A kind of flame retardant high temperature resistant concrete and preparation method thereof

A concrete and high temperature resistant technology, applied in the field of building materials, can solve the problems of complex construction process, weak cohesion, easy breakage, etc., and achieve the effects of reducing casualties and property losses, reducing shrinkage and cracking, and reducing volumetric water absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

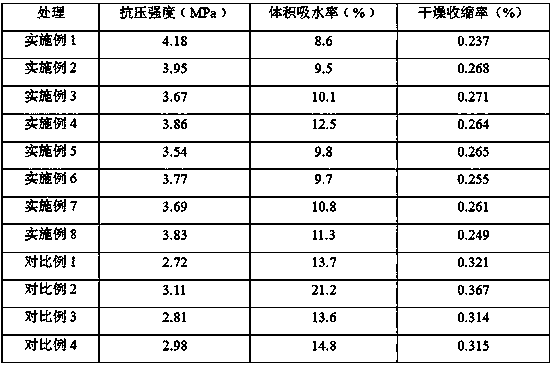

Examples

Embodiment 1

[0028] A flame-retardant and high-temperature-resistant concrete, made of the following components in parts by weight: 36 parts by weight of cement, 25 parts by weight of clay clinker, 24 parts by weight of water, 12 parts by weight of magnesia, 2.6 parts by weight of a water reducer, 8.6 parts by weight of alumina, 1.3 parts by weight of modifying agent, 1.9 parts by weight of graphene, 1.6 parts by weight of flame retardant, 0.28 parts by weight of hexenyl bisstearamide, 0.16 parts by weight of polyethylene glycol;

[0029] The water reducer is a mixture of naphthalene sulfonate, casein and sulfonated melamine formaldehyde resin in a weight ratio of 4:6:1;

[0030] The modifier is a mixture of sodium metaaluminate, zirconia and silicon carbide in a weight ratio of 16:5:1;

[0031] The flame retardant is a mixture of brominated epoxy resin, magnesium aluminum hydrotalcite and decabromodiphenylethane in a weight ratio of 9:6:1.

[0032] The preparation method of the above-men...

Embodiment 2

[0037] A flame-retardant and high-temperature-resistant concrete, made of the following components in parts by weight: 30 parts by weight of cement, 28 parts by weight of clay clinker, 22 parts by weight of water, 10 parts by weight of magnesia, 3 parts by weight of a water reducer, 9 parts by weight of alumina, 1 part by weight of modifier, 1.7 parts by weight of graphene, 1.2 parts by weight of flame retardant, 0.25 parts by weight of hexenyl bisstearamide, 0.3 parts by weight of polyethylene glycol;

[0038] The water reducer is a mixture of naphthalene sulfonate, casein and sulfonated melamine formaldehyde resin in a weight ratio of 3:7:1;

[0039] The modifier is a mixture of sodium metaaluminate, zirconia and silicon carbide in a weight ratio of 15:6:1;

[0040] The flame retardant is a mixture of brominated epoxy resin, magnesium aluminum hydrotalcite and decabromodiphenylethane in a weight ratio of 12:7:1.

[0041] The preparation method of the above-mentioned flame r...

Embodiment 3

[0046] A flame-retardant and high-temperature-resistant concrete, made of the following components in parts by weight: 38 parts by weight of cement, 20 parts by weight of clay clinker, 30 parts by weight of water, 15 parts by weight of magnesia, 2.5 parts by weight of a water reducer, 10 parts by weight of alumina, 2 parts by weight of modifying agent, 2 parts by weight of graphene, 1.8 parts by weight of flame retardant, 0.4 parts by weight of hexenyl bisstearamide, 0.2 parts by weight of polyethylene glycol;

[0047] The water reducer is a mixture of naphthalene sulfonate, casein and sulfonated melamine formaldehyde resin in a weight ratio of 5:4:1;

[0048] The modifier is a mixture of sodium metaaluminate, zirconia and silicon carbide in a weight ratio of 17:4:1;

[0049] The flame retardant is a mixture of brominated epoxy resin, magnesium aluminum hydrotalcite and decabromodiphenylethane in a weight ratio of 7:8:1.

[0050] The preparation method of the above-mentioned ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com