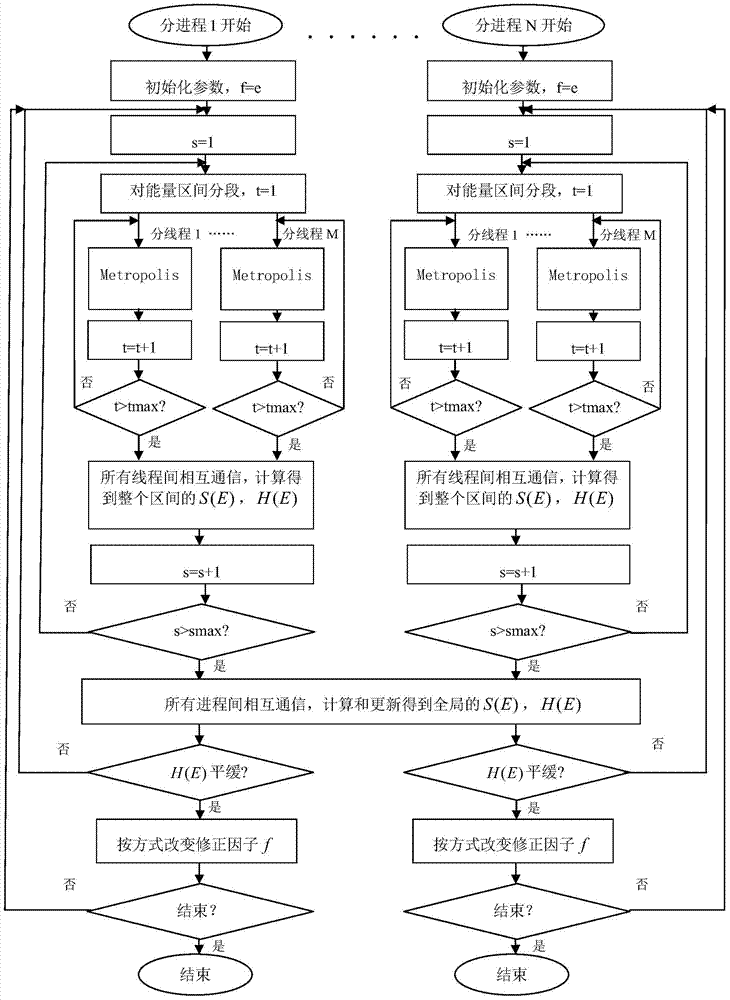

An Efficient Stochastic Simulation Method for Protein Thermodynamic Analysis Based on Hybrid Parallel Method

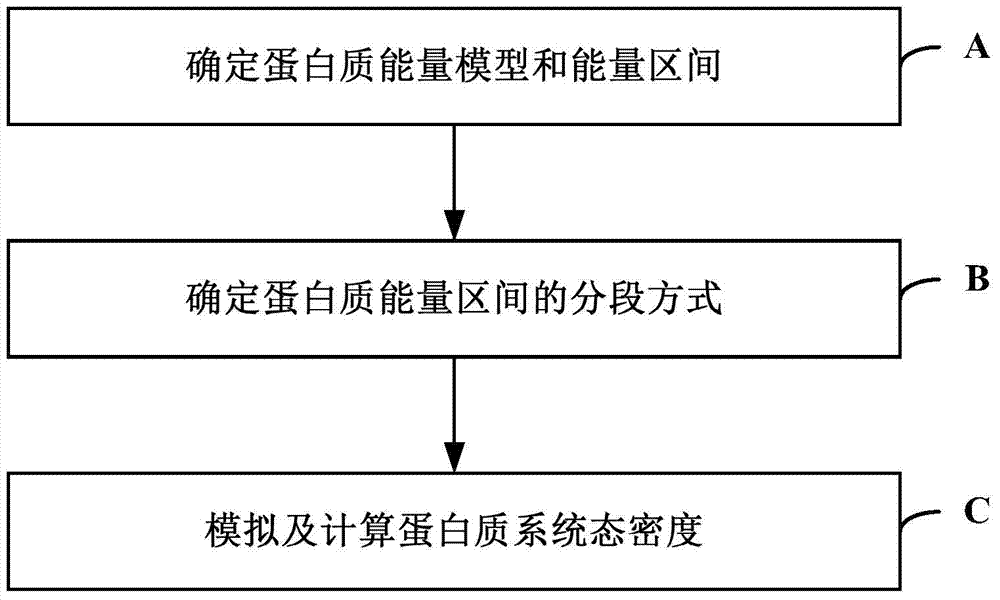

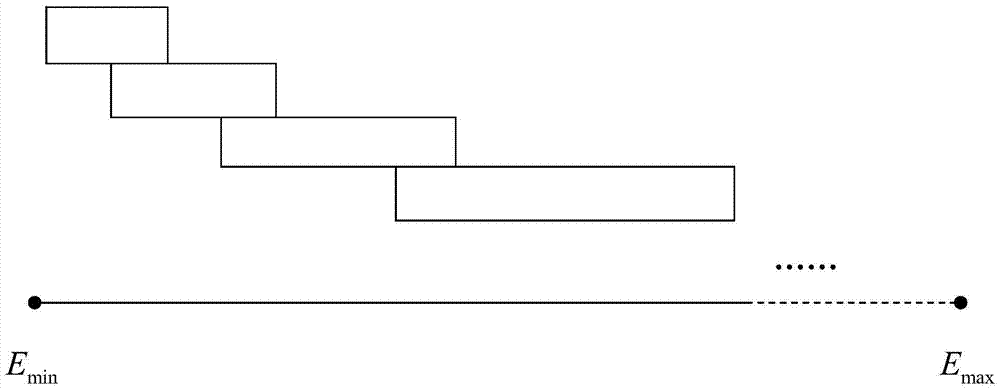

ActiveCN103729577BEfficient analysisImprove calculation accuracySpecial data processing applicationsHybrid proteinProtein thermodynamics

The invention relates to the technical field of biological information analysis, and provides an efficient stochastic simulation method for protein thermodynamic analysis based on a hybrid parallel method, comprising: step A: determining a protein energy model and an energy interval; step B: determining the fraction of the protein energy interval Section method; Step C: Simulate and calculate the density of states of the protein system. By using the method provided by the present invention, the whole thermodynamic process of protein folding can be efficiently analyzed and studied, and then the protein folding process can be explored and studied.

Owner:深圳市弘志拓新创业投资企业(有限合伙)

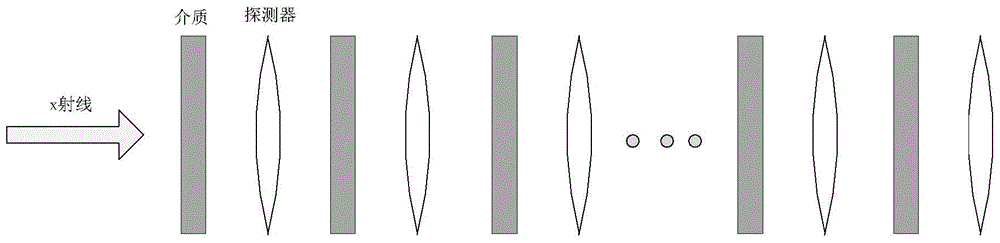

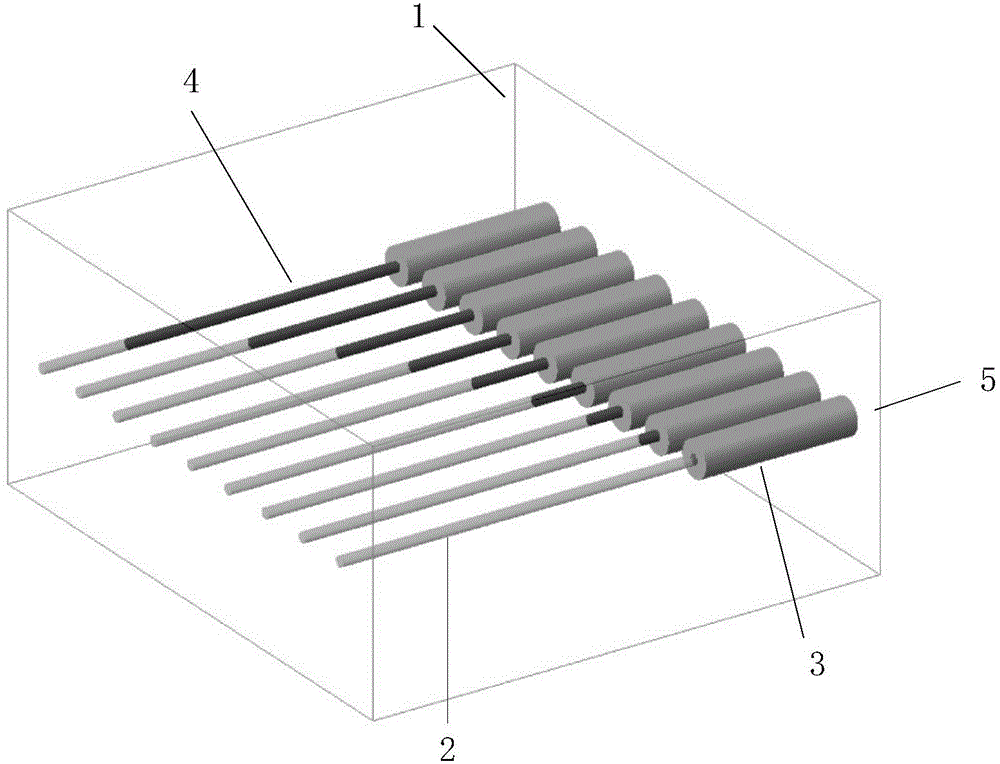

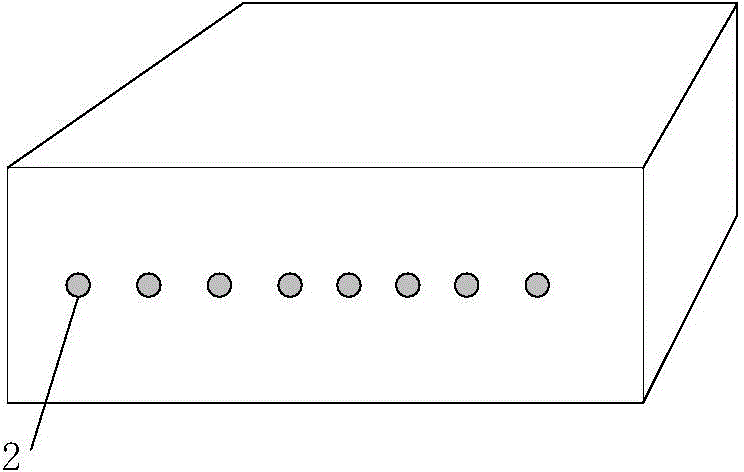

Apparatus and method of absorber array for measuring high flux X-ray power spectrum

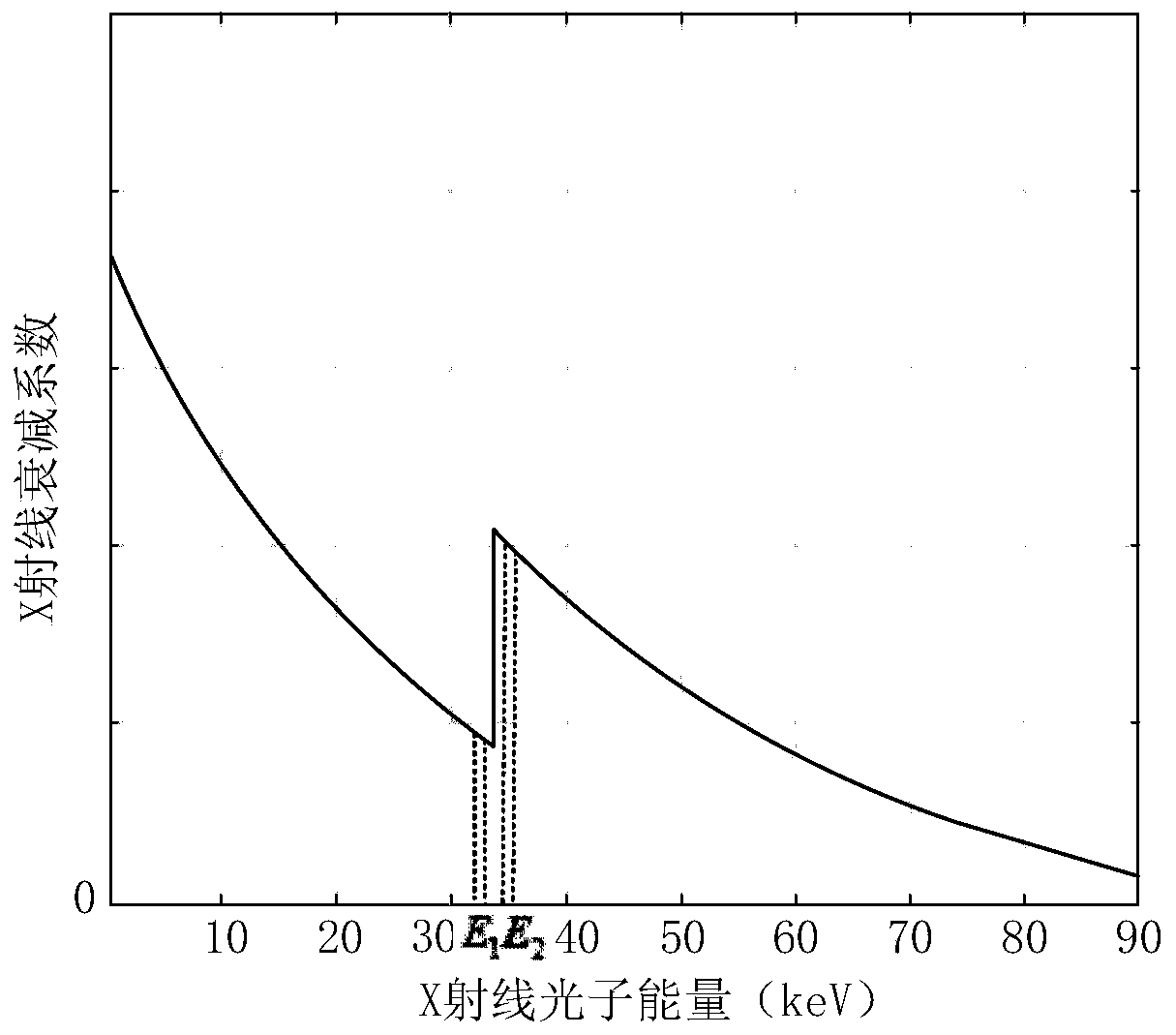

InactiveCN105425273AIngenious structureReduce volumeX-ray spectral distribution measurementPhotovoltaic detectorsHigh flux

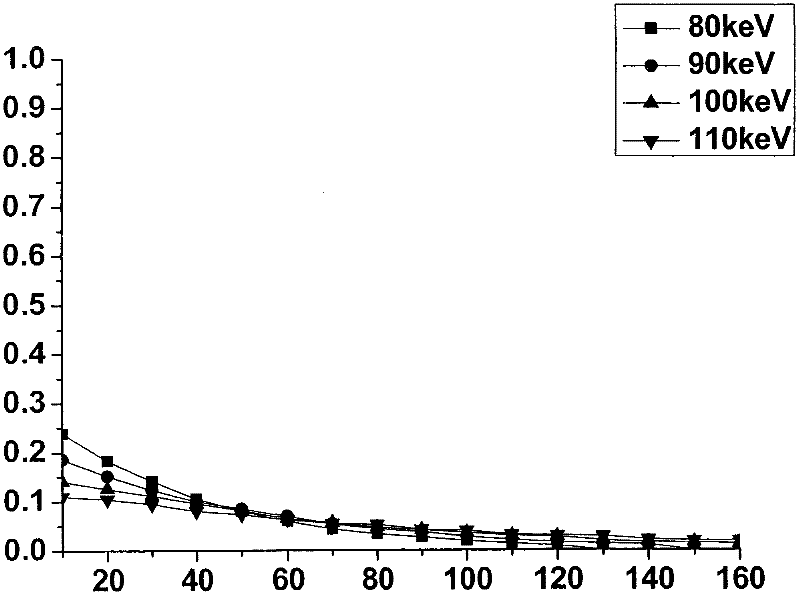

The invention discloses an apparatus and method of an absorber array for measuring high flux X-ray power spectrum. The apparatus includes a lead collimating body, absorber arrays and photoelectric detectors. A row of holes is disposed inside the lead collimating body. The front portion of each hole is a collimating hole used for holding one corresponding absorber array. The rear portion of each hole is a photoelectric detector containing hole used for containing one corresponding photoelectric detector. The collimating holes and the photoelectric detector containing holes are coaxial and connected with each other, but are different in diameter. The absorber arrays and the photoelectric detectors are arranged next to each other. X rays pass through the collimating holes and also are partially attenuated by the built-in absorber arrays, and outgoing X rays are detected by the photoelectric detectors. The collimating holes, absorbers and the detectors are installed in the same body, the adopted equal energy interval design principle enables a group of measured data to be discrete and to less affect each other, and therefore the spectrum unfolding is more accurate.

Owner:UNIV OF SCI & TECH OF CHINA

Gas radiation detector and radiation imaging system

ActiveCN102183776BRaise demand limit for source strengthLow costX/gamma/cosmic radiation measurmentRadiation imagingDual energy

Owner:NUCTECH CO LTD +1

Method for characterizing test sample

PendingCN114216917AAchieving precise characterizationOptimizing Process ParametersMaterial analysis by transmitting radiationTest sampleImage resolution

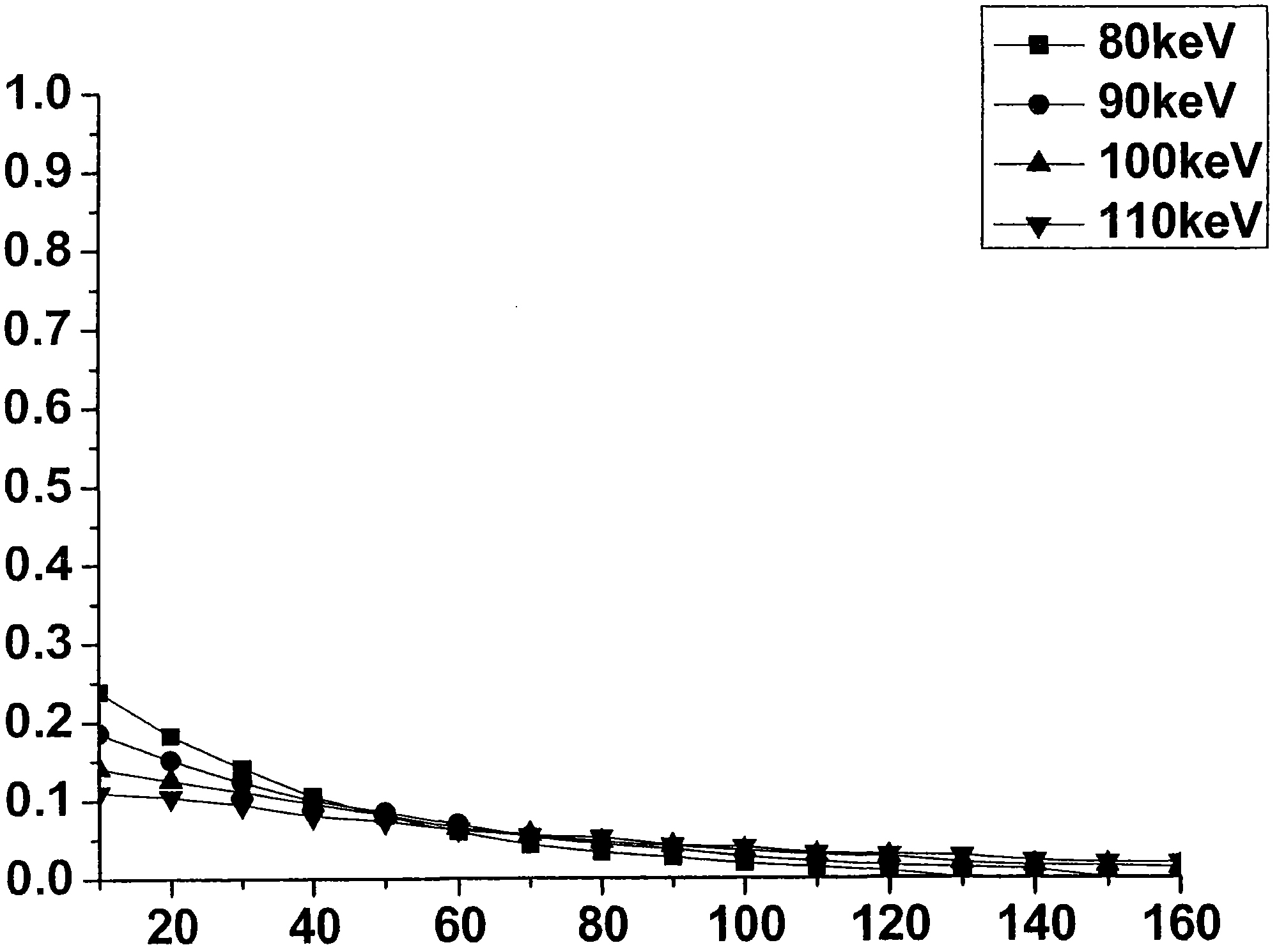

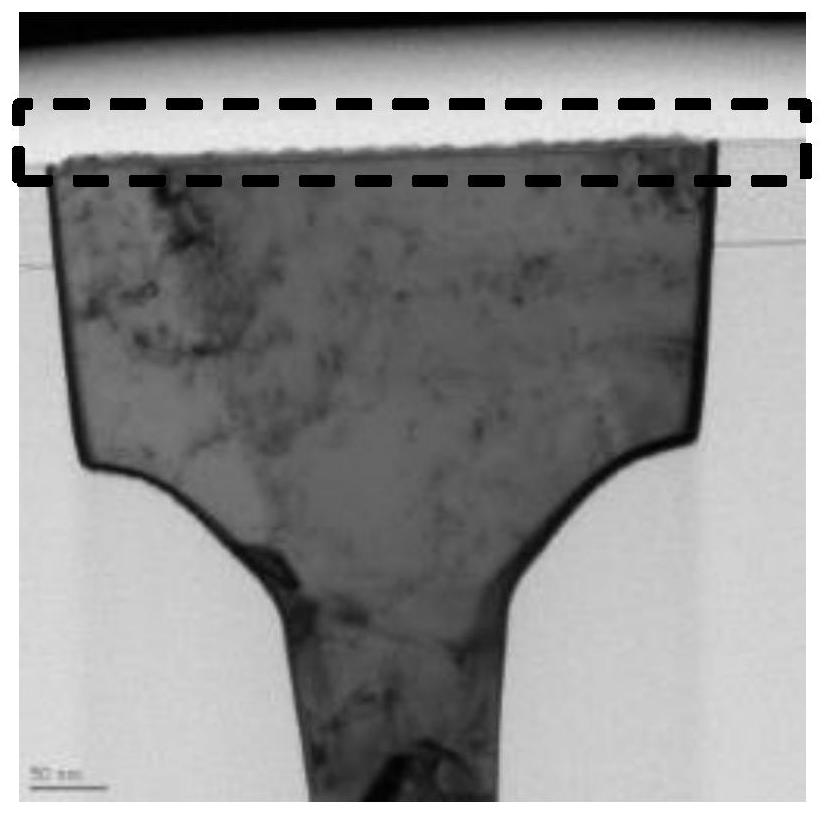

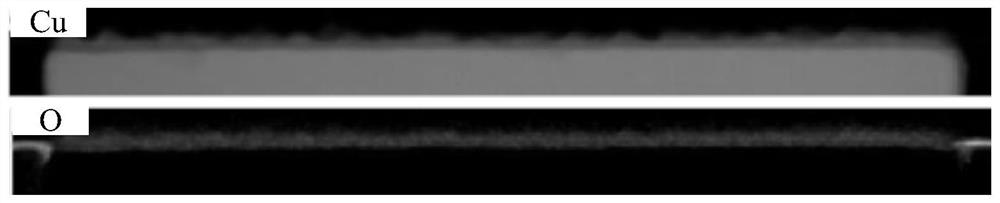

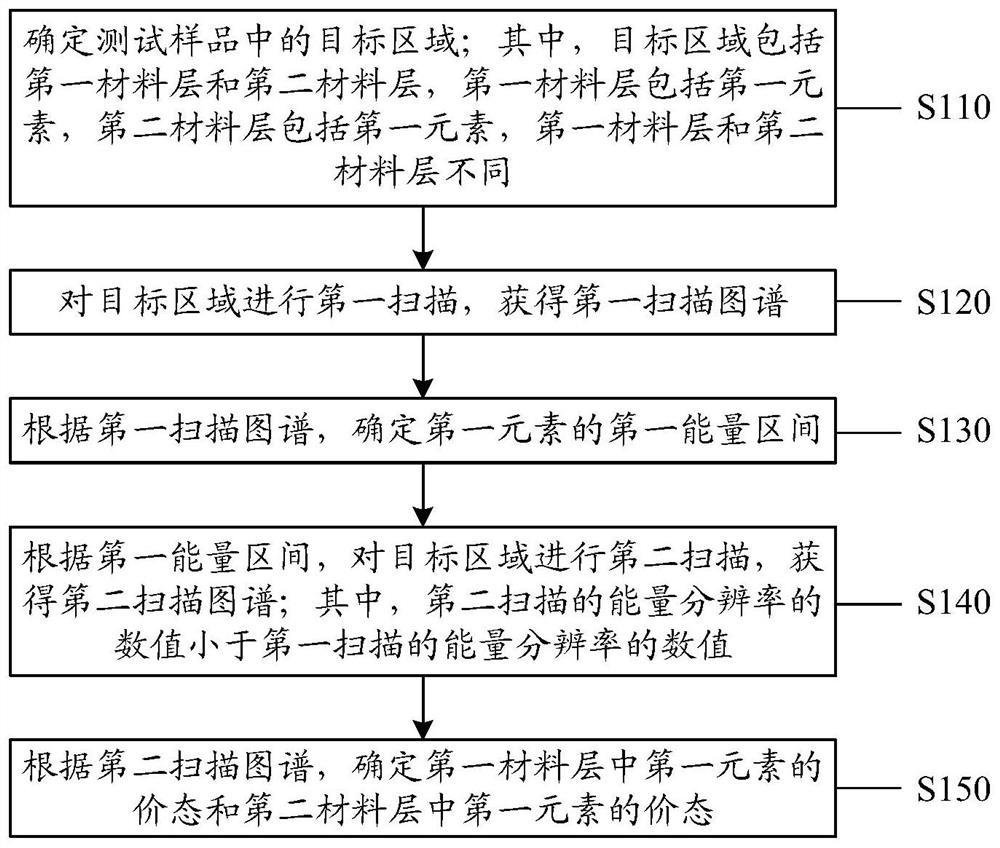

The embodiment of the invention discloses a characterization method of a test sample. The characterization method comprises the following steps: determining a target area in the test sample; wherein the target area comprises a first material layer and a second material layer, the first material layer comprises a first element, the second material layer comprises the first element, and the first material layer is different from the second material layer; performing first scanning on the target area to obtain a first scanning graph; determining a first energy interval of the first element according to the first scanning graph; performing second scanning on the target area according to the first energy interval to obtain a second scanning graph; wherein the numerical value of the energy resolution of the second scan is smaller than the numerical value of the energy resolution of the first scan; and determining the valence state of the first element in the first material layer and the valence state of the first element in the second material layer according to the second scanning map.

Owner:YANGTZE MEMORY TECH CO LTD

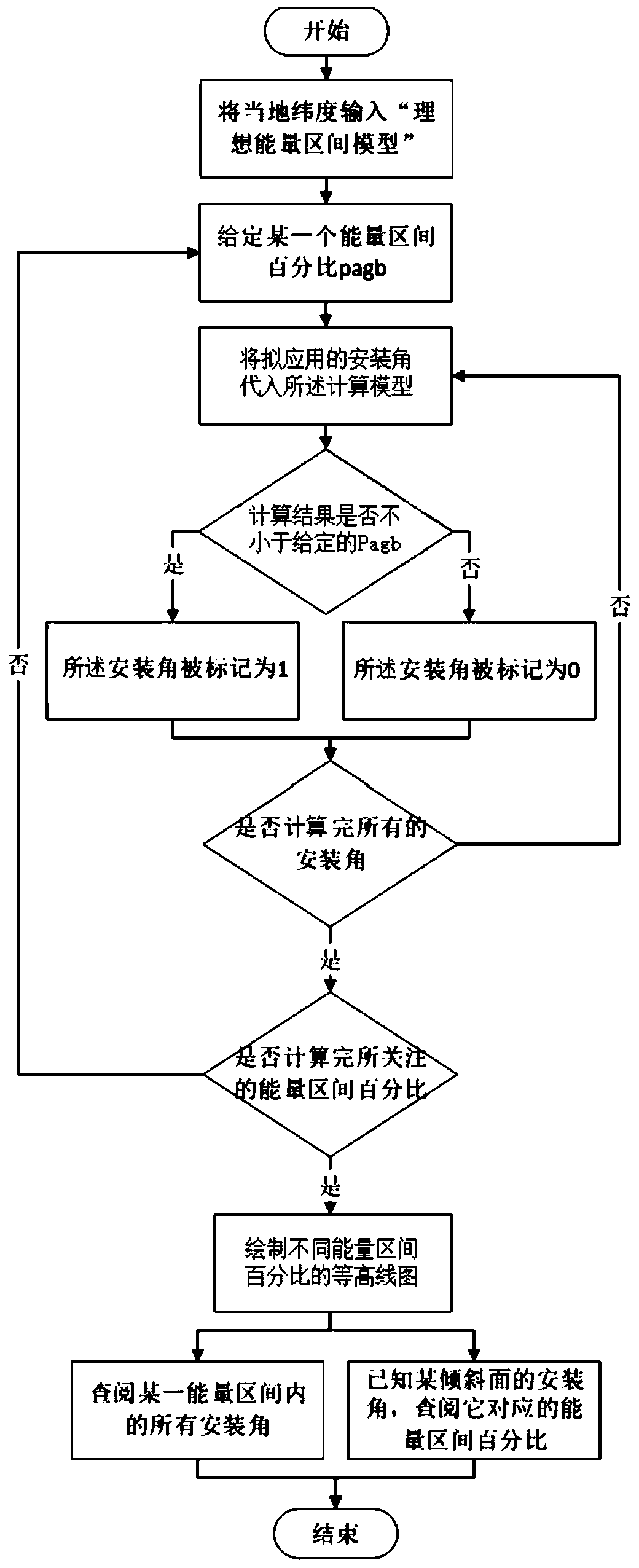

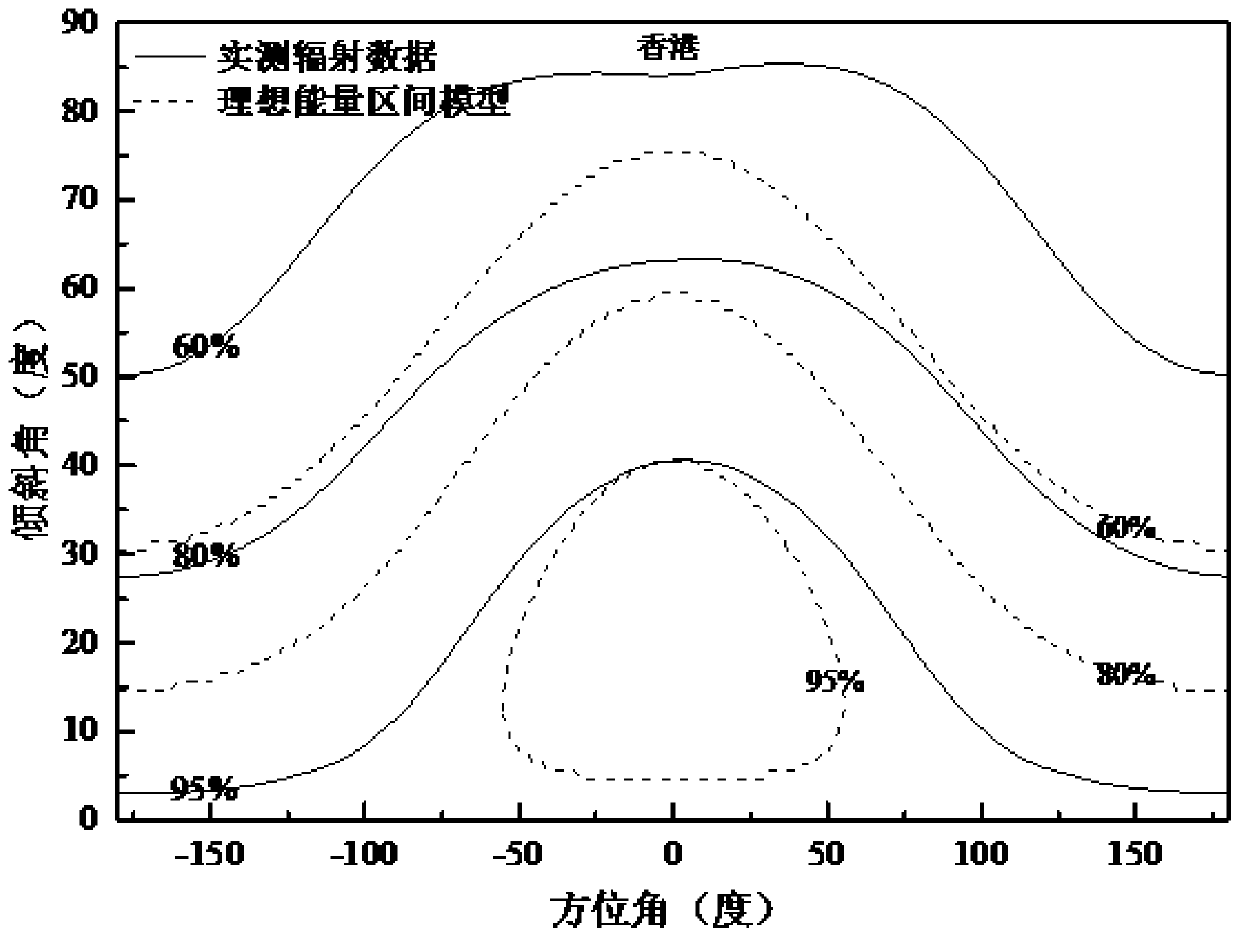

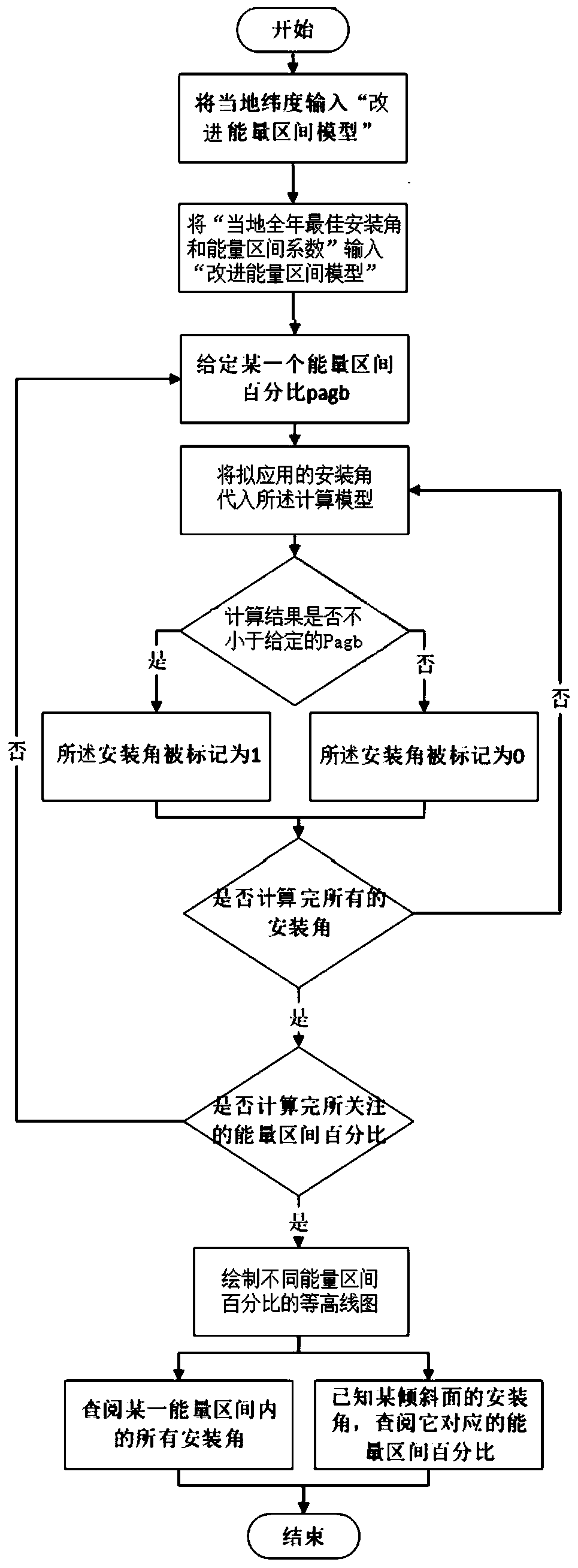

A method of calculating energy interval of photovoltaic module

PendingCN110083928AAvoid testingReduce measurementData processing applicationsDesign optimisation/simulationSpecific modelLatitude

The invention discloses a method for calculating an energy interval of a photovoltaic module. The method is characterized in that in combination with the local latitude of a to-be-installed photovoltaic module, all installation angles to be applied are sequentially substituted into a calculation model, whether the calculation result of the calculation model is not smaller than a given energy interval percentage is judged, and the installation angles meeting the judgment condition are included in an energy interval. The invention further provides three specific models, namely an ideal energy interval model, an improved energy interval model and a single-parameter energy interval model, so as to adapt to known conditions or conditions of various regions with different requirements. The method for an energy interval of a photovoltaic module has the advantages of few related variables, simplicity, rapidness and high accuracy, does not need to use local actual radiation quantity as input, omits long-time radiation data measurement and complex formula analysis and programming simulation, has great practical significance for rapid design or acceptance of photovoltaic module installation,and is particularly suitable for regions lack of meteorological data.

Owner:SHANGHAI JIAO TONG UNIV +1

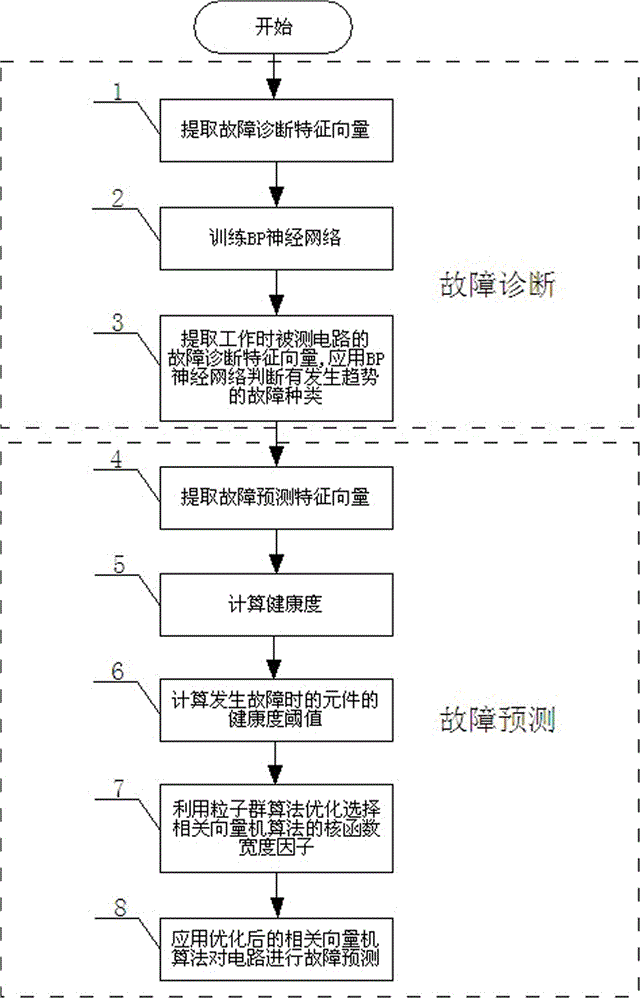

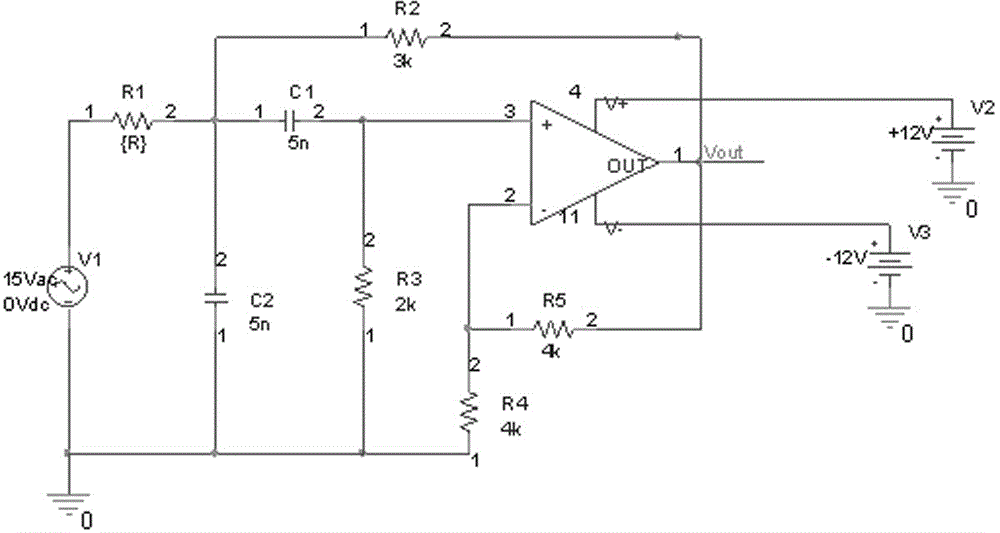

A Fault Prediction Method for Analog Circuits

ActiveCN103824135BEasy extractionSimple calculationAnalog circuit testingForecastingCapacitanceCircuit under test

A fault prediction method for an analog circuit, comprising the following steps: performing Monte Carlo analysis on each component of the analog circuit within a fault-free interval and extracting the energy of each frequency band signal; normalizing the extracted frequency band signal energy to obtain a feature vector; training BP Neural network; determine the types of faults that have a tendency to occur; extract the fault prediction feature vector when the component is at the initial value; extract the fault prediction feature vector when the circuit under test is working; calculate the cosine angle distance to characterize the health of the component; calculate the component when it fails The threshold value of the health degree; optimize the selection of the kernel function width factor of the correlation vector machine algorithm; perform fault prediction on the analog circuit. The present invention can be used in both real-time systems and non-real-time systems; it can predict the faults of linear analog circuits and non-linear analog circuits; it can predict the resistance, inductance and capacitance of analog circuits and other main components for failure prediction.

Owner:HEFEI UNIV OF TECH

Transmission parameter recognition apparatus and method thereof

InactiveUS7561630B2Reduce complexityReduce consumptionTime-division multiplexAmplitude-modulated carrier systemsProcess moduleGuard interval

A transmission parameter recognition apparatus and the method thereof are disclosed. The transmission parameter recognition apparatus includes a correlation function processing module, a correlation symbol summing module and an energy interval detection module. The correlation function processing module computes a correction between two adjoining symbols in a sample sequence to generate a correlation function sequence. The correlation symbol summing module accumulates M symbols in the correlation function sequence to generate an energy interval. Since the distribution of the energy interval is related to the guard interval type, therefore, the energy interval detection module detects the distribution of the energy interval to generate a piece of guard interval information.

Owner:SUNPLUS TECH CO LTD

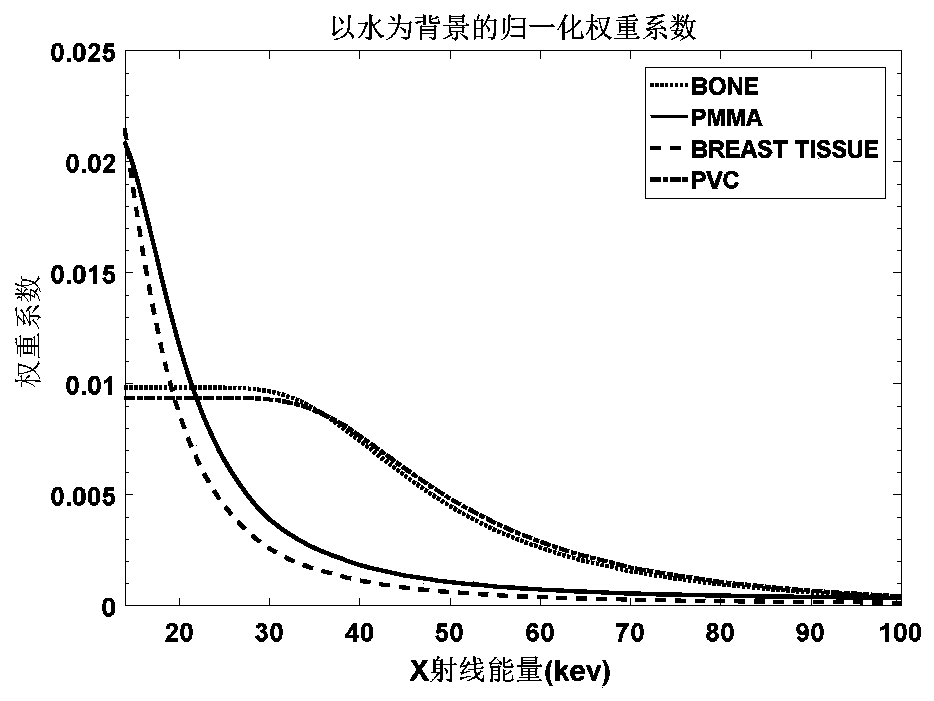

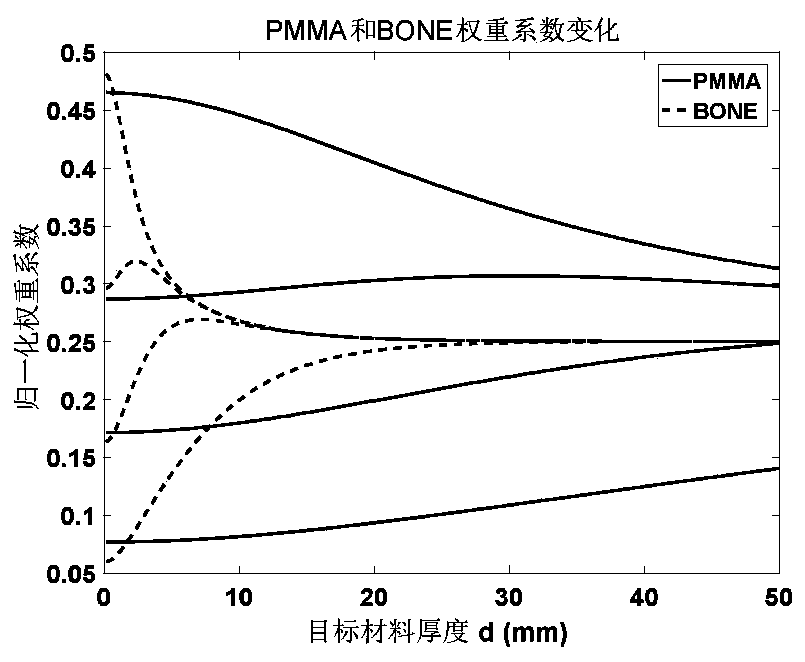

Material imaging weight determination method and device, medium and electronic equipment

ActiveCN109801243ABig Imaging ContributionImprove image signal-to-noise ratioImage enhancementWeight coefficientX-ray

The embodiment of the invention provides an imaging method and device, a medium and electronic equipment. The imaging method comprises the steps of acquiring signals and noise of electromagnetic wavespenetrating through a target material in a preset energy interval; constructing a signal-to-noise ratio function of the target material based on the signal and the noise; and maximizing a signal to noise ratio function and determining the weight coefficient of the target material. According to the technical scheme provided by the embodiment of the invention, after energy weighting, the contribution of the low-energy interval to imaging is greater, the signal-to-noise ratio of the image is improved, and the x-ray equivalent attenuation coefficient in the energy region is calculated by utilizing the acquired photon distribution information and the attenuation curve characteristics of photons in different materials, so that the calculation is more accurate.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI

A Method of Fault Diagnosis

A fault diagnosis method, which obtains the bearing impact energy value and frequency spectrum from the detection end; judges the interval according to the impact energy value, if the impact energy value is in the enhanced supervision interval, judges whether the frequency spectrum has a fault feature, and if there is a fault feature, calculate according to the frequency spectrum Whether there is a fault frequency, if there is a fault frequency, disassemble the bearing; the impact energy value is located in the fault zone of the equipment, judge whether there is abnormal temperature, abnormal noise, white noise, high-frequency components, if any of the above characteristics appear, then perform lubrication, lubrication After the abnormal temperature, abnormal noise, white noise, and high-frequency components have not all disappeared, judge whether there is a fault frequency. If there is a fault frequency, disassemble the bearing. Since the present invention processes the impact energy in different zones, the bearing can be judged in different energy ranges combined with various fault features and fault frequencies that appear in the frequency spectrum, and the state of the bearing can be accurately judged, so that the bearing can be adjusted in the corresponding state. disintegration.

Owner:LINGDONG NUCLEAR POWER +4

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com