Method for determining the concentration of an element in a material

An element and content technology, applied in the direction of material analysis using radiation, analyzing materials, and material analysis using wave/particle radiation, can solve problems such as unsatisfactory results and low mercury content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

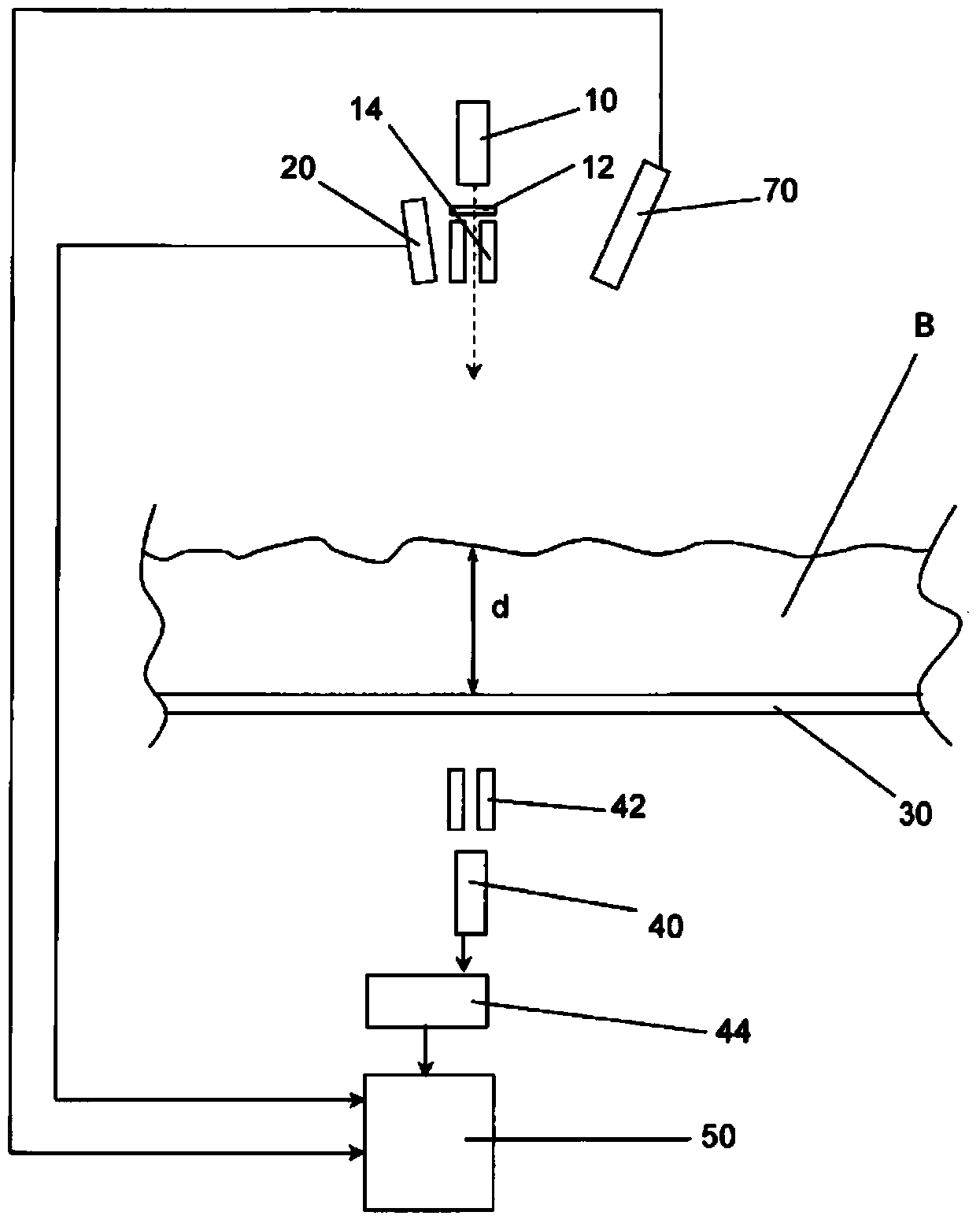

Method used

Image

Examples

no. 1 approach

[0038] An advantage over the first embodiment is that the detector need not be energy dispersive and a multi-channel analyzer is not necessary.

[0039] The operation is as follows:

[0040] First, apply the well-known general formula:

[0041] I=I 0 *e -μ*ρ*d (1)

[0042] in

[0043] I 0 = incident energy

[0044] I = measured energy

[0045] μ = absorption coefficient

[0046] so

[0047]

[0048] as well as

[0049]

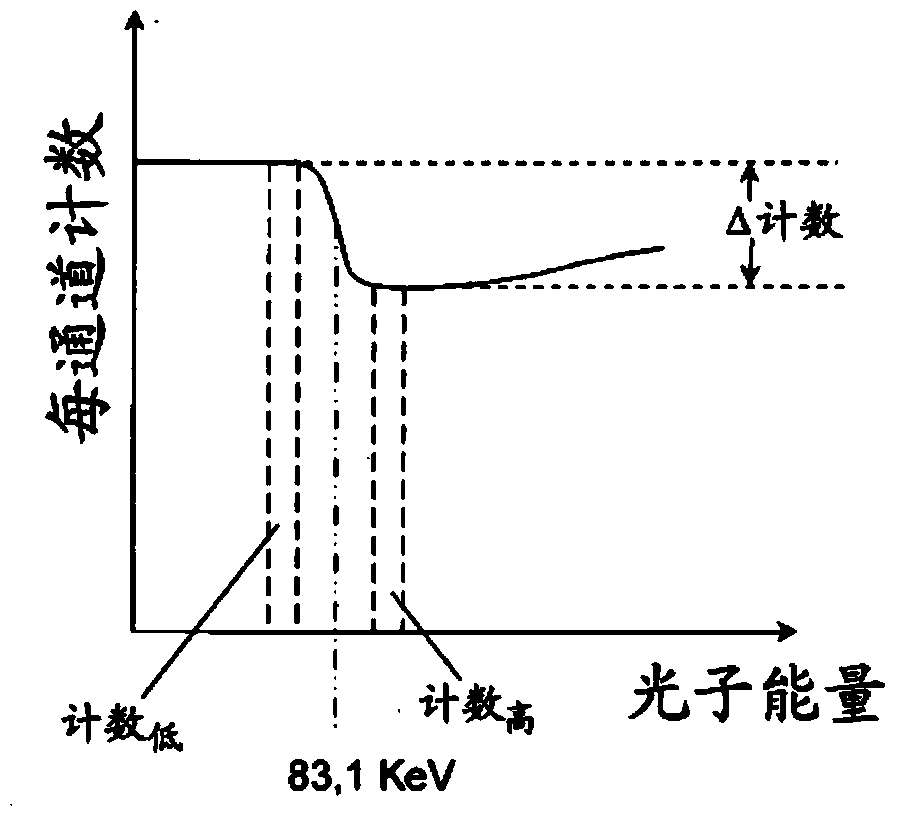

[0050] And, for measurements using a Cs source,

[0051] as from Figure 4 as can be seen

[0052] mu HG =μ 高 -μ 低

[0053] this gets

[0054]

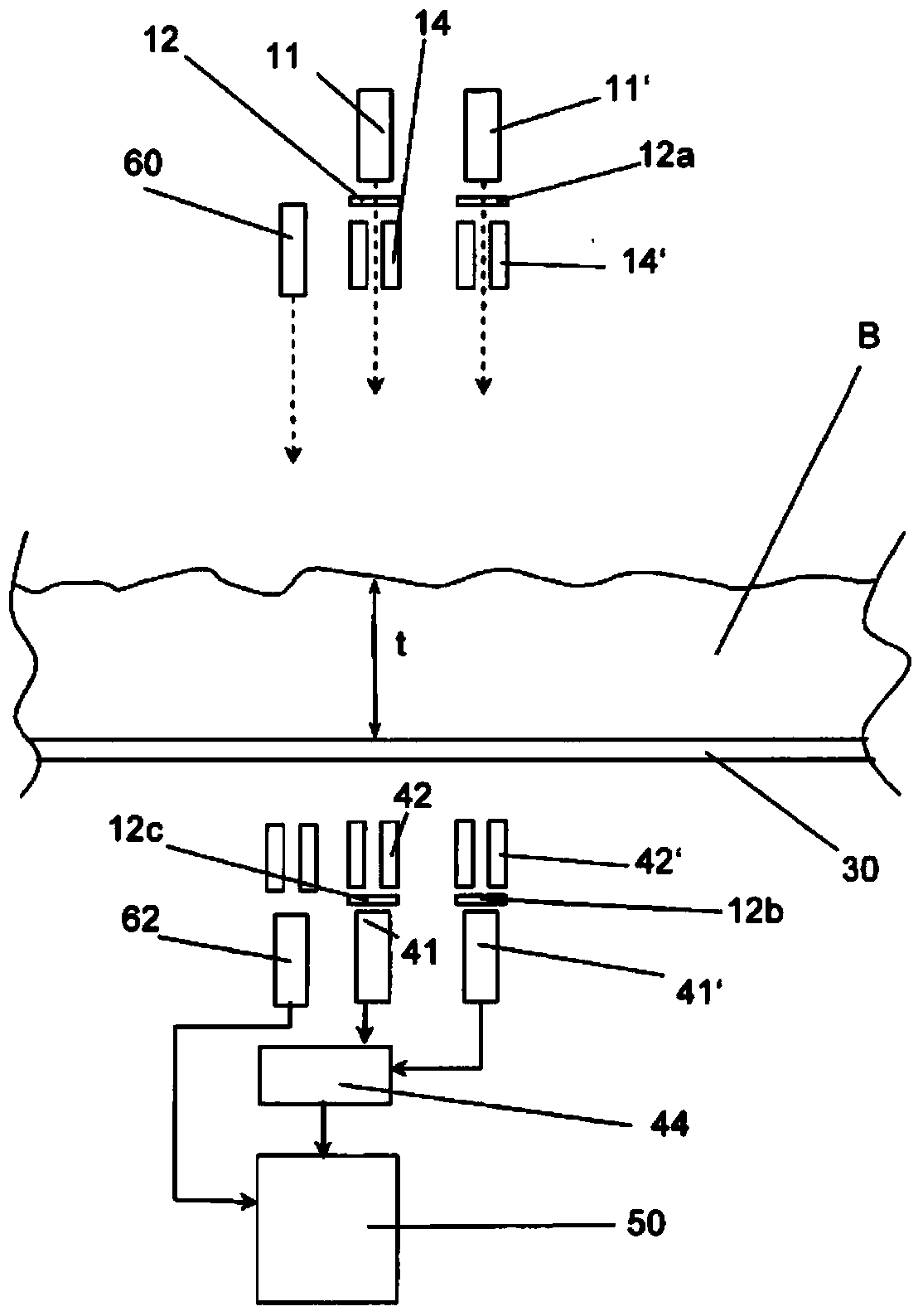

[0055] Figure 5 shown in Figure 4 changes in . Here, a normal detector 45 and a discriminator 65 are used. Am-241 source 11 and Cd-109 source 11 ′ are directed to this common detector 45 and the energy is separated by discriminator 65 .

[0056] Image 6 shown in Figure 5 changes in . Here, the beam of the Cd-109 source 11' is extended through the Am-241 source 11 so that both be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com