Mica powder activation method

An activation method and technology of mica powder, applied in the field of mica powder, can solve the problems of different colors and gloss, differences in characteristics of mica powder, affecting the properties of mica powder, etc., and achieve easy process control, high regeneration efficiency, and accelerated activation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

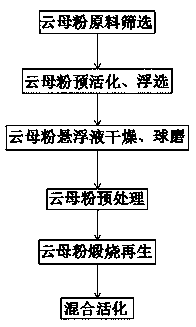

[0023] refer to figure 1 , an activation method of mica powder, comprising the following steps:

[0024] S1: Screening of mica powder raw materials: Mica powder is a silicate with a layered structure. The structure is composed of two layers of silicon-oxygen tetrahedron sandwiching a layer of aluminum-oxygen octahedron. Therefore, it needs to pass through before activation. The screening machine screens the uneven particles in the mica powder to ensure the purity of the mica powder raw material, which is convenient for subsequent activation;

[0025] S2: Pre-activation and flotation of mica powder: the oxidation layer on the surface of the screened mica powder is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com