A kind of recycled micropowder cement mixture material and preparation method thereof

A technology of recycled micropowder and mixed materials, which is applied in the direction of cement production, etc., can solve problems such as environmental and personal safety hazards, deterioration of the natural environment, and immature research, and achieve the effects of saving resources, low production costs, and promoting the development of circular economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

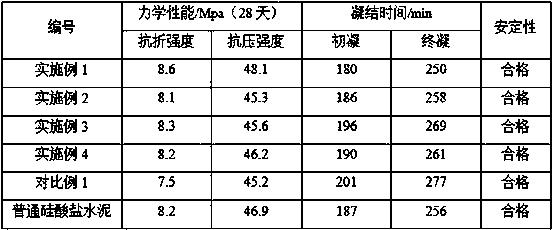

Examples

Embodiment 1

[0031] This embodiment provides a recycled micropowder cement mixture, which is obtained by grinding and mixing activated construction waste powder, activator, desulfurized gypsum, and cement clinker. The components are mixed according to the following mass ratio: active construction waste powder: activator: desulfurized gypsum : Cement clinker is 4:1.5:1:21.

[0032] The preparation method of above-mentioned recycled micropowder cement admixture comprises the steps:

[0033] 1) Crushing: crushing construction waste into 30mm particles;

[0034] 2) Pretreatment: Calcining 30mm construction waste at 400°C for 3 hours;

[0035] 3) Ball milling: mill the pretreated construction waste in a ball mill for 4 hours to obtain construction waste powder ≤ 80 μm;

[0036] 4) Calcination: calcining construction waste ≤ 80 μm at 600°C for 2 hours, raising the temperature to 900°C for 2 hours for 0.5 hours, and cooling to room temperature for 0.5 hours to obtain active construction waste p...

Embodiment 2

[0039] This embodiment provides a recycled micropowder cement mixture, which is obtained by grinding and mixing activated construction waste powder, activator, desulfurized gypsum, and cement clinker. The components are mixed according to the following mass ratio: active construction waste powder: activator: desulfurized gypsum : Cement clinker is 2.85:1.05:0.72:15.

[0040] The preparation method of above-mentioned recycled micropowder cement admixture comprises the steps:

[0041] 1) Crushing: crushing construction waste into 25mm particles;

[0042] 2) Pretreatment: Calcining 25mm of construction waste at 500°C for 2 hours;

[0043] 3) Ball milling: mill the pretreated construction waste in a ball mill for 3.5 hours to obtain construction waste powder with a size of 30 μm to 80 μm;

[0044] 4) Calcination: Calcining 30 μm ~ 80 μm construction waste at 600°C for 2 hours, raising the temperature to 900°C for 2 hours for 0.5 hours, and cooling to room temperature for 0.5 hou...

Embodiment 3

[0047] This embodiment provides a recycled micropowder cement mixture, which is obtained by grinding and mixing activated construction waste powder, activator, desulfurized gypsum, and cement clinker. The components are mixed according to the following mass ratio: active construction waste powder: activator: desulfurized gypsum : Cement clinker is 2:2.1:0.1:18.

[0048] The preparation method of above-mentioned recycled micropowder cement admixture comprises the steps:

[0049] 1) Crushing: crushing construction waste into 25mm particles;

[0050] 2) Pretreatment: Calcining 25mm of construction waste at 300°C for 5 hours;

[0051] 3) Ball milling: mill the pretreated construction waste in a ball mill for 2.5 hours to obtain construction waste powder smaller than 80 μm;

[0052] 4) Calcination: calcining construction waste smaller than 80 μm at 600°C for 2 hours, raising the temperature to 900°C for 2 hours for 0.5 hours, and cooling to room temperature for 0.5 hours to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com