Motor guide bar and preparation method thereof

A technology for guide strips and blanks, which is applied in the field of motor guide strips and the preparation of such motor guide strips, which can solve the problems of high cost and harsh preparation conditions, and achieve the effects of low production cost, simple preparation method, and easy control of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

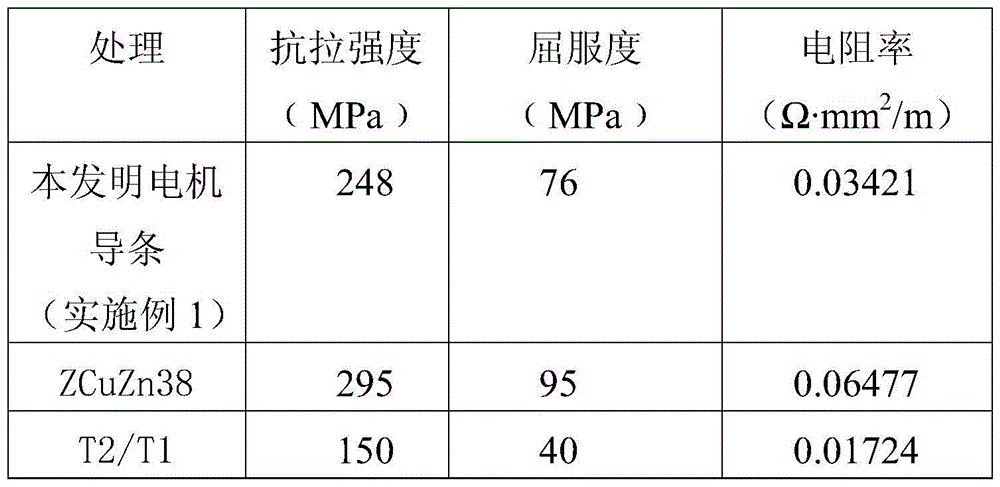

Examples

Embodiment 1

[0021] The motor bar is characterized in that it consists of the following components: 4 parts by weight of zinc, 0.3 parts by weight of chromium, 0.00151 parts by weight of arsenic, 0.00151 parts by weight of antimony, 0.000505 parts by weight of bismuth, 0.00252 parts by weight of iron, 0.001005 parts by weight of tin, 0.00201 parts by weight Parts by weight of nickel, 0.00252 parts by weight of sulfur, 0.001005 parts by weight of phosphorus, and the rest are copper.

[0022] A method for preparing a motor guide bar, comprising the steps of:

[0023] (1) Put 2 parts by weight of dry charcoal, 0.06 parts by weight of sodium chloride and 0.14 parts by weight of potassium chloride at the bottom of the crucible, then put 81 parts by weight of cathode copper, and then cover the surface with 2 parts by weight of charcoal, 0.03 parts by weight of Sodium chloride and 0.07 parts by weight of potassium chloride, when melting to 1200 ° C, quickly remove charcoal, and add 3 parts by wei...

Embodiment 2

[0031] The motor bar is characterized in that it consists of the following components: 5 parts by weight of zinc, 0.1 parts by weight of chromium, 0.0015 parts by weight of arsenic, 0.0015 parts by weight of antimony, 0.0005 parts by weight of bismuth, 0.0025 parts by weight of iron, 0.0010 parts by weight of tin, 0.0020 parts by weight Parts by weight of nickel, 0.0025 parts by weight of sulfur, 0.001 part by weight of phosphorus, and the rest are copper.

[0032] A method for preparing a motor guide bar, comprising the steps of:

[0033] (1) Put 3 parts by weight of dry charcoal, 0.12 parts by weight of sodium chloride and 0.18 parts by weight of potassium chloride at the bottom of the crucible, then put 80 parts by weight of cathode copper, and then cover the surface with 3 parts by weight of charcoal, 0.08 parts by weight of Part sodium chloride and the potassium chloride of 0.12 parts by weight, when melting to 1220 ℃, remove charcoal rapidly, add 5 parts by weight of per...

Embodiment 3

[0041] The motor bar is characterized in that it consists of the following components: 3 parts by weight of zinc, 0.2 parts by weight of chromium, 0.00152 parts by weight of arsenic, 0.00152 parts by weight of antimony, 0.00051 parts by weight of bismuth, 0.00253 parts by weight of iron, 0.00101 parts by weight of tin, 0.00202 parts by weight Parts by weight of nickel, 0.00253 parts by weight of sulfur, 0.00101 parts by weight of phosphorus, and the rest are copper.

[0042] A method for preparing a motor guide bar, comprising the steps of:

[0043] (1) Put 2.5 parts by weight of dry charcoal, 0.08 parts by weight of sodium chloride and 0.17 parts by weight of potassium chloride at the bottom of the crucible, then put 83 parts by weight of cathode copper, and then cover the surface with 2.5 parts by weight of charcoal, 0.05 parts by weight of chlorine Sodium chloride and 0.1 parts by weight of potassium chloride, when melting to 1210 ° C, quickly remove charcoal, and add 4 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com