A Method of Fault Diagnosis

A fault diagnosis and fault frequency technology, applied in the testing of machine/structural components, testing of mechanical components, instruments, etc., can solve problems such as incompleteness and inaccurate judgment of bearing faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

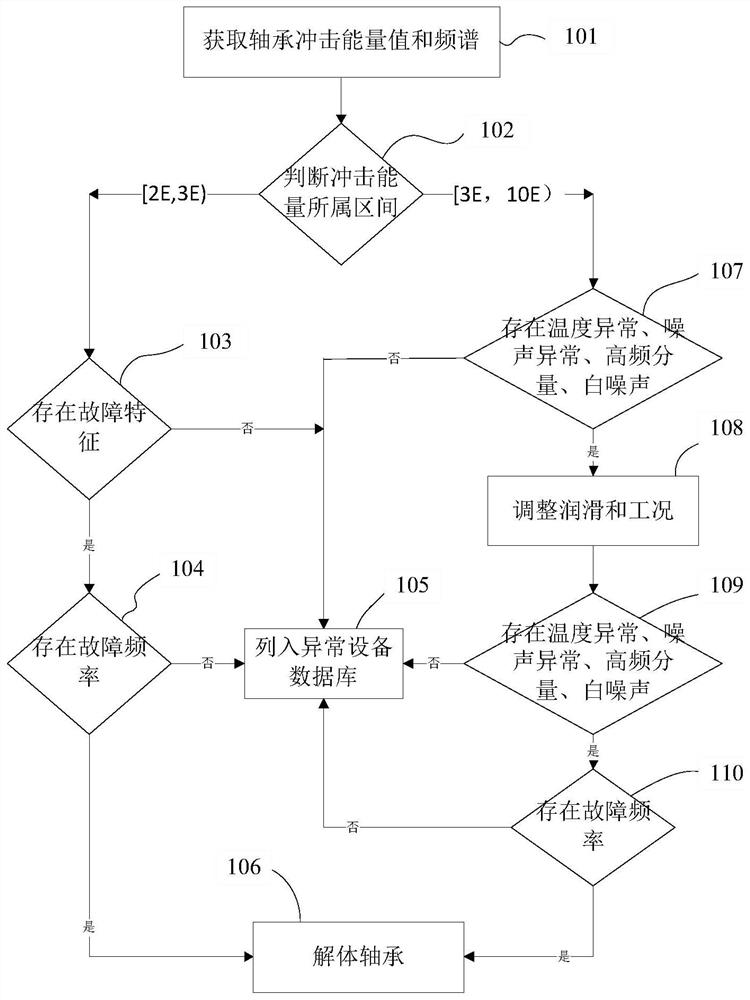

[0038] Please refer to figure 1 , fault diagnosis methods include:

[0039] 101. Detect the bearing, and obtain the bearing impact energy value and spectrum of the shaft from the detection end. Specifically, the vibration analyzer detects the bearing to obtain the vibration data of the bearing. The vibration data is processed by a computer to obtain the impact energy value, velocity spectrum, and velocity trend graph, waterfall graph;

[0040] 102. Determine the interval according to the impact energy value. If the impact energy value falls into the interval [2E, 3E), go to step 103. If the impact energy value falls in the interval [3E, 10E), go to step 107. E means the bearing is normal and stable. Impact energy value during operation;

[0041] 103. Judging from the speed trend graph whether the amplitude has doubled or more than doubled, whether there is frequency multiplication or high frequency in the speed spectrum, and whether there are fault characteristics that disti...

Embodiment 2

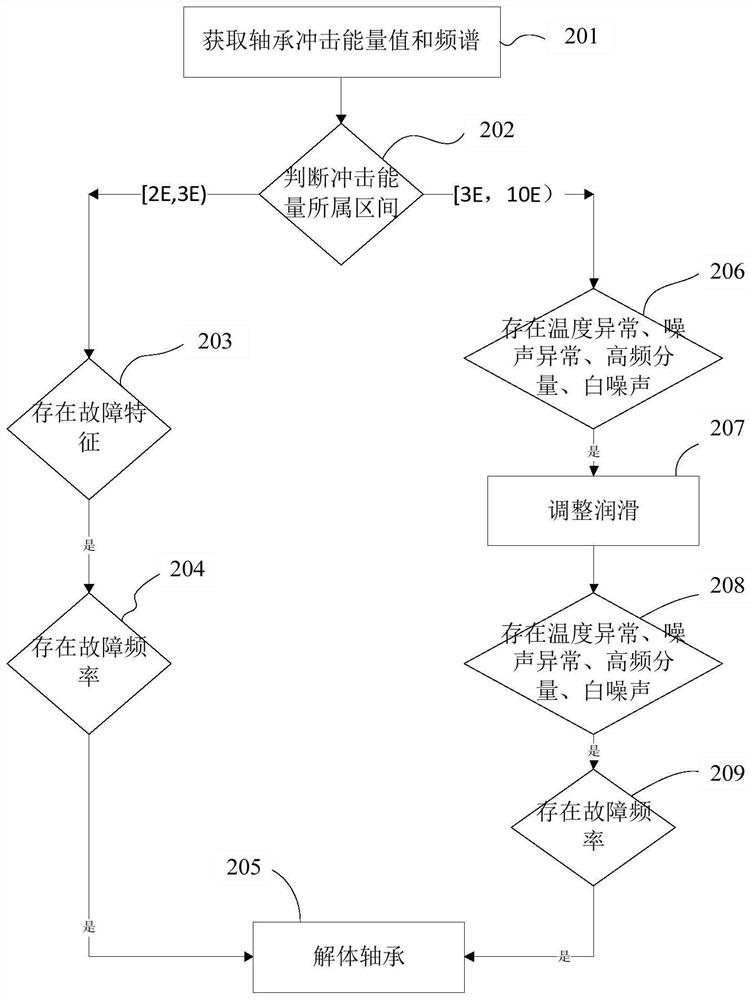

[0051] Please refer to figure 2 , fault diagnosis methods include:

[0052] 201. Obtain the bearing impact energy value and frequency spectrum from the detection end;

[0053] 202. Determine the interval according to the impact energy value, if the impact energy value falls into the interval [2E, 3E), enter step 203; if the impact energy value falls within the interval [3E, 10E), enter step 206;

[0054] 203. Judging from the speed trend graph whether the amplitude has doubled or more than doubled, whether there is frequency multiplication or high frequency in the speed spectrum, and whether there is a fault feature distinguishing peaks in the waterfall graph, if any of the above fault features exists, enter the step 204;

[0055] 204. Judging from the frequency spectrum whether there is a fault frequency, if there is a fault frequency, enter step 205;

[0056] 205. Disassemble the bearing;

[0057] 206. Determine whether abnormal temperature, abnormal noise, white noise,...

Embodiment 3

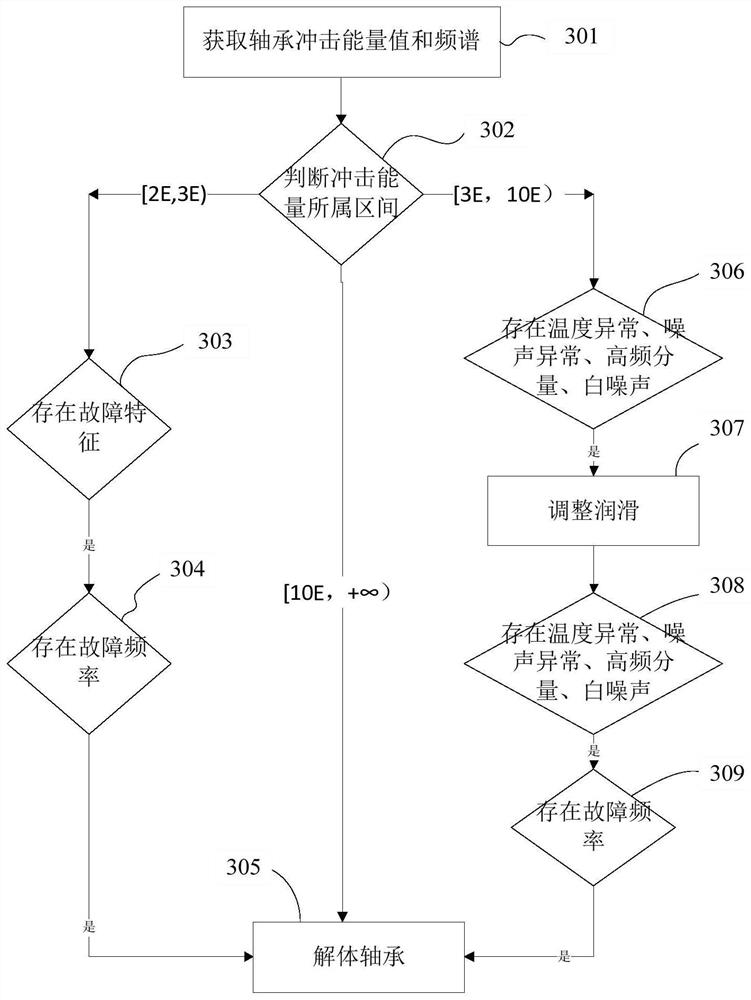

[0062] Please refer to image 3 , fault diagnosis methods include:

[0063] 301. Obtain the bearing impact energy value and frequency spectrum from the detection end;

[0064] 302. Determine the interval according to the impact energy value. If the impact energy value falls into the interval [2E, 3E), enter step 303; if the impact energy value falls within the interval [3E, 10E), enter step 306. If the impact energy value fall into the interval [10E, +∞), then enter step 305;

[0065] 303. Judging from the speed trend graph whether the amplitude has doubled or more than doubled, whether there is frequency multiplication or high frequency in the speed spectrum, and whether there is a fault feature that distinguishes peaks in the waterfall graph, if any of the above fault features exists, enter the step 304;

[0066] 304. Judging from the frequency spectrum whether there is a fault frequency, if there is a fault frequency, enter step 305;

[0067] 305. Disassemble the bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com